DIW For High-Throughput R&D: Rapid Prototyping Best Practices

DIW Technology Evolution and Objectives

Direct Ink Writing (DIW) technology has evolved significantly since its inception in the late 1990s, transforming from a simple material deposition technique to a sophisticated additive manufacturing method. Initially developed for ceramic processing, DIW has expanded across multiple disciplines including biomedical engineering, electronics, and materials science. The fundamental principle—controlled extrusion of viscoelastic materials through fine nozzles to create precise three-dimensional structures—has remained consistent, while capabilities have dramatically advanced.

The evolution of DIW technology can be traced through several key developmental phases. Early systems (1998-2005) focused on basic proof-of-concept demonstrations with limited material options and relatively simple geometries. The middle phase (2006-2015) saw significant improvements in precision control systems, multi-material capabilities, and the introduction of functional inks with specific electrical, optical, or mechanical properties.

Current generation DIW systems (2016-present) feature unprecedented resolution (sub-micron in some cases), integrated in-situ monitoring, and compatibility with an extensive range of materials including ceramics, polymers, hydrogels, composites, and metal-loaded inks. This technological maturation has positioned DIW as a versatile platform for rapid prototyping and high-throughput research and development applications.

The primary objective of high-throughput DIW implementation is to accelerate the materials development cycle by enabling rapid iteration through design-fabrication-testing loops. This approach aims to reduce traditional R&D timelines from months to days, particularly for applications requiring customized material formulations or complex geometrical features.

Secondary objectives include establishing standardized protocols for ink formulation optimization, process parameter selection, and quality control metrics that ensure reproducibility across different material systems and application domains. These standards are essential for transitioning DIW from primarily research-oriented applications to industrial implementation.

Technical objectives specifically focus on enhancing throughput capabilities through parallel processing architectures, developing automated characterization workflows, and creating robust design rules that account for material-process-structure-property relationships. Additionally, there is growing emphasis on integrating DIW with complementary technologies such as in-line rheological characterization, real-time defect detection, and machine learning algorithms for process optimization.

The convergence of these evolutionary trends and objectives positions DIW as a transformative technology for next-generation manufacturing paradigms, particularly in sectors requiring customized, high-performance components with complex architectures or gradient properties that cannot be achieved through conventional fabrication methods.

Market Demand for Rapid Prototyping Solutions

The rapid prototyping market has experienced significant growth in recent years, driven by increasing demand for faster product development cycles across multiple industries. The global rapid prototyping market was valued at approximately $2.2 billion in 2021 and is projected to reach $9.5 billion by 2030, growing at a CAGR of around 17.6% during the forecast period. Direct Ink Writing (DIW) technology has emerged as a particularly promising segment within this market.

Manufacturing industries, especially aerospace, automotive, and consumer electronics, are primary drivers of demand for DIW-based rapid prototyping solutions. These sectors require increasingly complex geometries, multi-material capabilities, and faster iteration cycles to maintain competitive advantage. The ability of DIW to produce functional prototypes with specific material properties addresses these needs directly.

Healthcare and biomedical sectors represent the fastest-growing market segment for DIW technology. The demand for customized medical devices, tissue engineering scaffolds, and drug delivery systems has created substantial opportunities for high-throughput DIW applications. Market research indicates that medical applications of DIW technology are expected to grow at over 22% annually through 2028.

Research institutions and academic laboratories constitute another significant market segment. The need for accessible, versatile prototyping platforms that can work with a wide range of materials has driven adoption of DIW systems in research environments. This segment values flexibility and adaptability over production speed, creating demand for modular DIW systems.

Market analysis reveals several key customer requirements driving DIW adoption. First is material versatility - the ability to work with multiple material types including polymers, ceramics, and composites. Second is resolution and precision, with industries demanding increasingly fine feature sizes. Third is throughput capacity, with manufacturers seeking systems capable of producing multiple iterations quickly.

Cost considerations remain a significant factor influencing market adoption. While large enterprises can afford high-end commercial DIW systems, small and medium enterprises (SMEs) and academic institutions seek more affordable solutions. This has created a market segment for modular, scalable DIW platforms that can be upgraded as needs evolve.

Regional market analysis shows North America leading in DIW adoption, accounting for approximately 38% of the global market, followed by Europe at 31% and Asia-Pacific at 26%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, and strong government support for advanced manufacturing technologies.

DIW Technical Challenges and Limitations

Despite its promising capabilities, Direct Ink Writing (DIW) faces several significant technical challenges that limit its widespread adoption in high-throughput R&D environments. The rheological properties of inks represent a primary constraint, as they must maintain precise viscoelastic characteristics to enable both smooth extrusion and structural integrity post-deposition. Achieving this balance requires extensive formulation expertise and often involves time-consuming trial-and-error processes that can impede rapid prototyping workflows.

Resolution limitations present another substantial hurdle. While DIW offers reasonable precision compared to conventional 3D printing methods, achieving features below 100 microns remains challenging due to nozzle diameter constraints, ink spreading behavior, and positioning system accuracy. These limitations restrict applications requiring extremely fine features or high-density integration of functional components.

Material compatibility issues further complicate DIW implementation. Many advanced functional materials exhibit properties that make them difficult to formulate into printable inks without compromising their performance characteristics. For instance, highly conductive materials often agglomerate or settle during printing, while certain ceramic precursors may undergo premature curing or degradation during the extrusion process.

Process reproducibility represents a significant challenge for high-throughput applications. Environmental factors such as temperature fluctuations, humidity variations, and air currents can dramatically affect ink behavior and final print quality. These sensitivities necessitate tightly controlled printing environments that add complexity and cost to DIW systems.

Multi-material printing capabilities, while theoretically possible with DIW, face practical implementation challenges. Cross-contamination between materials, alignment issues during tool changes, and compatibility problems between adjacent materials can compromise print quality and functional performance. These issues become particularly pronounced when attempting to integrate materials with vastly different rheological properties or curing mechanisms.

Scalability concerns also plague DIW technology. While excellent for prototyping, the relatively slow deposition rates compared to conventional manufacturing methods limit production throughput. Additionally, maintaining consistent quality across larger build volumes presents challenges related to material homogeneity and process control over extended print durations.

Post-processing requirements add further complexity to DIW workflows. Many DIW-printed structures require secondary processing steps such as thermal treatment, solvent removal, or sintering to achieve final properties. These additional steps introduce potential failure points, extend overall production time, and may induce dimensional changes that must be accounted for during design phases.

Current DIW High-Throughput Implementation Methods

01 Materials and compositions for DIW rapid prototyping

Various materials and compositions can be used in Direct Ink Writing (DIW) rapid prototyping to achieve specific properties in the final product. These materials include specialized inks, polymers, ceramics, and composite materials that possess appropriate rheological properties for extrusion. The composition of these materials affects viscosity, flow behavior, and structural integrity during the printing process, as well as the mechanical, thermal, and functional properties of the final printed object.- Materials and compositions for DIW rapid prototyping: Various materials and compositions can be used in Direct Ink Writing (DIW) rapid prototyping processes. These include specialized inks with specific rheological properties, ceramic slurries, polymer composites, and functional materials that can be extruded through nozzles. The composition of these materials affects the printing quality, structural integrity, and functional properties of the final printed objects. Proper formulation of these materials is essential for successful DIW applications in various fields including electronics, biomedical devices, and structural components.

- Equipment and hardware systems for DIW technology: DIW rapid prototyping requires specialized equipment and hardware systems for precise material deposition. These systems typically include extrusion mechanisms, precision motion control platforms, nozzle designs with varying diameters, and pressure control systems. Advanced DIW systems may incorporate multiple print heads for multi-material printing, temperature control for viscosity management, and integrated curing mechanisms. The hardware configuration significantly impacts the resolution, speed, and capabilities of the DIW printing process.

- Process parameters and optimization techniques: Successful DIW rapid prototyping depends on optimizing various process parameters. These include extrusion pressure, nozzle movement speed, layer height, printing path strategies, and curing conditions. The relationship between material properties and process parameters must be carefully balanced to achieve desired print quality. Advanced techniques such as real-time monitoring, feedback control systems, and machine learning algorithms can be employed to optimize these parameters dynamically during the printing process, resulting in improved print quality and reproducibility.

- Multi-material and functional printing approaches: DIW technology enables multi-material printing and the creation of functional structures with specific properties. By using multiple print heads or changing materials during the printing process, objects with varying mechanical, electrical, or biological properties can be created. This approach allows for the fabrication of complex devices such as sensors, actuators, and biomedical implants with spatially controlled properties. The integration of functional materials such as conductive inks, piezoelectric materials, or cell-laden bioinks expands the application range of DIW technology.

- Post-processing and finishing techniques: After DIW printing, various post-processing techniques are often required to achieve the final desired properties. These include thermal treatments such as sintering for ceramic materials, UV curing for photopolymers, and chemical treatments to enhance mechanical properties. Surface finishing techniques may also be applied to improve surface quality and dimensional accuracy. The selection of appropriate post-processing methods depends on the materials used and the intended application of the printed object, with each technique offering specific advantages for enhancing the functional properties of DIW-printed parts.

02 Equipment and hardware systems for DIW technology

Direct Ink Writing requires specialized equipment and hardware systems for precise material deposition. These systems typically include extrusion mechanisms, nozzle designs, positioning systems, and control interfaces. Advanced DIW systems may incorporate multiple print heads, temperature control systems, and real-time monitoring capabilities to ensure accurate deposition of materials. The hardware configuration significantly impacts printing resolution, speed, and the ability to create complex geometries.Expand Specific Solutions03 Process parameters and optimization techniques

Successful DIW rapid prototyping depends on optimizing various process parameters such as extrusion pressure, nozzle diameter, printing speed, and layer height. These parameters must be carefully controlled to achieve desired print quality and structural integrity. Optimization techniques may include computational modeling, machine learning algorithms, and experimental design methodologies to determine the optimal printing conditions for specific materials and geometries. Process optimization is crucial for improving print resolution, reducing defects, and enhancing overall part quality.Expand Specific Solutions04 Multi-material and functional DIW printing

Advanced DIW techniques enable multi-material printing and the creation of functional components with integrated properties. This approach allows for the fabrication of objects with spatially varying compositions, embedded electronics, or gradient structures. Multi-material DIW can combine different materials within a single print to achieve specific mechanical, electrical, or thermal properties. These techniques are particularly valuable for creating smart devices, sensors, and components with region-specific functionalities.Expand Specific Solutions05 Post-processing methods for DIW printed parts

Post-processing techniques are essential for enhancing the properties of DIW printed parts. These methods include thermal treatments, sintering, curing, surface finishing, and infiltration processes. Post-processing can significantly improve mechanical strength, surface quality, and functional properties of the printed objects. The selection of appropriate post-processing methods depends on the material composition, intended application, and desired final properties of the printed part.Expand Specific Solutions

Leading Companies in DIW Technology Ecosystem

Direct Ink Writing (DIW) for high-throughput R&D is currently in a growth phase, with increasing adoption across research institutions and industry. The market is expanding rapidly as organizations seek efficient prototyping solutions, estimated to reach significant scale within advanced manufacturing sectors. Technologically, DIW is maturing with varying levels of sophistication among key players. Leading research institutions like MIT, Swiss Federal Institute of Technology, and Lawrence Livermore National Security are advancing fundamental capabilities, while companies including Applied Materials, Xerox, and GE are developing commercial applications. Chinese universities (Central South, Jiangnan, Southeast) are making notable contributions to material science aspects. Core Voxel and Base System represent emerging specialized players focusing on DIW-specific innovations, indicating a diversifying competitive landscape with both established entities and new entrants driving technological advancement.

Lawrence Livermore National Security LLC

General Electric Company

Key Patents and Innovations in DIW Printing

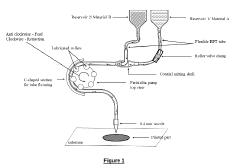

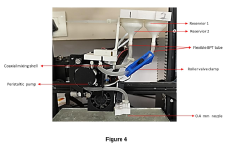

- A system utilizing a continuous feed mechanism with a peristaltic pump and a specialized coaxial casing for mixing inks from separate supplies, allowing for controlled ink propulsion and in-process composition modulation, enabling precise deposition of composite inks for intricate 3D structures.

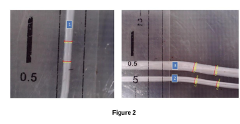

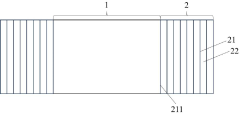

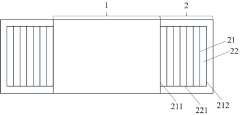

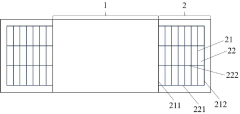

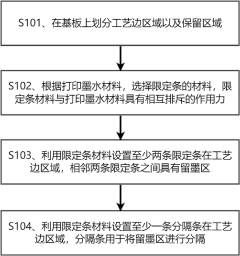

- Design a substrate that sets a limiter strip that intersects the printing lines in the process edge area. The mutual repulsive force between the ink and the limiter strip is used to form an ink retention area, trap the ink, shorten the length of the process edge, and use the position and shape of the limiter strip. Optimize to improve the shape uniformity and cutting utilization of printed products.

Material Compatibility and Formulation Guidelines

Material compatibility represents a critical factor in the successful implementation of Direct Ink Writing (DIW) for high-throughput research and development applications. The rheological properties of inks must be carefully tailored to achieve optimal printability while maintaining functional performance in the final printed structure. Viscosity typically should range between 10^2-10^6 mPa·s, with shear-thinning behavior being particularly advantageous for extrusion processes.

Particle size distribution significantly impacts printing resolution and nozzle clogging tendencies. For standard DIW applications, particles should ideally be at least 50 times smaller than the nozzle diameter to prevent obstruction. Homogeneous dispersions require effective stabilization mechanisms, whether steric, electrostatic, or electrosteric, depending on the carrier medium properties.

Solvent selection must balance evaporation rate with viscosity control. Fast-evaporating solvents may cause nozzle clogging during printing pauses, while slow-evaporating systems can lead to poor shape retention. Hybrid solvent systems often provide the optimal balance for high-throughput operations, allowing for initial shape retention followed by controlled solidification.

Additives play crucial roles in formulation optimization. Rheology modifiers such as fumed silica or cellulose derivatives can enhance printability by introducing yield stress behavior. Dispersants like polyelectrolytes or block copolymers improve colloidal stability, while plasticizers may be necessary for flexibility in the final printed structures.

Formulation guidelines should follow systematic development protocols. Initial screening should establish baseline viscosity and yield stress parameters, followed by optimization of solid loading and additive concentrations. Standardized characterization methods including oscillatory rheology, extrusion tests, and shape retention evaluations provide quantitative metrics for formulation comparison.

Material-specific considerations vary significantly across material classes. Ceramic inks typically require high solid loading (40-60 vol%) with appropriate dispersants, while polymeric systems may need careful control of molecular weight distribution and crosslinking kinetics. Composite formulations present additional challenges in maintaining homogeneous distribution of reinforcement phases throughout the printing process.

Cross-compatibility between materials in multi-material printing scenarios demands careful consideration of interface interactions. Chemical compatibility at material junctions, similar shrinkage behaviors during post-processing, and matched mechanical properties are essential for functional gradient structures or devices with integrated functionalities.

Quality Control Metrics for DIW Prototyping

Establishing robust quality control metrics is essential for ensuring the reliability and reproducibility of Direct Ink Writing (DIW) prototyping processes. These metrics serve as quantifiable standards against which the performance of DIW systems and the quality of printed components can be evaluated.

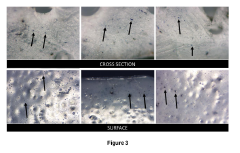

Dimensional accuracy represents a primary quality control metric for DIW prototyping. This includes measurements of feature size, layer thickness, and overall geometric fidelity compared to the original CAD model. Advanced metrology techniques such as optical profilometry and micro-CT scanning enable precise quantification of dimensional variations, with industry standards typically requiring tolerances within ±50-100 μm for high-precision applications.

Rheological properties of printing inks must be continuously monitored to maintain consistent extrusion behavior. Key parameters include viscosity, yield stress, and shear-thinning characteristics, which should remain within predetermined ranges throughout the printing process. Real-time rheological monitoring systems can detect anomalies that might compromise print quality, with viscosity variations typically maintained below 5% for optimal results.

Surface quality metrics encompass roughness measurements (Ra values), surface defect quantification, and uniformity assessments. For high-throughput R&D applications, Ra values below 10 μm are generally targeted, with automated optical inspection systems increasingly employed to detect and classify surface irregularities according to standardized defect taxonomies.

Mechanical performance testing provides critical insights into the structural integrity of DIW-printed components. Standardized tests for tensile strength, compression resistance, and flexural properties should be conducted according to established protocols (e.g., ASTM D638 for tensile testing). Performance consistency across multiple prints serves as a key indicator of process reliability.

Inter-layer adhesion strength represents a particularly important metric for DIW processes, as weak interfaces often constitute failure points. Specialized testing protocols have been developed to quantify bonding quality between successive layers, with T-peel tests and lap-shear measurements being commonly employed methodologies.

Porosity and density measurements provide insights into material consolidation quality. Techniques such as mercury intrusion porosimetry and helium pycnometry enable quantitative assessment of void content and distribution, with target porosity levels typically specified based on application requirements.

Process parameter stability metrics track variations in critical printing parameters including extrusion pressure, nozzle travel speed, and environmental conditions. Statistical process control methodologies can be applied to establish control limits and detect deviations that might compromise print quality, with modern systems implementing automated feedback loops for real-time adjustments.