DIW For Large-Scale Structural Ceramic Panels: Challenges And Solutions

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Ceramic Technology Background and Objectives

Direct Ink Writing (DIW) technology has evolved significantly over the past two decades as an additive manufacturing technique for ceramic materials. Originally developed in the late 1990s, DIW emerged from the broader field of robotic deposition systems, offering unprecedented control over material placement and structural design. The technology enables the extrusion of ceramic-loaded inks through fine nozzles to create complex three-dimensional structures layer by layer, without the need for molds or extensive post-processing.

The evolution of DIW has been marked by continuous improvements in ink formulation, extrusion precision, and multi-material capabilities. Early systems were limited to simple geometries and small-scale applications, but recent advancements have expanded the potential for larger structural components with enhanced mechanical properties and functional characteristics. The integration of computational design tools and automated control systems has further accelerated the development of DIW technology for industrial applications.

Current market trends indicate growing demand for large-scale ceramic panels in various sectors, including architecture, energy systems, aerospace, and advanced manufacturing. These applications require ceramic components with specific structural properties, such as high strength-to-weight ratios, thermal resistance, and customizable geometries. Traditional manufacturing methods often struggle to meet these requirements cost-effectively, creating an opportunity for DIW technology to fill this gap.

The primary technical objective of DIW for large-scale structural ceramic panels is to overcome the inherent challenges of scale while maintaining precision, structural integrity, and production efficiency. This includes developing ink formulations that balance rheological properties for extrusion while ensuring minimal shrinkage and deformation during drying and sintering processes. Additionally, the technology aims to achieve consistent material properties throughout large components, which is particularly challenging due to variations in drying rates and internal stresses.

Another critical objective is to enhance the production speed without compromising quality, as large-scale applications demand higher throughput than traditional ceramic manufacturing processes. This necessitates innovations in multi-nozzle systems, optimized printing paths, and advanced curing techniques to reduce production time while maintaining dimensional accuracy and structural performance.

Furthermore, the technology seeks to integrate functional gradients and multi-material capabilities, allowing for the creation of ceramic panels with spatially varied properties to meet specific performance requirements. This includes the ability to incorporate porosity gradients, compositional variations, and embedded functional elements within a single manufacturing process.

The evolution of DIW has been marked by continuous improvements in ink formulation, extrusion precision, and multi-material capabilities. Early systems were limited to simple geometries and small-scale applications, but recent advancements have expanded the potential for larger structural components with enhanced mechanical properties and functional characteristics. The integration of computational design tools and automated control systems has further accelerated the development of DIW technology for industrial applications.

Current market trends indicate growing demand for large-scale ceramic panels in various sectors, including architecture, energy systems, aerospace, and advanced manufacturing. These applications require ceramic components with specific structural properties, such as high strength-to-weight ratios, thermal resistance, and customizable geometries. Traditional manufacturing methods often struggle to meet these requirements cost-effectively, creating an opportunity for DIW technology to fill this gap.

The primary technical objective of DIW for large-scale structural ceramic panels is to overcome the inherent challenges of scale while maintaining precision, structural integrity, and production efficiency. This includes developing ink formulations that balance rheological properties for extrusion while ensuring minimal shrinkage and deformation during drying and sintering processes. Additionally, the technology aims to achieve consistent material properties throughout large components, which is particularly challenging due to variations in drying rates and internal stresses.

Another critical objective is to enhance the production speed without compromising quality, as large-scale applications demand higher throughput than traditional ceramic manufacturing processes. This necessitates innovations in multi-nozzle systems, optimized printing paths, and advanced curing techniques to reduce production time while maintaining dimensional accuracy and structural performance.

Furthermore, the technology seeks to integrate functional gradients and multi-material capabilities, allowing for the creation of ceramic panels with spatially varied properties to meet specific performance requirements. This includes the ability to incorporate porosity gradients, compositional variations, and embedded functional elements within a single manufacturing process.

Market Analysis for Large-Scale Structural Ceramic Panels

The global market for large-scale structural ceramic panels is experiencing significant growth, driven by increasing demand in construction, architecture, and industrial applications. These panels offer superior durability, aesthetic versatility, and environmental benefits compared to traditional building materials. The market size for advanced ceramic materials used in construction was valued at approximately $56 billion in 2022, with large-scale structural panels representing a rapidly growing segment projected to reach $12 billion by 2028.

The construction sector remains the primary consumer of large-scale ceramic panels, accounting for nearly 65% of market demand. Within this sector, commercial buildings and high-end residential projects constitute the largest application segments. The architectural trend toward sustainable, aesthetically pleasing, and low-maintenance façade solutions has particularly accelerated adoption in urban development projects across North America, Europe, and East Asia.

Regional analysis reveals that Europe currently leads the market with approximately 40% share, driven by strong architectural traditions and stringent building regulations favoring sustainable materials. Italy and Spain remain manufacturing hubs, while Germany and the UK represent significant consumption markets. Asia-Pacific represents the fastest-growing region with a compound annual growth rate of 8.7%, primarily fueled by China's massive infrastructure development and Japan's technological innovation in ceramic manufacturing.

Market segmentation by application shows that exterior cladding represents the largest segment (45%), followed by interior wall applications (30%), flooring (15%), and specialized industrial applications (10%). The premium segment of the market, featuring customized designs and advanced technical properties, is growing at twice the rate of standard products, indicating increasing sophistication of consumer demands.

Key market drivers include the growing emphasis on sustainable construction materials, technological advancements in manufacturing processes like Direct Ink Writing (DIW), and increasing awareness of the life-cycle cost benefits of ceramic panels. The DIW technology specifically has opened new possibilities for customization and complex geometries in large-scale panels, creating premium market segments that were previously unattainable with traditional manufacturing methods.

Challenges affecting market growth include high initial production costs, technical limitations in achieving consistent quality at scale, and competition from alternative materials such as engineered stone and high-performance concrete. The relatively high energy consumption in traditional ceramic manufacturing also presents sustainability concerns, though DIW and other advanced manufacturing techniques are addressing this issue through more efficient production processes.

Future market trends indicate growing demand for multifunctional ceramic panels with integrated properties such as self-cleaning surfaces, photocatalytic air purification, and improved thermal insulation. The development of DIW technology for large-scale applications is expected to significantly impact market dynamics by enabling more complex designs and reducing production costs over the next five years.

The construction sector remains the primary consumer of large-scale ceramic panels, accounting for nearly 65% of market demand. Within this sector, commercial buildings and high-end residential projects constitute the largest application segments. The architectural trend toward sustainable, aesthetically pleasing, and low-maintenance façade solutions has particularly accelerated adoption in urban development projects across North America, Europe, and East Asia.

Regional analysis reveals that Europe currently leads the market with approximately 40% share, driven by strong architectural traditions and stringent building regulations favoring sustainable materials. Italy and Spain remain manufacturing hubs, while Germany and the UK represent significant consumption markets. Asia-Pacific represents the fastest-growing region with a compound annual growth rate of 8.7%, primarily fueled by China's massive infrastructure development and Japan's technological innovation in ceramic manufacturing.

Market segmentation by application shows that exterior cladding represents the largest segment (45%), followed by interior wall applications (30%), flooring (15%), and specialized industrial applications (10%). The premium segment of the market, featuring customized designs and advanced technical properties, is growing at twice the rate of standard products, indicating increasing sophistication of consumer demands.

Key market drivers include the growing emphasis on sustainable construction materials, technological advancements in manufacturing processes like Direct Ink Writing (DIW), and increasing awareness of the life-cycle cost benefits of ceramic panels. The DIW technology specifically has opened new possibilities for customization and complex geometries in large-scale panels, creating premium market segments that were previously unattainable with traditional manufacturing methods.

Challenges affecting market growth include high initial production costs, technical limitations in achieving consistent quality at scale, and competition from alternative materials such as engineered stone and high-performance concrete. The relatively high energy consumption in traditional ceramic manufacturing also presents sustainability concerns, though DIW and other advanced manufacturing techniques are addressing this issue through more efficient production processes.

Future market trends indicate growing demand for multifunctional ceramic panels with integrated properties such as self-cleaning surfaces, photocatalytic air purification, and improved thermal insulation. The development of DIW technology for large-scale applications is expected to significantly impact market dynamics by enabling more complex designs and reducing production costs over the next five years.

Technical Challenges in DIW Ceramic Manufacturing

Direct Ink Writing (DIW) technology faces significant technical hurdles when applied to large-scale structural ceramic panels. The primary challenge lies in maintaining consistent rheological properties throughout the printing process. Ceramic inks must exhibit pseudoplastic behavior—flowing under pressure yet maintaining shape post-extrusion. For large panels, even minor viscosity fluctuations can lead to structural defects, particularly at the interfaces between printed layers.

Material homogeneity presents another critical challenge. Large-scale DIW requires substantial volumes of ceramic slurry with uniform particle distribution. Agglomeration and sedimentation become increasingly problematic as batch size increases, potentially causing nozzle clogging and structural weaknesses. Current mixing technologies struggle to maintain homogeneity in large batches without introducing air bubbles that compromise final part integrity.

Dimensional accuracy and warping control represent significant technical barriers. As panel dimensions increase, differential shrinkage during drying and sintering becomes more pronounced. This leads to warping, cracking, and internal stresses that can compromise structural integrity. The industry currently lacks reliable computational models to predict and compensate for these dimensional changes in large ceramic components.

Nozzle design optimization remains problematic for large-scale applications. Current nozzle configurations face trade-offs between extrusion pressure, flow rate, and resolution. Higher flow rates needed for large panels often result in decreased precision and surface quality. Additionally, nozzle wear accelerates when processing abrasive ceramic particles at industrial volumes, leading to inconsistent extrusion profiles over time.

The drying and sintering processes pose particular challenges for large ceramic panels. Uniform heat distribution becomes increasingly difficult to achieve as panel size increases. Temperature gradients within large components lead to differential densification, resulting in internal stresses and potential failure points. Current kiln technologies struggle to provide the precise temperature control required across large ceramic bodies.

Multi-material integration capabilities remain limited in large-scale DIW systems. Creating functionally graded ceramics or incorporating reinforcement structures requires sophisticated material transition strategies and print head configurations. Current systems lack the precision control mechanisms needed to seamlessly integrate different ceramic compositions within large structural panels.

Finally, quality control and in-process monitoring systems are inadequate for large-scale ceramic DIW. Real-time defect detection becomes increasingly critical as component size increases, yet current sensing technologies cannot reliably identify internal flaws or structural weaknesses during the printing process. This gap significantly impacts production efficiency and final part reliability.

Material homogeneity presents another critical challenge. Large-scale DIW requires substantial volumes of ceramic slurry with uniform particle distribution. Agglomeration and sedimentation become increasingly problematic as batch size increases, potentially causing nozzle clogging and structural weaknesses. Current mixing technologies struggle to maintain homogeneity in large batches without introducing air bubbles that compromise final part integrity.

Dimensional accuracy and warping control represent significant technical barriers. As panel dimensions increase, differential shrinkage during drying and sintering becomes more pronounced. This leads to warping, cracking, and internal stresses that can compromise structural integrity. The industry currently lacks reliable computational models to predict and compensate for these dimensional changes in large ceramic components.

Nozzle design optimization remains problematic for large-scale applications. Current nozzle configurations face trade-offs between extrusion pressure, flow rate, and resolution. Higher flow rates needed for large panels often result in decreased precision and surface quality. Additionally, nozzle wear accelerates when processing abrasive ceramic particles at industrial volumes, leading to inconsistent extrusion profiles over time.

The drying and sintering processes pose particular challenges for large ceramic panels. Uniform heat distribution becomes increasingly difficult to achieve as panel size increases. Temperature gradients within large components lead to differential densification, resulting in internal stresses and potential failure points. Current kiln technologies struggle to provide the precise temperature control required across large ceramic bodies.

Multi-material integration capabilities remain limited in large-scale DIW systems. Creating functionally graded ceramics or incorporating reinforcement structures requires sophisticated material transition strategies and print head configurations. Current systems lack the precision control mechanisms needed to seamlessly integrate different ceramic compositions within large structural panels.

Finally, quality control and in-process monitoring systems are inadequate for large-scale ceramic DIW. Real-time defect detection becomes increasingly critical as component size increases, yet current sensing technologies cannot reliably identify internal flaws or structural weaknesses during the printing process. This gap significantly impacts production efficiency and final part reliability.

Current DIW Solutions for Large Ceramic Components

01 DIW techniques for large-scale ceramic panel fabrication

Direct Ink Writing (DIW) techniques enable the fabrication of large-scale structural ceramic panels through precise deposition of ceramic-loaded inks. These methods allow for controlled layer-by-layer construction of complex geometries with high resolution and structural integrity. The process typically involves extruding ceramic slurries through fine nozzles following digital designs, allowing for customization and scalability in panel production.- DIW techniques for large-scale ceramic panel fabrication: Direct Ink Writing (DIW) techniques enable the fabrication of large-scale structural ceramic panels through precise deposition of ceramic-loaded inks. These methods allow for controlled layer-by-layer construction of complex geometries with high resolution and structural integrity. The process typically involves extruding ceramic slurries through nozzles following predetermined paths to create panels with customizable dimensions and properties suitable for architectural and industrial applications.

- Ceramic ink formulations for DIW applications: Specialized ceramic ink formulations are essential for successful Direct Ink Writing of large-scale structural panels. These inks combine ceramic powders with rheological modifiers, binders, and dispersants to achieve optimal flow properties during extrusion while maintaining shape fidelity after deposition. Advanced formulations incorporate nanomaterials and additives that enhance mechanical strength, control shrinkage during drying and sintering, and improve overall panel performance.

- Post-processing treatments for DIW ceramic panels: After Direct Ink Writing, ceramic panels undergo essential post-processing treatments to achieve final properties. These include controlled drying to prevent warping and cracking, debinding to remove organic components, and high-temperature sintering to densify the ceramic structure. Additional surface treatments such as glazing, polishing, or coating may be applied to enhance aesthetic qualities, improve durability, or add functional properties like water resistance or thermal insulation.

- Multi-material and functionally graded ceramic panels: Advanced DIW techniques enable the fabrication of multi-material and functionally graded ceramic panels with spatially varying compositions and properties. By precisely controlling the deposition of different ceramic materials or adjusting ink formulations during printing, panels can be created with optimized mechanical, thermal, or electrical properties in specific regions. This approach allows for the integration of multiple functionalities within a single panel structure, such as combining high strength with thermal insulation or electrical conductivity.

- Scaling and automation of DIW for industrial production: Scaling Direct Ink Writing technology for industrial production of large ceramic panels involves developing automated systems with multiple print heads, advanced motion control, and in-line quality monitoring. These systems incorporate sophisticated software for toolpath generation, process parameter optimization, and defect detection. Innovations in equipment design focus on increasing throughput while maintaining precision, enabling the efficient production of architectural-scale ceramic panels with consistent quality and customizable features.

02 Ceramic ink formulations for DIW applications

Specialized ceramic ink formulations are essential for successful DIW of large-scale panels. These inks combine ceramic powders with binders, dispersants, and rheological modifiers to achieve optimal flow properties during extrusion while maintaining shape fidelity after deposition. The formulations must balance viscosity, yield stress, and solidification behavior to enable proper layer adhesion and prevent structural defects during the printing and drying processes.Expand Specific Solutions03 Post-processing treatments for DIW ceramic panels

After DIW fabrication, ceramic panels undergo various post-processing treatments to achieve final properties. These include controlled drying to prevent cracking, debinding to remove organic components, and sintering at high temperatures to densify the ceramic structure. Additional surface treatments may be applied to enhance mechanical properties, appearance, or functionality. These post-processing steps are critical for ensuring the structural integrity and performance of large-scale ceramic panels.Expand Specific Solutions04 Multi-material and functionally graded ceramic panels via DIW

Advanced DIW techniques enable the fabrication of multi-material and functionally graded ceramic panels. By switching between different ceramic ink compositions during the printing process, panels with spatially varying properties can be created. This approach allows for optimization of mechanical, thermal, or electrical properties in different regions of the panel, enabling tailored performance for specific applications while maintaining structural integrity across material transitions.Expand Specific Solutions05 Reinforcement strategies for large-scale DIW ceramic panels

Various reinforcement strategies are employed to enhance the mechanical properties and durability of large-scale DIW ceramic panels. These include incorporating fiber reinforcements into the ceramic ink, designing internal lattice or honeycomb structures, and creating composite architectures with complementary materials. Such reinforcement approaches help overcome the inherent brittleness of ceramics and enable the production of larger panels with improved impact resistance and load-bearing capacity.Expand Specific Solutions

Leading Companies in Ceramic Additive Manufacturing

The DIW (Direct Ink Writing) market for large-scale structural ceramic panels is currently in its growth phase, with an estimated market size expanding as industrial applications increase. The technology maturity varies across applications, with leading research institutions like Central South University, Harbin Institute of Technology, and Lawrence Livermore National Security advancing fundamental capabilities. Commercial players demonstrate different specialization levels: established ceramic manufacturers (NGK Insulators, Murata Manufacturing) focus on scaling production, while materials specialists (LG Chem, Taiyo Yuden) develop advanced formulations. Equipment providers (Foshan Henglitai Machinery) are addressing automation challenges. The competitive landscape shows regional strengths with Asian companies leading in electronics applications while European firms (SCHOTT AG, Moeding Keramikfassaden) focus on architectural implementations.

Asociacion De Investigacion De Las Industrias Ceramicas

Technical Solution: Asociacion De Investigacion De Las Industrias Ceramicas (ITC) has developed an advanced Direct Ink Writing (DIW) system specifically optimized for large-scale structural ceramic panels. Their technology utilizes a multi-nozzle extrusion system with precise rheological control of ceramic slurries containing up to 65 vol% solid loading. The system incorporates real-time viscosity monitoring and adjustment mechanisms to maintain consistent flow properties throughout the printing process. ITC's approach includes a proprietary drying control system that prevents warping and cracking in large panels by creating microclimate chambers with controlled humidity gradients. Their multi-layer printing strategy incorporates structural reinforcement patterns between layers to enhance mechanical strength while maintaining dimensional stability during sintering. The system can produce panels up to 1.2 × 2.4 meters with thickness variations from 5-50mm while maintaining tight dimensional tolerances.

Strengths: Superior dimensional control for large panels with minimal warping; integrated quality monitoring system ensures consistent production; scalable technology suitable for industrial implementation. Weaknesses: Relatively slow production speed compared to traditional ceramic manufacturing; high initial equipment investment; limited to specific ceramic formulations optimized for their rheological system.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed a specialized DIW system for large-scale structural ceramic panels that addresses key challenges through their proprietary "Gradient Viscosity Control" technology. Their approach utilizes a dynamic ink formulation system that adjusts rheological properties in real-time based on printing parameters and environmental conditions. The system incorporates multiple print heads working in synchronized coordination to produce panels up to 1.5 meters in width while maintaining structural integrity. Murata's technology features an innovative layer-bonding mechanism that creates strong interlayer adhesion through controlled partial sintering between successive layers. Their process includes a specialized drying chamber with zoned climate control that prevents differential shrinkage across large panels. The system utilizes AI-driven process monitoring that continuously adjusts printing parameters based on feedback from embedded sensors tracking moisture content, temperature gradients, and dimensional changes during fabrication. This approach has enabled Murata to achieve consistent quality in panels with complex internal structures while minimizing common defects like warping, cracking, and delamination.

Strengths: Exceptional dimensional stability in large panels; high throughput capability suitable for industrial production; versatile system adaptable to various ceramic compositions. Weaknesses: Requires specialized ink formulations that increase material costs; complex control systems demand regular maintenance and calibration; limited to certain panel geometries and thicknesses.

Key Innovations in Ceramic Ink Formulations

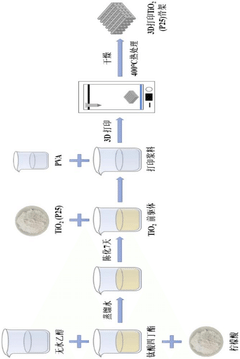

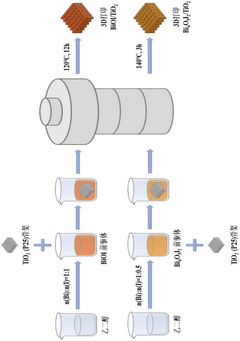

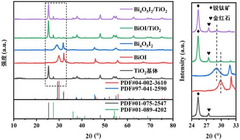

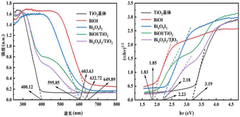

Composite photocatalytic material for 3D printing and preparation method thereof

PatentPendingCN118788402A

Innovation

- Composite photocatalytic materials are prepared using 3D printing technology. The TiO2 precursor solution is formed by mixing citric acid, absolute ethanol, tetrabutyl titanate and titanium dioxide P25 powder, and mixed with bismuth nitrate pentahydrate, potassium iodide and ethylene glycol. The BixOyIz precursor solution undergoes a solvothermal reaction to form a BixOyIz/TiO2 composite material, which improves the recovery rate and photocatalytic performance of the material.

Material Science Considerations for Ceramic Panels

The selection of appropriate materials for ceramic panels in Direct Ink Writing (DIW) applications represents a critical factor determining the structural integrity, performance characteristics, and manufacturing feasibility of large-scale components. Traditional ceramic materials such as alumina, zirconia, and silicon carbide exhibit excellent thermal stability and mechanical strength but present significant challenges when formulated into printable inks with appropriate rheological properties.

The particle size distribution of ceramic powders significantly impacts both the printing process and final material properties. Optimally, ceramic powders should feature a bimodal or multimodal distribution, with particles ranging from 0.1 to 10 μm. This distribution enables higher solid loading while maintaining suitable viscosity for extrusion through fine nozzles. Research indicates that solid loading between 45-60 vol% represents the optimal balance between printability and final mechanical properties.

Rheological modifiers and binders play essential roles in DIW formulations for large ceramic panels. Polymeric binders such as polyvinyl alcohol (PVA), polyethylene glycol (PEG), and various cellulose derivatives provide green strength to printed structures before sintering. Recent advances have introduced stimuli-responsive additives that enable precise control over gelation behavior during and after printing, significantly improving shape retention in large-format applications.

The sintering behavior of ceramic materials presents particular challenges for large-scale panels. Differential shrinkage across extensive dimensions can lead to warping, cracking, and dimensional inaccuracies. Advanced sintering protocols incorporating controlled heating rates (typically 1-3°C/min) and strategic hold temperatures have demonstrated improved outcomes. Additionally, the incorporation of sintering aids such as MgO for alumina or Y2O3 for zirconia can lower sintering temperatures and promote more uniform densification.

Composite approaches incorporating ceramic matrices with reinforcing elements have shown promising results for enhancing mechanical properties. Fiber-reinforced ceramic composites utilizing short carbon or ceramic fibers (typically 50-200 μm in length) can significantly improve fracture toughness without severely compromising printability. These composites demonstrate crack deflection mechanisms that enhance damage tolerance in large structural panels.

Surface functionalization of ceramic particles represents an emerging strategy to improve ink homogeneity and final material properties. Treatments using silanes, phosphates, or polymer grafting can enhance particle-binder interactions, resulting in more stable suspensions and improved green strength. This approach has demonstrated particular efficacy in preventing sedimentation and phase separation during the extended printing times required for large-scale components.

The particle size distribution of ceramic powders significantly impacts both the printing process and final material properties. Optimally, ceramic powders should feature a bimodal or multimodal distribution, with particles ranging from 0.1 to 10 μm. This distribution enables higher solid loading while maintaining suitable viscosity for extrusion through fine nozzles. Research indicates that solid loading between 45-60 vol% represents the optimal balance between printability and final mechanical properties.

Rheological modifiers and binders play essential roles in DIW formulations for large ceramic panels. Polymeric binders such as polyvinyl alcohol (PVA), polyethylene glycol (PEG), and various cellulose derivatives provide green strength to printed structures before sintering. Recent advances have introduced stimuli-responsive additives that enable precise control over gelation behavior during and after printing, significantly improving shape retention in large-format applications.

The sintering behavior of ceramic materials presents particular challenges for large-scale panels. Differential shrinkage across extensive dimensions can lead to warping, cracking, and dimensional inaccuracies. Advanced sintering protocols incorporating controlled heating rates (typically 1-3°C/min) and strategic hold temperatures have demonstrated improved outcomes. Additionally, the incorporation of sintering aids such as MgO for alumina or Y2O3 for zirconia can lower sintering temperatures and promote more uniform densification.

Composite approaches incorporating ceramic matrices with reinforcing elements have shown promising results for enhancing mechanical properties. Fiber-reinforced ceramic composites utilizing short carbon or ceramic fibers (typically 50-200 μm in length) can significantly improve fracture toughness without severely compromising printability. These composites demonstrate crack deflection mechanisms that enhance damage tolerance in large structural panels.

Surface functionalization of ceramic particles represents an emerging strategy to improve ink homogeneity and final material properties. Treatments using silanes, phosphates, or polymer grafting can enhance particle-binder interactions, resulting in more stable suspensions and improved green strength. This approach has demonstrated particular efficacy in preventing sedimentation and phase separation during the extended printing times required for large-scale components.

Sustainability Aspects of DIW Ceramic Production

The sustainability of Direct Ink Writing (DIW) for ceramic production represents a critical dimension in evaluating this technology's viability for large-scale structural ceramic panels. Environmental considerations have become increasingly paramount in manufacturing processes, and DIW offers several advantages in this regard compared to traditional ceramic production methods.

Energy efficiency stands as one of the primary sustainability benefits of DIW ceramic production. Traditional ceramic manufacturing typically requires high-temperature firing across entire batches, whereas DIW enables more targeted energy application. Studies indicate that DIW processes can reduce energy consumption by 20-35% compared to conventional methods, particularly when optimized for large structural panels.

Material utilization represents another significant sustainability advantage. DIW's additive nature minimizes waste generation compared to subtractive manufacturing techniques. The precise deposition of ceramic materials allows for near-net-shape production, reducing the need for post-processing and associated material losses. For large-scale panels, this translates to material savings of approximately 15-25%, depending on geometry complexity.

Water conservation emerges as an additional environmental benefit. Traditional ceramic slip casting and other wet forming techniques require substantial water usage, whereas DIW formulations typically employ lower water content and more efficient recycling systems. This aspect becomes particularly relevant when scaling production to industrial levels for architectural applications.

The carbon footprint of DIW ceramic production also merits consideration. While the process itself may require specialized equipment, the overall lifecycle assessment reveals potential carbon reductions through optimized material usage, reduced firing requirements, and decreased transportation needs due to the possibility of localized production.

Recyclability and circular economy principles can be effectively integrated into DIW ceramic production systems. Failed prints and production scrap can often be reprocessed into new feedstock, creating closed-loop material cycles that further enhance sustainability. This becomes increasingly important when considering the volume of material involved in large-scale structural panel production.

Toxicity reduction represents a final sustainability consideration. DIW formulations can be engineered to minimize harmful additives and binders, potentially reducing workplace exposure risks and environmental impacts compared to some traditional ceramic processing methods that rely on more hazardous components.

Energy efficiency stands as one of the primary sustainability benefits of DIW ceramic production. Traditional ceramic manufacturing typically requires high-temperature firing across entire batches, whereas DIW enables more targeted energy application. Studies indicate that DIW processes can reduce energy consumption by 20-35% compared to conventional methods, particularly when optimized for large structural panels.

Material utilization represents another significant sustainability advantage. DIW's additive nature minimizes waste generation compared to subtractive manufacturing techniques. The precise deposition of ceramic materials allows for near-net-shape production, reducing the need for post-processing and associated material losses. For large-scale panels, this translates to material savings of approximately 15-25%, depending on geometry complexity.

Water conservation emerges as an additional environmental benefit. Traditional ceramic slip casting and other wet forming techniques require substantial water usage, whereas DIW formulations typically employ lower water content and more efficient recycling systems. This aspect becomes particularly relevant when scaling production to industrial levels for architectural applications.

The carbon footprint of DIW ceramic production also merits consideration. While the process itself may require specialized equipment, the overall lifecycle assessment reveals potential carbon reductions through optimized material usage, reduced firing requirements, and decreased transportation needs due to the possibility of localized production.

Recyclability and circular economy principles can be effectively integrated into DIW ceramic production systems. Failed prints and production scrap can often be reprocessed into new feedstock, creating closed-loop material cycles that further enhance sustainability. This becomes increasingly important when considering the volume of material involved in large-scale structural panel production.

Toxicity reduction represents a final sustainability consideration. DIW formulations can be engineered to minimize harmful additives and binders, potentially reducing workplace exposure risks and environmental impacts compared to some traditional ceramic processing methods that rely on more hazardous components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!