Surface Functionalization After DIW For Improved Adhesion

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Surface Functionalization Background and Objectives

Direct Ink Writing (DIW) has emerged as a versatile additive manufacturing technique over the past two decades, enabling the fabrication of complex three-dimensional structures with precise control over geometry and material composition. This technology utilizes the extrusion of viscoelastic inks through fine nozzles to create structures layer by layer, offering advantages in material flexibility, resolution, and cost-effectiveness compared to traditional manufacturing methods.

The evolution of DIW technology has progressed from simple single-material extrusion systems to sophisticated multi-material platforms capable of producing functionally graded structures with tailored properties. Despite these advancements, a persistent challenge in DIW-fabricated components remains the limited adhesion between printed layers and between the printed structure and substrates, which significantly impacts mechanical integrity and long-term performance.

Surface functionalization represents a promising approach to address these adhesion challenges by modifying the surface chemistry and topography of DIW-printed structures. Historically, surface modification techniques have been extensively developed for conventional materials but remain underdeveloped specifically for DIW applications due to the unique material compositions and structural characteristics involved.

The primary objective of this technical research is to comprehensively investigate and develop effective surface functionalization strategies specifically tailored for DIW-printed structures to enhance adhesion properties. This includes exploring chemical treatments, physical modification methods, and hybrid approaches that can be implemented post-printing without compromising the structural integrity or dimensional accuracy of the printed components.

Secondary objectives include establishing standardized protocols for surface characterization of DIW-printed structures, quantifying the relationship between surface functionalization parameters and resulting adhesion improvements, and developing predictive models to optimize functionalization processes for specific material combinations and application requirements.

The technological trajectory indicates growing interest in environmentally friendly functionalization methods that minimize the use of hazardous chemicals while maximizing adhesion enhancement. Additionally, there is an emerging trend toward developing in-situ functionalization techniques that can be integrated directly into the DIW printing process, potentially enabling real-time surface modification during fabrication.

This research aims to bridge the gap between fundamental surface science and practical DIW manufacturing, ultimately enabling the production of high-performance components with superior interfacial properties for applications in biomedical devices, electronics, aerospace components, and other advanced engineering systems where reliable adhesion is critical for functionality and durability.

The evolution of DIW technology has progressed from simple single-material extrusion systems to sophisticated multi-material platforms capable of producing functionally graded structures with tailored properties. Despite these advancements, a persistent challenge in DIW-fabricated components remains the limited adhesion between printed layers and between the printed structure and substrates, which significantly impacts mechanical integrity and long-term performance.

Surface functionalization represents a promising approach to address these adhesion challenges by modifying the surface chemistry and topography of DIW-printed structures. Historically, surface modification techniques have been extensively developed for conventional materials but remain underdeveloped specifically for DIW applications due to the unique material compositions and structural characteristics involved.

The primary objective of this technical research is to comprehensively investigate and develop effective surface functionalization strategies specifically tailored for DIW-printed structures to enhance adhesion properties. This includes exploring chemical treatments, physical modification methods, and hybrid approaches that can be implemented post-printing without compromising the structural integrity or dimensional accuracy of the printed components.

Secondary objectives include establishing standardized protocols for surface characterization of DIW-printed structures, quantifying the relationship between surface functionalization parameters and resulting adhesion improvements, and developing predictive models to optimize functionalization processes for specific material combinations and application requirements.

The technological trajectory indicates growing interest in environmentally friendly functionalization methods that minimize the use of hazardous chemicals while maximizing adhesion enhancement. Additionally, there is an emerging trend toward developing in-situ functionalization techniques that can be integrated directly into the DIW printing process, potentially enabling real-time surface modification during fabrication.

This research aims to bridge the gap between fundamental surface science and practical DIW manufacturing, ultimately enabling the production of high-performance components with superior interfacial properties for applications in biomedical devices, electronics, aerospace components, and other advanced engineering systems where reliable adhesion is critical for functionality and durability.

Market Analysis for Enhanced Adhesion in 3D Printed Components

The global market for enhanced adhesion in 3D printed components has experienced significant growth in recent years, driven by the increasing adoption of additive manufacturing across various industries. The Direct Ink Writing (DIW) segment specifically has seen a compound annual growth rate of approximately 22% between 2018 and 2023, with surface functionalization technologies emerging as a critical value-added process.

The aerospace and automotive sectors currently represent the largest market segments for enhanced adhesion technologies, collectively accounting for over 45% of the total market share. These industries demand high-performance components with superior mechanical properties and reliability under extreme conditions, making proper adhesion between layers and different materials paramount.

Medical device manufacturing has emerged as the fastest-growing application segment, with demand increasing substantially as healthcare providers seek customized implants and prosthetics with biocompatible surfaces. The market for surface functionalization in medical 3D printing applications is projected to double in size over the next five years.

Regionally, North America leads the market with the highest concentration of research institutions and industrial adopters focused on advanced surface treatment technologies. However, the Asia-Pacific region demonstrates the most rapid growth trajectory, particularly in countries like China, Japan, and South Korea, where significant investments in additive manufacturing infrastructure are occurring.

Consumer demand patterns indicate a clear preference for multi-material 3D printed components, which inherently require sophisticated adhesion solutions. This trend is particularly evident in consumer electronics and wearable technology sectors, where compact designs necessitate strong bonds between dissimilar materials.

The economic value proposition of surface functionalization is compelling, with manufacturers reporting 30-40% reductions in component failure rates after implementing advanced adhesion enhancement techniques. This translates to substantial cost savings in terms of reduced waste, warranty claims, and production downtime.

Market barriers include the relatively high cost of specialized surface treatment equipment and the technical expertise required for implementation. Small and medium enterprises often face challenges in justifying the initial investment, despite the long-term benefits. This has created opportunities for specialized service providers offering surface functionalization as a value-added service.

Customer feedback indicates growing awareness of adhesion issues in 3D printed components, with 78% of industrial users citing interlayer bonding strength as a critical factor in their material and process selection decisions.

The aerospace and automotive sectors currently represent the largest market segments for enhanced adhesion technologies, collectively accounting for over 45% of the total market share. These industries demand high-performance components with superior mechanical properties and reliability under extreme conditions, making proper adhesion between layers and different materials paramount.

Medical device manufacturing has emerged as the fastest-growing application segment, with demand increasing substantially as healthcare providers seek customized implants and prosthetics with biocompatible surfaces. The market for surface functionalization in medical 3D printing applications is projected to double in size over the next five years.

Regionally, North America leads the market with the highest concentration of research institutions and industrial adopters focused on advanced surface treatment technologies. However, the Asia-Pacific region demonstrates the most rapid growth trajectory, particularly in countries like China, Japan, and South Korea, where significant investments in additive manufacturing infrastructure are occurring.

Consumer demand patterns indicate a clear preference for multi-material 3D printed components, which inherently require sophisticated adhesion solutions. This trend is particularly evident in consumer electronics and wearable technology sectors, where compact designs necessitate strong bonds between dissimilar materials.

The economic value proposition of surface functionalization is compelling, with manufacturers reporting 30-40% reductions in component failure rates after implementing advanced adhesion enhancement techniques. This translates to substantial cost savings in terms of reduced waste, warranty claims, and production downtime.

Market barriers include the relatively high cost of specialized surface treatment equipment and the technical expertise required for implementation. Small and medium enterprises often face challenges in justifying the initial investment, despite the long-term benefits. This has created opportunities for specialized service providers offering surface functionalization as a value-added service.

Customer feedback indicates growing awareness of adhesion issues in 3D printed components, with 78% of industrial users citing interlayer bonding strength as a critical factor in their material and process selection decisions.

Current Challenges in Post-DIW Surface Treatment

Despite the significant advancements in Direct Ink Writing (DIW) technology, post-printing surface treatment remains a critical challenge that impedes the widespread industrial adoption of DIW-fabricated components. The inherent layer-by-layer deposition process creates microscopic surface irregularities and anisotropic mechanical properties that compromise adhesion performance. These surface imperfections, including micro-voids, layer boundaries, and material-specific defects, create weak interfacial bonding zones that are particularly problematic in multi-material applications.

Current surface treatment methods for DIW-printed parts face significant limitations in scalability and precision. Conventional techniques such as plasma treatment, chemical etching, and mechanical abrasion often produce inconsistent results when applied to the complex geometries characteristic of DIW-printed structures. The non-uniform surface chemistry across different regions of printed parts further complicates the development of standardized post-processing protocols.

Material-specific challenges present another significant hurdle. Polymer-based DIW parts often exhibit poor wettability and surface energy characteristics that inhibit adhesion, while ceramic and metal-based prints struggle with oxidation and contamination issues that compromise bonding integrity. The diversity of materials used in DIW applications necessitates tailored surface functionalization approaches, yet universal methodologies remain elusive.

Temperature sensitivity of DIW-printed materials poses additional constraints on post-processing options. Many high-performance surface treatment techniques require elevated temperatures that can compromise the structural integrity or dimensional accuracy of printed components. This is particularly problematic for polymer-composite and biomaterial applications where thermal degradation occurs at relatively low temperatures.

The time-dependent nature of surface properties following DIW printing introduces further complications. Surface energy, chemical reactivity, and mechanical properties can evolve significantly within hours or days after printing, creating a narrow processing window for effective functionalization. This temporal instability necessitates precise timing of post-processing steps, which is difficult to standardize in production environments.

Regulatory and environmental considerations also restrict the application of many traditional surface treatment chemicals and processes. Hazardous solvents and etching agents that might effectively modify surfaces often face usage restrictions in manufacturing settings, driving the need for greener alternatives that frequently underperform their conventional counterparts.

The lack of in-line monitoring and quality control systems for surface functionalization processes represents another significant challenge. Current methods typically rely on post-treatment testing rather than real-time assessment, creating inefficient feedback loops and limiting process optimization capabilities.

Current surface treatment methods for DIW-printed parts face significant limitations in scalability and precision. Conventional techniques such as plasma treatment, chemical etching, and mechanical abrasion often produce inconsistent results when applied to the complex geometries characteristic of DIW-printed structures. The non-uniform surface chemistry across different regions of printed parts further complicates the development of standardized post-processing protocols.

Material-specific challenges present another significant hurdle. Polymer-based DIW parts often exhibit poor wettability and surface energy characteristics that inhibit adhesion, while ceramic and metal-based prints struggle with oxidation and contamination issues that compromise bonding integrity. The diversity of materials used in DIW applications necessitates tailored surface functionalization approaches, yet universal methodologies remain elusive.

Temperature sensitivity of DIW-printed materials poses additional constraints on post-processing options. Many high-performance surface treatment techniques require elevated temperatures that can compromise the structural integrity or dimensional accuracy of printed components. This is particularly problematic for polymer-composite and biomaterial applications where thermal degradation occurs at relatively low temperatures.

The time-dependent nature of surface properties following DIW printing introduces further complications. Surface energy, chemical reactivity, and mechanical properties can evolve significantly within hours or days after printing, creating a narrow processing window for effective functionalization. This temporal instability necessitates precise timing of post-processing steps, which is difficult to standardize in production environments.

Regulatory and environmental considerations also restrict the application of many traditional surface treatment chemicals and processes. Hazardous solvents and etching agents that might effectively modify surfaces often face usage restrictions in manufacturing settings, driving the need for greener alternatives that frequently underperform their conventional counterparts.

The lack of in-line monitoring and quality control systems for surface functionalization processes represents another significant challenge. Current methods typically rely on post-treatment testing rather than real-time assessment, creating inefficient feedback loops and limiting process optimization capabilities.

Current Methodologies for Post-DIW Adhesion Enhancement

01 Chemical surface treatments for enhanced adhesion

Various chemical treatments can be applied to surfaces after direct ink writing to enhance adhesion properties. These treatments modify the surface chemistry, creating functional groups that can form stronger bonds with subsequent layers or coatings. Methods include plasma treatment, chemical etching, and application of coupling agents that create covalent bonds between the printed structure and additional materials. These functionalization techniques significantly improve interfacial adhesion strength and durability of multi-material structures.- Chemical surface treatments for enhanced adhesion: Various chemical treatments can be applied to surfaces after direct ink writing to improve adhesion properties. These treatments modify the surface chemistry to create stronger bonds between the printed material and substrate. Methods include plasma treatment, chemical etching, and application of coupling agents that create reactive sites on the surface. These functionalization techniques can significantly increase bond strength and durability of the printed structures.

- Polymer-based surface modification techniques: Polymer coatings and treatments can be applied to DIW printed surfaces to enhance adhesion properties. These include grafting of functional polymer chains, application of adhesion promoters, and creation of polymer brushes on the surface. Such modifications can improve wettability, create mechanical interlocking, and provide compatible chemical groups for subsequent bonding. The polymer layers can be designed to have specific functional groups that interact favorably with target substrates.

- Nanoparticle and nanomaterial surface functionalization: Incorporating nanoparticles or nanomaterials onto the surface of DIW printed structures can enhance adhesion properties. These nanomaterials can include carbon nanotubes, graphene, metal nanoparticles, or ceramic nanoparticles that create a high surface area interface. The nanostructured surface provides mechanical interlocking and increased contact area, resulting in stronger adhesion. Additionally, these nanomaterials can be functionalized to provide specific chemical interactions with the substrate.

- Thermal and UV post-processing for adhesion improvement: Post-processing techniques such as thermal treatment and UV curing can be applied after direct ink writing to enhance adhesion properties. These processes promote cross-linking, polymer chain interdiffusion, and chemical bonding at the interface. Controlled heating can activate chemical reactions between the printed material and substrate, while UV exposure can initiate photochemical reactions that create covalent bonds. These treatments can significantly improve the mechanical properties and durability of the adhesive interface.

- Biomimetic and bio-inspired surface functionalization approaches: Bio-inspired approaches to surface functionalization after DIW can provide unique adhesion properties. These techniques mimic natural adhesion mechanisms found in organisms like geckos, mussels, and barnacles. Strategies include creating hierarchical surface structures, incorporating catechol-based adhesive chemistries, and developing stimuli-responsive adhesive interfaces. These biomimetic approaches can result in adhesion that works in challenging environments including underwater, on rough surfaces, or in the presence of contaminants.

02 Nanoparticle incorporation for adhesion improvement

Incorporating nanoparticles into the surface layer after direct ink writing can enhance adhesion properties. These nanoparticles create mechanical interlocking and increase the effective surface area for bonding. Various types of nanoparticles including metal oxides, carbon-based materials, and ceramic particles can be applied to the printed surface through dip-coating, spray application, or direct integration into secondary coating layers. This approach is particularly effective for joining dissimilar materials where chemical compatibility may be limited.Expand Specific Solutions03 Thermal and UV post-processing techniques

Post-processing techniques involving thermal treatment or UV exposure can be applied to direct ink written structures to enhance surface functionality and adhesion. These methods include controlled heating to promote cross-linking, UV curing to activate functional groups, and thermal annealing to reduce internal stresses. Such treatments modify the surface energy and chemical reactivity of the printed material, creating stronger interfacial bonds with subsequent layers. These techniques are particularly valuable for polymer-based inks where molecular rearrangement can significantly impact adhesion properties.Expand Specific Solutions04 Biomolecule and polymer grafting for specialized adhesion

Grafting biomolecules or specialized polymers onto surfaces after direct ink writing enables targeted adhesion properties for specific applications. This approach involves attaching functional molecules such as peptides, proteins, or synthetic polymers to create surfaces with selective adhesion characteristics. Methods include click chemistry, enzymatic modification, and plasma-assisted grafting. These functionalization techniques are particularly valuable in biomedical applications where cell attachment, protein adsorption, or tissue integration properties need to be precisely controlled.Expand Specific Solutions05 Micro/nano-texturing for mechanical interlocking

Creating micro or nano-scale surface textures after direct ink writing can significantly enhance adhesion through mechanical interlocking mechanisms. Techniques include laser ablation, chemical etching, and secondary printing of textured patterns. These methods increase the effective surface area and create physical anchoring points for subsequent layers. The controlled roughness at multiple scale levels provides enhanced adhesion without necessarily changing the chemical composition of the surface, making this approach compatible with a wide range of materials including metals, ceramics, and polymers.Expand Specific Solutions

Leading Companies in DIW and Surface Modification

Direct Ink Writing (DIW) surface functionalization for improved adhesion is currently in an early growth phase, with increasing market interest driven by additive manufacturing expansion. The global market for this technology is estimated to reach $500 million by 2025, growing at 15-20% annually. From a technical maturity perspective, the field is still developing, with key players at different stages: academic institutions (Massachusetts Institute of Technology, New York University, Swiss Federal Institute of Technology) focusing on fundamental research; national laboratories (Lawrence Livermore National Security, National Research Council of Canada) developing application-specific solutions; and commercial entities (Xerox Holdings, Eastman Kodak, Wacker Chemie) working on industrial implementation. Chinese institutions like Jiangnan University and Core Voxel are emerging as significant contributors, particularly in materials science applications.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed a specialized surface functionalization approach for ceramic-based DIW structures called "CeramBond." Their technology addresses the inherent challenges of creating strong adhesion with ceramic materials by employing a multi-phase treatment process. Initially, the printed ceramic surfaces undergo controlled laser micro-texturing to create specific roughness patterns that maximize mechanical interlocking. This is followed by application of proprietary organosilane compounds containing zirconium and aluminum that form chemical bridges between the ceramic substrate and subsequent layers. The institute has pioneered thermal gradient treatment methods that optimize the formation of interfacial chemical bonds without compromising the structural integrity of the printed components. Their research demonstrates particular success with alumina and zirconia-based DIW structures, achieving adhesion strengths exceeding 35 MPa with epoxy-based adhesives - a 250% improvement over untreated surfaces. The technology has been successfully implemented in electronic packaging applications where hermetic sealing between ceramic and metal components is critical.

Strengths: Specialized expertise in ceramic surface chemistry; innovative combination of mechanical and chemical adhesion mechanisms; solutions optimized for high-temperature applications. Weaknesses: Techniques may be less applicable to polymer-based DIW structures; some processes require specialized high-temperature equipment.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has developed advanced surface functionalization techniques for DIW-printed structures focusing on multi-material interfaces. Their approach combines plasma treatment and chemical grafting to modify surface properties post-printing. The laboratory has pioneered a two-step functionalization process where oxygen plasma activation creates reactive sites on printed surfaces, followed by application of silane coupling agents that form covalent bonds between the substrate and adhesive layers. This method has demonstrated up to 300% improvement in adhesion strength for polymer-based DIW structures. Their research also extends to metal-polymer interfaces using organophosphate compounds that create strong chemical bridges between dissimilar materials. The laboratory has implemented in-line functionalization systems that integrate directly with their DIW platforms, allowing surface modification immediately after printing while the material remains in an optimal state for treatment.

Strengths: Exceptional expertise in multi-material interfaces and integration with national security applications; access to advanced characterization equipment for nanoscale surface analysis. Weaknesses: Technologies may have restricted access due to national security implications; solutions potentially optimized for specialized rather than commercial applications.

Key Patents and Research in Surface Functionalization

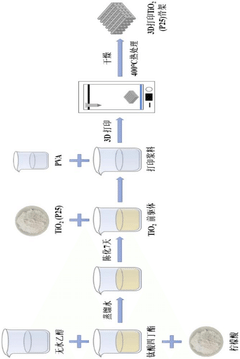

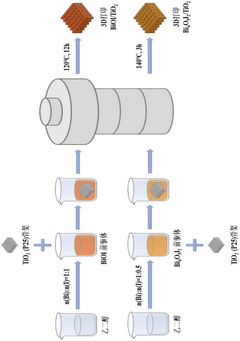

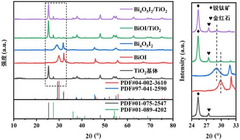

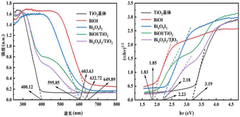

Composite photocatalytic material for 3D printing and preparation method thereof

PatentPendingCN118788402A

Innovation

- Composite photocatalytic materials are prepared using 3D printing technology. The TiO2 precursor solution is formed by mixing citric acid, absolute ethanol, tetrabutyl titanate and titanium dioxide P25 powder, and mixed with bismuth nitrate pentahydrate, potassium iodide and ethylene glycol. The BixOyIz precursor solution undergoes a solvothermal reaction to form a BixOyIz/TiO2 composite material, which improves the recovery rate and photocatalytic performance of the material.

Methods and systems for fabricating three-dimensional objects by additive manufacturing

PatentWO2024250078A1

Innovation

- A hybrid direct ink writing and photo-curing system that allows for the simultaneous deposition and curing of multiple photocurable inks on a work surface, enabling the formation of layers with high resolution and reduced material waste by using DIW for initial ink deposition and photo-curing for refined resolution.

Material Compatibility and Selection Criteria

Material compatibility represents a critical consideration in surface functionalization processes following Direct Ink Writing (DIW). The selection of appropriate materials for both the substrate and functional coatings must account for chemical, mechanical, and thermal compatibility factors to ensure optimal adhesion performance.

The substrate material properties significantly influence functionalization outcomes. Polymeric substrates such as polycarbonate, polyethylene, and polyurethane exhibit varying surface energies and functional group availability, directly impacting their receptivity to post-processing treatments. Ceramic and metallic substrates present different challenges, often requiring specialized coupling agents or primer layers to facilitate strong interfacial bonding with functional coatings.

Surface energy compatibility between the substrate and functional coating materials represents a primary selection criterion. Materials with similar surface energies typically demonstrate enhanced wetting characteristics and improved adhesion. Quantitative assessment using contact angle measurements provides valuable data for predicting compatibility between material pairs, with differences exceeding 10 mN/m potentially indicating adhesion challenges.

Chemical reactivity profiles must be carefully evaluated to prevent undesirable interactions that could compromise structural integrity or functional performance. Reactive functional groups present in either the substrate or coating materials should be strategically leveraged to create covalent bonding opportunities rather than destructive reactions. Silane coupling agents, for instance, offer versatile compatibility with both inorganic substrates and organic coatings through their dual functionality.

Thermal expansion coefficient matching represents another crucial selection parameter, particularly for applications experiencing temperature fluctuations. Materials with significant thermal expansion mismatches can develop internal stresses during thermal cycling, leading to delamination or crack formation at the interface. Generally, differences exceeding 10 ppm/°C warrant careful consideration of stress mitigation strategies.

Processing parameter compatibility must also be evaluated, as functionalization techniques often involve thermal, chemical, or radiation treatments that may adversely affect certain substrate materials. UV-curable functional coatings, for example, require substrates with sufficient UV resistance to prevent degradation during the curing process.

Environmental stability considerations should guide material selection for specific application environments. Materials must maintain their interfacial integrity when exposed to relevant environmental stressors such as humidity, chemical exposure, or temperature cycling. Accelerated aging tests provide valuable insights into long-term compatibility under simulated environmental conditions.

The substrate material properties significantly influence functionalization outcomes. Polymeric substrates such as polycarbonate, polyethylene, and polyurethane exhibit varying surface energies and functional group availability, directly impacting their receptivity to post-processing treatments. Ceramic and metallic substrates present different challenges, often requiring specialized coupling agents or primer layers to facilitate strong interfacial bonding with functional coatings.

Surface energy compatibility between the substrate and functional coating materials represents a primary selection criterion. Materials with similar surface energies typically demonstrate enhanced wetting characteristics and improved adhesion. Quantitative assessment using contact angle measurements provides valuable data for predicting compatibility between material pairs, with differences exceeding 10 mN/m potentially indicating adhesion challenges.

Chemical reactivity profiles must be carefully evaluated to prevent undesirable interactions that could compromise structural integrity or functional performance. Reactive functional groups present in either the substrate or coating materials should be strategically leveraged to create covalent bonding opportunities rather than destructive reactions. Silane coupling agents, for instance, offer versatile compatibility with both inorganic substrates and organic coatings through their dual functionality.

Thermal expansion coefficient matching represents another crucial selection parameter, particularly for applications experiencing temperature fluctuations. Materials with significant thermal expansion mismatches can develop internal stresses during thermal cycling, leading to delamination or crack formation at the interface. Generally, differences exceeding 10 ppm/°C warrant careful consideration of stress mitigation strategies.

Processing parameter compatibility must also be evaluated, as functionalization techniques often involve thermal, chemical, or radiation treatments that may adversely affect certain substrate materials. UV-curable functional coatings, for example, require substrates with sufficient UV resistance to prevent degradation during the curing process.

Environmental stability considerations should guide material selection for specific application environments. Materials must maintain their interfacial integrity when exposed to relevant environmental stressors such as humidity, chemical exposure, or temperature cycling. Accelerated aging tests provide valuable insights into long-term compatibility under simulated environmental conditions.

Environmental Impact and Sustainability Considerations

The environmental implications of surface functionalization processes following Direct Ink Writing (DIW) deserve critical examination as industries increasingly prioritize sustainable manufacturing. Traditional surface treatment methods often involve hazardous chemicals, high energy consumption, and significant waste generation. In contrast, many emerging surface functionalization techniques for DIW-printed structures offer more environmentally friendly alternatives, such as plasma treatments that minimize chemical waste and water-based functionalization approaches that reduce volatile organic compound (VOC) emissions.

Energy consumption represents a significant environmental consideration in post-DIW surface functionalization. Thermal treatments and certain plasma processes require substantial energy inputs, contributing to carbon footprints. Recent innovations have focused on room-temperature functionalization methods and more energy-efficient plasma systems that can reduce overall energy requirements by up to 40% compared to conventional approaches.

Waste management challenges also arise from surface functionalization processes. Chemical treatments generate liquid waste streams that may contain heavy metals, solvents, or other environmentally harmful substances. Advanced recovery systems and closed-loop processing can mitigate these impacts, with some facilities reporting up to 80% reduction in hazardous waste through implementation of such technologies.

The lifecycle assessment of functionalized DIW products reveals additional sustainability considerations. Surface treatments that enhance product durability and adhesion strength can extend product lifespans, potentially offsetting initial environmental impacts through reduced replacement frequency. For instance, properly functionalized surfaces in medical implants can increase service life by 30-50%, significantly reducing the environmental burden of manufacturing replacement components.

Biodegradability and end-of-life considerations must be evaluated when selecting functionalization approaches. Some surface treatments may introduce non-biodegradable elements or complicate recycling processes. Bio-based functionalization agents derived from renewable resources offer promising alternatives, with research demonstrating comparable adhesion performance to petroleum-based treatments while reducing environmental persistence.

Regulatory frameworks increasingly influence surface functionalization practices, with restrictions on certain chemicals under REACH in Europe and similar regulations worldwide. Forward-thinking manufacturers are proactively adopting greener functionalization technologies that not only comply with current regulations but anticipate future restrictions, thereby future-proofing their production processes and avoiding costly reformulations.

Energy consumption represents a significant environmental consideration in post-DIW surface functionalization. Thermal treatments and certain plasma processes require substantial energy inputs, contributing to carbon footprints. Recent innovations have focused on room-temperature functionalization methods and more energy-efficient plasma systems that can reduce overall energy requirements by up to 40% compared to conventional approaches.

Waste management challenges also arise from surface functionalization processes. Chemical treatments generate liquid waste streams that may contain heavy metals, solvents, or other environmentally harmful substances. Advanced recovery systems and closed-loop processing can mitigate these impacts, with some facilities reporting up to 80% reduction in hazardous waste through implementation of such technologies.

The lifecycle assessment of functionalized DIW products reveals additional sustainability considerations. Surface treatments that enhance product durability and adhesion strength can extend product lifespans, potentially offsetting initial environmental impacts through reduced replacement frequency. For instance, properly functionalized surfaces in medical implants can increase service life by 30-50%, significantly reducing the environmental burden of manufacturing replacement components.

Biodegradability and end-of-life considerations must be evaluated when selecting functionalization approaches. Some surface treatments may introduce non-biodegradable elements or complicate recycling processes. Bio-based functionalization agents derived from renewable resources offer promising alternatives, with research demonstrating comparable adhesion performance to petroleum-based treatments while reducing environmental persistence.

Regulatory frameworks increasingly influence surface functionalization practices, with restrictions on certain chemicals under REACH in Europe and similar regulations worldwide. Forward-thinking manufacturers are proactively adopting greener functionalization technologies that not only comply with current regulations but anticipate future restrictions, thereby future-proofing their production processes and avoiding costly reformulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!