Ink Formulation Strategies For High-Solid Ceramic DIW Printing

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic DIW Printing Ink Evolution and Objectives

Direct Ink Writing (DIW) technology for ceramic materials has evolved significantly over the past three decades, transforming from basic extrusion methods to sophisticated additive manufacturing processes. The journey began in the 1990s with rudimentary paste extrusion systems that offered limited precision and material options. By the early 2000s, researchers had developed more refined ink formulations that enabled better flow properties and structural integrity during printing.

The evolution of ceramic DIW printing inks has been characterized by progressive improvements in rheological properties, particularly in achieving the delicate balance between flowability during extrusion and shape retention after deposition. Early formulations relied heavily on organic binders and plasticizers, resulting in relatively low solid loading (typically below 40 vol%) and significant shrinkage during sintering.

A pivotal advancement came with the introduction of colloidal science principles to ink formulation around 2010, enabling better control of particle interactions and stability. This scientific approach facilitated the development of inks with higher solid content while maintaining printability, marking the beginning of high-solid ceramic DIW printing technology.

Recent years have witnessed accelerated development in high-solid ceramic ink formulations, driven by demands for improved dimensional accuracy, reduced shrinkage, and enhanced mechanical properties in printed components. Current state-of-the-art formulations can achieve solid loadings exceeding 55 vol% while maintaining suitable rheological properties for extrusion through fine nozzles.

The primary objective in high-solid ceramic DIW ink development is to maximize ceramic particle content while maintaining appropriate flow behavior under shear conditions during printing. This requires precise control of particle size distribution, surface chemistry, and the selection of appropriate dispersants and rheology modifiers that contribute minimally to the final organic content.

Additional technical goals include developing formulations that exhibit strong shear-thinning behavior (to facilitate flow during extrusion) coupled with rapid recovery of yield stress (to maintain shape after deposition). Furthermore, inks must demonstrate consistent properties throughout the printing process, resist nozzle clogging, and provide uniform drying behavior to prevent warping or cracking.

Looking forward, the field aims to develop "smart" ceramic inks that can respond to external stimuli, self-heal defects during printing, or incorporate functionality through material composition. There is also growing interest in environmentally friendly formulations that reduce or eliminate toxic components while maintaining high performance standards.

The evolution of ceramic DIW printing inks has been characterized by progressive improvements in rheological properties, particularly in achieving the delicate balance between flowability during extrusion and shape retention after deposition. Early formulations relied heavily on organic binders and plasticizers, resulting in relatively low solid loading (typically below 40 vol%) and significant shrinkage during sintering.

A pivotal advancement came with the introduction of colloidal science principles to ink formulation around 2010, enabling better control of particle interactions and stability. This scientific approach facilitated the development of inks with higher solid content while maintaining printability, marking the beginning of high-solid ceramic DIW printing technology.

Recent years have witnessed accelerated development in high-solid ceramic ink formulations, driven by demands for improved dimensional accuracy, reduced shrinkage, and enhanced mechanical properties in printed components. Current state-of-the-art formulations can achieve solid loadings exceeding 55 vol% while maintaining suitable rheological properties for extrusion through fine nozzles.

The primary objective in high-solid ceramic DIW ink development is to maximize ceramic particle content while maintaining appropriate flow behavior under shear conditions during printing. This requires precise control of particle size distribution, surface chemistry, and the selection of appropriate dispersants and rheology modifiers that contribute minimally to the final organic content.

Additional technical goals include developing formulations that exhibit strong shear-thinning behavior (to facilitate flow during extrusion) coupled with rapid recovery of yield stress (to maintain shape after deposition). Furthermore, inks must demonstrate consistent properties throughout the printing process, resist nozzle clogging, and provide uniform drying behavior to prevent warping or cracking.

Looking forward, the field aims to develop "smart" ceramic inks that can respond to external stimuli, self-heal defects during printing, or incorporate functionality through material composition. There is also growing interest in environmentally friendly formulations that reduce or eliminate toxic components while maintaining high performance standards.

Market Analysis for High-Solid Ceramic Printing Applications

The high-solid ceramic Direct Ink Writing (DIW) printing market is experiencing significant growth, driven by increasing demand across multiple industrial sectors. The global market for advanced ceramics, which includes DIW printing applications, is currently valued at approximately $75 billion and is projected to grow at a compound annual growth rate of 6.2% through 2028. This growth is particularly pronounced in the aerospace, healthcare, electronics, and energy sectors.

In the aerospace industry, high-solid ceramic components manufactured through DIW printing are gaining traction for their exceptional thermal resistance and lightweight properties. These components are increasingly being utilized in engine parts and thermal protection systems, with the aerospace ceramic components market segment alone estimated at $5.3 billion.

The healthcare sector represents another substantial market opportunity, with ceramic biomaterials for implants and prosthetics showing a market value of $3.8 billion. The precision offered by DIW printing enables the creation of patient-specific implants with complex geometries and controlled porosity, driving adoption in orthopedic and dental applications.

Electronics manufacturers are increasingly turning to high-solid ceramic DIW printing for the production of substrates, insulators, and packaging materials. This segment accounts for approximately $12 billion of the market, with particular growth in 5G infrastructure components and semiconductor packaging applications.

Energy sector applications, including solid oxide fuel cells and battery components, represent a rapidly expanding market valued at $4.2 billion. The ability of DIW printing to create precise microstructures with high solid loading is particularly valuable for enhancing energy conversion efficiency and storage capacity.

Regionally, Asia-Pacific dominates the market with a 42% share, driven by strong manufacturing bases in China, Japan, and South Korea. North America follows with 28% market share, with significant research and development activities in advanced ceramic applications. Europe accounts for 24% of the market, with particular strength in precision engineering and medical applications.

Customer demand is increasingly focused on materials that enable higher resolution printing, improved surface finish, and enhanced mechanical properties. There is also growing interest in multi-material printing capabilities and environmentally sustainable formulations. Market research indicates that customers are willing to pay premium prices for ink formulations that can achieve higher solid loading (>60% by volume) while maintaining printability.

The market is expected to see further expansion as manufacturing industries continue to adopt additive manufacturing technologies for production rather than just prototyping. This shift is creating new opportunities for specialized high-solid ceramic ink formulations tailored to specific industrial applications.

In the aerospace industry, high-solid ceramic components manufactured through DIW printing are gaining traction for their exceptional thermal resistance and lightweight properties. These components are increasingly being utilized in engine parts and thermal protection systems, with the aerospace ceramic components market segment alone estimated at $5.3 billion.

The healthcare sector represents another substantial market opportunity, with ceramic biomaterials for implants and prosthetics showing a market value of $3.8 billion. The precision offered by DIW printing enables the creation of patient-specific implants with complex geometries and controlled porosity, driving adoption in orthopedic and dental applications.

Electronics manufacturers are increasingly turning to high-solid ceramic DIW printing for the production of substrates, insulators, and packaging materials. This segment accounts for approximately $12 billion of the market, with particular growth in 5G infrastructure components and semiconductor packaging applications.

Energy sector applications, including solid oxide fuel cells and battery components, represent a rapidly expanding market valued at $4.2 billion. The ability of DIW printing to create precise microstructures with high solid loading is particularly valuable for enhancing energy conversion efficiency and storage capacity.

Regionally, Asia-Pacific dominates the market with a 42% share, driven by strong manufacturing bases in China, Japan, and South Korea. North America follows with 28% market share, with significant research and development activities in advanced ceramic applications. Europe accounts for 24% of the market, with particular strength in precision engineering and medical applications.

Customer demand is increasingly focused on materials that enable higher resolution printing, improved surface finish, and enhanced mechanical properties. There is also growing interest in multi-material printing capabilities and environmentally sustainable formulations. Market research indicates that customers are willing to pay premium prices for ink formulations that can achieve higher solid loading (>60% by volume) while maintaining printability.

The market is expected to see further expansion as manufacturing industries continue to adopt additive manufacturing technologies for production rather than just prototyping. This shift is creating new opportunities for specialized high-solid ceramic ink formulations tailored to specific industrial applications.

Technical Barriers in High-Solid Ceramic Ink Development

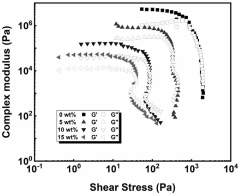

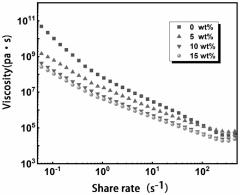

The development of high-solid ceramic inks for Direct Ink Writing (DIW) faces several significant technical barriers that impede widespread adoption and optimal performance. One of the primary challenges is achieving the delicate rheological balance required for successful printing. High-solid ceramic inks must exhibit both shear-thinning behavior during extrusion and rapid structural recovery post-extrusion to maintain shape fidelity. This paradoxical requirement creates a narrow processing window that is difficult to consistently achieve.

Particle loading optimization presents another major hurdle. While higher ceramic content (typically >40 vol%) is desirable for minimizing shrinkage and defects during sintering, increased solid loading dramatically affects flow properties. As solid content increases, viscosity rises exponentially, often exceeding the pressure capabilities of standard DIW systems. Additionally, high particle concentrations promote agglomeration, leading to nozzle clogging and print inconsistencies.

Dispersion stability remains problematic across the formulation lifecycle. High-solid ceramic suspensions are inherently thermodynamically unstable, with particles tending to agglomerate due to van der Waals forces. While dispersants can mitigate this issue, their effectiveness diminishes at higher solid loadings, and they may interfere with subsequent gelation mechanisms necessary for shape retention.

The binder-ceramic interface presents complex compatibility challenges. Organic binders and ceramic particles often have poor interfacial compatibility, resulting in weak particle-matrix interactions. This weakness manifests as reduced green body strength and potential delamination during post-processing. Furthermore, the high surface area of ceramic particles requires substantial amounts of binder, which later creates significant outgassing issues during debinding.

Nozzle design constraints further complicate high-solid ceramic printing. The high viscosity of these formulations necessitates greater extrusion pressures, which can lead to die swell phenomena and pressure-induced separation of ceramic and liquid phases. Current nozzle materials and geometries are often inadequate for handling the abrasive nature of ceramic particles at high concentrations.

Drying kinetics control represents another significant barrier. High-solid ceramic inks are prone to non-uniform drying, creating internal stresses that lead to warping and cracking. The reduced liquid content limits the time window for proper layer adhesion, making multi-layer structures particularly challenging to fabricate without defects.

Finally, batch-to-batch reproducibility remains elusive due to the sensitivity of high-solid formulations to minor variations in raw materials, processing conditions, and environmental factors. Small deviations in particle size distribution, moisture content, or mixing parameters can dramatically alter rheological properties, making standardization difficult.

Particle loading optimization presents another major hurdle. While higher ceramic content (typically >40 vol%) is desirable for minimizing shrinkage and defects during sintering, increased solid loading dramatically affects flow properties. As solid content increases, viscosity rises exponentially, often exceeding the pressure capabilities of standard DIW systems. Additionally, high particle concentrations promote agglomeration, leading to nozzle clogging and print inconsistencies.

Dispersion stability remains problematic across the formulation lifecycle. High-solid ceramic suspensions are inherently thermodynamically unstable, with particles tending to agglomerate due to van der Waals forces. While dispersants can mitigate this issue, their effectiveness diminishes at higher solid loadings, and they may interfere with subsequent gelation mechanisms necessary for shape retention.

The binder-ceramic interface presents complex compatibility challenges. Organic binders and ceramic particles often have poor interfacial compatibility, resulting in weak particle-matrix interactions. This weakness manifests as reduced green body strength and potential delamination during post-processing. Furthermore, the high surface area of ceramic particles requires substantial amounts of binder, which later creates significant outgassing issues during debinding.

Nozzle design constraints further complicate high-solid ceramic printing. The high viscosity of these formulations necessitates greater extrusion pressures, which can lead to die swell phenomena and pressure-induced separation of ceramic and liquid phases. Current nozzle materials and geometries are often inadequate for handling the abrasive nature of ceramic particles at high concentrations.

Drying kinetics control represents another significant barrier. High-solid ceramic inks are prone to non-uniform drying, creating internal stresses that lead to warping and cracking. The reduced liquid content limits the time window for proper layer adhesion, making multi-layer structures particularly challenging to fabricate without defects.

Finally, batch-to-batch reproducibility remains elusive due to the sensitivity of high-solid formulations to minor variations in raw materials, processing conditions, and environmental factors. Small deviations in particle size distribution, moisture content, or mixing parameters can dramatically alter rheological properties, making standardization difficult.

Current High-Solid Ceramic Ink Formulation Approaches

01 High solid content ceramic ink formulations

Ceramic ink formulations with high solid content typically contain 30-70% ceramic particles by weight. These formulations are designed to achieve optimal viscosity while maintaining high pigment loading. The high solid content provides better coverage, enhanced color intensity, and improved printing quality. These inks require careful selection of dispersants and rheology modifiers to prevent sedimentation and maintain stability during storage and application.- High solid content ceramic ink formulations: Ceramic ink formulations with high solid content typically contain increased amounts of ceramic particles suspended in the ink vehicle. These formulations offer advantages such as improved print density, enhanced color development, and reduced ink consumption. The high solid content allows for better coverage and more vibrant colors after firing, while maintaining suitable rheological properties for printing applications.

- Dispersants and rheology modifiers for high-solid ceramic inks: Specialized dispersants and rheology modifiers are essential components in high-solid content ceramic ink formulations. These additives prevent particle agglomeration, maintain ink stability, and ensure proper flow characteristics despite the high particle loading. Effective dispersants enable higher solid content while maintaining printability by creating steric or electrostatic barriers between ceramic particles, while rheology modifiers control viscosity and thixotropic behavior.

- Binder systems for high-solid ceramic inks: Advanced binder systems are crucial for high-solid content ceramic ink formulations to provide adequate particle adhesion and green strength before firing. These binders must be compatible with high particle loadings while maintaining proper ink rheology. Specialized organic and inorganic binder combinations help achieve optimal suspension stability, print definition, and firing performance, while minimizing defects such as cracking or delamination during the drying and sintering processes.

- Milling and particle size control techniques: Precise milling and particle size control techniques are essential for achieving high-solid content ceramic ink formulations. Advanced milling processes ensure uniform particle size distribution, which enables higher solid loading while maintaining ink stability and printability. Optimized particle size ranges and distributions allow for better packing efficiency, reduced viscosity at high solid loadings, and improved sintering behavior during the firing process.

- Solvent and vehicle systems for high-solid ceramic inks: Specialized solvent and vehicle systems are developed specifically for high-solid content ceramic ink formulations. These systems must effectively suspend high concentrations of ceramic particles while maintaining appropriate viscosity, surface tension, and drying characteristics. The selection of compatible solvents, co-solvents, and carrier fluids is critical for ink stability, printhead performance, and print quality, particularly when dealing with elevated solid content levels.

02 Dispersants and rheology modifiers for high-solid ceramic inks

Specialized dispersants and rheology modifiers are essential components in high-solid ceramic ink formulations. These additives prevent agglomeration of ceramic particles and maintain proper flow characteristics despite the high solid loading. Effective dispersants include polyelectrolytes, phosphate esters, and siloxane-based compounds that adsorb onto particle surfaces to provide steric and/or electrostatic stabilization. Rheology modifiers such as cellulose derivatives and polyacrylates help control viscosity and prevent settling during storage.Expand Specific Solutions03 Nanoparticle incorporation in high-solid ceramic inks

Incorporating nanoparticles into ceramic ink formulations allows for higher solid content while maintaining printability. Nano-sized ceramic particles provide improved suspension stability, enhanced sintering properties, and better surface finish in the final product. The use of nanoparticles enables the formulation of inks with solid content exceeding 50% by weight while maintaining suitable viscosity for various printing methods. These formulations often require specialized processing techniques such as high-energy milling to achieve proper dispersion.Expand Specific Solutions04 Organic vehicle systems for high-solid ceramic inks

The organic vehicle system plays a crucial role in high-solid ceramic ink formulations. These systems typically consist of solvents, binders, and plasticizers that provide the appropriate rheological properties and drying characteristics. Solvent selection is critical for dissolving binders while maintaining compatibility with ceramic particles. Common vehicle components include glycol ethers, alcohols, and esters combined with acrylic resins, cellulose derivatives, or polyvinyl butyral as binders. The vehicle system must facilitate high solid loading while ensuring proper ink transfer and adhesion to substrates.Expand Specific Solutions05 Processing techniques for high-solid ceramic ink production

Specialized processing techniques are required to produce stable high-solid ceramic ink formulations. These include multi-stage milling processes, high-shear mixing, and ultrasonic treatment to break down agglomerates and achieve uniform particle distribution. Temperature-controlled processing helps manage viscosity during manufacturing. Filtration steps remove oversized particles that could cause nozzle clogging in digital printing applications. These techniques enable the production of ceramic inks with solid content up to 70% while maintaining the necessary flow properties for various application methods.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ceramic DIW

The ceramic Direct Ink Writing (DIW) printing market is currently in a growth phase, with increasing adoption across industrial and research sectors. The market size is expanding as high-solid ceramic DIW printing enables complex geometries with enhanced mechanical properties. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant R&D ongoing. Leading academic institutions like Central South University, Shanghai Institute of Ceramics, and Xi'an Jiaotong University are driving fundamental research, while companies including Applied Materials, Sun Chemical, and Torrecid SA are commercializing advanced ink formulations. The industry faces challenges in balancing rheological properties with printability, with recent innovations focusing on multi-material printing capabilities and environmentally sustainable formulations.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

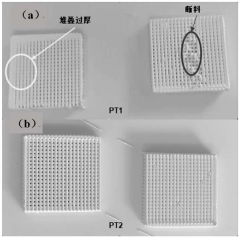

Technical Solution: Shanghai Institute of Ceramics has developed a comprehensive ink formulation strategy for high-solid ceramic DIW printing that focuses on rheological control through multi-component systems. Their approach utilizes a combination of primary ceramic powders (typically 40-55 vol%) with carefully selected dispersants (often phosphate-based) to achieve optimal particle dispersion[1]. They've pioneered the use of fumed silica as a rheology modifier to create shear-thinning behavior essential for DIW printing. Their formulations typically incorporate hydrogel-forming polymers like hydroxypropyl methylcellulose (HPMC) or alginate that provide the necessary viscoelastic properties[3]. A key innovation is their dual-modifier system that combines traditional polymeric binders with nano-additives to simultaneously achieve high solid loading (up to 60 vol%) while maintaining printability. Their research has demonstrated successful printing of complex alumina, zirconia, and silicon nitride structures with minimal deformation during post-processing[5].

Strengths: Exceptional control over rheological properties allowing for higher solid loading than many competitors; demonstrated success with multiple ceramic material systems; strong scientific foundation with extensive characterization capabilities. Weaknesses: Some formulations require complex multi-step mixing protocols that may be challenging to scale industrially; certain proprietary additives may have limited commercial availability.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed an innovative approach to high-solid ceramic DIW printing through their patented "Gradient Viscoelastic Ink System" (GVIS). This technology employs a core-shell microstructure within the ink formulation, where ceramic particles are encapsulated in a hydrogel network with varying crosslinking density[2]. Their formulation typically achieves solid loadings of 45-58 vol% while maintaining excellent printability. The GVIS approach utilizes temperature-responsive polymers (such as modified Pluronic F-127) combined with inorganic binding agents to create inks that exhibit strong shear-thinning behavior during extrusion but rapid structural recovery post-deposition[4]. A distinctive feature is their use of surface-modified ceramic particles with grafted polymer chains that enhance particle-binder interactions. Their research has demonstrated successful printing of complex alumina and zirconia components with minimal shape distortion during sintering, achieving final densities exceeding 98% of theoretical values[6]. Recent advancements include the incorporation of nano-sized sintering aids distributed homogeneously throughout the ink to enhance densification at lower sintering temperatures.

Strengths: Exceptional shape retention in complex geometries due to rapid structural recovery; high final part density with minimal defects; versatile system adaptable to multiple ceramic materials. Weaknesses: Temperature sensitivity during printing process requires precise environmental control; relatively complex formulation process with multiple chemical modification steps; some proprietary additives may increase overall material costs.

Key Patents and Research in Rheology Control for DIW Inks

Direct-writing 3D printing titanium dioxide ceramic slurry and preparation method thereof

PatentActiveCN113307620A

Innovation

- Using a specific combination of nano-titanium dioxide, adhesive, ionic liquid and solvent, the ionic liquid and titanium dioxide form hydrogen bonds and electrostatic repulsion to improve the dispersion and rheology of the slurry, and remove air bubbles through mechanical vibration to prepare stable titanium dioxide slurry.

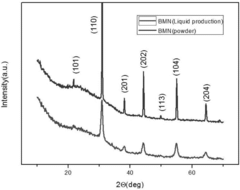

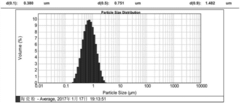

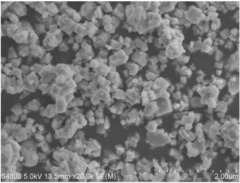

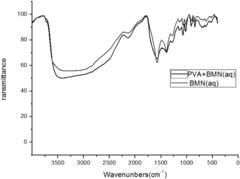

High-solid-content BMN suspension liquid ink suitable for direct writing printing and preparation method thereof

PatentActiveCN107098700A

Innovation

- A high solid content suspension ink composed of BMN precursor liquid, polymer additives and BMN ceramic powder is used. Through specific preparation methods and heat treatment processes, the density and rheological properties of the ink are improved to achieve pattern design and rapid prototyping.

Sustainability Aspects of Advanced Ceramic Ink Formulations

The environmental impact of ceramic manufacturing has become increasingly scrutinized as sustainability concerns rise across industrial sectors. Advanced ceramic ink formulations for Direct Ink Writing (DIW) present significant opportunities to address these environmental challenges while maintaining technical performance. High-solid ceramic DIW printing inherently offers sustainability advantages through material efficiency, with reduced waste compared to traditional subtractive manufacturing methods.

Water-based ceramic ink systems represent a major advancement in sustainable formulation, eliminating harmful volatile organic compounds (VOCs) that are commonly found in solvent-based alternatives. These aqueous systems significantly reduce air pollution and workplace hazards while decreasing the carbon footprint associated with ink production and application processes. Furthermore, the development of bio-derived binders and dispersants from renewable resources such as cellulose derivatives, alginate, and chitosan provides environmentally friendly alternatives to petroleum-based additives.

Energy consumption represents another critical sustainability aspect of ceramic ink formulations. High-solid loading inks typically require less energy for drying and sintering compared to dilute suspensions, translating to reduced carbon emissions during the manufacturing process. Innovations in low-temperature sintering additives further enhance energy efficiency by enabling ceramic consolidation at temperatures 100-200°C lower than conventional methods.

Circular economy principles are increasingly being incorporated into advanced ceramic ink development. Research shows promising results in utilizing industrial waste streams as raw materials for ceramic inks, including fly ash, slag, and glass waste. These approaches not only divert materials from landfills but also reduce the environmental impact of virgin material extraction. Additionally, the precise deposition capability of DIW printing minimizes material waste during fabrication, with material utilization rates exceeding 95% compared to 60-70% in traditional ceramic processing.

Lifecycle assessment (LCA) studies indicate that high-solid ceramic DIW printing can reduce the overall environmental footprint by 30-40% compared to conventional ceramic manufacturing. This improvement stems from combined benefits in material efficiency, energy reduction, and waste minimization. However, challenges remain in scaling these sustainable formulations for industrial applications while maintaining the rheological properties essential for successful DIW printing.

Regulatory compliance is driving further innovation in sustainable ceramic ink formulations, with global initiatives like REACH in Europe and similar programs worldwide pushing manufacturers to develop environmentally benign alternatives. The industry trend clearly points toward formulations that balance technical performance with reduced environmental impact, positioning sustainable high-solid ceramic inks as a key enabler for future advanced manufacturing paradigms.

Water-based ceramic ink systems represent a major advancement in sustainable formulation, eliminating harmful volatile organic compounds (VOCs) that are commonly found in solvent-based alternatives. These aqueous systems significantly reduce air pollution and workplace hazards while decreasing the carbon footprint associated with ink production and application processes. Furthermore, the development of bio-derived binders and dispersants from renewable resources such as cellulose derivatives, alginate, and chitosan provides environmentally friendly alternatives to petroleum-based additives.

Energy consumption represents another critical sustainability aspect of ceramic ink formulations. High-solid loading inks typically require less energy for drying and sintering compared to dilute suspensions, translating to reduced carbon emissions during the manufacturing process. Innovations in low-temperature sintering additives further enhance energy efficiency by enabling ceramic consolidation at temperatures 100-200°C lower than conventional methods.

Circular economy principles are increasingly being incorporated into advanced ceramic ink development. Research shows promising results in utilizing industrial waste streams as raw materials for ceramic inks, including fly ash, slag, and glass waste. These approaches not only divert materials from landfills but also reduce the environmental impact of virgin material extraction. Additionally, the precise deposition capability of DIW printing minimizes material waste during fabrication, with material utilization rates exceeding 95% compared to 60-70% in traditional ceramic processing.

Lifecycle assessment (LCA) studies indicate that high-solid ceramic DIW printing can reduce the overall environmental footprint by 30-40% compared to conventional ceramic manufacturing. This improvement stems from combined benefits in material efficiency, energy reduction, and waste minimization. However, challenges remain in scaling these sustainable formulations for industrial applications while maintaining the rheological properties essential for successful DIW printing.

Regulatory compliance is driving further innovation in sustainable ceramic ink formulations, with global initiatives like REACH in Europe and similar programs worldwide pushing manufacturers to develop environmentally benign alternatives. The industry trend clearly points toward formulations that balance technical performance with reduced environmental impact, positioning sustainable high-solid ceramic inks as a key enabler for future advanced manufacturing paradigms.

Quality Control Standards for High-Performance Ceramic Printing

Quality control in high-solid ceramic DIW (Direct Ink Writing) printing represents a critical component for ensuring consistent performance and reliability of printed components. Establishing comprehensive quality standards requires systematic approaches that address both the ink formulation process and the final printed structures.

The primary quality parameters for high-performance ceramic printing include rheological properties, particle size distribution, homogeneity, and stability over time. These factors directly influence printability, structural integrity, and final mechanical properties of the printed components. Standardized testing protocols must be implemented at multiple stages of the manufacturing process to ensure consistency.

Rheological measurements should follow established standards such as ASTM D4287 for viscosity and ASTM D4440 for viscoelastic properties. For high-solid ceramic inks specifically, yield stress measurements using controlled stress rheometers provide critical data on printability thresholds. The acceptable range for yield stress typically falls between 200-800 Pa for optimal printing performance, with viscosity requirements varying based on nozzle diameter and printing speed.

Particle characterization standards must address both size distribution and morphology. Laser diffraction techniques following ISO 13320 provide reliable particle size distribution data, with optimal distributions typically showing D50 values between 0.5-5 μm depending on the specific ceramic material. Scanning electron microscopy (SEM) analysis should be conducted according to ASTM E986 guidelines to verify particle morphology and agglomeration status.

Post-printing quality assessment requires standardized protocols for dimensional accuracy, surface finish, and internal defect detection. Coordinate measuring machines (CMMs) following ISO 10360 standards can verify dimensional tolerances, while surface roughness measurements should adhere to ISO 25178. Non-destructive testing methods including X-ray computed tomography following ASTM E1570 enable internal defect detection without compromising the printed structure.

Mechanical property testing represents the final validation of print quality. Flexural strength testing (ASTM C1161), hardness measurements (ASTM C1327), and fracture toughness evaluations (ASTM C1421) provide quantitative metrics for performance assessment. For high-performance applications, these properties must meet or exceed those of conventionally manufactured ceramic components.

Implementation of statistical process control (SPC) methodologies following ISO 7870 guidelines enables continuous monitoring of critical quality parameters. Establishing control charts for key variables such as viscosity, yield stress, and particle size distribution allows for early detection of process drift and timely intervention before quality issues manifest in the final printed components.

The primary quality parameters for high-performance ceramic printing include rheological properties, particle size distribution, homogeneity, and stability over time. These factors directly influence printability, structural integrity, and final mechanical properties of the printed components. Standardized testing protocols must be implemented at multiple stages of the manufacturing process to ensure consistency.

Rheological measurements should follow established standards such as ASTM D4287 for viscosity and ASTM D4440 for viscoelastic properties. For high-solid ceramic inks specifically, yield stress measurements using controlled stress rheometers provide critical data on printability thresholds. The acceptable range for yield stress typically falls between 200-800 Pa for optimal printing performance, with viscosity requirements varying based on nozzle diameter and printing speed.

Particle characterization standards must address both size distribution and morphology. Laser diffraction techniques following ISO 13320 provide reliable particle size distribution data, with optimal distributions typically showing D50 values between 0.5-5 μm depending on the specific ceramic material. Scanning electron microscopy (SEM) analysis should be conducted according to ASTM E986 guidelines to verify particle morphology and agglomeration status.

Post-printing quality assessment requires standardized protocols for dimensional accuracy, surface finish, and internal defect detection. Coordinate measuring machines (CMMs) following ISO 10360 standards can verify dimensional tolerances, while surface roughness measurements should adhere to ISO 25178. Non-destructive testing methods including X-ray computed tomography following ASTM E1570 enable internal defect detection without compromising the printed structure.

Mechanical property testing represents the final validation of print quality. Flexural strength testing (ASTM C1161), hardness measurements (ASTM C1327), and fracture toughness evaluations (ASTM C1421) provide quantitative metrics for performance assessment. For high-performance applications, these properties must meet or exceed those of conventionally manufactured ceramic components.

Implementation of statistical process control (SPC) methodologies following ISO 7870 guidelines enables continuous monitoring of critical quality parameters. Establishing control charts for key variables such as viscosity, yield stress, and particle size distribution allows for early detection of process drift and timely intervention before quality issues manifest in the final printed components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!