DIW Print Parameter Optimization For Mechanical Strength

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Printing Technology Background and Objectives

Direct Ink Writing (DIW), also known as robotic material extrusion or robotic deposition, has emerged as a transformative additive manufacturing technology over the past two decades. Initially developed in the early 2000s, DIW has evolved from simple extrusion systems to sophisticated multi-material printing platforms capable of producing complex functional structures with tailored properties. The technology leverages the controlled deposition of viscoelastic inks through nozzles to create three-dimensional structures layer by layer without requiring complex tooling or molds.

The evolution of DIW technology has been marked by significant advancements in ink formulations, hardware capabilities, and process control systems. Early DIW systems were limited to simple ceramic pastes and polymer melts, but current technology accommodates a diverse range of materials including hydrogels, composites, metal pastes, and functional materials with embedded properties. This versatility has expanded DIW applications across numerous sectors including biomedical engineering, electronics, aerospace, and energy storage.

A critical aspect of DIW technology development has been the growing understanding of the relationship between printing parameters and the mechanical properties of printed structures. Parameters such as extrusion pressure, nozzle diameter, printing speed, layer height, and infill patterns significantly influence the structural integrity and mechanical performance of printed objects. Despite these advances, optimizing these parameters remains largely empirical, with limited predictive capabilities for achieving specific mechanical strength requirements.

The primary objective of DIW print parameter optimization for mechanical strength is to establish systematic methodologies and predictive models that can reliably correlate printing parameters with mechanical outcomes. This includes developing comprehensive understanding of how material rheology interacts with printing conditions to determine final part properties, creating robust simulation tools that can predict mechanical behavior based on printing parameters, and establishing standardized testing protocols for mechanical property evaluation.

Additionally, the optimization aims to overcome current limitations in DIW technology, particularly the trade-offs between printing resolution, speed, and mechanical performance. Current DIW systems often struggle to simultaneously achieve high resolution, rapid production, and superior mechanical properties, necessitating compromises that limit application potential. By systematically optimizing printing parameters, the technology seeks to expand the performance envelope and enable new applications requiring specific mechanical strength profiles.

The ultimate goal is to transition DIW technology from its current state of empirical parameter selection to a knowledge-based approach where printing parameters can be precisely tailored to achieve targeted mechanical properties for specific applications, thereby enhancing the technology's industrial relevance and commercial viability.

The evolution of DIW technology has been marked by significant advancements in ink formulations, hardware capabilities, and process control systems. Early DIW systems were limited to simple ceramic pastes and polymer melts, but current technology accommodates a diverse range of materials including hydrogels, composites, metal pastes, and functional materials with embedded properties. This versatility has expanded DIW applications across numerous sectors including biomedical engineering, electronics, aerospace, and energy storage.

A critical aspect of DIW technology development has been the growing understanding of the relationship between printing parameters and the mechanical properties of printed structures. Parameters such as extrusion pressure, nozzle diameter, printing speed, layer height, and infill patterns significantly influence the structural integrity and mechanical performance of printed objects. Despite these advances, optimizing these parameters remains largely empirical, with limited predictive capabilities for achieving specific mechanical strength requirements.

The primary objective of DIW print parameter optimization for mechanical strength is to establish systematic methodologies and predictive models that can reliably correlate printing parameters with mechanical outcomes. This includes developing comprehensive understanding of how material rheology interacts with printing conditions to determine final part properties, creating robust simulation tools that can predict mechanical behavior based on printing parameters, and establishing standardized testing protocols for mechanical property evaluation.

Additionally, the optimization aims to overcome current limitations in DIW technology, particularly the trade-offs between printing resolution, speed, and mechanical performance. Current DIW systems often struggle to simultaneously achieve high resolution, rapid production, and superior mechanical properties, necessitating compromises that limit application potential. By systematically optimizing printing parameters, the technology seeks to expand the performance envelope and enable new applications requiring specific mechanical strength profiles.

The ultimate goal is to transition DIW technology from its current state of empirical parameter selection to a knowledge-based approach where printing parameters can be precisely tailored to achieve targeted mechanical properties for specific applications, thereby enhancing the technology's industrial relevance and commercial viability.

Market Demand Analysis for High-Strength DIW Printed Components

The global market for high-strength DIW (Direct Ink Writing) printed components is experiencing significant growth, driven by increasing demand across multiple industries. The additive manufacturing market, within which DIW technology operates, was valued at approximately $13.7 billion in 2021 and is projected to reach $51.0 billion by 2030, with a compound annual growth rate of 15.2%. DIW printing specifically is gaining traction due to its versatility in material selection and precision in creating complex geometries with enhanced mechanical properties.

Aerospace and defense sectors represent primary markets for high-strength DIW components, with requirements for lightweight yet durable parts that can withstand extreme conditions. These industries demand components with specific strength-to-weight ratios and thermal resistance properties that optimized DIW processes can deliver. Market research indicates that aerospace companies are increasingly adopting additive manufacturing technologies, with DIW being particularly valuable for custom, low-volume production of critical components.

The medical device industry presents another substantial market opportunity, particularly for patient-specific implants and prosthetics. The global medical 3D printing market is expected to grow at 16.3% CAGR through 2028, with DIW technology being crucial for creating biocompatible structures with precisely controlled mechanical properties. Hospitals and medical research institutions are increasingly investing in on-site manufacturing capabilities, creating demand for optimized DIW printing parameters that ensure consistent mechanical strength.

Automotive manufacturers are adopting DIW technology for prototyping and production of specialized components. The trend toward vehicle lightweighting to improve fuel efficiency and reduce emissions is driving interest in high-strength printed parts that can replace traditional metal components. Market analysis shows that automotive companies are particularly interested in DIW printing for composite materials that offer superior strength-to-weight ratios.

Consumer electronics represents an emerging market for high-strength DIW components, particularly for customized housings and internal structural elements. The industry's rapid product development cycles benefit from DIW's ability to quickly iterate designs while maintaining mechanical integrity. Market forecasts suggest this sector will see accelerated adoption of DIW technology over the next five years.

Industrial equipment manufacturers are increasingly utilizing DIW printing for tooling and end-use parts that require specific mechanical properties. This sector values the ability to optimize printing parameters to achieve targeted strength characteristics for specialized applications. Market research indicates growing demand for parameter optimization solutions that can be integrated into existing manufacturing workflows.

The geographical distribution of market demand shows North America and Europe leading adoption, with Asia-Pacific regions showing the fastest growth rate. This global demand is further supported by increasing research funding and government initiatives promoting advanced manufacturing technologies across major economies.

Aerospace and defense sectors represent primary markets for high-strength DIW components, with requirements for lightweight yet durable parts that can withstand extreme conditions. These industries demand components with specific strength-to-weight ratios and thermal resistance properties that optimized DIW processes can deliver. Market research indicates that aerospace companies are increasingly adopting additive manufacturing technologies, with DIW being particularly valuable for custom, low-volume production of critical components.

The medical device industry presents another substantial market opportunity, particularly for patient-specific implants and prosthetics. The global medical 3D printing market is expected to grow at 16.3% CAGR through 2028, with DIW technology being crucial for creating biocompatible structures with precisely controlled mechanical properties. Hospitals and medical research institutions are increasingly investing in on-site manufacturing capabilities, creating demand for optimized DIW printing parameters that ensure consistent mechanical strength.

Automotive manufacturers are adopting DIW technology for prototyping and production of specialized components. The trend toward vehicle lightweighting to improve fuel efficiency and reduce emissions is driving interest in high-strength printed parts that can replace traditional metal components. Market analysis shows that automotive companies are particularly interested in DIW printing for composite materials that offer superior strength-to-weight ratios.

Consumer electronics represents an emerging market for high-strength DIW components, particularly for customized housings and internal structural elements. The industry's rapid product development cycles benefit from DIW's ability to quickly iterate designs while maintaining mechanical integrity. Market forecasts suggest this sector will see accelerated adoption of DIW technology over the next five years.

Industrial equipment manufacturers are increasingly utilizing DIW printing for tooling and end-use parts that require specific mechanical properties. This sector values the ability to optimize printing parameters to achieve targeted strength characteristics for specialized applications. Market research indicates growing demand for parameter optimization solutions that can be integrated into existing manufacturing workflows.

The geographical distribution of market demand shows North America and Europe leading adoption, with Asia-Pacific regions showing the fastest growth rate. This global demand is further supported by increasing research funding and government initiatives promoting advanced manufacturing technologies across major economies.

Current Technical Challenges in DIW Printing for Mechanical Properties

Direct Ink Writing (DIW) technology faces several significant technical challenges when optimizing for mechanical strength properties. The primary obstacle lies in the complex interrelationship between printing parameters and the resulting mechanical performance of printed structures. Viscosity management presents a fundamental challenge, as ink formulations must maintain precise rheological properties—exhibiting shear-thinning behavior during extrusion while rapidly recovering structural integrity post-deposition to support subsequent layers.

Nozzle design and extrusion pressure calibration remain problematic areas, with researchers struggling to establish universal parameters across different material systems. The delicate balance between extrusion pressure and printing speed directly impacts filament uniformity and inter-layer adhesion, both critical factors for mechanical integrity. Even minor variations in these parameters can lead to significant inconsistencies in mechanical properties throughout the printed structure.

Layer height optimization presents another significant challenge, as it must be precisely calibrated to the material's rheological recovery rate. Insufficient layer heights result in over-compression and potential nozzle clogging, while excessive heights lead to poor interlayer bonding and mechanical weakness. This challenge is compounded by the difficulty in maintaining consistent layer heights across complex geometries with varying overhang features.

Print path planning significantly impacts mechanical anisotropy in DIW structures. Current slicing algorithms often fail to account for the directional mechanical properties inherent to filament-based printing, resulting in structures with unpredictable mechanical behavior under multi-directional stress conditions. The industry lacks standardized approaches for optimizing tool paths specifically for mechanical performance rather than merely geometric accuracy.

Temperature management during printing represents another critical challenge, particularly for thermally sensitive materials. The temperature gradient between the nozzle, freshly extruded material, and previously deposited layers can create internal stresses that compromise mechanical integrity. Current systems offer limited capabilities for precise thermal control throughout the printing process.

Post-processing integration remains poorly understood in the context of parameter optimization. The relationship between printing parameters and subsequent post-processing requirements (such as curing conditions, thermal treatments, or solvent exposure) lacks comprehensive models, making it difficult to predict final mechanical properties from initial printing parameters alone.

Finally, real-time monitoring and feedback systems for mechanical property prediction during printing remain underdeveloped. Unlike traditional manufacturing processes with established in-situ quality control methods, DIW printing lacks reliable technologies for detecting mechanical property deviations during fabrication, necessitating extensive post-production testing and limiting industrial scalability.

Nozzle design and extrusion pressure calibration remain problematic areas, with researchers struggling to establish universal parameters across different material systems. The delicate balance between extrusion pressure and printing speed directly impacts filament uniformity and inter-layer adhesion, both critical factors for mechanical integrity. Even minor variations in these parameters can lead to significant inconsistencies in mechanical properties throughout the printed structure.

Layer height optimization presents another significant challenge, as it must be precisely calibrated to the material's rheological recovery rate. Insufficient layer heights result in over-compression and potential nozzle clogging, while excessive heights lead to poor interlayer bonding and mechanical weakness. This challenge is compounded by the difficulty in maintaining consistent layer heights across complex geometries with varying overhang features.

Print path planning significantly impacts mechanical anisotropy in DIW structures. Current slicing algorithms often fail to account for the directional mechanical properties inherent to filament-based printing, resulting in structures with unpredictable mechanical behavior under multi-directional stress conditions. The industry lacks standardized approaches for optimizing tool paths specifically for mechanical performance rather than merely geometric accuracy.

Temperature management during printing represents another critical challenge, particularly for thermally sensitive materials. The temperature gradient between the nozzle, freshly extruded material, and previously deposited layers can create internal stresses that compromise mechanical integrity. Current systems offer limited capabilities for precise thermal control throughout the printing process.

Post-processing integration remains poorly understood in the context of parameter optimization. The relationship between printing parameters and subsequent post-processing requirements (such as curing conditions, thermal treatments, or solvent exposure) lacks comprehensive models, making it difficult to predict final mechanical properties from initial printing parameters alone.

Finally, real-time monitoring and feedback systems for mechanical property prediction during printing remain underdeveloped. Unlike traditional manufacturing processes with established in-situ quality control methods, DIW printing lacks reliable technologies for detecting mechanical property deviations during fabrication, necessitating extensive post-production testing and limiting industrial scalability.

Current Parameter Optimization Approaches for DIW Mechanical Strength

01 Material composition for enhanced mechanical strength in DIW printing

The mechanical strength of DIW printed structures can be significantly improved through careful selection of material compositions. Incorporating reinforcing agents such as nanoparticles, fibers, or composite materials into the printing ink formulation enhances the structural integrity of the final printed object. These additives create a reinforcement network within the printed structure, improving tensile strength, compression resistance, and overall durability. The proper balance of these components is crucial for maintaining printability while achieving optimal mechanical properties.- Material composition for enhanced mechanical strength: The mechanical strength of DIW printed structures can be significantly improved by optimizing the material composition. This includes incorporating reinforcing agents such as nanoparticles, fibers, or composite materials into the printing ink. These additives create a more robust internal structure that can withstand higher mechanical loads. Additionally, the ratio of binders, plasticizers, and functional materials in the ink formulation plays a crucial role in determining the final mechanical properties of the printed object.

- Post-processing techniques to improve strength: Various post-processing methods can be applied to DIW printed objects to enhance their mechanical strength. These include thermal treatments like sintering or annealing, which promote particle fusion and densification. Chemical treatments such as crosslinking agents or curing processes can also be employed to strengthen the molecular bonds within the printed structure. Additionally, controlled drying conditions help minimize internal stresses and prevent crack formation, resulting in stronger final products.

- Printing parameter optimization for strength enhancement: The mechanical properties of DIW printed structures are heavily influenced by printing parameters. Factors such as extrusion pressure, nozzle diameter, printing speed, and layer height significantly impact the structural integrity of the final object. Optimizing these parameters ensures proper material deposition and layer adhesion, which are critical for mechanical strength. Advanced printing strategies, including infill patterns and printing path optimization, can also be implemented to distribute mechanical loads more effectively throughout the printed structure.

- Multi-material and functional gradient printing: Implementing multi-material DIW printing or functional gradient materials can significantly enhance the mechanical properties of printed structures. By strategically combining materials with complementary properties, such as rigid and flexible components, the overall mechanical performance can be optimized. This approach allows for the creation of structures with location-specific mechanical properties, enabling parts that can withstand complex loading conditions while maintaining overall structural integrity. The controlled transition between different material compositions helps prevent stress concentration and failure points.

- Structural design optimization for mechanical performance: The mechanical strength of DIW printed objects can be enhanced through intelligent structural design. This includes implementing biomimetic structures inspired by nature, such as honeycomb patterns or cellular architectures, which provide excellent strength-to-weight ratios. Computational modeling and simulation techniques can be used to predict mechanical behavior and optimize the design accordingly. Strategic reinforcement of high-stress areas and the incorporation of support structures during the design phase also contribute to improved mechanical performance of the final printed object.

02 Post-processing techniques to improve mechanical properties

Various post-processing methods can be applied to DIW printed structures to enhance their mechanical strength. These techniques include thermal treatments, UV curing, chemical crosslinking, and sintering processes that promote stronger bonding between printed layers. Post-processing helps to eliminate structural weaknesses at layer interfaces and reduces porosity, resulting in more homogeneous mechanical properties throughout the printed object. The selection of appropriate post-processing parameters depends on the specific ink composition and the desired final properties.Expand Specific Solutions03 Printing parameter optimization for structural integrity

The mechanical strength of DIW printed structures is heavily influenced by printing parameters such as extrusion pressure, nozzle diameter, printing speed, and layer height. Optimizing these parameters ensures proper material flow and layer adhesion, which directly impacts the structural integrity of the final product. Controlled deposition rates and path planning strategies can minimize internal stresses and defects that would otherwise compromise mechanical performance. Advanced control systems that dynamically adjust printing parameters based on real-time feedback can further enhance mechanical properties.Expand Specific Solutions04 Multi-material and gradient structures for tailored mechanical properties

DIW printing enables the fabrication of multi-material and functionally graded structures with customized mechanical properties. By strategically varying material composition throughout the printed object, regions requiring higher strength can be reinforced while maintaining flexibility where needed. This approach allows for the creation of structures with optimized weight-to-strength ratios and localized mechanical properties tailored to specific application requirements. The controlled transition between different materials or compositions minimizes stress concentration and enhances overall structural performance.Expand Specific Solutions05 Rheological control for improved structural performance

The rheological properties of printing inks significantly impact the mechanical strength of DIW printed structures. Inks with optimized viscoelastic behavior exhibit shear-thinning during extrusion and rapid recovery after deposition, enabling precise shape retention and strong layer-to-layer adhesion. Controlling parameters such as viscosity, yield stress, and thixotropy ensures proper flow through the nozzle while maintaining structural integrity during and after printing. Additives that modify rheological properties can be incorporated to enhance printability without compromising the mechanical performance of the final structure.Expand Specific Solutions

Key Industry Players in DIW Printing Technology

The DIW Print Parameter Optimization for Mechanical Strength technology landscape is currently in an early growth phase, with academic institutions leading research efforts. The market is expanding as industries recognize the potential for enhanced mechanical properties in direct ink writing (DIW) printed components. Universities including Jiangnan University, Shanghai Jiao Tong University, and Massachusetts Institute of Technology are driving fundamental research, while companies like MarkForged, GLOBALFOUNDRIES, and Core Voxel are beginning to commercialize applications. The technology remains in development with varying maturity levels across different material systems. Academic-industrial partnerships between institutions like Purdue Research Foundation and companies such as Mercedes-Benz Group AG are accelerating progress toward standardized optimization methodologies for DIW printing parameters that consistently deliver superior mechanical strength.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced parameter optimization frameworks for DIW printing that focus on mechanical strength enhancement. Their approach combines multi-physics modeling with machine learning algorithms to predict and optimize printing parameters. MIT researchers have created a comprehensive system that correlates extrusion pressure, nozzle diameter, print speed, and material rheology with final part mechanical properties. Their platform incorporates real-time feedback systems that adjust printing parameters dynamically based on in-situ measurements of filament geometry and layer adhesion quality[1]. MIT has also pioneered the development of multi-material DIW printing with parameter sets specifically optimized for interface strength between dissimilar materials, addressing one of the key challenges in achieving robust mechanical properties in heterogeneous structures[3].

Strengths: Superior integration of computational modeling with experimental validation, enabling precise prediction of mechanical properties based on printing parameters. Advanced machine learning algorithms that continuously improve parameter optimization through iterative learning. Weaknesses: Solutions often require sophisticated equipment and sensors that may not be accessible for industrial-scale implementation. Parameter optimization frameworks may be overly complex for standard manufacturing environments.

Arevo, Inc.

Technical Solution: Arevo has developed a proprietary DIW printing technology specifically optimized for high-strength composite materials. Their approach focuses on continuous fiber reinforcement during the direct ink writing process, with carefully calibrated parameters to maximize mechanical strength. Arevo's system incorporates real-time monitoring and closed-loop control of critical parameters including extrusion pressure, temperature gradients, and deposition speed to ensure optimal fiber alignment and matrix consolidation[2]. Their technology employs a multi-axis robotic printing platform that enables true 3D fiber placement rather than conventional layer-by-layer approaches, resulting in parts with isotropic mechanical properties. Arevo has developed specialized algorithms that optimize toolpaths and printing parameters based on finite element analysis of stress distributions in the final part, ensuring material is deposited in orientations that maximize mechanical performance for specific loading conditions[4].

Strengths: Industry-leading fiber reinforcement technology that achieves mechanical properties comparable to traditional composites manufacturing. Comprehensive parameter optimization that considers both process variables and end-use requirements. Weaknesses: System requires specialized materials formulated specifically for their process, limiting material selection flexibility. High capital investment required for their robotic printing platforms.

Critical Technical Innovations in DIW Printing Parameters

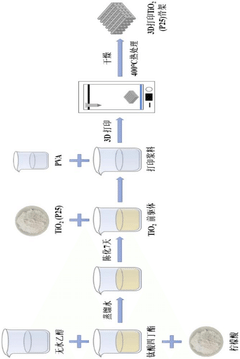

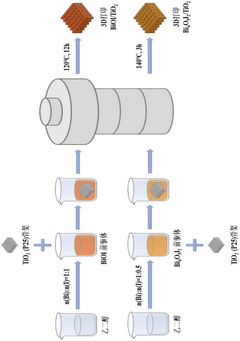

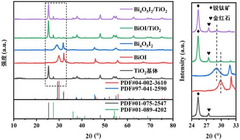

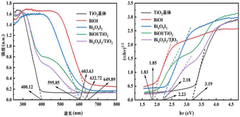

Composite photocatalytic material for 3D printing and preparation method thereof

PatentPendingCN118788402A

Innovation

- Composite photocatalytic materials are prepared using 3D printing technology. The TiO2 precursor solution is formed by mixing citric acid, absolute ethanol, tetrabutyl titanate and titanium dioxide P25 powder, and mixed with bismuth nitrate pentahydrate, potassium iodide and ethylene glycol. The BixOyIz precursor solution undergoes a solvothermal reaction to form a BixOyIz/TiO2 composite material, which improves the recovery rate and photocatalytic performance of the material.

Material Science Considerations for DIW Printing Strength

The material science aspects of Direct Ink Writing (DIW) printing significantly influence the mechanical strength of printed structures. Material selection represents the foundation of strength optimization, with polymer-based inks requiring careful consideration of molecular weight distribution and chain entanglement properties. Higher molecular weight polymers typically yield stronger prints but present viscosity challenges during extrusion. Ceramic and metal-filled composite inks demand precise particle size distribution control to achieve optimal packing density while maintaining printability.

Rheological properties of printing materials directly impact structural integrity. The ideal DIW ink exhibits shear-thinning behavior—maintaining high viscosity at rest to preserve shape fidelity while flowing readily under extrusion pressure. This non-Newtonian characteristic must be carefully balanced through formulation adjustments. Thixotropic recovery rate after extrusion critically determines layer adhesion strength and overall structural cohesion.

Material-nozzle interactions introduce complex variables affecting mechanical performance. Surface chemistry between the ink and nozzle material can create friction patterns that influence filament uniformity. Nozzle material selection (stainless steel, ceramic, or polymer) creates different thermal gradients during printing that affect material crystallization and subsequent mechanical properties. These interactions must be characterized and controlled to ensure consistent strength outcomes.

Post-printing material transformation mechanisms substantially determine final strength characteristics. Crosslinking kinetics in photocurable resins, solvent evaporation rates in solution-based inks, and sintering behavior in ceramic/metal systems all require optimization. The transformation timeline must align with the printing process to prevent internal stress accumulation that could compromise structural integrity.

Environmental sensitivity of materials during printing presents additional challenges. Humidity fluctuations can dramatically alter the rheological properties of hydrophilic materials, while temperature variations affect viscosity and curing rates. Establishing environmental control protocols specific to each material system is essential for reproducible mechanical strength outcomes. Material aging effects must also be considered, as some ink formulations experience property drift during storage that impacts print strength consistency.

Rheological properties of printing materials directly impact structural integrity. The ideal DIW ink exhibits shear-thinning behavior—maintaining high viscosity at rest to preserve shape fidelity while flowing readily under extrusion pressure. This non-Newtonian characteristic must be carefully balanced through formulation adjustments. Thixotropic recovery rate after extrusion critically determines layer adhesion strength and overall structural cohesion.

Material-nozzle interactions introduce complex variables affecting mechanical performance. Surface chemistry between the ink and nozzle material can create friction patterns that influence filament uniformity. Nozzle material selection (stainless steel, ceramic, or polymer) creates different thermal gradients during printing that affect material crystallization and subsequent mechanical properties. These interactions must be characterized and controlled to ensure consistent strength outcomes.

Post-printing material transformation mechanisms substantially determine final strength characteristics. Crosslinking kinetics in photocurable resins, solvent evaporation rates in solution-based inks, and sintering behavior in ceramic/metal systems all require optimization. The transformation timeline must align with the printing process to prevent internal stress accumulation that could compromise structural integrity.

Environmental sensitivity of materials during printing presents additional challenges. Humidity fluctuations can dramatically alter the rheological properties of hydrophilic materials, while temperature variations affect viscosity and curing rates. Establishing environmental control protocols specific to each material system is essential for reproducible mechanical strength outcomes. Material aging effects must also be considered, as some ink formulations experience property drift during storage that impacts print strength consistency.

Quality Control Methods for DIW Printed Structures

Quality control is a critical aspect of Direct Ink Writing (DIW) printed structures, particularly when optimizing for mechanical strength. Effective quality control methods ensure consistency, reliability, and performance of printed components across production batches.

In-situ monitoring systems represent the frontline of quality control for DIW processes. These systems typically incorporate high-resolution cameras and sensors that track nozzle movement, extrusion rates, and material deposition patterns in real-time. Advanced systems may employ machine vision algorithms to detect anomalies such as line width variations, gaps, or overlaps that could compromise mechanical integrity.

Rheological testing of ink materials before printing serves as a preventive quality control measure. Viscosity measurements at varying shear rates help predict flow behavior during extrusion, while yield stress testing ensures structural stability post-deposition. These parameters directly correlate with the mechanical properties of the final printed structure and must be consistently monitored.

Post-printing dimensional analysis using optical or laser scanning techniques provides crucial feedback on geometric accuracy. Deviations from designed dimensions often indicate process inconsistencies that may affect mechanical performance. Modern systems can generate heat maps highlighting areas of concern where dimensional tolerances have been exceeded.

Mechanical testing protocols form the backbone of strength verification. Standardized tests including tensile, compression, flexural, and impact resistance measurements provide quantitative data on structural performance. These tests should be conducted on both test specimens and actual components to validate mechanical properties across different geometries and loading conditions.

Non-destructive testing methods such as ultrasonic inspection and X-ray computed tomography allow for internal structure examination without compromising the printed part. These techniques can reveal internal voids, layer delamination, or inclusion defects that may act as stress concentrators and initiate mechanical failure under load.

Statistical process control (SPC) methodologies help establish control limits for critical parameters and identify trends that may indicate process drift. Implementation of SPC charts for parameters such as extrusion pressure, temperature, and dimensional measurements enables proactive intervention before quality issues manifest in mechanical properties.

Digital twin modeling, combining real-time process data with simulation, represents an emerging quality control approach. By comparing actual printing behavior with predicted outcomes, manufacturers can identify potential mechanical weakness areas and adjust parameters accordingly, creating a feedback loop that continuously improves print quality and structural performance.

In-situ monitoring systems represent the frontline of quality control for DIW processes. These systems typically incorporate high-resolution cameras and sensors that track nozzle movement, extrusion rates, and material deposition patterns in real-time. Advanced systems may employ machine vision algorithms to detect anomalies such as line width variations, gaps, or overlaps that could compromise mechanical integrity.

Rheological testing of ink materials before printing serves as a preventive quality control measure. Viscosity measurements at varying shear rates help predict flow behavior during extrusion, while yield stress testing ensures structural stability post-deposition. These parameters directly correlate with the mechanical properties of the final printed structure and must be consistently monitored.

Post-printing dimensional analysis using optical or laser scanning techniques provides crucial feedback on geometric accuracy. Deviations from designed dimensions often indicate process inconsistencies that may affect mechanical performance. Modern systems can generate heat maps highlighting areas of concern where dimensional tolerances have been exceeded.

Mechanical testing protocols form the backbone of strength verification. Standardized tests including tensile, compression, flexural, and impact resistance measurements provide quantitative data on structural performance. These tests should be conducted on both test specimens and actual components to validate mechanical properties across different geometries and loading conditions.

Non-destructive testing methods such as ultrasonic inspection and X-ray computed tomography allow for internal structure examination without compromising the printed part. These techniques can reveal internal voids, layer delamination, or inclusion defects that may act as stress concentrators and initiate mechanical failure under load.

Statistical process control (SPC) methodologies help establish control limits for critical parameters and identify trends that may indicate process drift. Implementation of SPC charts for parameters such as extrusion pressure, temperature, and dimensional measurements enables proactive intervention before quality issues manifest in mechanical properties.

Digital twin modeling, combining real-time process data with simulation, represents an emerging quality control approach. By comparing actual printing behavior with predicted outcomes, manufacturers can identify potential mechanical weakness areas and adjust parameters accordingly, creating a feedback loop that continuously improves print quality and structural performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!