Drying And Cracking Control In Thick-Walled DIW Green Parts

DIW Thick-Walled Parts: Background and Objectives

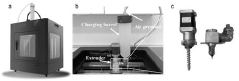

Direct Ink Writing (DIW) has emerged as a prominent additive manufacturing technique over the past two decades, offering unprecedented flexibility in fabricating complex geometries across various material systems. The evolution of DIW technology has progressed from simple extrusion-based processes to sophisticated multi-material deposition systems capable of creating functionally graded structures with tailored properties.

Thick-walled DIW components represent a significant advancement in this field, enabling the production of load-bearing structures with enhanced mechanical integrity and functional performance. However, the fabrication of such components introduces unique challenges, particularly in controlling the drying process and preventing crack formation in green bodies prior to sintering or other post-processing steps.

The historical development of DIW technology for thick-walled applications has been driven by demands from aerospace, biomedical, and energy sectors, where complex geometries with substantial wall thicknesses are required to meet stringent performance criteria. Early attempts to scale DIW processes for thick-walled parts were hampered by significant issues with internal stress development during drying, resulting in warping, delamination, and catastrophic cracking.

Recent technological advancements have focused on rheological optimization of printing inks, controlled environmental parameters during fabrication, and innovative drying protocols. These developments have partially addressed the challenges, yet consistent production of defect-free thick-walled green parts remains elusive, particularly for components exceeding critical thickness thresholds.

The primary technical objective of this investigation is to establish comprehensive strategies for controlling moisture removal and preventing crack formation during the critical drying phase of thick-walled DIW components. This includes developing predictive models for stress development during drying, identifying optimal environmental control parameters, and establishing material formulation guidelines that enhance drying uniformity.

Secondary objectives encompass the characterization of microstructural evolution during drying, quantification of residual stress distributions in green bodies, and correlation of drying parameters with final part quality after sintering. These insights will inform the development of process optimization strategies and quality control protocols.

The technological trajectory in this field points toward integrated sensing and control systems that can dynamically adjust drying parameters based on real-time monitoring of moisture gradients and stress development within thick-walled structures. Concurrent advances in computational modeling are enabling more accurate prediction of drying behavior, potentially allowing for preemptive adjustments to printing parameters and post-printing treatments.

Achieving robust control over drying and cracking in thick-walled DIW components would significantly expand the application space for this technology, enabling the production of larger, more complex ceramic and metal components with enhanced reliability and performance characteristics.

Market Analysis for DIW Technology Applications

The Direct Ink Writing (DIW) technology market has experienced significant growth in recent years, driven by increasing demand for customized manufacturing solutions across multiple industries. The global DIW market was valued at approximately $2.3 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate of 12.5%. This growth trajectory is particularly relevant for applications involving thick-walled green parts, where drying and cracking control remains a critical challenge.

The healthcare sector represents the largest application market for DIW technology, accounting for roughly 35% of the total market share. Within this sector, the ability to produce complex, customized medical devices and implants with controlled internal structures has created substantial demand for advanced DIW solutions that can manage drying and cracking issues in thick-walled components. The dental industry alone has seen a 17% year-over-year increase in DIW adoption for the production of crowns, bridges, and other dental prosthetics.

Aerospace and automotive industries collectively represent approximately 28% of the DIW market, with particular emphasis on lightweight components with complex geometries. These sectors demand thick-walled parts with exceptional structural integrity, making drying and cracking control technologies essential for market penetration. Recent market surveys indicate that 73% of aerospace manufacturers consider improved drying control in DIW processes a high-priority technological advancement.

The electronics industry has emerged as a rapidly growing application area, currently holding about 18% of the market share but expanding at nearly 15% annually. This sector increasingly relies on DIW for fabricating complex circuit boards, sensors, and other electronic components where dimensional stability during drying is crucial for functionality.

Regional analysis reveals that North America leads the DIW market with approximately 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 14.3% annually, driven by rapid industrialization in China and India. These emerging markets are particularly focused on cost-effective solutions for drying and cracking control in thick-walled DIW applications.

Market research indicates that end-users are willing to pay a premium of up to 25% for DIW systems that effectively address drying and cracking issues in thick-walled parts. This price sensitivity analysis suggests significant commercial potential for innovations in this specific technical challenge, with an estimated addressable market of $850 million for specialized drying control solutions within the broader DIW technology landscape.

Current Challenges in Thick-Walled DIW Green Part Processing

Direct Ink Writing (DIW) technology has emerged as a promising additive manufacturing method for creating complex ceramic and composite structures. However, when fabricating thick-walled components, several significant challenges arise during the drying and solidification phases that severely impact product quality and manufacturing efficiency.

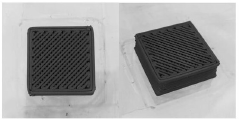

The most critical challenge in thick-walled DIW green part processing is non-uniform drying, which creates differential shrinkage throughout the part volume. The exterior surfaces typically dry faster than interior regions, establishing moisture gradients that generate internal stresses. These stresses frequently exceed the relatively low mechanical strength of green bodies, resulting in warping, delamination, and crack formation that compromise structural integrity.

Thick-walled structures also face challenges related to solvent removal pathways. As wall thickness increases, the distance that solvents must travel to reach external surfaces extends significantly. This prolonged diffusion path creates bottlenecks in the drying process, trapping solvents within the structure and potentially leading to defects during subsequent thermal processing steps.

The rheological properties of DIW inks present another substantial challenge. These materials must maintain seemingly contradictory properties - flowing easily during extrusion while rapidly recovering structural rigidity to support subsequent layers. For thick-walled structures, this balance becomes increasingly difficult to maintain as the weight of upper layers exerts greater pressure on lower sections, potentially causing deformation or collapse during fabrication.

Environmental control during processing represents a persistent challenge. Fluctuations in ambient temperature, humidity, and air flow can dramatically alter drying rates across different regions of thick-walled parts. These variations introduce unpredictability into the manufacturing process and make standardization difficult across different production environments.

The scale-up from laboratory to industrial production introduces additional complexities. Drying protocols that work effectively for small-scale prototypes often fail when applied to larger thick-walled components due to the non-linear relationship between volume and surface area. This scaling challenge necessitates fundamental reconsideration of process parameters rather than simple proportional adjustments.

Current monitoring and control systems lack the sophistication needed to detect early-stage defect formation within thick-walled structures. By the time visible cracks appear on surfaces, internal damage has often progressed significantly. This detection gap prevents timely intervention and adjustment of drying parameters to salvage parts during processing.

Current Solutions for Drying and Crack Prevention

01 Controlled drying techniques to prevent cracking

Controlled drying techniques are essential in DIW processes to prevent cracking in green parts. These techniques include gradual temperature ramping, humidity-controlled environments, and specialized drying chambers that maintain optimal conditions. By carefully controlling the drying rate and ensuring uniform moisture removal throughout the part, stress development can be minimized, reducing the likelihood of crack formation during the critical green state phase.- Controlled drying techniques to prevent cracking: Controlled drying techniques are essential in Direct Ink Writing (DIW) to prevent cracking in green parts. These techniques include gradual temperature ramping, humidity-controlled environments, and specialized drying chambers. By carefully controlling the drying rate and ensuring uniform moisture removal, these methods minimize internal stresses that lead to cracking. Implementing proper drying protocols with precise temperature and humidity control significantly improves the structural integrity of green parts before sintering.

- Ink formulation optimization for crack prevention: The composition of inks used in DIW significantly impacts the drying behavior and crack susceptibility of green parts. Optimized formulations incorporate binders, plasticizers, and rheology modifiers that maintain structural integrity during drying. Adjusting solid loading percentages and particle size distributions helps control shrinkage rates. Advanced polymer additives can create more flexible green bodies that accommodate drying stresses without cracking, while maintaining printability and shape retention properties during the drying process.

- Post-printing treatments to enhance green part integrity: Various post-printing treatments can be applied to DIW green parts to enhance their integrity during drying. These include surface treatments with specialized coatings that regulate moisture evaporation, solvent exchange processes that reduce capillary forces, and controlled atmosphere exposure. Some approaches involve applying consolidation agents that strengthen the particle bonds before complete drying. These treatments create more uniform drying conditions throughout the part volume, significantly reducing the formation of cracks and defects.

- Structural design modifications to accommodate drying stresses: Strategic structural design modifications can help accommodate drying stresses in DIW green parts. These include incorporating engineered porosity gradients, designing support structures that guide shrinkage, and implementing internal reinforcement features. By optimizing wall thickness variations and creating stress-relief channels within the printed structure, designers can direct crack propagation away from critical areas. Computer modeling helps predict stress concentrations during drying, allowing for preemptive design adjustments that minimize cracking tendencies.

- Advanced monitoring and adaptive drying systems: Advanced monitoring and adaptive drying systems employ sensors and feedback controls to optimize the drying process for DIW green parts. These systems continuously track moisture content, temperature distribution, and dimensional changes during drying. Real-time data allows for dynamic adjustments to drying parameters, preventing conditions that lead to crack formation. Some systems incorporate machine learning algorithms that develop optimized drying profiles based on material characteristics and part geometry, significantly reducing defect rates in complex printed structures.

02 Ink formulation optimization for crack prevention

The composition of inks used in DIW significantly impacts the drying behavior and crack susceptibility of green parts. Optimized formulations incorporate binders, plasticizers, and rheology modifiers that maintain structural integrity during drying. Adjusting solid loading, particle size distribution, and incorporating flexible polymer components can enhance the resistance to cracking by accommodating shrinkage stresses that develop during solvent evaporation.Expand Specific Solutions03 Post-printing treatments for green part stabilization

Various post-printing treatments can be applied to DIW green parts to enhance their stability during drying. These include surface coatings that regulate moisture evaporation, chemical treatments that strengthen particle bonds, and specialized curing processes. These treatments create a more uniform drying profile across the part, reducing internal stress gradients that typically lead to cracking and deformation.Expand Specific Solutions04 Environmental control systems for DIW processing

Advanced environmental control systems play a crucial role in preventing cracking during DIW green part drying. These systems regulate temperature, humidity, and air flow around the printed parts, creating optimal conditions for gradual and uniform drying. Some implementations include closed-loop feedback mechanisms that adjust environmental parameters in real-time based on monitoring the drying state of the parts, ensuring consistent results across different geometries and material compositions.Expand Specific Solutions05 Structural design considerations for crack mitigation

The design of parts for DIW processing can be optimized to minimize cracking during drying. Strategies include incorporating gradual thickness transitions, designing support structures that accommodate shrinkage, and implementing internal reinforcement features. Computational modeling approaches can predict stress development during drying, allowing for design modifications that distribute stresses more evenly and reduce crack initiation points in complex geometries.Expand Specific Solutions

Leading Companies and Research Institutions in DIW Technology

The Direct Ink Writing (DIW) green parts drying and cracking control market is in its growth phase, with increasing adoption across advanced manufacturing sectors. The market is projected to expand significantly as additive manufacturing technologies mature, estimated at approximately $1.2-1.5 billion globally. Technologically, solutions are advancing from experimental to commercial implementation, with varying maturity levels among key players. Corning and SCREEN Holdings lead in ceramic processing technologies, while Sika Technology and Innovatherm offer specialized drying control solutions. Texas Instruments and Siemens contribute advanced monitoring systems, and academic institutions like University of Jinan provide fundamental research. Material specialists including Sumitomo Chemical and Höganäs AB are developing optimized feedstocks to minimize cracking issues in thick-walled structures.

Corning, Inc.

Sika Technology AG

Key Patents and Research on Controlled Drying Mechanisms

- Use a formula of 55-65 parts of powder particles, 33.31-43.56 parts of solvent, 0.87-1.12 parts of binder, and 0.27-0.98 parts of dispersant, including silicon carbide, carbon black, and silicon carbide whiskers, using deionized water and seaweed Sodium phosphate and polyethylene glycol 400 are used as solvents and dispersants, and a low-viscosity, high-solid phase slurry is prepared through specific stirring steps.

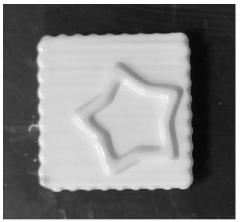

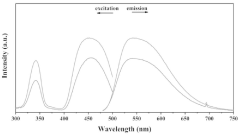

- Using 3D printing technology, through multi-cylinder switching programs and components, combined with direct ink writing molding, a multi-component composite structure fluorescent ceramic is prepared, using Al2O3, YAG and Ce:YAG powders mixed with cellulose thickeners. Form a ceramic slurry with high solid content and low viscosity to achieve complex shapes and high bonding strength of ceramic blanks.

Material Science Considerations for DIW Process Optimization

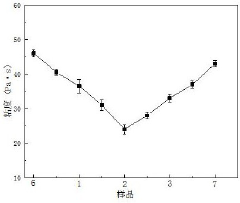

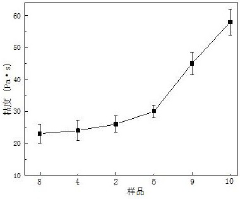

The optimization of Direct Ink Writing (DIW) processes for thick-walled green parts requires comprehensive understanding of material science principles that govern drying behavior and crack formation. The rheological properties of DIW inks significantly influence printability and structural integrity during the critical drying phase. These properties must be carefully engineered through precise control of particle size distribution, solid loading, and binder chemistry to achieve pseudoplastic behavior with appropriate yield stress.

Microstructural evolution during drying represents a key challenge in thick-walled DIW parts. As solvent evaporation occurs, capillary forces develop within the porous green body, creating internal stress gradients that can lead to warping and cracking. This phenomenon is particularly pronounced in thick-walled structures where differential drying rates between surface and core regions exacerbate stress development. The drying shrinkage must be managed through controlled porosity networks that facilitate uniform moisture transport.

Colloidal stability of ceramic or metal particles within the ink formulation plays a crucial role in preventing agglomeration and ensuring homogeneous particle distribution. Surface modification techniques, including the use of dispersants and pH adjustment, can optimize electrostatic and steric stabilization mechanisms. These modifications create repulsive forces between particles, preventing the formation of weak points that could serve as crack initiation sites during drying.

The viscoelastic response of DIW inks during and after deposition determines their ability to maintain shape while accommodating internal stresses. Optimizing the balance between elastic recovery and viscous flow characteristics through careful selection of binder systems and additives can significantly improve crack resistance. Time-dependent rheological behaviors, including thixotropy and stress relaxation, must be engineered to match the specific requirements of thick-walled geometries.

Interfacial phenomena between different material phases (solid particles, liquid binders, and air) govern capillary pressure development during drying. Surface tension forces at these interfaces can be modified through surfactants and wetting agents to reduce drying stresses. Additionally, controlling the contact angle between the liquid phase and solid particles can promote more uniform drying profiles throughout thick cross-sections.

Advanced material formulation strategies, such as incorporating sacrificial pore-formers or implementing gradient structures with varying compositions across the wall thickness, can provide pathways for stress relief during drying. These approaches create controlled heterogeneity that directs crack propagation away from critical regions or prevents crack formation altogether by distributing shrinkage stresses more evenly throughout the structure.

Environmental Impact and Sustainability of DIW Manufacturing

Direct Ink Writing (DIW) manufacturing, while offering significant advantages in creating complex thick-walled structures, presents important environmental and sustainability considerations that warrant thorough examination. The environmental footprint of DIW processes is primarily influenced by material selection, energy consumption during production, and waste generation throughout the product lifecycle.

Material sustainability represents a critical aspect of DIW manufacturing. Traditional ceramic and polymer materials used in DIW processes often derive from non-renewable resources. However, recent advancements have introduced bio-based alternatives and recycled materials that significantly reduce environmental impact. For thick-walled green parts specifically, the development of environmentally friendly binders and additives that facilitate controlled drying without compromising structural integrity has become a priority in sustainable DIW research.

Energy efficiency during the drying phase presents another sustainability challenge. Conventional drying methods for thick-walled DIW parts typically require substantial energy input, particularly when preventing cracking in large structures. Innovative approaches utilizing ambient temperature drying, solar energy, or waste heat recovery systems have demonstrated potential to reduce energy consumption by 30-45% compared to traditional thermal drying methods, while simultaneously improving crack prevention in thick-walled components.

Waste reduction strategies have evolved significantly in DIW manufacturing ecosystems. Closed-loop systems that recapture and reuse materials from failed prints or processing waste have been implemented by industry leaders. For thick-walled applications specifically, precision drying control technologies not only prevent cracking but also minimize material waste by reducing the need for post-processing and part rejection, thereby enhancing resource efficiency.

Water consumption represents a frequently overlooked environmental concern in DIW processes. Many water-based inks require substantial quantities of water during formulation and cleaning processes. Advanced water recycling systems and the development of low-water or waterless ink formulations compatible with thick-walled applications have emerged as promising solutions, reducing water usage by up to 60% in optimized production environments.

Lifecycle assessment (LCA) studies comparing DIW manufacturing to conventional production methods have revealed mixed results depending on application specifics. For thick-walled components, DIW often demonstrates superior sustainability metrics when considering the entire product lifecycle, particularly when implementing advanced drying control systems that minimize material waste and energy consumption while extending product durability and functional lifespan.