DIW For Transparent Ceramic Components: Optical Requirements

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Ceramic Technology Background and Objectives

Direct Ink Writing (DIW) technology has emerged as a promising additive manufacturing method for creating complex ceramic components with precise geometries. The evolution of DIW for ceramics began in the early 2000s, initially focusing on structural applications. However, recent advancements have expanded its potential toward optical and transparent ceramic components, representing a significant technological frontier with substantial commercial implications.

The development trajectory of DIW ceramic technology has been characterized by progressive improvements in material formulations, printing precision, and post-processing techniques. Early iterations struggled with issues of porosity and optical clarity, limiting applications primarily to structural components where transparency was not required. The technological inflection point occurred around 2015-2018, when researchers began successfully addressing these limitations through innovations in colloidal processing and sintering protocols.

Current DIW technology for transparent ceramics leverages highly controlled rheological properties of ceramic inks, typically composed of nanoscale ceramic particles suspended in carefully designed polymer matrices. These inks must simultaneously satisfy contradictory requirements: maintaining flowability during extrusion while exhibiting shape retention post-deposition. This delicate balance represents one of the fundamental technical challenges in the field.

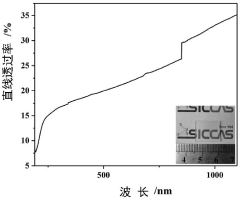

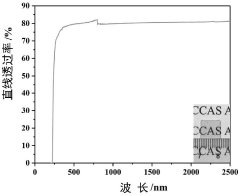

The primary technical objective for DIW transparent ceramic components centers on achieving optical performance comparable to conventionally manufactured counterparts. Specifically, this entails transmission values exceeding 80% in the visible spectrum, refractive index uniformity within ±0.0001 across the component, and scattering coefficients below 0.1 cm^-1. These demanding optical requirements necessitate exceptional control over material homogeneity and microstructural development during both printing and sintering phases.

Secondary objectives include expanding the range of printable transparent ceramic materials beyond the current limitations of primarily alumina (Al₂O₃) and yttria (Y₂O₃) based compositions. Materials such as spinel (MgAl₂O₄), YAG (Y₃Al₅O₁₂), and various sesquioxides represent high-value targets due to their superior optical and mechanical properties in specific application contexts.

The technological trajectory aims toward multi-material printing capabilities, enabling gradient optical properties and integrated optical-structural components. This represents a paradigm shift from conventional manufacturing approaches, which typically require complex assembly of discretely manufactured components. The ultimate vision encompasses the direct printing of optically functional ceramic components with embedded optical features such as lenses, waveguides, and diffractive elements.

The development trajectory of DIW ceramic technology has been characterized by progressive improvements in material formulations, printing precision, and post-processing techniques. Early iterations struggled with issues of porosity and optical clarity, limiting applications primarily to structural components where transparency was not required. The technological inflection point occurred around 2015-2018, when researchers began successfully addressing these limitations through innovations in colloidal processing and sintering protocols.

Current DIW technology for transparent ceramics leverages highly controlled rheological properties of ceramic inks, typically composed of nanoscale ceramic particles suspended in carefully designed polymer matrices. These inks must simultaneously satisfy contradictory requirements: maintaining flowability during extrusion while exhibiting shape retention post-deposition. This delicate balance represents one of the fundamental technical challenges in the field.

The primary technical objective for DIW transparent ceramic components centers on achieving optical performance comparable to conventionally manufactured counterparts. Specifically, this entails transmission values exceeding 80% in the visible spectrum, refractive index uniformity within ±0.0001 across the component, and scattering coefficients below 0.1 cm^-1. These demanding optical requirements necessitate exceptional control over material homogeneity and microstructural development during both printing and sintering phases.

Secondary objectives include expanding the range of printable transparent ceramic materials beyond the current limitations of primarily alumina (Al₂O₃) and yttria (Y₂O₃) based compositions. Materials such as spinel (MgAl₂O₄), YAG (Y₃Al₅O₁₂), and various sesquioxides represent high-value targets due to their superior optical and mechanical properties in specific application contexts.

The technological trajectory aims toward multi-material printing capabilities, enabling gradient optical properties and integrated optical-structural components. This represents a paradigm shift from conventional manufacturing approaches, which typically require complex assembly of discretely manufactured components. The ultimate vision encompasses the direct printing of optically functional ceramic components with embedded optical features such as lenses, waveguides, and diffractive elements.

Market Analysis for Transparent Ceramic Applications

The transparent ceramics market has witnessed substantial growth in recent years, driven by increasing demand across multiple high-tech industries. The global market for transparent ceramics was valued at approximately $286 million in 2021 and is projected to reach $712 million by 2028, growing at a CAGR of 14.2% during the forecast period. This growth trajectory is primarily fueled by expanding applications in optics, electronics, aerospace, defense, and healthcare sectors.

Optical applications represent the largest market segment for transparent ceramics, accounting for nearly 40% of the total market share. This dominance stems from the superior optical properties of transparent ceramics compared to traditional glass and polymers, including higher refractive indices, better transmission across broader wavelength ranges, and enhanced durability under extreme conditions. The defense sector follows closely, with applications in armor windows, IR domes, and sensor components.

Regionally, North America currently leads the transparent ceramics market with approximately 35% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by increasing industrial activities in China, Japan, and South Korea, coupled with rising investments in advanced materials research and development.

The market landscape is characterized by a growing preference for customized transparent ceramic components with specific optical requirements. End-users are increasingly demanding materials with precise refractive indices, controlled dispersion characteristics, and tailored transmission spectra. This trend aligns perfectly with the capabilities of Direct Ink Writing (DIW) technology, which offers unprecedented design freedom and material composition control.

Key market drivers include the miniaturization trend in optoelectronics, growing demand for high-performance materials in extreme environments, and increasing adoption of transparent ceramics in medical imaging devices. The healthcare segment, in particular, is emerging as a promising growth area, with applications in dental restorations, bone implants, and diagnostic equipment components.

Market challenges primarily revolve around high production costs, complex manufacturing processes, and limited awareness about the benefits of transparent ceramics over conventional materials. The average cost of transparent ceramic components remains 3-5 times higher than their glass counterparts, creating a significant barrier to widespread adoption in cost-sensitive applications.

Customer requirements analysis reveals that optical clarity, mechanical strength, thermal stability, and chemical resistance are the most valued properties in transparent ceramic components. DIW technology's ability to precisely control material composition and microstructure positions it as a promising manufacturing approach to meet these demanding requirements while potentially reducing production costs through material efficiency and design optimization.

Optical applications represent the largest market segment for transparent ceramics, accounting for nearly 40% of the total market share. This dominance stems from the superior optical properties of transparent ceramics compared to traditional glass and polymers, including higher refractive indices, better transmission across broader wavelength ranges, and enhanced durability under extreme conditions. The defense sector follows closely, with applications in armor windows, IR domes, and sensor components.

Regionally, North America currently leads the transparent ceramics market with approximately 35% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by increasing industrial activities in China, Japan, and South Korea, coupled with rising investments in advanced materials research and development.

The market landscape is characterized by a growing preference for customized transparent ceramic components with specific optical requirements. End-users are increasingly demanding materials with precise refractive indices, controlled dispersion characteristics, and tailored transmission spectra. This trend aligns perfectly with the capabilities of Direct Ink Writing (DIW) technology, which offers unprecedented design freedom and material composition control.

Key market drivers include the miniaturization trend in optoelectronics, growing demand for high-performance materials in extreme environments, and increasing adoption of transparent ceramics in medical imaging devices. The healthcare segment, in particular, is emerging as a promising growth area, with applications in dental restorations, bone implants, and diagnostic equipment components.

Market challenges primarily revolve around high production costs, complex manufacturing processes, and limited awareness about the benefits of transparent ceramics over conventional materials. The average cost of transparent ceramic components remains 3-5 times higher than their glass counterparts, creating a significant barrier to widespread adoption in cost-sensitive applications.

Customer requirements analysis reveals that optical clarity, mechanical strength, thermal stability, and chemical resistance are the most valued properties in transparent ceramic components. DIW technology's ability to precisely control material composition and microstructure positions it as a promising manufacturing approach to meet these demanding requirements while potentially reducing production costs through material efficiency and design optimization.

Technical Challenges in DIW Transparent Ceramics

Direct Ink Writing (DIW) for transparent ceramics faces significant technical hurdles that must be overcome to achieve optical-grade components. The primary challenge lies in achieving the necessary transparency, which requires near-perfect microstructural control. Conventional DIW processes typically produce components with residual porosity of 0.1-1%, whereas optical applications demand porosity levels below 0.01% to minimize light scattering effects. This represents a fundamental materials processing challenge that requires innovative approaches to ink formulation and post-processing techniques.

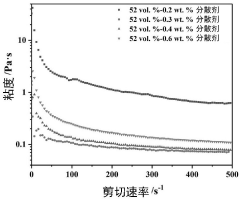

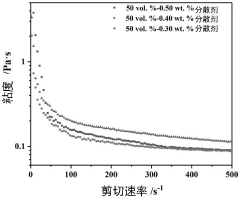

The rheological properties of ceramic inks present another major obstacle. For DIW, inks must exhibit both shear-thinning behavior for extrusion and sufficient yield stress to maintain structural integrity after deposition. However, the high solid loading (typically >50 vol%) required for minimal shrinkage and defect formation during sintering often conflicts with the flow characteristics needed for fine feature printing. This delicate balance becomes even more critical when targeting optical applications where structural homogeneity directly impacts light transmission properties.

Surface finish quality presents a third significant challenge. Optical components require surface roughness values typically below 10 nm, while standard DIW processes typically achieve only micron-level surface finishes. The layer-by-layer nature of DIW inherently creates surface striations that can cause light scattering and distortion, necessitating extensive post-processing which may compromise dimensional accuracy or introduce new defects.

Material selection constraints further complicate the development process. Only certain ceramic compositions can achieve the required transparency, with yttrium aluminum garnet (YAG), aluminum oxynitride (ALON), and magnesium aluminate spinel being among the few viable candidates. Each material requires specific processing parameters, sintering aids, and thermal treatments to achieve transparency, making ink formulation highly material-specific and complex.

The sintering process represents perhaps the most critical challenge. Transparent ceramics require full densification without grain boundary phases that could scatter light. Traditional sintering approaches often result in either incomplete densification or abnormal grain growth, both detrimental to optical performance. Advanced techniques like hot isostatic pressing (HIP) or spark plasma sintering (SPS) may be required as post-processing steps, adding complexity and cost to the manufacturing process.

Dimensional accuracy and geometric fidelity during the entire process chain from printing through sintering present additional challenges. The substantial volumetric shrinkage (typically 40-50%) during sintering must be precisely controlled and predicted to achieve final components with the required optical specifications, including precise radii of curvature for lenses or exact dimensions for optical windows.

The rheological properties of ceramic inks present another major obstacle. For DIW, inks must exhibit both shear-thinning behavior for extrusion and sufficient yield stress to maintain structural integrity after deposition. However, the high solid loading (typically >50 vol%) required for minimal shrinkage and defect formation during sintering often conflicts with the flow characteristics needed for fine feature printing. This delicate balance becomes even more critical when targeting optical applications where structural homogeneity directly impacts light transmission properties.

Surface finish quality presents a third significant challenge. Optical components require surface roughness values typically below 10 nm, while standard DIW processes typically achieve only micron-level surface finishes. The layer-by-layer nature of DIW inherently creates surface striations that can cause light scattering and distortion, necessitating extensive post-processing which may compromise dimensional accuracy or introduce new defects.

Material selection constraints further complicate the development process. Only certain ceramic compositions can achieve the required transparency, with yttrium aluminum garnet (YAG), aluminum oxynitride (ALON), and magnesium aluminate spinel being among the few viable candidates. Each material requires specific processing parameters, sintering aids, and thermal treatments to achieve transparency, making ink formulation highly material-specific and complex.

The sintering process represents perhaps the most critical challenge. Transparent ceramics require full densification without grain boundary phases that could scatter light. Traditional sintering approaches often result in either incomplete densification or abnormal grain growth, both detrimental to optical performance. Advanced techniques like hot isostatic pressing (HIP) or spark plasma sintering (SPS) may be required as post-processing steps, adding complexity and cost to the manufacturing process.

Dimensional accuracy and geometric fidelity during the entire process chain from printing through sintering present additional challenges. The substantial volumetric shrinkage (typically 40-50%) during sintering must be precisely controlled and predicted to achieve final components with the required optical specifications, including precise radii of curvature for lenses or exact dimensions for optical windows.

Current DIW Solutions for Optical Transparency

01 Ink formulation for transparent ceramic components

Specialized ink formulations are crucial for Direct Ink Writing (DIW) of transparent ceramic components. These formulations typically include ceramic powders with specific particle sizes and distributions, dispersants to prevent agglomeration, and binders to provide appropriate rheological properties. The composition must be carefully controlled to achieve high solid loading while maintaining printability and ensuring minimal optical defects in the final sintered component.- Ink formulation for transparent ceramic components: Specialized ink formulations are critical for Direct Ink Writing (DIW) of transparent ceramic components. These formulations typically contain ceramic nanoparticles with controlled particle size distribution to minimize light scattering. The inks must maintain appropriate rheological properties for extrusion while ensuring homogeneous particle dispersion. Additives such as dispersants and binders are incorporated to prevent agglomeration and maintain stability, which directly impacts the optical transparency of the final ceramic component.

- Post-processing techniques for optical transparency: After Direct Ink Writing, post-processing techniques are essential to achieve high optical transparency in ceramic components. These include controlled drying to prevent defects, debinding to remove organic components, and sintering at precise temperature profiles to eliminate porosity. Advanced techniques such as hot isostatic pressing and vacuum sintering can further enhance transparency by removing residual pores that scatter light. These post-processing steps are crucial for achieving the required optical clarity and transmittance in the final ceramic components.

- Microstructure control for optical performance: Controlling the microstructure of DIW-fabricated transparent ceramics is vital for meeting optical requirements. This involves strategies to minimize grain boundaries, pores, and defects that cause light scattering. Techniques include precise control of grain growth during sintering, incorporation of dopants to inhibit abnormal grain growth, and optimization of cooling rates. The resulting microstructure directly affects optical properties such as refractive index homogeneity, birefringence, and transmittance across different wavelengths, which are critical for optical applications.

- Printing parameters optimization for optical quality: Printing parameters in DIW significantly impact the optical quality of transparent ceramic components. Critical parameters include nozzle diameter, extrusion pressure, printing speed, and layer height. These must be optimized to minimize defects such as voids, layer misalignment, and internal stresses that can cause light scattering or birefringence. Advanced printing strategies such as controlled environmental conditions and real-time monitoring systems help maintain consistency throughout the printing process, ensuring uniform optical properties in the final component.

- Characterization and testing of optical properties: Comprehensive characterization and testing methods are essential for evaluating the optical performance of DIW-fabricated transparent ceramics. These include measurements of transmittance, refractive index, birefringence, and optical homogeneity. Advanced techniques such as spectrophotometry, interferometry, and laser-based testing are employed to assess optical quality across different wavelengths. Non-destructive testing methods help identify internal defects that might affect optical performance. These characterization techniques guide process optimization to meet specific optical requirements for applications such as lenses, windows, and optical sensors.

02 Post-processing techniques for optical transparency

After Direct Ink Writing, various post-processing techniques are essential to achieve optical transparency in ceramic components. These include controlled drying to prevent cracking, debinding to remove organic components, and sintering under specific temperature profiles and atmospheres. Advanced techniques such as hot isostatic pressing may be employed to eliminate residual porosity that would otherwise scatter light and reduce transparency.Expand Specific Solutions03 Microstructure control for optical performance

The microstructure of DIW-fabricated transparent ceramics must be precisely controlled to meet optical requirements. This involves minimizing grain boundaries, pores, and other defects that cause light scattering. Techniques include using nano-sized starting powders, controlling grain growth during sintering, and ensuring homogeneous densification. The final microstructure should have uniform grain size distribution and minimal residual porosity to achieve high transmittance across the desired wavelength range.Expand Specific Solutions04 Printing parameters optimization for optical quality

Printing parameters significantly impact the optical quality of DIW-fabricated transparent ceramics. These parameters include nozzle diameter, printing speed, layer height, and extrusion pressure. Optimizing these parameters helps minimize defects such as voids, layer lines, and inhomogeneities that would otherwise compromise optical transparency. Advanced printing strategies, such as controlled environmental conditions during printing and adaptive layer deposition, can further enhance the optical quality of the final components.Expand Specific Solutions05 Characterization and testing of optical properties

Comprehensive characterization and testing methods are essential for evaluating the optical properties of DIW-fabricated transparent ceramics. These include measurements of transmittance, refractive index, birefringence, and optical homogeneity. Advanced techniques such as spectrophotometry, interferometry, and laser-based testing are employed to assess optical performance across different wavelengths. These measurements help verify that the fabricated components meet the required optical specifications for applications such as lenses, windows, and other optical elements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The DIW for transparent ceramic components market is in a growth phase, characterized by increasing demand for high-precision optical applications requiring exceptional transparency and performance. The market is expanding as industries like medical technology, electronics, and telecommunications adopt advanced ceramic solutions. Technologically, the field shows varying maturity levels across players, with established leaders like SCHOTT AG and Corning demonstrating advanced capabilities in transparent ceramic manufacturing, while Murata Manufacturing and Shanghai Institute of Ceramics are making significant R&D investments. Companies like FUJIFILM and EssilorLuxottica are leveraging these materials for specialized optical applications, while academic institutions such as Wuhan University of Technology and Sichuan University are contributing fundamental research to address optical requirements challenges in transparency, refractive index control, and surface quality.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a proprietary DIW system for transparent ceramic optical components that integrates advanced materials science with precision manufacturing techniques. Their approach utilizes specially formulated ceramic slurries containing nano-sized particles (typically 50-150nm) with carefully controlled surface chemistry to prevent agglomeration and ensure optical homogeneity. Murata's process incorporates high-precision extrusion systems with multi-axis motion control that enables the fabrication of complex three-dimensional optical structures with feature resolution down to 15 microns. Their technology includes in-line rheology monitoring and adjustment systems that maintain optimal flow properties throughout the printing process. Post-processing involves specialized thermal treatments in controlled atmospheres that achieve densification while preserving optical clarity, resulting in components with up to 99.6% theoretical density. Murata has successfully applied this technology to produce transparent alumina and zirconia components with transmittance values exceeding 70% in specific wavelength ranges. The company has focused on applications including optical sensors, specialized filters, and custom waveguides for telecommunications and industrial systems.

Strengths: Extensive manufacturing expertise; established quality control systems; integration capabilities with electronic components. Weaknesses: More limited experience with purely optical applications; narrower range of ceramic compositions compared to specialized optical companies; challenges with larger optical components.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered a comprehensive DIW system for transparent ceramic optical components that addresses the critical challenges of optical homogeneity and surface quality. Their technology utilizes specially engineered ceramic nanoparticle suspensions with precise control over particle size distribution (typically 20-100nm) to minimize light scattering. SCHOTT's process incorporates real-time viscosity monitoring and adjustment systems that maintain optimal rheological properties throughout the printing process, ensuring consistent material deposition. Their multi-nozzle printing system achieves gradient refractive index profiles by dynamically mixing different ceramic compositions during deposition. Post-processing involves proprietary sintering protocols with controlled atmosphere and temperature profiles that achieve up to 99.8% theoretical density while maintaining optical homogeneity. The resulting components exhibit transmission values exceeding 75% in the visible spectrum with refractive index control within ±0.001. SCHOTT has successfully applied this technology to produce custom optical filters, waveguides, and specialized lenses for industrial and scientific applications.

Strengths: Exceptional control over optical properties; established expertise in specialty glass and ceramics; advanced quality control systems for optical homogeneity. Weaknesses: Complex processing requirements increase production time; higher material costs than conventional ceramics; limited to smaller component sizes.

Key Innovations in Transparent Ceramic Formulations

Preparation method of transparent ceramic slurry for direct writing

PatentActiveCN115432998A

Innovation

- Cellulose thickener is used to modify high solid content water-based ceramic slurry, and the ceramic powder particles are evenly dispersed through surface coating treatment and electrostatic dispersant. Water-soluble cellulose is added to adjust the viscosity and free water content of the slurry to improve Printing effect, and prepare transparent ceramic body through 3D printing technology.

Material Characterization Techniques for Transparency

Transparency assessment in ceramic components requires sophisticated characterization techniques to evaluate optical properties with precision. Spectrophotometry serves as a fundamental method, measuring transmittance across visible and near-infrared wavelengths (typically 300-2500 nm). This technique quantifies the percentage of light passing through the ceramic sample, providing critical data on transparency levels and wavelength-dependent behavior. Modern spectrophotometers can detect subtle variations in transparency that might affect final component performance in optical applications.

Refractive index measurement represents another essential characterization approach, commonly performed using ellipsometry or prism coupling techniques. For transparent ceramics intended for optical applications, precise refractive index values and their uniformity throughout the component are crucial parameters that directly influence light path manipulation capabilities. Variations in refractive index can lead to undesired optical distortions in the final printed components.

Haze measurement techniques quantify the percentage of transmitted light that deviates from the incident beam direction due to internal scattering. This parameter is particularly important for DIW-printed transparent ceramics, as residual porosity or phase boundaries can significantly increase haze values. Instruments like haze meters provide standardized measurements according to ASTM D1003 or similar standards, offering quantitative data on optical clarity.

Laser scattering analysis enables the detection of microscopic defects that might be invisible to conventional optical inspection but could compromise transparency. By measuring the angular distribution of scattered light when a laser beam passes through the ceramic sample, researchers can identify and characterize scattering centers such as pores, grain boundaries, or secondary phases. This technique proves especially valuable for process optimization in DIW manufacturing.

Advanced imaging techniques including optical coherence tomography (OCT) and confocal microscopy allow for non-destructive 3D visualization of internal structures in transparent ceramics. These methods can reveal spatial distribution of defects and structural heterogeneities that affect optical performance. For DIW-printed components, these techniques help correlate printing parameters with resulting microstructural features that influence transparency.

Birefringence measurement using polarized light microscopy identifies stress-induced optical anisotropy in ceramic components. This characterization is critical for applications requiring polarization maintenance or specific polarization effects. The printing process in DIW can introduce residual stresses that manifest as birefringence, potentially compromising optical performance in polarization-sensitive applications.

Refractive index measurement represents another essential characterization approach, commonly performed using ellipsometry or prism coupling techniques. For transparent ceramics intended for optical applications, precise refractive index values and their uniformity throughout the component are crucial parameters that directly influence light path manipulation capabilities. Variations in refractive index can lead to undesired optical distortions in the final printed components.

Haze measurement techniques quantify the percentage of transmitted light that deviates from the incident beam direction due to internal scattering. This parameter is particularly important for DIW-printed transparent ceramics, as residual porosity or phase boundaries can significantly increase haze values. Instruments like haze meters provide standardized measurements according to ASTM D1003 or similar standards, offering quantitative data on optical clarity.

Laser scattering analysis enables the detection of microscopic defects that might be invisible to conventional optical inspection but could compromise transparency. By measuring the angular distribution of scattered light when a laser beam passes through the ceramic sample, researchers can identify and characterize scattering centers such as pores, grain boundaries, or secondary phases. This technique proves especially valuable for process optimization in DIW manufacturing.

Advanced imaging techniques including optical coherence tomography (OCT) and confocal microscopy allow for non-destructive 3D visualization of internal structures in transparent ceramics. These methods can reveal spatial distribution of defects and structural heterogeneities that affect optical performance. For DIW-printed components, these techniques help correlate printing parameters with resulting microstructural features that influence transparency.

Birefringence measurement using polarized light microscopy identifies stress-induced optical anisotropy in ceramic components. This characterization is critical for applications requiring polarization maintenance or specific polarization effects. The printing process in DIW can introduce residual stresses that manifest as birefringence, potentially compromising optical performance in polarization-sensitive applications.

Sustainability Aspects of DIW Ceramic Production

The sustainability of Direct Ink Writing (DIW) for ceramic production represents a critical dimension in evaluating this manufacturing technology for transparent ceramic components. Environmental considerations have become increasingly important as industries seek to reduce their ecological footprint while maintaining high-quality production standards.

Energy consumption during DIW ceramic processing is significantly lower compared to traditional ceramic manufacturing methods. The process operates at lower temperatures during the initial forming stage, requiring less energy for material deposition. However, post-processing steps including debinding and sintering still demand substantial energy inputs to achieve the optical transparency required for high-performance applications.

Raw material efficiency constitutes another sustainability advantage of DIW technology. The precise deposition mechanism minimizes material waste compared to subtractive manufacturing approaches. For transparent ceramic components specifically, the ability to create near-net-shape structures reduces the need for extensive grinding and polishing, which traditionally generates substantial ceramic waste that is difficult to recycle or reprocess.

Water usage in DIW ceramic production presents a mixed sustainability profile. While the process generally requires less water than conventional slip casting methods, the preparation of ceramic inks often involves aqueous solutions that must be carefully managed. Closed-loop water systems can significantly improve this aspect of the production process.

Chemical sustainability concerns primarily relate to the additives required for ink formulation. Dispersants, binders, and plasticizers necessary for achieving proper rheological properties and green body strength may introduce environmental challenges. Research into bio-derived alternatives to petroleum-based polymers shows promising results for reducing the environmental impact of these essential components.

End-of-life considerations for transparent ceramic components manufactured via DIW are generally favorable. The high durability and long service life of ceramic materials reduce replacement frequency. Additionally, many technical ceramics are chemically inert and do not leach harmful substances into the environment when disposed of properly.

Carbon footprint analysis of the complete DIW ceramic production lifecycle reveals opportunities for improvement, particularly in sintering operations which remain energy-intensive. Implementation of renewable energy sources for these high-temperature processes could substantially improve the overall sustainability profile of transparent ceramic components manufactured through DIW technology.

Energy consumption during DIW ceramic processing is significantly lower compared to traditional ceramic manufacturing methods. The process operates at lower temperatures during the initial forming stage, requiring less energy for material deposition. However, post-processing steps including debinding and sintering still demand substantial energy inputs to achieve the optical transparency required for high-performance applications.

Raw material efficiency constitutes another sustainability advantage of DIW technology. The precise deposition mechanism minimizes material waste compared to subtractive manufacturing approaches. For transparent ceramic components specifically, the ability to create near-net-shape structures reduces the need for extensive grinding and polishing, which traditionally generates substantial ceramic waste that is difficult to recycle or reprocess.

Water usage in DIW ceramic production presents a mixed sustainability profile. While the process generally requires less water than conventional slip casting methods, the preparation of ceramic inks often involves aqueous solutions that must be carefully managed. Closed-loop water systems can significantly improve this aspect of the production process.

Chemical sustainability concerns primarily relate to the additives required for ink formulation. Dispersants, binders, and plasticizers necessary for achieving proper rheological properties and green body strength may introduce environmental challenges. Research into bio-derived alternatives to petroleum-based polymers shows promising results for reducing the environmental impact of these essential components.

End-of-life considerations for transparent ceramic components manufactured via DIW are generally favorable. The high durability and long service life of ceramic materials reduce replacement frequency. Additionally, many technical ceramics are chemically inert and do not leach harmful substances into the environment when disposed of properly.

Carbon footprint analysis of the complete DIW ceramic production lifecycle reveals opportunities for improvement, particularly in sintering operations which remain energy-intensive. Implementation of renewable energy sources for these high-temperature processes could substantially improve the overall sustainability profile of transparent ceramic components manufactured through DIW technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!