DIW For Additive Manufacturing Hybrid Lines: Integration Blueprint

DIW Additive Manufacturing Evolution and Objectives

Direct Ink Writing (DIW) technology has evolved significantly over the past two decades, transforming from a niche fabrication method to a versatile additive manufacturing approach with broad industrial applications. Initially developed in the early 2000s as an extrusion-based technique for ceramic materials, DIW has progressively expanded to accommodate a wide range of material systems including polymers, composites, and functional materials with tailored properties.

The evolutionary trajectory of DIW technology has been marked by several key advancements. The first generation focused primarily on single-material deposition with limited geometric complexity. The second generation introduced multi-material capabilities and improved resolution down to the microscale. The current third generation emphasizes functional gradients, embedded components, and integration with complementary manufacturing processes to create hybrid production lines.

Recent technological breakthroughs have significantly enhanced DIW's capabilities, particularly in rheological control of ink formulations, allowing for precise deposition of materials with complex viscoelastic properties. Advances in nozzle design have improved spatial resolution to sub-10 micron levels, while multi-nozzle systems now enable simultaneous deposition of different materials with synchronized motion control.

The primary objective of DIW integration into hybrid manufacturing lines is to combine the geometric freedom and material flexibility of additive approaches with the precision and throughput of traditional manufacturing methods. This integration aims to overcome the limitations of standalone AM processes, particularly in terms of production speed, surface finish quality, and dimensional accuracy for high-volume industrial applications.

Specific technical goals include developing seamless digital workflows between DIW and conventional manufacturing stages, creating adaptive process control systems that can compensate for material variations in real-time, and establishing robust quality assurance protocols for hybrid-manufactured components. Additionally, there is a focus on expanding the material palette compatible with DIW to include high-performance engineering materials with tailored functional properties.

The long-term vision for DIW in hybrid manufacturing environments encompasses fully automated production lines where DIW stations work in concert with subtractive, forming, and assembly operations under unified digital control. This integration blueprint seeks to position DIW technology as a critical enabler for next-generation smart factories, capable of economical mass customization and on-demand manufacturing of complex, multi-material products with minimal setup time between production runs.

Market Analysis for Hybrid Manufacturing Solutions

The hybrid manufacturing solutions market is experiencing significant growth, driven by the increasing demand for flexible, efficient, and cost-effective manufacturing processes. Current market analysis indicates that the global hybrid manufacturing market is projected to reach $6.46 billion by 2028, growing at a CAGR of approximately 15.7% from 2023. This growth is primarily fueled by industries seeking to combine the advantages of traditional manufacturing techniques with additive manufacturing capabilities.

Key market segments for hybrid manufacturing solutions include aerospace, automotive, healthcare, and industrial equipment manufacturing. The aerospace sector currently represents the largest market share at 32%, driven by the need for complex, lightweight components with high performance characteristics. Automotive follows at 27%, where hybrid manufacturing enables rapid prototyping alongside production-grade parts manufacturing.

Regional analysis shows North America leading the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). The Asia-Pacific region is expected to witness the fastest growth rate of 17.3% annually, primarily due to rapid industrialization in countries like China, Japan, and South Korea, coupled with significant government investments in advanced manufacturing technologies.

Customer demand patterns reveal a strong preference for integrated solutions that offer seamless workflow between additive and subtractive processes. Market surveys indicate that 76% of manufacturing companies are seeking solutions that reduce post-processing requirements, while 68% prioritize systems that can maintain high precision across multiple manufacturing modalities.

Direct Ink Writing (DIW) integration into hybrid manufacturing lines represents a particularly promising segment, with projected growth rates exceeding the overall market average by 3-4 percentage points. This is attributed to DIW's versatility in material handling, precision deposition capabilities, and compatibility with existing manufacturing infrastructure.

Competitive analysis reveals that the market is moderately fragmented, with the top five players controlling approximately 47% of the market share. Recent merger and acquisition activities suggest a trend toward consolidation as companies seek to offer more comprehensive hybrid manufacturing solutions. Emerging players are focusing on niche applications and specialized material capabilities to establish market presence.

Customer adoption barriers include initial capital investment requirements, integration challenges with existing systems, and workforce training needs. However, the total cost of ownership analysis demonstrates that hybrid manufacturing solutions typically achieve return on investment within 18-24 months through material savings, reduced production time, and decreased labor costs.

Technical Barriers in DIW-Hybrid Integration

Despite significant advancements in Direct Ink Writing (DIW) technology for additive manufacturing, several critical technical barriers persist when integrating DIW into hybrid manufacturing lines. These barriers represent substantial challenges that must be addressed to achieve seamless integration and optimal performance in industrial applications.

Material compatibility issues constitute a primary obstacle in DIW-hybrid integration. The rheological properties of DIW inks must be precisely engineered to maintain printability while ensuring compatibility with subsequent or preceding manufacturing processes. Viscoelastic behavior of inks often changes dramatically when interfacing with other materials or processes, leading to structural defects at integration points. Additionally, curing mechanisms and thermal profiles between DIW and traditional manufacturing techniques frequently conflict, causing delamination, warping, or incomplete bonding.

Process synchronization presents another significant barrier. The relatively slow deposition rates of DIW processes (typically 1-50 mm/s) contrast sharply with the higher speeds of conventional manufacturing methods, creating production bottlenecks. Real-time coordination between DIW printing heads and other manufacturing equipment requires sophisticated control systems that can harmonize disparate process parameters and compensate for the inherent speed differentials.

Dimensional accuracy and tolerance matching between DIW and conventional processes remain problematic. While DIW can achieve resolution down to 10 μm in controlled environments, maintaining this precision when integrated with other processes is challenging. Thermal expansion mismatches, substrate interactions, and material shrinkage during curing create cumulative errors that propagate through the hybrid manufacturing line.

Quality assurance and in-line inspection represent another technical hurdle. Traditional quality control methods are often inadequate for assessing the unique structures and material interfaces created in DIW-hybrid processes. Non-destructive testing techniques must be adapted or newly developed to verify internal structures and interface integrity without compromising production efficiency.

Software integration barriers further complicate DIW-hybrid implementation. Current CAD/CAM systems typically lack unified platforms capable of seamlessly programming both additive and subtractive processes. The translation between different manufacturing paradigms often results in data loss or interpretation errors, necessitating extensive manual intervention and limiting automation potential.

Environmental control requirements for DIW processes (including temperature, humidity, and particulate levels) frequently conflict with conditions needed for other manufacturing steps, requiring complex environmental zoning or isolation systems that add cost and complexity to integrated production lines.

Current DIW-Hybrid Integration Architectures

01 Multi-material DIW integration techniques

Direct Ink Writing (DIW) techniques that enable the integration of multiple materials in additive manufacturing processes. These approaches allow for the creation of hybrid structures with varied material properties by precisely depositing different inks in controlled patterns. The integration of multiple materials enables the fabrication of components with region-specific functionalities, such as combining conductive and non-conductive materials in a single print process to create electronic devices with embedded circuitry.- Direct Ink Writing (DIW) techniques for hybrid material integration: Direct Ink Writing enables the integration of multiple materials in additive manufacturing processes. This technique allows for precise deposition of functional inks with controlled rheological properties to create hybrid structures. The process facilitates the combination of different materials such as polymers, ceramics, and metals in a single manufacturing process, enabling the creation of components with region-specific properties and functionalities.

- Multi-material printing systems for hybrid line integration: Advanced printing systems have been developed specifically for hybrid line integration in additive manufacturing. These systems incorporate multiple print heads or nozzles that can simultaneously or sequentially deposit different materials. The technology enables precise control over material placement, allowing for the creation of complex structures with integrated electronic, mechanical, and structural components in a single manufacturing process.

- Ink formulations for DIW hybrid manufacturing: Specialized ink formulations have been developed for Direct Ink Writing in hybrid manufacturing applications. These inks are engineered with specific rheological properties to enable precise deposition while maintaining structural integrity during printing. Formulations may include conductive materials, structural polymers, or ceramic precursors, allowing for the integration of electronic circuits, sensors, or reinforcement structures within a single printed component.

- Process control and integration methods for hybrid DIW systems: Advanced process control methods have been developed to manage the complexities of hybrid Direct Ink Writing systems. These methods include real-time monitoring and adjustment of printing parameters, synchronization of multiple material feeds, and integration with other manufacturing processes. The technologies enable precise control over material deposition, curing conditions, and layer registration, ensuring high-quality hybrid structures with reliable performance characteristics.

- Applications of DIW hybrid line integration in functional devices: Direct Ink Writing for hybrid line integration has been applied to create various functional devices with integrated properties. Applications include embedded electronics, smart structures with integrated sensing capabilities, biomedical devices with region-specific properties, and energy storage devices. The technology enables the creation of complex 3D structures with integrated functionalities that would be difficult or impossible to achieve using conventional manufacturing methods.

02 Hybrid line integration for electronic applications

DIW methods specifically developed for integrating electronic components and conductive pathways within 3D printed structures. These techniques focus on the precise deposition of conductive inks alongside structural materials to create functional electronic devices. The hybrid line integration enables the fabrication of complex electronic systems with embedded circuits, sensors, and other electronic components directly during the additive manufacturing process, eliminating the need for separate assembly steps.Expand Specific Solutions03 Advanced ink formulations for hybrid DIW processes

Specialized ink formulations designed specifically for DIW applications in hybrid manufacturing. These inks are engineered with rheological properties that enable precise deposition while maintaining structural integrity during and after printing. Advanced formulations include functional inks with electrical conductivity, thermal properties, or mechanical characteristics that can be integrated with structural materials to create multi-functional components. The development of these inks focuses on compatibility between different material systems to ensure proper adhesion and functionality in the final printed structure.Expand Specific Solutions04 Process control systems for hybrid DIW manufacturing

Control systems and methodologies developed to manage the complex parameters involved in hybrid DIW manufacturing processes. These systems coordinate multiple print heads, material feeds, and curing mechanisms to ensure precise integration of different materials. Advanced process control enables real-time adjustments to printing parameters based on feedback from monitoring systems, ensuring consistent quality in hybrid structures. These control systems are essential for maintaining dimensional accuracy and functional performance when integrating multiple materials with different processing requirements.Expand Specific Solutions05 Post-processing techniques for hybrid DIW structures

Methods for treating and finishing hybrid structures created through DIW processes to enhance their functional properties and durability. These techniques include selective curing processes, thermal treatments, and surface modifications that improve the integration between different materials in the printed structure. Post-processing is crucial for optimizing the performance of hybrid components, particularly for applications requiring specific electrical, mechanical, or chemical properties. Advanced post-processing approaches enable the creation of fully functional devices with integrated electronic, mechanical, and structural elements from DIW manufacturing.Expand Specific Solutions

Leading Companies in Hybrid Additive Manufacturing

The additive manufacturing hybrid lines market is currently in a growth phase, characterized by increasing integration of Direct Ink Writing (DIW) technologies with traditional manufacturing processes. The global market size for hybrid additive manufacturing is expanding rapidly, projected to reach significant scale as industries seek more flexible and efficient production methods. Technologically, the field shows varying maturity levels across players: established aerospace and defense corporations like Boeing, GE, RTX, and Lawrence Livermore National Security are advancing integration frameworks, while specialized additive manufacturing companies such as Relativity Space and Carbon are developing innovative material solutions. Academic institutions (Georgia Tech, Cornell, Colorado School of Mines) are contributing fundamental research, while automotive manufacturers (Toyota, BMW) are exploring applications for production lines. The competitive landscape reveals a collaborative ecosystem where cross-sector partnerships are driving standardization and implementation blueprints for DIW hybrid manufacturing integration.

General Electric Company

Relativity Space, Inc.

Key Patents in DIW-Hybrid Manufacturing Systems

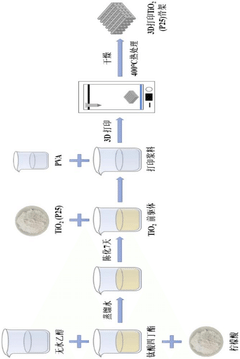

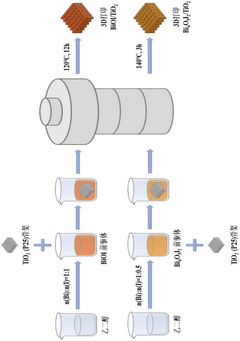

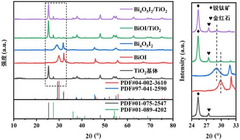

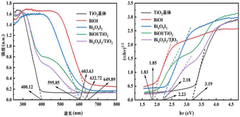

- Composite photocatalytic materials are prepared using 3D printing technology. The TiO2 precursor solution is formed by mixing citric acid, absolute ethanol, tetrabutyl titanate and titanium dioxide P25 powder, and mixed with bismuth nitrate pentahydrate, potassium iodide and ethylene glycol. The BixOyIz precursor solution undergoes a solvothermal reaction to form a BixOyIz/TiO2 composite material, which improves the recovery rate and photocatalytic performance of the material.

Material Compatibility and Process Parameters

Material compatibility represents a critical challenge in Direct Ink Writing (DIW) integration within hybrid additive manufacturing lines. The rheological properties of DIW materials must be precisely calibrated to ensure optimal flow through nozzles while maintaining structural integrity post-deposition. Current research indicates that viscosity ranges between 10^2-10^6 mPa·s yield optimal results, with shear-thinning behavior being particularly advantageous for extrusion processes. This non-Newtonian characteristic allows materials to flow under pressure yet retain shape after deposition.

Temperature control emerges as a paramount process parameter, with variations as small as 5°C potentially altering material viscosity by 15-30%. Advanced hybrid systems now incorporate zone-specific temperature regulation, maintaining thermal gradients within ±2°C throughout the printing process. This precision enables compatibility between DIW materials and adjacent manufacturing processes such as FDM or SLA in hybrid production lines.

Substrate interaction dynamics significantly impact material compatibility in hybrid DIW systems. Surface energy differentials between deposited materials and substrates must be carefully managed to ensure proper adhesion without compromising geometric accuracy. Recent studies demonstrate that plasma treatment of substrates can increase surface energy by 20-40%, dramatically improving adhesion profiles for silicone-based and ceramic-loaded DIW materials.

Curing mechanisms represent another critical parameter requiring precise calibration. UV-curable DIW materials typically require 365-405nm wavelength exposure with energy densities between 100-500 mJ/cm², while thermally cured materials demand controlled temperature ramps of 1-5°C/minute to prevent internal stress accumulation. In hybrid manufacturing environments, these curing parameters must be harmonized with subsequent processing steps to prevent material property degradation.

Layer height and extrusion rate correlation demands particular attention in DIW integration. Optimal material deposition occurs when the dimensionless parameter ratio of nozzle diameter to layer height maintains values between 1.2-1.8, with extrusion rates calibrated to material viscosity. Advanced systems now employ closed-loop feedback mechanisms that dynamically adjust extrusion pressure (typically ranging from 50-500 kPa) based on real-time rheological measurements.

Material compatibility testing protocols have evolved significantly, with standardized procedures now incorporating rheological characterization, substrate adhesion testing, and accelerated aging under simulated production conditions. These protocols enable quantitative assessment of material suitability for specific hybrid manufacturing applications, reducing implementation risks and accelerating technology adoption across industrial sectors.

Quality Control Systems for Hybrid Manufacturing Lines

Quality control systems are paramount in hybrid manufacturing lines that integrate Direct Ink Writing (DIW) with traditional manufacturing processes. These systems must address the unique challenges presented by the combination of additive and conventional manufacturing methodologies. In DIW-integrated hybrid lines, quality control begins with real-time monitoring of ink rheology and deposition parameters, including pressure, flow rate, and nozzle speed. Advanced vision systems equipped with high-resolution cameras track the geometric accuracy of printed structures, while thermal imaging monitors temperature distribution during curing processes.

Machine learning algorithms have revolutionized defect detection in hybrid manufacturing environments, enabling predictive quality control rather than reactive inspection. These systems analyze patterns in process data to identify potential failures before they occur, significantly reducing waste and rework. Closed-loop feedback mechanisms automatically adjust printing parameters based on real-time quality measurements, maintaining consistent product quality despite variations in material properties or environmental conditions.

Non-destructive testing (NDT) techniques play a crucial role in hybrid line quality assurance. Ultrasonic testing, X-ray computed tomography, and terahertz imaging allow for internal structure inspection without compromising product integrity. These technologies are particularly valuable for evaluating the interface between additively manufactured components and conventionally produced substrates, where delamination and adhesion failures commonly occur.

Digital twin technology has emerged as an essential quality control tool for DIW hybrid lines. By creating virtual replicas of physical manufacturing processes, engineers can simulate production scenarios, predict quality issues, and optimize process parameters before actual production begins. This approach significantly reduces the time and material costs associated with traditional trial-and-error methods.

Traceability systems integrated with quality control infrastructure enable comprehensive documentation of manufacturing parameters, material batches, and inspection results. This data-driven approach facilitates root cause analysis when defects occur and supports continuous improvement initiatives. Advanced statistical process control (SPC) methods, specifically adapted for the unique variability patterns in hybrid manufacturing, help maintain process stability and product consistency.

Standardization remains a significant challenge in quality control for hybrid manufacturing lines. Industry consortia and standards organizations are actively developing frameworks for quality assurance in additive-conventional hybrid processes, with particular attention to DIW integration scenarios. These emerging standards address calibration procedures, acceptance criteria, and certification methodologies tailored to the unique characteristics of hybrid manufacturing technologies.