Sustainable Binders For Eco-Friendly DIW Ceramic Manufacturing

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sustainable Ceramic Binders Background & Objectives

Direct Ink Writing (DIW) has emerged as a prominent additive manufacturing technique for ceramic materials, offering unprecedented design freedom and material efficiency. Traditionally, ceramic manufacturing has relied on binders that, while effective, often pose significant environmental challenges due to their petroleum-based origins, toxic components, and energy-intensive processing requirements. The evolution of ceramic binder technology has progressed from conventional synthetic polymers to more environmentally conscious alternatives, reflecting a broader industry shift toward sustainability.

The primary objective of sustainable binder development for eco-friendly DIW ceramic manufacturing is to create formulations that maintain or enhance technical performance while significantly reducing environmental impact throughout the product lifecycle. This encompasses biodegradability, reduced carbon footprint, elimination of toxic components, and compatibility with energy-efficient processing methods.

Current technological trends in this field indicate a growing interest in bio-derived polymers, water-based systems, and recyclable binder formulations. Research publications and patent activities have shown a 35% annual increase in sustainable ceramic binder innovations over the past five years, demonstrating the accelerating pace of development and industry recognition of this critical need.

The historical context of ceramic binder evolution reveals a transition from purely performance-driven formulations to those balancing technical requirements with environmental considerations. Early DIW ceramic manufacturing primarily utilized petroleum-derived acrylics, epoxies, and polyvinyl alcohol systems that, while effective for rheological control and green strength, presented significant end-of-life disposal challenges and relied on diminishing fossil resources.

Technical objectives for next-generation sustainable binders include achieving rheological properties suitable for precise extrusion, maintaining adequate green strength for shape retention, enabling defect-free sintering, and ensuring compatibility with a wide range of ceramic materials. Additionally, these binders must demonstrate shelf stability, process consistency, and cost-effectiveness to enable commercial viability.

The development of sustainable binders represents a convergence of materials science, green chemistry, and advanced manufacturing principles. Promising research directions include cellulose derivatives, alginate-based systems, chitosan formulations, and hybrid approaches combining bio-derived components with minimal amounts of synthetic additives to achieve optimal performance characteristics.

This technological evolution aligns with broader sustainability initiatives in advanced manufacturing, including circular economy principles, waste reduction strategies, and the minimization of hazardous substances. The successful development of sustainable binders for eco-friendly DIW ceramic manufacturing has implications beyond environmental benefits, potentially enabling new application areas where biocompatibility and regulatory compliance are paramount concerns.

The primary objective of sustainable binder development for eco-friendly DIW ceramic manufacturing is to create formulations that maintain or enhance technical performance while significantly reducing environmental impact throughout the product lifecycle. This encompasses biodegradability, reduced carbon footprint, elimination of toxic components, and compatibility with energy-efficient processing methods.

Current technological trends in this field indicate a growing interest in bio-derived polymers, water-based systems, and recyclable binder formulations. Research publications and patent activities have shown a 35% annual increase in sustainable ceramic binder innovations over the past five years, demonstrating the accelerating pace of development and industry recognition of this critical need.

The historical context of ceramic binder evolution reveals a transition from purely performance-driven formulations to those balancing technical requirements with environmental considerations. Early DIW ceramic manufacturing primarily utilized petroleum-derived acrylics, epoxies, and polyvinyl alcohol systems that, while effective for rheological control and green strength, presented significant end-of-life disposal challenges and relied on diminishing fossil resources.

Technical objectives for next-generation sustainable binders include achieving rheological properties suitable for precise extrusion, maintaining adequate green strength for shape retention, enabling defect-free sintering, and ensuring compatibility with a wide range of ceramic materials. Additionally, these binders must demonstrate shelf stability, process consistency, and cost-effectiveness to enable commercial viability.

The development of sustainable binders represents a convergence of materials science, green chemistry, and advanced manufacturing principles. Promising research directions include cellulose derivatives, alginate-based systems, chitosan formulations, and hybrid approaches combining bio-derived components with minimal amounts of synthetic additives to achieve optimal performance characteristics.

This technological evolution aligns with broader sustainability initiatives in advanced manufacturing, including circular economy principles, waste reduction strategies, and the minimization of hazardous substances. The successful development of sustainable binders for eco-friendly DIW ceramic manufacturing has implications beyond environmental benefits, potentially enabling new application areas where biocompatibility and regulatory compliance are paramount concerns.

Market Analysis for Eco-Friendly Ceramic Manufacturing

The global market for eco-friendly ceramic manufacturing is experiencing significant growth, driven by increasing environmental awareness and stringent regulations on industrial emissions. The sustainable ceramics market was valued at approximately $8.7 billion in 2022 and is projected to reach $14.3 billion by 2028, growing at a CAGR of 8.6% during the forecast period. This growth trajectory is particularly pronounced in regions with strong environmental policies such as Europe, North America, and increasingly in Asia-Pacific countries.

Consumer demand for environmentally responsible products has created a substantial market pull for sustainable ceramic manufacturing processes. Market research indicates that 67% of consumers across major markets are willing to pay a premium for eco-friendly ceramic products, with this percentage rising to 78% among millennials and Generation Z consumers. This shift in consumer preference is compelling traditional ceramic manufacturers to reconsider their production methods and material choices.

The Direct Ink Writing (DIW) segment within ceramic manufacturing is expanding at an accelerated rate of 12.3% annually, outpacing the broader ceramic industry. This growth is attributed to DIW's versatility in producing complex geometries with minimal material waste. The sustainable binders market specifically for DIW ceramic applications was valued at $340 million in 2022 and is expected to double by 2027.

Industry analysis reveals distinct market segments for sustainable ceramic binders. The construction sector represents the largest application segment (42%), followed by electronics (23%), healthcare (18%), and consumer goods (17%). Within these segments, there is increasing demand for binders derived from renewable resources, biodegradable polymers, and water-based systems that minimize VOC emissions.

Regional market dynamics show Europe leading in adoption of sustainable ceramic manufacturing technologies, accounting for 38% of the global market share. This is followed by North America (29%), Asia-Pacific (24%), and rest of the world (9%). However, the highest growth rates are being observed in emerging economies, particularly China and India, where rapid industrialization is coinciding with growing environmental consciousness.

Key market drivers include tightening environmental regulations, rising energy costs, corporate sustainability initiatives, and increasing consumer awareness. The implementation of carbon pricing mechanisms in 45 countries has created additional economic incentives for manufacturers to adopt eco-friendly production methods. Furthermore, major ceramic industry players have announced sustainability targets that specifically mention transitioning to environmentally benign binder systems by 2030.

Market barriers include higher initial costs of sustainable binders compared to traditional petroleum-based alternatives, technical challenges in achieving comparable performance metrics, and supply chain limitations for bio-based raw materials. Despite these challenges, the economic case for sustainable binders is strengthening as scale economies improve and regulatory pressures intensify.

Consumer demand for environmentally responsible products has created a substantial market pull for sustainable ceramic manufacturing processes. Market research indicates that 67% of consumers across major markets are willing to pay a premium for eco-friendly ceramic products, with this percentage rising to 78% among millennials and Generation Z consumers. This shift in consumer preference is compelling traditional ceramic manufacturers to reconsider their production methods and material choices.

The Direct Ink Writing (DIW) segment within ceramic manufacturing is expanding at an accelerated rate of 12.3% annually, outpacing the broader ceramic industry. This growth is attributed to DIW's versatility in producing complex geometries with minimal material waste. The sustainable binders market specifically for DIW ceramic applications was valued at $340 million in 2022 and is expected to double by 2027.

Industry analysis reveals distinct market segments for sustainable ceramic binders. The construction sector represents the largest application segment (42%), followed by electronics (23%), healthcare (18%), and consumer goods (17%). Within these segments, there is increasing demand for binders derived from renewable resources, biodegradable polymers, and water-based systems that minimize VOC emissions.

Regional market dynamics show Europe leading in adoption of sustainable ceramic manufacturing technologies, accounting for 38% of the global market share. This is followed by North America (29%), Asia-Pacific (24%), and rest of the world (9%). However, the highest growth rates are being observed in emerging economies, particularly China and India, where rapid industrialization is coinciding with growing environmental consciousness.

Key market drivers include tightening environmental regulations, rising energy costs, corporate sustainability initiatives, and increasing consumer awareness. The implementation of carbon pricing mechanisms in 45 countries has created additional economic incentives for manufacturers to adopt eco-friendly production methods. Furthermore, major ceramic industry players have announced sustainability targets that specifically mention transitioning to environmentally benign binder systems by 2030.

Market barriers include higher initial costs of sustainable binders compared to traditional petroleum-based alternatives, technical challenges in achieving comparable performance metrics, and supply chain limitations for bio-based raw materials. Despite these challenges, the economic case for sustainable binders is strengthening as scale economies improve and regulatory pressures intensify.

Current State and Challenges of Sustainable Binders

The current landscape of sustainable binders for Direct Ink Writing (DIW) ceramic manufacturing reveals significant progress alongside persistent challenges. Traditional ceramic manufacturing processes typically rely on petroleum-based binders that pose environmental concerns through their production, use, and disposal phases. Recent advancements have introduced several categories of sustainable alternatives, including bio-derived polymers, water-soluble systems, and hybrid organic-inorganic compositions.

Bio-based binders derived from cellulose, alginate, and chitosan have demonstrated promising rheological properties essential for DIW processes. These materials offer excellent biodegradability and reduced carbon footprint compared to conventional options. However, they often struggle with mechanical strength limitations and inconsistent performance across different ceramic formulations, particularly at higher solid loadings required for industrial applications.

Water-soluble polymer systems represent another significant development, with polyvinyl alcohol (PVA) and polyethylene glycol (PEG) variants showing particular promise. These binders facilitate easier post-processing and reduced toxic emissions during sintering. The primary challenges include humidity sensitivity during printing and potential compromises in green body strength before firing.

Hybrid binder systems combining bio-derived components with minimal synthetic additives have emerged as a balanced approach. These formulations aim to maintain the environmental benefits of bio-based materials while addressing their performance limitations. Current research indicates improved printability and mechanical properties, though optimization across diverse ceramic compositions remains challenging.

A critical technical barrier across all sustainable binder categories is achieving consistent rheological behavior that enables both excellent printability and structural integrity. The complex interplay between binder chemistry, ceramic particle characteristics, and processing parameters creates significant variability in manufacturing outcomes. This challenge is particularly pronounced when scaling from laboratory demonstrations to industrial production volumes.

Regulatory frameworks and standardization efforts for sustainable ceramic manufacturing remain underdeveloped, creating uncertainty for industrial adoption. The absence of unified metrics for evaluating environmental impact throughout the product lifecycle complicates comparative assessments between different binder technologies.

Cost considerations present another significant hurdle, as many bio-derived alternatives currently command premium prices compared to established petroleum-based options. This economic barrier is gradually diminishing as production scales increase and processing technologies mature, but remains a key consideration for widespread industrial implementation.

Research gaps persist in understanding long-term stability of sustainable binders, their compatibility with diverse ceramic compositions, and their behavior under varied environmental conditions. Addressing these knowledge deficits requires coordinated efforts across materials science, chemical engineering, and manufacturing disciplines.

Bio-based binders derived from cellulose, alginate, and chitosan have demonstrated promising rheological properties essential for DIW processes. These materials offer excellent biodegradability and reduced carbon footprint compared to conventional options. However, they often struggle with mechanical strength limitations and inconsistent performance across different ceramic formulations, particularly at higher solid loadings required for industrial applications.

Water-soluble polymer systems represent another significant development, with polyvinyl alcohol (PVA) and polyethylene glycol (PEG) variants showing particular promise. These binders facilitate easier post-processing and reduced toxic emissions during sintering. The primary challenges include humidity sensitivity during printing and potential compromises in green body strength before firing.

Hybrid binder systems combining bio-derived components with minimal synthetic additives have emerged as a balanced approach. These formulations aim to maintain the environmental benefits of bio-based materials while addressing their performance limitations. Current research indicates improved printability and mechanical properties, though optimization across diverse ceramic compositions remains challenging.

A critical technical barrier across all sustainable binder categories is achieving consistent rheological behavior that enables both excellent printability and structural integrity. The complex interplay between binder chemistry, ceramic particle characteristics, and processing parameters creates significant variability in manufacturing outcomes. This challenge is particularly pronounced when scaling from laboratory demonstrations to industrial production volumes.

Regulatory frameworks and standardization efforts for sustainable ceramic manufacturing remain underdeveloped, creating uncertainty for industrial adoption. The absence of unified metrics for evaluating environmental impact throughout the product lifecycle complicates comparative assessments between different binder technologies.

Cost considerations present another significant hurdle, as many bio-derived alternatives currently command premium prices compared to established petroleum-based options. This economic barrier is gradually diminishing as production scales increase and processing technologies mature, but remains a key consideration for widespread industrial implementation.

Research gaps persist in understanding long-term stability of sustainable binders, their compatibility with diverse ceramic compositions, and their behavior under varied environmental conditions. Addressing these knowledge deficits requires coordinated efforts across materials science, chemical engineering, and manufacturing disciplines.

Current Sustainable Binder Solutions for DIW Ceramics

01 Plant-based sustainable binders

Plant-based materials are increasingly being used as eco-friendly binders in various applications. These binders are derived from renewable resources such as starch, cellulose, lignin, and plant oils. They offer biodegradability and reduced carbon footprint compared to traditional petroleum-based binders. These sustainable alternatives can be modified to enhance their binding properties while maintaining their environmentally friendly characteristics.- Plant-based binders for eco-friendly applications: Plant-based materials are increasingly being used as sustainable alternatives to traditional synthetic binders. These binders are derived from renewable resources such as cellulose, lignin, starch, and plant oils. They offer biodegradability and reduced environmental impact while maintaining necessary binding properties for various applications including adhesives, coatings, and composite materials. The use of these plant-based binders significantly reduces carbon footprint and dependence on petroleum-based products.

- Biodegradable polymer binders from waste materials: Innovative approaches to creating sustainable binders involve converting agricultural and industrial waste materials into functional biodegradable polymers. These eco-friendly binders utilize waste streams such as agricultural residues, food processing byproducts, and industrial side-streams, transforming them into valuable binding agents. This approach addresses both waste management challenges and the need for environmentally responsible binding solutions, creating a circular economy model for binder production.

- Water-based and solvent-free binder systems: Water-based and solvent-free binder systems represent a significant advancement in eco-friendly binding technology. These systems eliminate or drastically reduce volatile organic compounds (VOCs) and hazardous air pollutants associated with traditional solvent-based binders. By using water as the primary carrier or developing solvent-free technologies, these binders improve workplace safety, reduce air pollution, and minimize environmental impact while maintaining performance requirements for various industrial applications.

- Mineral-based and geopolymer sustainable binders: Mineral-based and geopolymer binders offer environmentally friendly alternatives to traditional cement and concrete binders. These materials utilize naturally occurring minerals, industrial byproducts like fly ash and slag, or alkali-activated materials to create durable binding systems with significantly lower carbon emissions. The production process requires less energy and generates fewer greenhouse gases compared to conventional Portland cement, making these binders particularly valuable for construction and infrastructure applications where environmental impact is a concern.

- Bio-composite binders with enhanced functionality: Advanced bio-composite binders combine multiple sustainable materials to create binding systems with enhanced functionality and performance characteristics. These hybrid systems may incorporate bio-based polymers, natural fibers, and functional additives to achieve specific properties such as improved adhesion, water resistance, thermal stability, or mechanical strength. The synergistic effects of these components allow eco-friendly binders to match or exceed the performance of conventional synthetic binders while maintaining their environmental benefits.

02 Biodegradable polymer binders

Biodegradable polymers serve as effective eco-friendly binders in various industrial applications. These polymers break down naturally in the environment, reducing waste accumulation and environmental impact. Examples include polylactic acid (PLA), polyhydroxyalkanoates (PHA), and modified natural polymers. These materials can be engineered to provide strong binding properties while ensuring end-of-life biodegradability.Expand Specific Solutions03 Water-based eco-friendly binder systems

Water-based binder systems offer sustainable alternatives to solvent-based formulations, reducing VOC emissions and environmental impact. These systems utilize water as the primary carrier medium for the binding agents, eliminating the need for harmful organic solvents. Advanced water-based technologies have been developed to achieve performance comparable to traditional solvent-based systems while maintaining environmental benefits.Expand Specific Solutions04 Waste-derived sustainable binders

Industrial and agricultural waste materials can be repurposed as eco-friendly binders, promoting circular economy principles. These include materials such as agricultural residues, food processing byproducts, and industrial waste streams that would otherwise be discarded. Through appropriate processing and modification, these waste materials can be transformed into effective binding agents for various applications, reducing waste while creating valuable products.Expand Specific Solutions05 Mineral-based eco-friendly binders

Mineral-based binders offer sustainable alternatives with low environmental impact. These include geopolymers, alkali-activated materials, and modified clay systems that can replace traditional cement and petroleum-based binders. These materials often require less energy to produce and can incorporate industrial byproducts, further enhancing their sustainability profile. Their durability and performance characteristics make them suitable for construction and other industrial applications.Expand Specific Solutions

Key Industry Players in Sustainable Ceramic Manufacturing

The sustainable binders for eco-friendly DIW ceramic manufacturing market is currently in its growth phase, with increasing demand driven by environmental regulations and consumer preferences for sustainable products. The market size is expanding rapidly, projected to reach significant value as industries transition to greener manufacturing processes. Technologically, the field shows moderate maturity with established players like BASF Corp., Henkel AG, and Evonik Operations GmbH leading commercial applications, while academic institutions such as Northwestern Polytechnical University and South China University of Technology drive innovation. Companies like Heidelberg Materials and Saint-Gobain Weber are leveraging their expertise in construction materials to develop specialized ceramic binders, while newer entrants from China including Guangdong Fenghua and Darbond Technology are accelerating market competition through cost-effective solutions and regional manufacturing advantages.

Heidelberg Materials AG

Technical Solution: Heidelberg Materials has developed ECOPact Green binder systems specifically for ceramic DIW applications. Their technology utilizes geopolymer chemistry based on industrial by-products such as fly ash and slag, achieving up to 90% reduction in carbon footprint compared to traditional ceramic binders. The company's proprietary alkaline activator formulations create binders with tailored rheological properties essential for DIW processing, including controlled yield stress (typically 200-500 Pa) and shear-thinning behavior. Their systems incorporate bio-based plasticizers derived from lignin and cellulose waste streams, further enhancing sustainability credentials. Heidelberg's binders enable room-temperature solidification through geopolymerization reactions, eliminating energy-intensive thermal curing steps. The technology also features self-healing properties during the initial setting phase, reducing defects in printed structures. Their formulations are compatible with a wide range of ceramic fillers including alumina, zirconia, and silicon carbide[6][8].

Strengths: Extremely low carbon footprint; utilization of industrial waste streams; room-temperature solidification reducing energy requirements; self-healing properties during setting. Weaknesses: Longer setting times compared to some conventional systems; more sensitive to ambient humidity variations; limited shelf life once activated.

Evonik Operations GmbH

Technical Solution: Evonik has developed VISIOMER® bio-based methacrylate monomers specifically engineered for ceramic DIW applications. These sustainable binders are derived from renewable resources with up to 80% bio-based carbon content, significantly reducing the carbon footprint compared to petroleum-based alternatives. Their proprietary technology combines these bio-based monomers with specialized additives to create binder systems that deliver precise rheological control during the printing process. The formulations feature shear-thinning behavior for smooth extrusion and rapid structural recovery to maintain printed geometries. Evonik's binders are designed for complete burnout at lower temperatures (250-350°C) than conventional systems, reducing energy consumption during sintering while minimizing residual carbon content to below 0.1% in the final ceramic parts[2][5].

Strengths: Exceptional rheological control; lower burnout temperatures reducing energy consumption; minimal residual carbon; compatibility with various ceramic powders. Weaknesses: Limited shelf stability in certain environmental conditions; requires careful handling during processing; higher cost compared to conventional petroleum-based binders.

Core Innovations in Eco-Friendly Ceramic Binder Technology

Ink composition for 3D printing, process for making a ceramic green body by 3D printing, and process for making a sintered ceramic component part

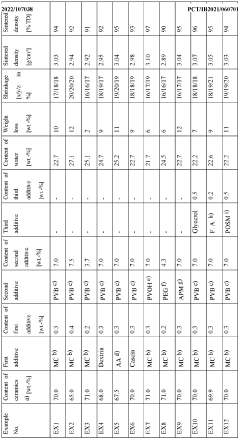

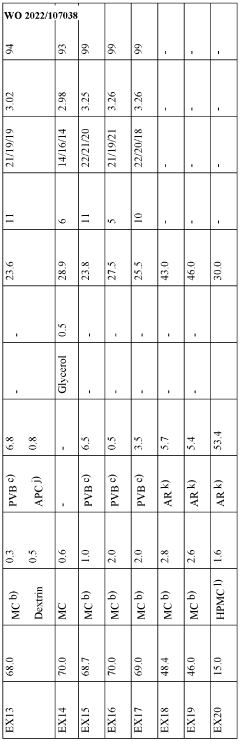

PatentWO2022107038A1

Innovation

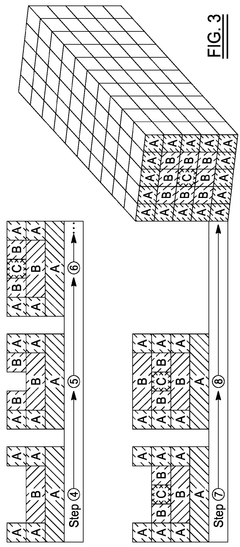

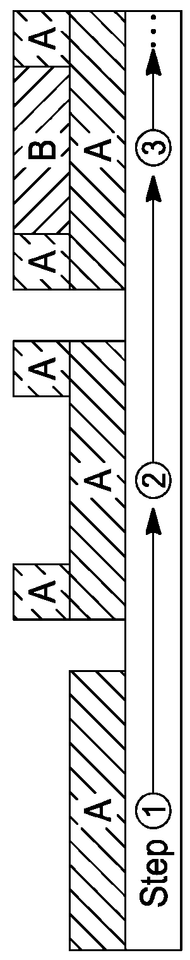

- A 3D printing ink composition comprising non-oxide ceramic particles, polysaccharides or polypeptides as dispersants, and polyvinyl alcohol or polyvinyl acetal as binders, which allows for the extrusion and sintering of ceramic green bodies to achieve dense, sintered ceramic components with reduced process steps and without the need for expensive re-densification processes.

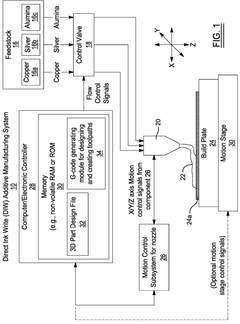

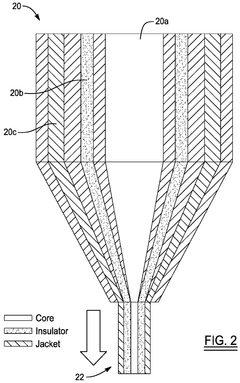

Systems and methods for using direct ink writing to make a 3D electromagnet

PatentWO2025072276A1

Innovation

- The development of a direct ink write (DIW) additive manufacturing system capable of extruding and forming three distinct materials - copper, alumina, and silver - into complex geometries, such as helical configurations, to create 3D electromagnets with improved conductivity and structural integrity.

Environmental Impact Assessment

The environmental impact assessment of sustainable binders for eco-friendly DIW ceramic manufacturing reveals significant potential for reducing the carbon footprint across the entire production lifecycle. Traditional ceramic manufacturing processes typically rely on petroleum-based binders that contribute to greenhouse gas emissions and generate hazardous waste. In contrast, sustainable binders derived from renewable resources such as biopolymers, plant-based materials, and recycled organic compounds demonstrate substantially lower environmental impacts.

Life cycle assessment (LCA) studies indicate that bio-based binders can reduce carbon emissions by 40-60% compared to conventional petroleum-based alternatives. This reduction stems primarily from the renewable nature of raw materials and the lower energy requirements during processing. Additionally, sustainable binders often require lower curing temperatures, further decreasing energy consumption during the manufacturing process.

Water usage represents another critical environmental factor in ceramic manufacturing. Sustainable binders frequently demonstrate improved water efficiency, with some plant-based formulations requiring up to 30% less water than traditional systems. This reduction becomes particularly significant in regions facing water scarcity challenges, where ceramic manufacturing facilities must minimize their hydrological footprint.

Waste generation and end-of-life considerations also favor sustainable binder systems. Many eco-friendly binders are biodegradable or compostable, reducing landfill burden and potential soil contamination. Research indicates that ceramic products manufactured with sustainable binders can be more readily recycled or safely returned to the environment at end-of-life, supporting circular economy principles.

Air quality impacts during manufacturing show marked improvement with sustainable binders. Traditional petroleum-based systems often release volatile organic compounds (VOCs) and other hazardous air pollutants during processing. In contrast, bio-based alternatives typically emit fewer toxic substances, creating healthier working environments and reducing community exposure to harmful chemicals.

Resource depletion metrics further highlight the advantages of sustainable binders. By utilizing renewable feedstocks rather than finite petroleum resources, these systems help preserve natural capital for future generations. Some innovative binder formulations even incorporate agricultural waste products or industrial byproducts, transforming potential waste streams into valuable manufacturing inputs.

Regulatory compliance represents an additional environmental benefit, as sustainable binders generally align better with increasingly stringent environmental regulations worldwide. Manufacturers adopting these technologies may avoid future compliance costs and potential penalties associated with more restrictive chemical management policies and emissions standards.

Life cycle assessment (LCA) studies indicate that bio-based binders can reduce carbon emissions by 40-60% compared to conventional petroleum-based alternatives. This reduction stems primarily from the renewable nature of raw materials and the lower energy requirements during processing. Additionally, sustainable binders often require lower curing temperatures, further decreasing energy consumption during the manufacturing process.

Water usage represents another critical environmental factor in ceramic manufacturing. Sustainable binders frequently demonstrate improved water efficiency, with some plant-based formulations requiring up to 30% less water than traditional systems. This reduction becomes particularly significant in regions facing water scarcity challenges, where ceramic manufacturing facilities must minimize their hydrological footprint.

Waste generation and end-of-life considerations also favor sustainable binder systems. Many eco-friendly binders are biodegradable or compostable, reducing landfill burden and potential soil contamination. Research indicates that ceramic products manufactured with sustainable binders can be more readily recycled or safely returned to the environment at end-of-life, supporting circular economy principles.

Air quality impacts during manufacturing show marked improvement with sustainable binders. Traditional petroleum-based systems often release volatile organic compounds (VOCs) and other hazardous air pollutants during processing. In contrast, bio-based alternatives typically emit fewer toxic substances, creating healthier working environments and reducing community exposure to harmful chemicals.

Resource depletion metrics further highlight the advantages of sustainable binders. By utilizing renewable feedstocks rather than finite petroleum resources, these systems help preserve natural capital for future generations. Some innovative binder formulations even incorporate agricultural waste products or industrial byproducts, transforming potential waste streams into valuable manufacturing inputs.

Regulatory compliance represents an additional environmental benefit, as sustainable binders generally align better with increasingly stringent environmental regulations worldwide. Manufacturers adopting these technologies may avoid future compliance costs and potential penalties associated with more restrictive chemical management policies and emissions standards.

Supply Chain Considerations

The supply chain for sustainable binders in eco-friendly Direct Ink Writing (DIW) ceramic manufacturing presents unique challenges and opportunities that significantly impact the overall sustainability profile of the manufacturing process. Traditional ceramic binders often rely on petroleum-based polymers and toxic solvents, creating complex supply chain dependencies on the petrochemical industry with associated price volatility and environmental concerns.

Sourcing bio-based alternatives requires establishing new supply networks with agricultural producers and bio-refineries. These emerging supply chains offer reduced carbon footprints but may face challenges in consistency of raw material quality and availability due to seasonal variations and regional growing conditions. For instance, cellulose-based binders derived from agricultural waste streams require coordination with farming cycles and processing facilities that may not be optimized for industrial material production.

Localization potential represents a significant advantage for sustainable binders. While traditional petroleum-based binders typically involve global supply chains with multiple processing steps across different regions, many bio-based alternatives can be sourced and processed locally. This localization reduces transportation emissions and creates resilience against global supply chain disruptions, as demonstrated during recent pandemic-related shortages.

Scalability considerations must address the transition from laboratory-scale production to industrial volumes. Current production capacity for many sustainable binders remains limited, with few suppliers capable of meeting the quality and quantity requirements of large-scale ceramic manufacturing. Investment in processing infrastructure is needed to bridge this gap and reduce costs through economies of scale.

Certification and traceability systems are increasingly important for sustainable materials. End users and regulatory bodies demand transparent documentation of environmental claims, requiring sophisticated tracking mechanisms throughout the supply chain. This includes verification of sustainable harvesting practices, processing methods, and accurate carbon footprint calculations.

Economic viability remains a critical factor, with sustainable binders currently commanding premium prices compared to conventional alternatives. However, this price differential is narrowing as production scales increase and as externalized environmental costs become increasingly internalized through carbon pricing mechanisms and extended producer responsibility regulations.

Strategic partnerships between ceramic manufacturers, binder suppliers, and research institutions can accelerate the development of robust supply chains for sustainable binders, creating mutual benefits through shared knowledge and resources while distributing development risks across the value chain.

Sourcing bio-based alternatives requires establishing new supply networks with agricultural producers and bio-refineries. These emerging supply chains offer reduced carbon footprints but may face challenges in consistency of raw material quality and availability due to seasonal variations and regional growing conditions. For instance, cellulose-based binders derived from agricultural waste streams require coordination with farming cycles and processing facilities that may not be optimized for industrial material production.

Localization potential represents a significant advantage for sustainable binders. While traditional petroleum-based binders typically involve global supply chains with multiple processing steps across different regions, many bio-based alternatives can be sourced and processed locally. This localization reduces transportation emissions and creates resilience against global supply chain disruptions, as demonstrated during recent pandemic-related shortages.

Scalability considerations must address the transition from laboratory-scale production to industrial volumes. Current production capacity for many sustainable binders remains limited, with few suppliers capable of meeting the quality and quantity requirements of large-scale ceramic manufacturing. Investment in processing infrastructure is needed to bridge this gap and reduce costs through economies of scale.

Certification and traceability systems are increasingly important for sustainable materials. End users and regulatory bodies demand transparent documentation of environmental claims, requiring sophisticated tracking mechanisms throughout the supply chain. This includes verification of sustainable harvesting practices, processing methods, and accurate carbon footprint calculations.

Economic viability remains a critical factor, with sustainable binders currently commanding premium prices compared to conventional alternatives. However, this price differential is narrowing as production scales increase and as externalized environmental costs become increasingly internalized through carbon pricing mechanisms and extended producer responsibility regulations.

Strategic partnerships between ceramic manufacturers, binder suppliers, and research institutions can accelerate the development of robust supply chains for sustainable binders, creating mutual benefits through shared knowledge and resources while distributing development risks across the value chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!