Direct Ink Writing Fundamentals For Ceramic And Metal Pastes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Technology Evolution and Objectives

Direct Ink Writing (DIW) technology has evolved significantly since its inception in the late 1990s at Sandia National Laboratories. Initially developed as a versatile additive manufacturing technique for creating complex three-dimensional structures, DIW has undergone substantial refinement particularly in the realm of ceramic and metal paste processing. The fundamental principle of DIW involves the extrusion of a viscous ink through a nozzle to create precise patterns and structures, with the ink subsequently solidifying through various mechanisms including evaporation, gelation, or chemical reactions.

The evolution of DIW for ceramic and metal pastes has been marked by several key technological advancements. Early systems faced challenges with ink rheology control and limited resolution capabilities. By the mid-2000s, significant improvements in nozzle design and precision motion control systems enabled the creation of more intricate structures with enhanced dimensional accuracy. The development of specialized inks with tailored viscoelastic properties represented another crucial milestone, allowing for improved shape retention and structural integrity during the printing process.

Recent years have witnessed the integration of DIW with complementary technologies such as in-situ monitoring systems and multi-material printing capabilities. These innovations have expanded the application scope of DIW beyond traditional ceramics to include advanced functional materials, biomedical implants, and electronic components. The incorporation of computational modeling and simulation tools has further enhanced the predictability and reliability of the DIW process, enabling more efficient optimization of printing parameters.

The primary objectives of current DIW technology development for ceramic and metal pastes focus on several critical areas. First, enhancing the resolution and surface quality of printed structures to meet increasingly demanding specifications for advanced applications. Second, expanding the range of compatible materials to include high-performance ceramics and metals with complex compositions. Third, improving process reliability and reproducibility to facilitate industrial-scale implementation.

Additional objectives include the development of multi-material printing capabilities to create functionally graded structures with spatially varying compositions and properties. The integration of in-situ curing mechanisms represents another important goal, potentially eliminating the need for post-processing steps and reducing production time. Furthermore, there is significant interest in scaling up DIW technology to accommodate larger build volumes while maintaining precision and quality.

Looking forward, the trajectory of DIW technology is moving toward fully automated systems with adaptive process control, capable of real-time adjustments based on feedback from integrated sensors. This evolution aims to establish DIW as a mainstream manufacturing technology for high-value ceramic and metal components across diverse industrial sectors.

The evolution of DIW for ceramic and metal pastes has been marked by several key technological advancements. Early systems faced challenges with ink rheology control and limited resolution capabilities. By the mid-2000s, significant improvements in nozzle design and precision motion control systems enabled the creation of more intricate structures with enhanced dimensional accuracy. The development of specialized inks with tailored viscoelastic properties represented another crucial milestone, allowing for improved shape retention and structural integrity during the printing process.

Recent years have witnessed the integration of DIW with complementary technologies such as in-situ monitoring systems and multi-material printing capabilities. These innovations have expanded the application scope of DIW beyond traditional ceramics to include advanced functional materials, biomedical implants, and electronic components. The incorporation of computational modeling and simulation tools has further enhanced the predictability and reliability of the DIW process, enabling more efficient optimization of printing parameters.

The primary objectives of current DIW technology development for ceramic and metal pastes focus on several critical areas. First, enhancing the resolution and surface quality of printed structures to meet increasingly demanding specifications for advanced applications. Second, expanding the range of compatible materials to include high-performance ceramics and metals with complex compositions. Third, improving process reliability and reproducibility to facilitate industrial-scale implementation.

Additional objectives include the development of multi-material printing capabilities to create functionally graded structures with spatially varying compositions and properties. The integration of in-situ curing mechanisms represents another important goal, potentially eliminating the need for post-processing steps and reducing production time. Furthermore, there is significant interest in scaling up DIW technology to accommodate larger build volumes while maintaining precision and quality.

Looking forward, the trajectory of DIW technology is moving toward fully automated systems with adaptive process control, capable of real-time adjustments based on feedback from integrated sensors. This evolution aims to establish DIW as a mainstream manufacturing technology for high-value ceramic and metal components across diverse industrial sectors.

Market Analysis for Ceramic and Metal Paste Applications

The global market for Direct Ink Writing (DIW) technology in ceramic and metal paste applications has witnessed substantial growth in recent years, driven by increasing demand for advanced manufacturing solutions across multiple industries. The market size for ceramic and metal additive manufacturing was valued at approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate of 21% through 2028, with DIW technologies representing a significant segment of this expansion.

The healthcare sector constitutes one of the largest application areas, particularly in the production of customized implants, dental prosthetics, and tissue engineering scaffolds. The biocompatibility of ceramic materials like hydroxyapatite and zirconia has positioned DIW as a preferred manufacturing method for patient-specific medical devices, with this segment accounting for nearly 30% of the total market share.

Aerospace and defense industries represent another substantial market for DIW ceramic and metal paste applications. The ability to create complex geometries with high-performance materials such as silicon carbide, alumina, and various metal alloys has enabled the production of lightweight components with superior thermal and mechanical properties. This sector is expected to grow at 25% annually as manufacturers increasingly adopt additive manufacturing for critical components.

The electronics industry has emerged as a rapidly growing application area, particularly for DIW of ceramic pastes in the production of sensors, actuators, and electronic packaging. The miniaturization trend in electronics has created demand for precise deposition of functional materials, with the market for DIW in electronics applications growing at 28% annually.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate due to significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Key market drivers include increasing demand for customized products, reduced material waste compared to traditional manufacturing methods, and the ability to create complex geometries that are difficult or impossible to achieve with conventional techniques. The growing emphasis on sustainable manufacturing practices has also contributed to market expansion, as DIW typically results in lower energy consumption and reduced material waste.

Challenges limiting market growth include high initial equipment costs, limited material options compared to traditional manufacturing, and the need for specialized expertise in formulating printable pastes with appropriate rheological properties. Additionally, quality control and standardization issues remain significant barriers to wider industrial adoption.

The healthcare sector constitutes one of the largest application areas, particularly in the production of customized implants, dental prosthetics, and tissue engineering scaffolds. The biocompatibility of ceramic materials like hydroxyapatite and zirconia has positioned DIW as a preferred manufacturing method for patient-specific medical devices, with this segment accounting for nearly 30% of the total market share.

Aerospace and defense industries represent another substantial market for DIW ceramic and metal paste applications. The ability to create complex geometries with high-performance materials such as silicon carbide, alumina, and various metal alloys has enabled the production of lightweight components with superior thermal and mechanical properties. This sector is expected to grow at 25% annually as manufacturers increasingly adopt additive manufacturing for critical components.

The electronics industry has emerged as a rapidly growing application area, particularly for DIW of ceramic pastes in the production of sensors, actuators, and electronic packaging. The miniaturization trend in electronics has created demand for precise deposition of functional materials, with the market for DIW in electronics applications growing at 28% annually.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate due to significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Key market drivers include increasing demand for customized products, reduced material waste compared to traditional manufacturing methods, and the ability to create complex geometries that are difficult or impossible to achieve with conventional techniques. The growing emphasis on sustainable manufacturing practices has also contributed to market expansion, as DIW typically results in lower energy consumption and reduced material waste.

Challenges limiting market growth include high initial equipment costs, limited material options compared to traditional manufacturing, and the need for specialized expertise in formulating printable pastes with appropriate rheological properties. Additionally, quality control and standardization issues remain significant barriers to wider industrial adoption.

Technical Challenges in DIW for High-Performance Materials

Direct Ink Writing (DIW) for ceramic and metal pastes faces significant technical hurdles that limit its widespread industrial adoption. The rheological properties of high-performance material pastes present a fundamental challenge, as they must exhibit both shear-thinning behavior during extrusion and rapid recovery of yield stress after deposition. Achieving this delicate balance remains difficult, particularly for metal pastes which often suffer from inconsistent flow characteristics and nozzle clogging during printing.

Particle size distribution and homogeneity represent another critical challenge. High-performance applications demand uniform microstructures, yet achieving consistent dispersion of ceramic and metal particles within carrier mediums proves problematic. Agglomeration frequently occurs, creating weak points in final structures and compromising mechanical integrity. This issue becomes more pronounced when working with nanoscale particles, which tend to cluster due to strong van der Waals forces.

The sintering process following DIW introduces additional complexities. Ceramic and metal parts typically require high-temperature post-processing to achieve desired densification and mechanical properties. During this phase, differential shrinkage often leads to warping, cracking, and dimensional inaccuracies. For multi-material structures, these challenges are compounded by mismatched thermal expansion coefficients between different material zones.

Resolution limitations persist in DIW technology, with current systems struggling to produce features below 100 μm while maintaining structural integrity. This constraint severely restricts applications in microelectronics, sensors, and other fields requiring fine-scale precision. The trade-off between resolution and structural strength remains a significant barrier to advancement.

Surface quality issues also plague DIW-produced components. The layer-by-layer deposition process inherently creates surface irregularities that require extensive post-processing. For high-performance applications where surface finish directly impacts functionality—such as fluid flow channels or optical components—these imperfections present serious limitations.

Scalability challenges further hinder industrial adoption. While DIW shows promise in laboratory settings, scaling to mass production introduces issues with process consistency, quality control, and production speed. The slow deposition rates typical of DIW processes make large-scale manufacturing economically unfeasible for many applications.

Material compatibility issues also persist, particularly when attempting to incorporate multiple materials within a single print. Creating effective interfaces between different ceramics or metals remains challenging, with delamination and interface weakness common. These problems are especially pronounced when combining materials with significantly different physical properties.

Particle size distribution and homogeneity represent another critical challenge. High-performance applications demand uniform microstructures, yet achieving consistent dispersion of ceramic and metal particles within carrier mediums proves problematic. Agglomeration frequently occurs, creating weak points in final structures and compromising mechanical integrity. This issue becomes more pronounced when working with nanoscale particles, which tend to cluster due to strong van der Waals forces.

The sintering process following DIW introduces additional complexities. Ceramic and metal parts typically require high-temperature post-processing to achieve desired densification and mechanical properties. During this phase, differential shrinkage often leads to warping, cracking, and dimensional inaccuracies. For multi-material structures, these challenges are compounded by mismatched thermal expansion coefficients between different material zones.

Resolution limitations persist in DIW technology, with current systems struggling to produce features below 100 μm while maintaining structural integrity. This constraint severely restricts applications in microelectronics, sensors, and other fields requiring fine-scale precision. The trade-off between resolution and structural strength remains a significant barrier to advancement.

Surface quality issues also plague DIW-produced components. The layer-by-layer deposition process inherently creates surface irregularities that require extensive post-processing. For high-performance applications where surface finish directly impacts functionality—such as fluid flow channels or optical components—these imperfections present serious limitations.

Scalability challenges further hinder industrial adoption. While DIW shows promise in laboratory settings, scaling to mass production introduces issues with process consistency, quality control, and production speed. The slow deposition rates typical of DIW processes make large-scale manufacturing economically unfeasible for many applications.

Material compatibility issues also persist, particularly when attempting to incorporate multiple materials within a single print. Creating effective interfaces between different ceramics or metals remains challenging, with delamination and interface weakness common. These problems are especially pronounced when combining materials with significantly different physical properties.

Current DIW Process Solutions for Advanced Materials

01 Materials and compositions for DIW

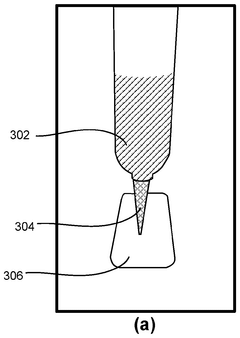

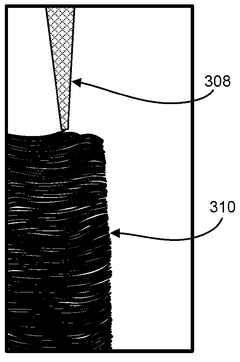

Direct Ink Writing (DIW) utilizes various specialized materials and compositions to create 3D structures. These materials include ceramic slurries, polymer composites, and functional inks with specific rheological properties that allow them to flow through nozzles yet maintain their shape after deposition. The compositions often contain additives to control viscosity, surface tension, and curing behavior, enabling precise control over the printing process and final material properties.- Materials and compositions for DIW printing: Direct Ink Writing (DIW) utilizes various specialized materials and compositions to create 3D structures. These materials include ceramic slurries, polymer composites, and functional inks with specific rheological properties that allow them to flow through nozzles yet maintain their shape after deposition. The compositions often contain additives to control viscosity, surface tension, and curing behavior, enabling precise control over the printing process and final material properties.

- DIW printing equipment and hardware configurations: The hardware components of DIW systems include precision extrusion mechanisms, multi-axis positioning systems, and specialized nozzle designs. These systems often feature pressure-controlled dispensers, high-precision motion stages, and temperature control units to maintain optimal printing conditions. Advanced DIW printers may incorporate multiple print heads for multi-material deposition and integrated monitoring systems to ensure print quality and consistency.

- Applications of DIW in manufacturing and fabrication: DIW technology has been applied across various industries including electronics, biomedical engineering, and advanced manufacturing. It enables the fabrication of complex structures such as tissue scaffolds, electronic components, sensors, and customized parts with specific functional properties. The ability to precisely deposit materials with controlled architecture makes DIW particularly valuable for creating structures with tailored mechanical, electrical, or biological properties.

- Process parameters and optimization for DIW: Successful DIW printing requires careful optimization of process parameters including extrusion pressure, nozzle diameter, print speed, and layer height. These parameters significantly influence the resolution, structural integrity, and functional properties of printed objects. Advanced DIW processes may incorporate real-time monitoring and feedback control systems to adjust printing parameters dynamically, ensuring consistent quality across complex geometries and different material systems.

- Post-processing techniques for DIW printed structures: After DIW printing, various post-processing techniques are employed to enhance the properties of printed structures. These include thermal treatments such as sintering for ceramic materials, UV curing for photopolymers, and surface treatments to improve finish quality. Post-processing steps are crucial for achieving desired mechanical properties, dimensional accuracy, and functional performance in the final printed objects.

02 DIW equipment and printing mechanisms

The equipment used in Direct Ink Writing includes specialized extrusion systems, precision nozzles, and motion control platforms. These systems enable the controlled deposition of ink materials through pneumatic pressure, mechanical pistons, or screw-driven mechanisms. Advanced DIW printers incorporate multiple print heads, temperature control systems, and real-time monitoring capabilities to ensure precise material placement and structure formation during the printing process.Expand Specific Solutions03 Applications of DIW in electronics and sensors

Direct Ink Writing technology has been applied to create electronic components and sensors by depositing conductive, semiconductive, or dielectric materials in precise patterns. This enables the fabrication of flexible electronics, printed circuit boards, antennas, and various sensing devices. The ability to print functional electronic materials directly onto substrates allows for customized designs, reduced material waste, and integration of electronics into complex three-dimensional structures.Expand Specific Solutions04 DIW for biomedical and tissue engineering

Direct Ink Writing has significant applications in biomedical fields, particularly for creating tissue engineering scaffolds, drug delivery systems, and medical devices. By using biocompatible and biodegradable materials, DIW can produce structures with controlled porosity, mechanical properties, and biochemical functionalities. This enables the fabrication of patient-specific implants, artificial tissues, and platforms for cell culture and drug testing.Expand Specific Solutions05 Post-processing and property enhancement of DIW structures

After the Direct Ink Writing process, various post-processing techniques are employed to enhance the properties of printed structures. These include thermal treatments like sintering and annealing, chemical treatments to improve surface properties, and additional coating processes. Post-processing is crucial for achieving desired mechanical strength, electrical conductivity, optical properties, or biological functionality in the final printed components.Expand Specific Solutions

Industry Leaders in Ceramic and Metal DIW Manufacturing

Direct Ink Writing (DIW) for ceramic and metal pastes is currently in a growth phase, with increasing adoption across industries. The market is expanding rapidly due to DIW's ability to create complex geometries with high precision. The global market size for ceramic and metal additive manufacturing is projected to reach several billion dollars by 2025, driven by applications in aerospace, healthcare, and electronics. Technologically, DIW is maturing with key players advancing different aspects: Central South University and Shanghai Institute of Ceramics lead academic research; General Electric and Boeing focus on industrial applications; Samsung Electro-Mechanics and Applied Materials develop equipment solutions; while specialized companies like Torrecid and Shandong SinoCera create advanced paste formulations. The technology is transitioning from research to commercial applications, with increasing focus on standardization and process optimization.

General Electric Company

Technical Solution: General Electric has developed advanced Direct Ink Writing (DIW) technology for ceramic and metal pastes with particular focus on high-temperature applications. Their approach utilizes custom-formulated ceramic and metal-based inks with precisely controlled rheological properties that exhibit shear-thinning behavior during extrusion and rapid recovery post-deposition. GE's system incorporates multi-nozzle printheads capable of depositing features with resolution down to 100 microns while maintaining structural integrity. Their proprietary ink formulations contain up to 60 vol% solid loading with carefully engineered binder systems that facilitate controlled drying and sintering processes. GE has successfully applied this technology to manufacture complex ceramic components for gas turbines, achieving microstructural control that enhances thermal and mechanical performance compared to conventional manufacturing methods.

Strengths: Exceptional control over material microstructure; integration with existing industrial manufacturing systems; proven scalability for production environments. Weaknesses: Higher equipment costs compared to conventional ceramic forming; limited to specific material systems that meet rheological requirements; requires specialized post-processing protocols.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed a sophisticated Direct Ink Writing platform specifically optimized for high-performance ceramic and metal-ceramic composite materials. Their system employs colloidal processing techniques to create highly stable suspensions with solid loadings of 45-65 vol% while maintaining printability through precise control of zeta potential and particle size distribution. Their technology incorporates a dual-feed extrusion system that allows for gradient material composition within single printed structures. The institute has pioneered specialized rheological modifiers that create strongly shear-thinning behavior during extrusion while enabling rapid structural recovery post-deposition. Their process achieves printing speeds up to 150 mm/s while maintaining dimensional accuracy within ±10 μm. Post-processing protocols include controlled humidity drying chambers and programmed sintering cycles that achieve densification exceeding 99% of theoretical density while minimizing grain growth. This technology has been successfully applied to biomedical implants, electronic substrates, and energy conversion devices.

Strengths: Exceptional material versatility including complex ceramic composites; high-precision gradient material capabilities; excellent final part density and microstructural control. Weaknesses: Relatively slower production rates compared to conventional ceramic forming; complex ink formulation requirements; specialized post-processing needs.

Key Patents and Research in Rheological Control

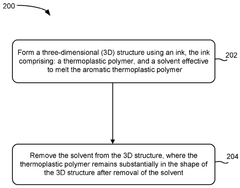

Direct ink write additive manufacturing of thermoplastic polymers and thermoplastic polymer composites at ambient conditions

PatentWO2025058759A1

Innovation

- The development of a direct ink write method using an ink comprising a thermoplastic polymer and a solvent effective to melt the polymer, allowing for the formation of 3D structures at ambient conditions and enabling the use of a wider range of fillers and additives.

Material Formulation Strategies for Optimal Printability

Material formulation represents the cornerstone of successful direct ink writing (DIW) for ceramic and metal pastes. The rheological properties of these pastes must be precisely engineered to achieve optimal printability while maintaining structural integrity throughout the printing process. Effective formulations typically exhibit shear-thinning behavior, allowing the material to flow under applied pressure during extrusion but rapidly recover viscosity upon deposition to maintain shape fidelity.

The primary components in ceramic and metal paste formulations include the functional particles (ceramic or metal powders), binders, dispersants, and rheology modifiers. Particle size distribution plays a critical role in determining flow characteristics and final part density. Optimized formulations typically utilize multimodal distributions, incorporating both fine particles (0.1-1 μm) and coarser particles (5-20 μm) to achieve high solid loading while maintaining printability.

Binder selection significantly impacts both printability and post-processing requirements. Polymeric binders such as polyvinyl alcohol (PVA), polyethylene glycol (PEG), and various cellulose derivatives provide the necessary viscoelastic properties. Recent advances have introduced stimuli-responsive binders that undergo controlled phase transitions during printing, enhancing shape retention without compromising flow during extrusion.

Dispersants are essential for preventing agglomeration of ceramic and metal particles, ensuring homogeneous distribution throughout the paste. Electrosteric stabilization mechanisms have proven particularly effective, with phosphate esters and polyelectrolytes commonly employed for ceramic systems, while fatty acids and oleylamine derivatives show promise for metal pastes.

Rheology modifiers, including fumed silica, clay minerals, and various synthetic polymers, enable fine-tuning of yield stress and recovery behavior. The incorporation of thixotropic additives has been particularly beneficial, allowing pastes to rapidly rebuild their internal structure after the shear forces of extrusion cease.

Solvent selection balances competing requirements of appropriate viscosity, evaporation rate, and compatibility with other formulation components. Water-based systems offer environmental and safety advantages but may present challenges with metal powders prone to oxidation. Non-aqueous systems utilizing alcohols or glycols provide alternatives for oxygen-sensitive materials.

Advanced formulation strategies increasingly incorporate in-situ polymerization or crosslinking mechanisms triggered during or immediately after printing. These approaches, including UV-curable systems and temperature-sensitive gelation, provide enhanced mechanical properties in the green state while maintaining excellent flow characteristics during extrusion.

The primary components in ceramic and metal paste formulations include the functional particles (ceramic or metal powders), binders, dispersants, and rheology modifiers. Particle size distribution plays a critical role in determining flow characteristics and final part density. Optimized formulations typically utilize multimodal distributions, incorporating both fine particles (0.1-1 μm) and coarser particles (5-20 μm) to achieve high solid loading while maintaining printability.

Binder selection significantly impacts both printability and post-processing requirements. Polymeric binders such as polyvinyl alcohol (PVA), polyethylene glycol (PEG), and various cellulose derivatives provide the necessary viscoelastic properties. Recent advances have introduced stimuli-responsive binders that undergo controlled phase transitions during printing, enhancing shape retention without compromising flow during extrusion.

Dispersants are essential for preventing agglomeration of ceramic and metal particles, ensuring homogeneous distribution throughout the paste. Electrosteric stabilization mechanisms have proven particularly effective, with phosphate esters and polyelectrolytes commonly employed for ceramic systems, while fatty acids and oleylamine derivatives show promise for metal pastes.

Rheology modifiers, including fumed silica, clay minerals, and various synthetic polymers, enable fine-tuning of yield stress and recovery behavior. The incorporation of thixotropic additives has been particularly beneficial, allowing pastes to rapidly rebuild their internal structure after the shear forces of extrusion cease.

Solvent selection balances competing requirements of appropriate viscosity, evaporation rate, and compatibility with other formulation components. Water-based systems offer environmental and safety advantages but may present challenges with metal powders prone to oxidation. Non-aqueous systems utilizing alcohols or glycols provide alternatives for oxygen-sensitive materials.

Advanced formulation strategies increasingly incorporate in-situ polymerization or crosslinking mechanisms triggered during or immediately after printing. These approaches, including UV-curable systems and temperature-sensitive gelation, provide enhanced mechanical properties in the green state while maintaining excellent flow characteristics during extrusion.

Sustainability Aspects of Additive Manufacturing Processes

The sustainability aspects of Direct Ink Writing (DIW) for ceramic and metal pastes represent a critical dimension in evaluating this additive manufacturing technology's environmental impact. DIW offers significant sustainability advantages through material efficiency, as it precisely deposits only the required amount of ceramic or metal paste, minimizing waste compared to traditional subtractive manufacturing methods. This reduction in material consumption directly translates to conservation of valuable and often rare resources used in ceramic and metallic components.

Energy efficiency constitutes another sustainability benefit of DIW processes. Operating at ambient or near-ambient temperatures, DIW requires substantially less energy than conventional sintering or casting methods that demand high-temperature processing. This reduced energy footprint becomes particularly significant when manufacturing complex ceramic or metal components that would otherwise require energy-intensive multi-stage production processes.

The localized production capability enabled by DIW technology contributes to reduced transportation emissions and supply chain simplification. Components can be manufactured on-demand and on-site, eliminating the need for extensive shipping networks and associated carbon emissions. This aspect becomes increasingly important as organizations seek to reduce their overall carbon footprint across the entire product lifecycle.

From a circular economy perspective, DIW presents opportunities for improved end-of-life management. The precise control over material composition in ceramic and metal pastes can facilitate easier recycling and reprocessing of components. Additionally, the ability to repair existing components through targeted material deposition represents a significant advancement in extending product lifecycles.

However, sustainability challenges remain in DIW implementation for ceramic and metal pastes. The environmental impact of specialized additives required for proper rheological properties needs careful assessment. These additives, while essential for printability, may introduce toxicity concerns or complicate recycling processes. Furthermore, post-processing requirements such as debinding and sintering still contribute significantly to the overall environmental footprint.

Water usage optimization represents another sustainability consideration, particularly for water-based ceramic pastes. Closed-loop water systems and efficient paste formulations can substantially reduce the water intensity of DIW processes, addressing growing concerns about water scarcity in manufacturing contexts.

As DIW technology for ceramic and metal pastes continues to mature, life cycle assessment (LCA) methodologies are being developed to quantify its environmental advantages compared to conventional manufacturing approaches. These assessments will be crucial in guiding future development toward truly sustainable implementation of this promising additive manufacturing technology.

Energy efficiency constitutes another sustainability benefit of DIW processes. Operating at ambient or near-ambient temperatures, DIW requires substantially less energy than conventional sintering or casting methods that demand high-temperature processing. This reduced energy footprint becomes particularly significant when manufacturing complex ceramic or metal components that would otherwise require energy-intensive multi-stage production processes.

The localized production capability enabled by DIW technology contributes to reduced transportation emissions and supply chain simplification. Components can be manufactured on-demand and on-site, eliminating the need for extensive shipping networks and associated carbon emissions. This aspect becomes increasingly important as organizations seek to reduce their overall carbon footprint across the entire product lifecycle.

From a circular economy perspective, DIW presents opportunities for improved end-of-life management. The precise control over material composition in ceramic and metal pastes can facilitate easier recycling and reprocessing of components. Additionally, the ability to repair existing components through targeted material deposition represents a significant advancement in extending product lifecycles.

However, sustainability challenges remain in DIW implementation for ceramic and metal pastes. The environmental impact of specialized additives required for proper rheological properties needs careful assessment. These additives, while essential for printability, may introduce toxicity concerns or complicate recycling processes. Furthermore, post-processing requirements such as debinding and sintering still contribute significantly to the overall environmental footprint.

Water usage optimization represents another sustainability consideration, particularly for water-based ceramic pastes. Closed-loop water systems and efficient paste formulations can substantially reduce the water intensity of DIW processes, addressing growing concerns about water scarcity in manufacturing contexts.

As DIW technology for ceramic and metal pastes continues to mature, life cycle assessment (LCA) methodologies are being developed to quantify its environmental advantages compared to conventional manufacturing approaches. These assessments will be crucial in guiding future development toward truly sustainable implementation of this promising additive manufacturing technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!