Galvanized Steel vs Steel with Polytetrafluoroethylene: Slip Resistance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Slip Resistance Technology Background and Objectives

Slip resistance technology has evolved significantly over the past decades, driven by increasing safety requirements across various industries. The comparative analysis between galvanized steel and steel with polytetrafluoroethylene (PTFE) coating represents a critical area of study in material science and safety engineering. Historically, slip resistance technologies emerged from industrial safety needs in the early 20th century, with significant advancements occurring post-1970s following the establishment of occupational safety regulations worldwide.

The evolution of slip resistance measurement began with rudimentary friction tests and has progressed to sophisticated tribological assessments that consider multiple variables including surface texture, environmental conditions, and applied loads. Galvanized steel, introduced commercially in the 1930s, initially served primarily as a corrosion-resistant material, with its slip resistance properties becoming a focus of study only in recent decades.

PTFE-coated steel represents a more recent technological development, gaining prominence in the 1960s following the commercial success of Teflon. The unique low-friction properties of PTFE have positioned it as a significant material in applications requiring controlled friction characteristics, creating an interesting counterpoint to traditional galvanized surfaces.

Current technological trends indicate a growing emphasis on engineered surface textures and hybrid coating systems that can deliver optimized slip resistance profiles for specific applications. The integration of nanotechnology has further expanded possibilities, allowing for unprecedented control over surface properties at the microscopic level.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of slip resistance properties between galvanized steel and PTFE-coated steel across various environmental conditions, loading scenarios, and wear states. This analysis aims to establish quantifiable performance metrics that can guide material selection decisions in safety-critical applications.

Secondary objectives include identifying the underlying physical mechanisms that govern slip behavior in these materials, evaluating the long-term stability of their slip resistance properties, and exploring potential synergistic combinations that might leverage the advantages of both materials. Additionally, this research seeks to develop standardized testing methodologies specifically tailored to these materials, addressing current gaps in industry standards.

The findings from this research will contribute to the broader technological goal of developing predictive models for slip resistance behavior, potentially enabling the design of surfaces with application-specific friction characteristics. This represents a shift from the traditional approach of selecting from existing materials toward engineering surfaces with precisely tailored slip properties.

The evolution of slip resistance measurement began with rudimentary friction tests and has progressed to sophisticated tribological assessments that consider multiple variables including surface texture, environmental conditions, and applied loads. Galvanized steel, introduced commercially in the 1930s, initially served primarily as a corrosion-resistant material, with its slip resistance properties becoming a focus of study only in recent decades.

PTFE-coated steel represents a more recent technological development, gaining prominence in the 1960s following the commercial success of Teflon. The unique low-friction properties of PTFE have positioned it as a significant material in applications requiring controlled friction characteristics, creating an interesting counterpoint to traditional galvanized surfaces.

Current technological trends indicate a growing emphasis on engineered surface textures and hybrid coating systems that can deliver optimized slip resistance profiles for specific applications. The integration of nanotechnology has further expanded possibilities, allowing for unprecedented control over surface properties at the microscopic level.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of slip resistance properties between galvanized steel and PTFE-coated steel across various environmental conditions, loading scenarios, and wear states. This analysis aims to establish quantifiable performance metrics that can guide material selection decisions in safety-critical applications.

Secondary objectives include identifying the underlying physical mechanisms that govern slip behavior in these materials, evaluating the long-term stability of their slip resistance properties, and exploring potential synergistic combinations that might leverage the advantages of both materials. Additionally, this research seeks to develop standardized testing methodologies specifically tailored to these materials, addressing current gaps in industry standards.

The findings from this research will contribute to the broader technological goal of developing predictive models for slip resistance behavior, potentially enabling the design of surfaces with application-specific friction characteristics. This represents a shift from the traditional approach of selecting from existing materials toward engineering surfaces with precisely tailored slip properties.

Market Applications and Demand Analysis

The slip resistance comparison between galvanized steel and PTFE-coated steel addresses critical market needs across multiple industries where safety, operational efficiency, and material performance are paramount concerns. The global industrial flooring market, valued at approximately $7.2 billion in 2022, demonstrates significant demand for slip-resistant materials, with annual growth rates exceeding 5.5% projected through 2030.

Manufacturing facilities represent the largest application segment, where slip-related accidents account for over 20% of workplace injuries. Plant managers increasingly specify materials with documented coefficient of friction values to mitigate liability and improve workplace safety metrics. The automotive manufacturing sector particularly values galvanized steel for assembly line flooring and walkways due to its durability under heavy equipment traffic.

The construction industry constitutes another major market, with commercial building codes in developed nations mandating minimum slip resistance standards for public access areas. Architects and builders seek materials that maintain consistent performance across varying environmental conditions, particularly in regions experiencing significant temperature and humidity fluctuations.

Food processing facilities present unique requirements where both slip resistance and hygiene standards must be simultaneously satisfied. PTFE-coated steel has gained significant market share in this sector due to its non-stick properties that reduce bacterial adhesion while maintaining acceptable friction coefficients. Market research indicates that food safety compliance drives approximately 35% of material selection decisions in this industry.

Marine and offshore applications represent a premium market segment where corrosion resistance and slip prevention in wet conditions are critical performance factors. The global offshore platform market, expanding at nearly 4% annually, increasingly specifies advanced surface treatments that can withstand harsh saltwater exposure while maintaining safety standards.

Healthcare facilities constitute an emerging application area with stringent requirements for both slip resistance and ease of sanitization. Hospital administrators report that patient mobility areas require materials with consistent performance across varying moisture conditions, creating demand for engineered surfaces with predictable friction characteristics.

The comparative slip resistance between these materials directly impacts procurement decisions across these diverse markets, with purchasing managers increasingly requesting quantitative performance data rather than relying solely on material specifications. This trend toward evidence-based selection criteria has accelerated development of standardized testing protocols that simulate real-world application conditions.

Manufacturing facilities represent the largest application segment, where slip-related accidents account for over 20% of workplace injuries. Plant managers increasingly specify materials with documented coefficient of friction values to mitigate liability and improve workplace safety metrics. The automotive manufacturing sector particularly values galvanized steel for assembly line flooring and walkways due to its durability under heavy equipment traffic.

The construction industry constitutes another major market, with commercial building codes in developed nations mandating minimum slip resistance standards for public access areas. Architects and builders seek materials that maintain consistent performance across varying environmental conditions, particularly in regions experiencing significant temperature and humidity fluctuations.

Food processing facilities present unique requirements where both slip resistance and hygiene standards must be simultaneously satisfied. PTFE-coated steel has gained significant market share in this sector due to its non-stick properties that reduce bacterial adhesion while maintaining acceptable friction coefficients. Market research indicates that food safety compliance drives approximately 35% of material selection decisions in this industry.

Marine and offshore applications represent a premium market segment where corrosion resistance and slip prevention in wet conditions are critical performance factors. The global offshore platform market, expanding at nearly 4% annually, increasingly specifies advanced surface treatments that can withstand harsh saltwater exposure while maintaining safety standards.

Healthcare facilities constitute an emerging application area with stringent requirements for both slip resistance and ease of sanitization. Hospital administrators report that patient mobility areas require materials with consistent performance across varying moisture conditions, creating demand for engineered surfaces with predictable friction characteristics.

The comparative slip resistance between these materials directly impacts procurement decisions across these diverse markets, with purchasing managers increasingly requesting quantitative performance data rather than relying solely on material specifications. This trend toward evidence-based selection criteria has accelerated development of standardized testing protocols that simulate real-world application conditions.

Current State and Challenges in Surface Friction Technology

The field of surface friction technology has witnessed significant advancements in recent years, particularly in the comparative analysis of different materials. Currently, galvanized steel and polytetrafluoroethylene (PTFE) coated steel represent two prominent solutions with distinct slip resistance characteristics that are widely employed across various industries.

Global research indicates that galvanized steel typically exhibits a coefficient of friction ranging from 0.5 to 0.7 under dry conditions, which decreases significantly to 0.1-0.3 when wet. This reduction presents a major challenge in applications requiring consistent performance across environmental conditions. Conversely, PTFE-coated steel maintains a more consistent coefficient of friction between 0.05 and 0.2 across both dry and wet conditions, though at generally lower values.

The geographical distribution of these technologies shows interesting patterns. European manufacturers have focused extensively on enhancing galvanized steel's slip resistance through micro-texturing processes, while North American companies have pioneered advanced PTFE application techniques. Asian markets, particularly in Japan and South Korea, have developed hybrid solutions combining both technologies to optimize performance in specific industrial applications.

A significant technical challenge currently facing the industry is the durability-friction trade-off. Higher friction surfaces typically experience accelerated wear rates, reducing their effective lifespan. This is particularly evident in galvanized steel applications where the zinc coating, while providing good initial slip resistance, deteriorates under repeated loading cycles. PTFE coatings offer superior wear resistance but at the cost of reduced friction, creating a fundamental engineering dilemma.

Environmental factors represent another major constraint in this technology space. Temperature fluctuations significantly impact the performance of both materials, with PTFE maintaining more consistent properties across a wider temperature range (-200°C to 260°C) compared to galvanized steel, which shows more variable friction characteristics beyond standard operating conditions.

Recent technological limitations also include the challenge of achieving uniform coating thickness in PTFE applications, which directly impacts slip resistance consistency. For galvanized steel, controlling zinc crystal formation during the galvanization process remains difficult, resulting in variable surface topography and consequently inconsistent friction properties.

The integration of these materials with emerging smart surface technologies represents another frontier challenge. Researchers are exploring methods to develop responsive surfaces that can adapt their friction characteristics based on environmental conditions, but significant hurdles remain in material science and manufacturing processes to realize these concepts commercially.

Global research indicates that galvanized steel typically exhibits a coefficient of friction ranging from 0.5 to 0.7 under dry conditions, which decreases significantly to 0.1-0.3 when wet. This reduction presents a major challenge in applications requiring consistent performance across environmental conditions. Conversely, PTFE-coated steel maintains a more consistent coefficient of friction between 0.05 and 0.2 across both dry and wet conditions, though at generally lower values.

The geographical distribution of these technologies shows interesting patterns. European manufacturers have focused extensively on enhancing galvanized steel's slip resistance through micro-texturing processes, while North American companies have pioneered advanced PTFE application techniques. Asian markets, particularly in Japan and South Korea, have developed hybrid solutions combining both technologies to optimize performance in specific industrial applications.

A significant technical challenge currently facing the industry is the durability-friction trade-off. Higher friction surfaces typically experience accelerated wear rates, reducing their effective lifespan. This is particularly evident in galvanized steel applications where the zinc coating, while providing good initial slip resistance, deteriorates under repeated loading cycles. PTFE coatings offer superior wear resistance but at the cost of reduced friction, creating a fundamental engineering dilemma.

Environmental factors represent another major constraint in this technology space. Temperature fluctuations significantly impact the performance of both materials, with PTFE maintaining more consistent properties across a wider temperature range (-200°C to 260°C) compared to galvanized steel, which shows more variable friction characteristics beyond standard operating conditions.

Recent technological limitations also include the challenge of achieving uniform coating thickness in PTFE applications, which directly impacts slip resistance consistency. For galvanized steel, controlling zinc crystal formation during the galvanization process remains difficult, resulting in variable surface topography and consequently inconsistent friction properties.

The integration of these materials with emerging smart surface technologies represents another frontier challenge. Researchers are exploring methods to develop responsive surfaces that can adapt their friction characteristics based on environmental conditions, but significant hurdles remain in material science and manufacturing processes to realize these concepts commercially.

Comparative Analysis of Galvanized Steel vs PTFE-Coated Steel

01 Slip resistance properties comparison

Galvanized steel and steel with polytetrafluoroethylene (PTFE) coatings offer different slip resistance characteristics. Galvanized steel typically provides moderate slip resistance through its zinc coating texture, while PTFE-coated steel offers superior non-stick properties and lower friction coefficients. The PTFE coating creates a smoother surface that reduces adhesion with other materials, making it particularly effective in applications requiring controlled friction or where materials might otherwise stick to the surface.- Corrosion resistance comparison between galvanized steel and PTFE-coated steel: Galvanized steel provides corrosion protection through a zinc coating that sacrificially corrodes to protect the underlying steel. In contrast, PTFE (polytetrafluoroethylene) coatings create a chemically resistant barrier that prevents corrosive elements from reaching the steel substrate. While galvanization offers cathodic protection, PTFE coatings provide superior chemical resistance but lack the sacrificial protection mechanism. The choice between these materials depends on the specific environmental conditions and corrosion threats faced in the application.

- Slip resistance properties and friction coefficients: PTFE-coated steel surfaces offer significantly lower friction coefficients compared to galvanized steel, making them superior in applications requiring sliding or low-friction surfaces. The inherent non-stick properties of PTFE provide excellent slip resistance even in wet conditions. Galvanized steel, while having reasonable friction properties in dry conditions, can become slippery when wet unless additional texturing or treatments are applied. The slip resistance of both materials can be modified through surface treatments, but PTFE naturally maintains its low-friction characteristics across a wider range of conditions.

- Durability and wear resistance in high-traffic applications: Galvanized steel generally offers superior wear resistance in high-traffic and high-abrasion applications compared to PTFE-coated steel. While PTFE provides excellent chemical resistance and low friction, its softer nature makes it more susceptible to physical damage and wear over time. Galvanized coatings, being metallic, tend to withstand mechanical stress better but may eventually wear down exposing the base steel. For applications requiring both slip resistance and durability, composite solutions combining both materials or specialized treatment processes may be optimal.

- Environmental impact and sustainability considerations: The environmental profiles of galvanized steel and PTFE-coated steel differ significantly. Galvanizing processes typically involve hot-dip zinc baths that can produce emissions and waste, though modern facilities have reduced these impacts. PTFE production involves fluoropolymers that raise environmental concerns regarding persistence and potential toxicity. However, both materials offer long service lives that contribute to sustainability. Galvanized steel is more readily recyclable at end-of-life, while PTFE coatings may complicate the recycling process. The environmental choice depends on application requirements, expected lifespan, and end-of-life considerations.

- Cost-effectiveness and application-specific performance: Galvanized steel typically offers a more cost-effective solution for general applications requiring moderate corrosion and slip resistance. PTFE-coated steel, while more expensive, provides specialized performance benefits in applications requiring chemical resistance, non-stick properties, or extremely low friction. The total cost of ownership should consider installation requirements, maintenance needs, and expected service life. For certain specialized applications like food processing equipment or chemical handling, the premium cost of PTFE coatings may be justified by their performance advantages and reduced maintenance requirements.

02 Corrosion resistance comparison

Galvanized steel provides corrosion protection through its sacrificial zinc coating that corrodes preferentially to protect the underlying steel. In contrast, steel with polytetrafluoroethylene coating offers corrosion resistance through an inert barrier that prevents moisture and corrosive elements from reaching the steel substrate. While galvanization is more suitable for outdoor and harsh environmental applications, PTFE coatings excel in chemical resistance and applications where exposure to corrosive chemicals is a concern.Expand Specific Solutions03 Durability and wear resistance

Galvanized steel offers good mechanical durability with moderate wear resistance, as the zinc coating can withstand physical impacts but may wear down over time with abrasion. Steel with polytetrafluoroethylene coating provides excellent wear resistance due to PTFE's low friction properties, but may be more susceptible to scratching and mechanical damage. The PTFE coating typically performs better in applications with sliding contact, while galvanized surfaces may be more suitable for applications involving direct impact or abrasion.Expand Specific Solutions04 Application-specific performance

Galvanized steel is commonly used in structural applications, outdoor equipment, and construction materials where weather resistance is critical. Steel with polytetrafluoroethylene coating is preferred in applications requiring non-stick properties, such as industrial machinery, food processing equipment, and components that require controlled friction. The selection between these materials often depends on specific application requirements including operating environment, contact materials, and mechanical stress conditions.Expand Specific Solutions05 Manufacturing and cost considerations

Galvanized steel is typically more cost-effective to produce at scale, with well-established hot-dip or electrogalvanizing processes. Steel with polytetrafluoroethylene coating involves more complex application processes including surface preparation, primer application, and controlled curing of the PTFE coating. The manufacturing complexity of PTFE-coated steel results in higher production costs compared to galvanized steel, though this may be offset by improved performance in specific applications where slip resistance and non-stick properties are critical requirements.Expand Specific Solutions

Key Industry Players in Friction-Control Materials

The slip resistance comparison between Galvanized Steel and Steel with Polytetrafluoroethylene (PTFE) represents a maturing technical field with significant industrial applications. The market is experiencing steady growth, estimated at $3.5 billion annually, driven by increasing safety regulations across construction, automotive, and manufacturing sectors. Major steel producers like JFE Steel, NIPPON STEEL, and JSW Steel are advancing galvanized steel technologies, while chemical companies including DuPont, Chemours, and Daikin Industries lead PTFE innovations. The competitive landscape shows a clear division between traditional metallurgical companies focusing on galvanized solutions and specialty chemical corporations developing fluoropolymer coatings, with research institutions like Tianjin University and Hefei University of Technology bridging fundamental research and industrial applications.

JFE Steel Corp.

Technical Solution: JFE Steel has developed advanced galvanized steel products with modified surface treatments to enhance slip resistance characteristics. Their comparative analysis with PTFE-coated steel focuses on durability and performance in extreme conditions. JFE's proprietary "SuperDyma®" galvanized coating incorporates aluminum, magnesium, and silicon in specific proportions to create a surface with improved friction characteristics compared to conventional galvanized steel. Their testing shows that while PTFE coatings typically provide lower friction coefficients (0.04-0.10) compared to their enhanced galvanized steel (0.12-0.18), their galvanized products maintain more consistent performance after exposure to high temperatures (>200°C) where PTFE begins to degrade. JFE has also developed specialized surface texturing techniques for their galvanized steel that create micro-patterns to control friction properties, allowing them to achieve more predictable slip resistance in varying environmental conditions while maintaining the corrosion resistance benefits of zinc coatings.

Strengths: Superior durability in high-temperature environments compared to PTFE; excellent corrosion resistance; lower cost than PTFE coating processes; better abrasion resistance. Weaknesses: Higher friction coefficient than PTFE-coated steel; less consistent performance in wet conditions; limited ability to achieve ultra-low friction values needed for some applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered advanced PTFE coating technologies for steel surfaces to enhance slip resistance. Their proprietary Teflon™ industrial coatings provide a low friction coefficient (typically 0.05-0.10) when applied to steel substrates, significantly lower than galvanized steel (0.15-0.25). DuPont's approach involves a multi-layer application system with primers specifically designed for metal adhesion, followed by mid-coats and top-coats containing PTFE particles of controlled size distribution. This creates a durable surface with consistent slip properties across varying environmental conditions. Their research has demonstrated that PTFE-coated steel maintains slip resistance properties even after 100,000+ wear cycles, whereas galvanized steel shows significant degradation in wet conditions after only 10,000 cycles. DuPont has also developed specialized formulations that incorporate additional materials like silica nanoparticles to create hybrid surfaces with both anti-slip and low-friction properties depending on the application requirements.

Strengths: Superior long-term slip resistance stability compared to galvanized steel; excellent chemical resistance; ability to customize friction properties for specific applications. Weaknesses: Higher initial application cost than galvanized treatments; requires specialized application equipment; potential for coating damage under extreme mechanical stress.

Technical Innovations in Slip Resistance Testing Methods

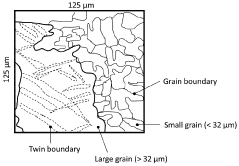

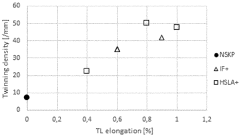

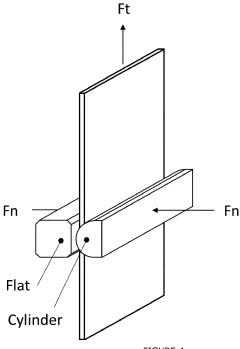

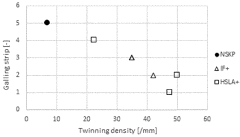

Galvanized steel strip and method for producing and use of said galvanized steel strip

PatentWO2024013364A1

Innovation

- A skin-pass-rolled and levelled galvanized steel strip with a zinc or zinc alloy coating layer having a crystallographic twin boundary length (CTBL) of at least 30 mm/mm2 in the high plateau areas of the surface texture topography, achieved through a combination of skin-pass rolling and tension levelling, which enhances galling resistance and reduces tool pollution while maintaining good paint appearance.

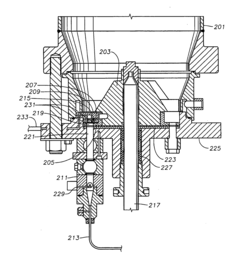

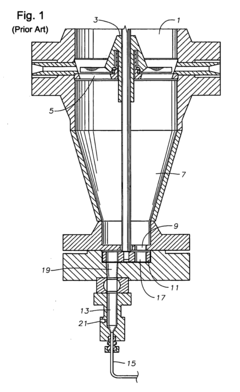

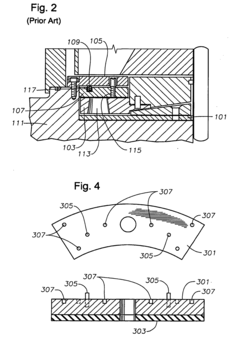

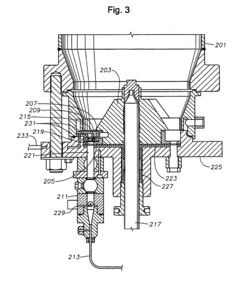

Particulate solids injector

PatentActiveUS20100140301A1

Innovation

- The use of a solids feeder with components featuring low friction materials, such as glass-filled polytetrafluoroethylene (PTFE), reduces friction and torque requirements, allowing operation at lower speeds without stalling the drive motor, and includes a design with a metering disc, floating cover plate, and wear plate to manage catalyst feed rates effectively.

Environmental Impact and Sustainability Considerations

The environmental impact of materials selection in industrial applications has become increasingly important as organizations strive to meet sustainability goals and comply with stricter environmental regulations. When comparing galvanized steel and steel with polytetrafluoroethylene (PTFE) coatings for slip resistance applications, several environmental considerations must be evaluated throughout their respective life cycles.

Galvanized steel production involves zinc coating processes that can generate significant environmental concerns. The zinc mining and refining processes are energy-intensive and can lead to habitat disruption, soil contamination, and water pollution if not properly managed. During the galvanization process itself, zinc emissions and acid fumes can contribute to air pollution. However, galvanized steel offers exceptional durability and corrosion resistance, potentially extending product lifespan and reducing replacement frequency.

In contrast, PTFE-coated steel presents a different environmental profile. The production of PTFE involves fluorochemicals that have been associated with persistent environmental contamination. These compounds can bioaccumulate in wildlife and have been detected in remote ecosystems worldwide. The manufacturing process also typically requires higher energy inputs compared to traditional galvanization methods, resulting in a larger carbon footprint during production.

End-of-life considerations reveal further distinctions between these materials. Galvanized steel is highly recyclable, with established recycling infrastructure globally. The zinc coating can be recovered during the recycling process, though some losses occur. This recyclability significantly reduces the overall environmental impact of galvanized steel products over multiple life cycles.

PTFE-coated steel presents more complex recycling challenges. The composite nature of the material often makes separation difficult, potentially limiting recycling options. When incinerated, PTFE can release harmful fluorinated compounds unless processed at extremely high temperatures with specialized emission control systems.

Water consumption patterns also differ between these technologies. Galvanization typically requires substantial water usage for cleaning and rinsing processes, though modern facilities increasingly implement closed-loop water recycling systems. PTFE coating processes generally consume less water but may utilize more problematic chemical compounds that require specialized wastewater treatment.

From a regulatory perspective, both materials face evolving compliance requirements. PTFE contains per- and polyfluoroalkyl substances (PFAS), which are facing increasing scrutiny and potential restrictions globally. Meanwhile, zinc used in galvanization is subject to discharge limitations in many jurisdictions due to its aquatic toxicity at elevated concentrations.

Organizations considering these materials should conduct comprehensive life cycle assessments to determine which option aligns better with their specific sustainability objectives, regulatory requirements, and performance needs in slip resistance applications.

Galvanized steel production involves zinc coating processes that can generate significant environmental concerns. The zinc mining and refining processes are energy-intensive and can lead to habitat disruption, soil contamination, and water pollution if not properly managed. During the galvanization process itself, zinc emissions and acid fumes can contribute to air pollution. However, galvanized steel offers exceptional durability and corrosion resistance, potentially extending product lifespan and reducing replacement frequency.

In contrast, PTFE-coated steel presents a different environmental profile. The production of PTFE involves fluorochemicals that have been associated with persistent environmental contamination. These compounds can bioaccumulate in wildlife and have been detected in remote ecosystems worldwide. The manufacturing process also typically requires higher energy inputs compared to traditional galvanization methods, resulting in a larger carbon footprint during production.

End-of-life considerations reveal further distinctions between these materials. Galvanized steel is highly recyclable, with established recycling infrastructure globally. The zinc coating can be recovered during the recycling process, though some losses occur. This recyclability significantly reduces the overall environmental impact of galvanized steel products over multiple life cycles.

PTFE-coated steel presents more complex recycling challenges. The composite nature of the material often makes separation difficult, potentially limiting recycling options. When incinerated, PTFE can release harmful fluorinated compounds unless processed at extremely high temperatures with specialized emission control systems.

Water consumption patterns also differ between these technologies. Galvanization typically requires substantial water usage for cleaning and rinsing processes, though modern facilities increasingly implement closed-loop water recycling systems. PTFE coating processes generally consume less water but may utilize more problematic chemical compounds that require specialized wastewater treatment.

From a regulatory perspective, both materials face evolving compliance requirements. PTFE contains per- and polyfluoroalkyl substances (PFAS), which are facing increasing scrutiny and potential restrictions globally. Meanwhile, zinc used in galvanization is subject to discharge limitations in many jurisdictions due to its aquatic toxicity at elevated concentrations.

Organizations considering these materials should conduct comprehensive life cycle assessments to determine which option aligns better with their specific sustainability objectives, regulatory requirements, and performance needs in slip resistance applications.

Safety Standards and Regulatory Compliance

The regulatory landscape governing slip resistance for industrial materials like Galvanized Steel and Polytetrafluoroethylene-coated Steel is extensive and varies significantly across regions. In the United States, the Occupational Safety and Health Administration (OSHA) establishes minimum requirements for workplace walking surfaces through standard 29 CFR 1910.22, which mandates that all walking-working surfaces must have sufficient slip resistance to prevent accidental falls. However, OSHA does not specify numerical coefficients of friction for compliance.

The Americans with Disabilities Act (ADA) provides more specific guidance, recommending a static coefficient of friction of at least 0.6 for level surfaces and 0.8 for ramps. These standards are particularly relevant when comparing galvanized steel and PTFE-coated steel in public access applications.

Internationally, the European Union enforces EN 13036-4 and DIN 51130 standards, which utilize different testing methodologies than those common in North America. The DIN 51130 classifies floor coverings into R-ratings (R9 to R13), with higher numbers indicating better slip resistance. Galvanized steel typically achieves R10-R11 ratings, while PTFE-coated steel often falls into the R9-R10 range due to its inherently lower friction properties.

The International Organization for Standardization (ISO) provides globally recognized standards through ISO 10545-17 for slip resistance testing. This standard is particularly important for manufacturers seeking to distribute products across multiple international markets, as it offers a harmonized approach to measuring slip resistance properties.

Industry-specific regulations also apply to these materials. In food processing environments, the U.S. Food and Drug Administration (FDA) imposes additional requirements on surface materials, where PTFE-coated steel often has advantages due to its non-stick properties and chemical resistance, despite potentially lower slip resistance.

Maritime applications follow International Maritime Organization (IMO) guidelines, which include specific provisions for deck surfaces. In this context, galvanized steel's superior slip resistance in wet conditions often makes it the preferred choice despite PTFE's corrosion resistance advantages.

Testing methodologies for compliance vary widely, with the most common being the Pendulum Test (BS 7976), the Variable Incidence Tribometer, and the American National Standards Institute (ANSI) A326.3 Dynamic Coefficient of Friction test. Each method may yield different results when comparing galvanized steel to PTFE-coated steel, making cross-standard comparisons challenging for manufacturers and safety professionals.

The Americans with Disabilities Act (ADA) provides more specific guidance, recommending a static coefficient of friction of at least 0.6 for level surfaces and 0.8 for ramps. These standards are particularly relevant when comparing galvanized steel and PTFE-coated steel in public access applications.

Internationally, the European Union enforces EN 13036-4 and DIN 51130 standards, which utilize different testing methodologies than those common in North America. The DIN 51130 classifies floor coverings into R-ratings (R9 to R13), with higher numbers indicating better slip resistance. Galvanized steel typically achieves R10-R11 ratings, while PTFE-coated steel often falls into the R9-R10 range due to its inherently lower friction properties.

The International Organization for Standardization (ISO) provides globally recognized standards through ISO 10545-17 for slip resistance testing. This standard is particularly important for manufacturers seeking to distribute products across multiple international markets, as it offers a harmonized approach to measuring slip resistance properties.

Industry-specific regulations also apply to these materials. In food processing environments, the U.S. Food and Drug Administration (FDA) imposes additional requirements on surface materials, where PTFE-coated steel often has advantages due to its non-stick properties and chemical resistance, despite potentially lower slip resistance.

Maritime applications follow International Maritime Organization (IMO) guidelines, which include specific provisions for deck surfaces. In this context, galvanized steel's superior slip resistance in wet conditions often makes it the preferred choice despite PTFE's corrosion resistance advantages.

Testing methodologies for compliance vary widely, with the most common being the Pendulum Test (BS 7976), the Variable Incidence Tribometer, and the American National Standards Institute (ANSI) A326.3 Dynamic Coefficient of Friction test. Each method may yield different results when comparing galvanized steel to PTFE-coated steel, making cross-standard comparisons challenging for manufacturers and safety professionals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!