How to Improve Galvanized Steel's Weather Resistance

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Weather Resistance Background & Objectives

Galvanized steel has been a cornerstone material in construction, automotive, and infrastructure industries for over 150 years. The process of galvanization, which involves coating steel with a protective layer of zinc, was first patented in 1837 by French engineer Stanislas Sorel. Since then, the technology has evolved significantly, with hot-dip galvanizing becoming the predominant method by the early 20th century. This evolution has been driven by the increasing demand for corrosion-resistant materials in various applications exposed to harsh environmental conditions.

The fundamental principle behind galvanization remains unchanged: zinc provides sacrificial protection to the underlying steel by corroding preferentially when exposed to moisture and oxygen. However, traditional galvanized steel still faces significant challenges in extreme weather conditions, particularly in coastal areas with high salt content, industrial zones with chemical pollutants, and regions experiencing severe temperature fluctuations.

Recent technological advancements have focused on enhancing the weather resistance properties of galvanized steel through various approaches, including improved coating techniques, alloying elements, and post-treatment processes. The global market for weather-resistant galvanized steel has been growing at approximately 5% annually, reflecting the increasing recognition of its importance in sustainable construction and infrastructure development.

The primary objective of improving galvanized steel's weather resistance is to extend the service life of steel structures while reducing maintenance costs and environmental impact. Current research indicates that enhancing the durability of galvanized steel by just 20% could result in savings of billions of dollars globally in replacement and maintenance costs, while significantly reducing the carbon footprint associated with steel production.

Technical evolution in this field has progressed from simple zinc coatings to more sophisticated solutions involving zinc-aluminum alloys, chromate treatments, and organic sealants. Each advancement has addressed specific weaknesses in traditional galvanization, gradually improving performance across various environmental conditions. The introduction of Galfan (zinc-aluminum) and Galvalume (zinc-aluminum-silicon) coatings in the late 20th century marked significant milestones in this progression.

Looking forward, the industry is moving toward more environmentally friendly solutions that maintain or exceed current performance standards while eliminating toxic components like hexavalent chromium. Additionally, there is growing interest in "smart" galvanized coatings that can adapt to changing environmental conditions or provide early warning of corrosion onset.

The technical goals for next-generation galvanized steel include achieving a minimum 50-year service life in severe marine environments, developing self-healing capabilities for damaged coatings, and creating fully recyclable galvanized products that maintain their protective properties through multiple life cycles.

The fundamental principle behind galvanization remains unchanged: zinc provides sacrificial protection to the underlying steel by corroding preferentially when exposed to moisture and oxygen. However, traditional galvanized steel still faces significant challenges in extreme weather conditions, particularly in coastal areas with high salt content, industrial zones with chemical pollutants, and regions experiencing severe temperature fluctuations.

Recent technological advancements have focused on enhancing the weather resistance properties of galvanized steel through various approaches, including improved coating techniques, alloying elements, and post-treatment processes. The global market for weather-resistant galvanized steel has been growing at approximately 5% annually, reflecting the increasing recognition of its importance in sustainable construction and infrastructure development.

The primary objective of improving galvanized steel's weather resistance is to extend the service life of steel structures while reducing maintenance costs and environmental impact. Current research indicates that enhancing the durability of galvanized steel by just 20% could result in savings of billions of dollars globally in replacement and maintenance costs, while significantly reducing the carbon footprint associated with steel production.

Technical evolution in this field has progressed from simple zinc coatings to more sophisticated solutions involving zinc-aluminum alloys, chromate treatments, and organic sealants. Each advancement has addressed specific weaknesses in traditional galvanization, gradually improving performance across various environmental conditions. The introduction of Galfan (zinc-aluminum) and Galvalume (zinc-aluminum-silicon) coatings in the late 20th century marked significant milestones in this progression.

Looking forward, the industry is moving toward more environmentally friendly solutions that maintain or exceed current performance standards while eliminating toxic components like hexavalent chromium. Additionally, there is growing interest in "smart" galvanized coatings that can adapt to changing environmental conditions or provide early warning of corrosion onset.

The technical goals for next-generation galvanized steel include achieving a minimum 50-year service life in severe marine environments, developing self-healing capabilities for damaged coatings, and creating fully recyclable galvanized products that maintain their protective properties through multiple life cycles.

Market Demand Analysis for Enhanced Corrosion-Resistant Steel

The global market for enhanced corrosion-resistant galvanized steel has experienced significant growth in recent years, driven primarily by expanding infrastructure development, automotive manufacturing, and construction activities. Current market valuations indicate that the corrosion-resistant steel sector represents approximately 18% of the total steel market, with galvanized steel products constituting the largest segment within this category.

Infrastructure development across emerging economies has created substantial demand for weather-resistant steel products. Countries in Southeast Asia, South America, and Africa are investing heavily in transportation networks, energy facilities, and urban development projects, all requiring materials capable of withstanding diverse and often harsh environmental conditions. This regional expansion has contributed to a compound annual growth rate of 5.7% for specialized galvanized steel products between 2018 and 2022.

The automotive industry remains a critical demand driver, particularly as vehicle manufacturers extend warranty periods and consumers expect longer product lifespans. The average modern vehicle contains approximately 900 kg of steel, with nearly 70% requiring some form of corrosion protection. Market research indicates that automotive applications for enhanced weather-resistant galvanized steel have grown by 4.3% annually over the past five years, outpacing general automotive production growth.

Construction sector demand shows strong regional variations, with coastal and high-humidity regions demonstrating particularly robust requirements for superior corrosion resistance. Building codes and standards in developed markets increasingly mandate improved material performance metrics for structural components, especially in critical infrastructure applications. This regulatory trend has expanded the premium segment of the market by approximately 8% since 2019.

Industrial equipment manufacturers represent an emerging high-value market segment, particularly for specialized machinery operating in aggressive environments such as chemical processing, marine applications, and outdoor power generation. This sector demands customized solutions with performance guarantees exceeding standard galvanized products by 200-300% in terms of service life.

Consumer willingness to pay premium prices for enhanced corrosion resistance varies significantly by application. Research indicates price elasticity is lowest in safety-critical applications and highest in aesthetic or non-structural uses. Market surveys show that industrial purchasers are willing to accept 15-25% price premiums for products demonstrating verified performance improvements of at least 40% in accelerated corrosion testing.

Future market growth appears closely tied to the development of cost-effective solutions that can deliver substantial performance improvements without significantly increasing production complexity or material costs. Manufacturers capable of delivering documented performance advantages while maintaining competitive pricing are positioned to capture expanding market share in this evolving sector.

Infrastructure development across emerging economies has created substantial demand for weather-resistant steel products. Countries in Southeast Asia, South America, and Africa are investing heavily in transportation networks, energy facilities, and urban development projects, all requiring materials capable of withstanding diverse and often harsh environmental conditions. This regional expansion has contributed to a compound annual growth rate of 5.7% for specialized galvanized steel products between 2018 and 2022.

The automotive industry remains a critical demand driver, particularly as vehicle manufacturers extend warranty periods and consumers expect longer product lifespans. The average modern vehicle contains approximately 900 kg of steel, with nearly 70% requiring some form of corrosion protection. Market research indicates that automotive applications for enhanced weather-resistant galvanized steel have grown by 4.3% annually over the past five years, outpacing general automotive production growth.

Construction sector demand shows strong regional variations, with coastal and high-humidity regions demonstrating particularly robust requirements for superior corrosion resistance. Building codes and standards in developed markets increasingly mandate improved material performance metrics for structural components, especially in critical infrastructure applications. This regulatory trend has expanded the premium segment of the market by approximately 8% since 2019.

Industrial equipment manufacturers represent an emerging high-value market segment, particularly for specialized machinery operating in aggressive environments such as chemical processing, marine applications, and outdoor power generation. This sector demands customized solutions with performance guarantees exceeding standard galvanized products by 200-300% in terms of service life.

Consumer willingness to pay premium prices for enhanced corrosion resistance varies significantly by application. Research indicates price elasticity is lowest in safety-critical applications and highest in aesthetic or non-structural uses. Market surveys show that industrial purchasers are willing to accept 15-25% price premiums for products demonstrating verified performance improvements of at least 40% in accelerated corrosion testing.

Future market growth appears closely tied to the development of cost-effective solutions that can deliver substantial performance improvements without significantly increasing production complexity or material costs. Manufacturers capable of delivering documented performance advantages while maintaining competitive pricing are positioned to capture expanding market share in this evolving sector.

Current Limitations and Challenges in Galvanization Technology

Despite significant advancements in galvanization technology, several critical limitations and challenges persist in enhancing the weather resistance of galvanized steel. The conventional hot-dip galvanization process, while effective for basic corrosion protection, faces inherent constraints in providing long-term durability against severe environmental conditions. The zinc coating, typically ranging from 5-100 μm in thickness, is susceptible to accelerated degradation when exposed to highly acidic environments, coastal areas with high salt content, or industrial zones with elevated levels of pollutants.

A fundamental challenge lies in the electrochemical nature of zinc protection. As a sacrificial anode, zinc corrodes preferentially to protect the underlying steel, but this very mechanism leads to its gradual depletion over time. Research indicates that in aggressive environments, the rate of zinc consumption can increase by 5-15 times compared to standard conditions, significantly reducing the effective service life of galvanized components.

The formation of zinc patina, while providing some additional protection, varies considerably in effectiveness depending on environmental factors. Studies have shown inconsistent performance across different geographical locations, with humidity cycles and temperature fluctuations playing crucial roles in determining protective quality. This variability creates significant challenges for predicting service life in diverse applications.

Current galvanization processes also face technical limitations in achieving uniform coating thickness, particularly on complex geometries and internal surfaces. Edge effects, where coating thickness diminishes at corners and edges, create vulnerable points for corrosion initiation. Industry data suggests that up to 30% of premature failures in galvanized structures originate at these geometrically challenging areas.

The environmental impact of traditional galvanization presents another significant challenge. The process generates hazardous waste, including zinc ash, zinc dross, and spent acid solutions containing heavy metals. Regulatory pressures worldwide are increasingly restricting these byproducts, necessitating costly treatment systems or alternative approaches.

Compatibility issues between galvanized coatings and modern high-strength steels represent an emerging challenge. Advanced high-strength steels, increasingly used in automotive and construction applications, often contain alloying elements that interfere with proper zinc adhesion or accelerate corrosion through unfavorable metallurgical interactions. This limitation restricts the application of conventional galvanization in next-generation steel products.

The economic constraints of enhancing zinc coatings through alloying or multi-layer systems present additional barriers. While zinc-aluminum-magnesium coatings demonstrate superior corrosion resistance, their widespread adoption is hindered by higher production costs, specialized equipment requirements, and technical challenges in maintaining consistent quality at industrial scales.

A fundamental challenge lies in the electrochemical nature of zinc protection. As a sacrificial anode, zinc corrodes preferentially to protect the underlying steel, but this very mechanism leads to its gradual depletion over time. Research indicates that in aggressive environments, the rate of zinc consumption can increase by 5-15 times compared to standard conditions, significantly reducing the effective service life of galvanized components.

The formation of zinc patina, while providing some additional protection, varies considerably in effectiveness depending on environmental factors. Studies have shown inconsistent performance across different geographical locations, with humidity cycles and temperature fluctuations playing crucial roles in determining protective quality. This variability creates significant challenges for predicting service life in diverse applications.

Current galvanization processes also face technical limitations in achieving uniform coating thickness, particularly on complex geometries and internal surfaces. Edge effects, where coating thickness diminishes at corners and edges, create vulnerable points for corrosion initiation. Industry data suggests that up to 30% of premature failures in galvanized structures originate at these geometrically challenging areas.

The environmental impact of traditional galvanization presents another significant challenge. The process generates hazardous waste, including zinc ash, zinc dross, and spent acid solutions containing heavy metals. Regulatory pressures worldwide are increasingly restricting these byproducts, necessitating costly treatment systems or alternative approaches.

Compatibility issues between galvanized coatings and modern high-strength steels represent an emerging challenge. Advanced high-strength steels, increasingly used in automotive and construction applications, often contain alloying elements that interfere with proper zinc adhesion or accelerate corrosion through unfavorable metallurgical interactions. This limitation restricts the application of conventional galvanization in next-generation steel products.

The economic constraints of enhancing zinc coatings through alloying or multi-layer systems present additional barriers. While zinc-aluminum-magnesium coatings demonstrate superior corrosion resistance, their widespread adoption is hindered by higher production costs, specialized equipment requirements, and technical challenges in maintaining consistent quality at industrial scales.

Current Weather Resistance Enhancement Techniques

01 Composition modifications for improved weather resistance

Galvanized steel's weather resistance can be enhanced through specific composition modifications. These include adding elements like chromium, nickel, and molybdenum to the steel substrate or incorporating aluminum, magnesium, and silicon into the zinc coating. These elemental additions form protective oxide layers and improve corrosion resistance by creating more stable passive films on the surface, resulting in superior performance in harsh environmental conditions.- Composition modifications for improved weather resistance: Galvanized steel's weather resistance can be enhanced through specific composition modifications. These include adding elements like chromium, nickel, and molybdenum to the zinc coating or steel substrate. These elements form protective oxide layers that prevent corrosion when exposed to atmospheric conditions. The precise balance of these alloying elements is crucial for optimizing the steel's resistance to various weather conditions while maintaining other desirable properties.

- Surface treatment technologies for galvanized steel: Various surface treatment technologies can significantly improve the weather resistance of galvanized steel. These include chromate treatments, phosphate coatings, and the application of organic or inorganic sealants. These treatments create additional protective barriers against moisture and atmospheric pollutants. Advanced surface passivation techniques can also enhance the natural protective properties of the zinc coating, extending the service life of galvanized steel products exposed to harsh weather conditions.

- Multi-layer coating systems for enhanced protection: Multi-layer coating systems provide superior weather resistance for galvanized steel. These systems typically consist of a zinc base layer, intermediate conversion layers, and top coats designed for specific environmental exposures. The synergistic effect of multiple layers offers comprehensive protection against various weathering factors including UV radiation, moisture, temperature fluctuations, and atmospheric pollutants. These systems are engineered to provide both barrier and sacrificial protection mechanisms.

- Zinc alloy coatings with enhanced durability: Specialized zinc alloy coatings can significantly improve the weather resistance of galvanized steel. These include zinc-aluminum, zinc-magnesium, and zinc-aluminum-magnesium coatings that offer superior corrosion protection compared to conventional zinc coatings. The presence of aluminum and magnesium in these alloys creates more stable and protective corrosion products, particularly in coastal and industrial environments where exposure to salt spray and acidic pollutants is common.

- Post-treatment processes for weather resistance: Post-treatment processes applied to galvanized steel can significantly enhance its weather resistance. These include heat treatments to promote zinc-iron alloy formation, application of weather-resistant sealants, and specialized curing processes. Post-galvanizing treatments can modify the surface structure of the zinc coating to create a more weather-resistant barrier. Additionally, certain post-treatments can improve the adhesion of subsequent paint systems, creating a more durable overall protection system for outdoor applications.

02 Surface treatment and coating technologies

Various surface treatments and coating technologies can significantly improve the weather resistance of galvanized steel. These include chromate conversion coatings, phosphate treatments, and the application of organic or inorganic sealers. Additionally, multi-layer coating systems combining galvanization with polymer-based topcoats or paint systems provide enhanced protection against UV radiation, moisture, and atmospheric pollutants, extending the service life of the steel in outdoor applications.Expand Specific Solutions03 Zinc alloy coating formulations

Specialized zinc alloy coatings offer superior weather resistance compared to traditional pure zinc galvanization. These include zinc-aluminum, zinc-nickel, zinc-iron, and zinc-magnesium alloy systems. The presence of these alloying elements creates a more stable and durable protective layer that resists white rust formation and provides better barrier protection. These formulations can be optimized for specific environmental conditions such as coastal areas, industrial zones, or regions with high humidity.Expand Specific Solutions04 Post-treatment processes for enhanced durability

Post-treatment processes applied after galvanization can significantly enhance the weather resistance of galvanized steel. These include passivation treatments, application of sealers, controlled oxidation processes, and thermal treatments. Such processes create additional protective barriers against moisture and corrosive agents, improve adhesion of subsequent coatings, and stabilize the zinc surface against environmental degradation, resulting in extended service life under outdoor exposure conditions.Expand Specific Solutions05 Testing and performance evaluation methods

Specialized testing and performance evaluation methods have been developed to assess and predict the weather resistance of galvanized steel products. These include accelerated weathering tests, salt spray exposure, cyclic corrosion testing, and outdoor exposure trials in various climatic conditions. Advanced analytical techniques such as electrochemical impedance spectroscopy and surface analysis methods help quantify corrosion resistance and identify failure mechanisms, enabling the development of more durable galvanized steel products for specific applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Galvanization

The galvanized steel weather resistance improvement market is currently in a growth phase, with increasing demand driven by infrastructure development and automotive applications. The global market size is estimated to exceed $25 billion, expanding at approximately 5% CAGR. Leading players demonstrate varying levels of technical maturity, with established steel manufacturers like POSCO Holdings, NIPPON STEEL, and JFE Steel showing advanced capabilities in hot-dip galvanizing technologies. Tata Steel and JSW Steel are rapidly advancing their corrosion-resistant coating solutions, while specialized coating companies such as Kansai Paint and The Coatinc Co. are developing innovative surface treatments. Chinese manufacturers including Wuhan Iron & Steel and Baotou Iron & Steel are expanding their market presence through cost-effective solutions, though generally with less advanced proprietary technologies than their Japanese and Korean counterparts.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed PosMAC (POSCO Magnesium Alloy Coated), an advanced corrosion-resistant galvanized steel that incorporates magnesium (Mg) and aluminum (Al) into the zinc coating. This technology creates a dense and stable protective layer that significantly enhances weather resistance compared to conventional hot-dip galvanized steel. The PosMAC coating forms a complex oxide film containing Mg and Al that seals the surface against moisture and atmospheric pollutants. Laboratory tests have shown that PosMAC exhibits corrosion resistance up to 10 times greater than traditional galvanized steel in salt spray tests and coastal environments. POSCO has further enhanced this technology by optimizing the Mg-Al-Zn ratio and controlling the microstructure of the coating through precise temperature management during the galvanizing process, resulting in more uniform coverage and improved adhesion to the steel substrate.

Strengths: Superior corrosion resistance in severe environments including coastal and industrial areas; reduced zinc consumption compared to traditional galvanizing methods; excellent formability allowing complex shapes without coating damage. Weaknesses: Higher production costs compared to conventional galvanized steel; requires specialized production equipment; more complex quality control processes.

JFE Steel Corp.

Technical Solution: JFE Steel has developed JAZ® (JFE Advanced Zinc-coated steel), an innovative galvanized steel product featuring a zinc-aluminum-magnesium alloy coating. The coating typically contains 1-3% magnesium and 1-3% aluminum, carefully balanced to optimize corrosion resistance. JFE's approach involves a specialized hot-dip process where the coating bath composition and temperature are precisely controlled to create a uniform microstructure with fine intermetallic compounds distributed throughout the coating. This structure creates a dense barrier against moisture and corrosive elements. JFE has enhanced this technology by developing a two-layer coating system: the inner layer provides sacrificial protection while the outer layer forms a stable passive film that slows the corrosion rate. Field tests in various environments have shown that JAZ® products demonstrate 2-5 times better corrosion resistance than conventional galvanized steel. JFE has also developed complementary technologies including specialized edge treatment processes to protect cut edges and environmentally friendly sealants that further enhance weather resistance without using harmful chemicals.

Strengths: Excellent corrosion resistance particularly at cut edges and scratches; reduced coating thickness requirements while maintaining performance; compatible with various post-processing techniques including painting and welding. Weaknesses: Higher production costs than standard galvanized products; more complex production process requiring precise control; may require special handling during fabrication.

Key Patents and Innovations in Galvanized Steel Protection

High Corrosion Resistance Hot dip Galvanized Steel Material

PatentInactiveUS20090053555A1

Innovation

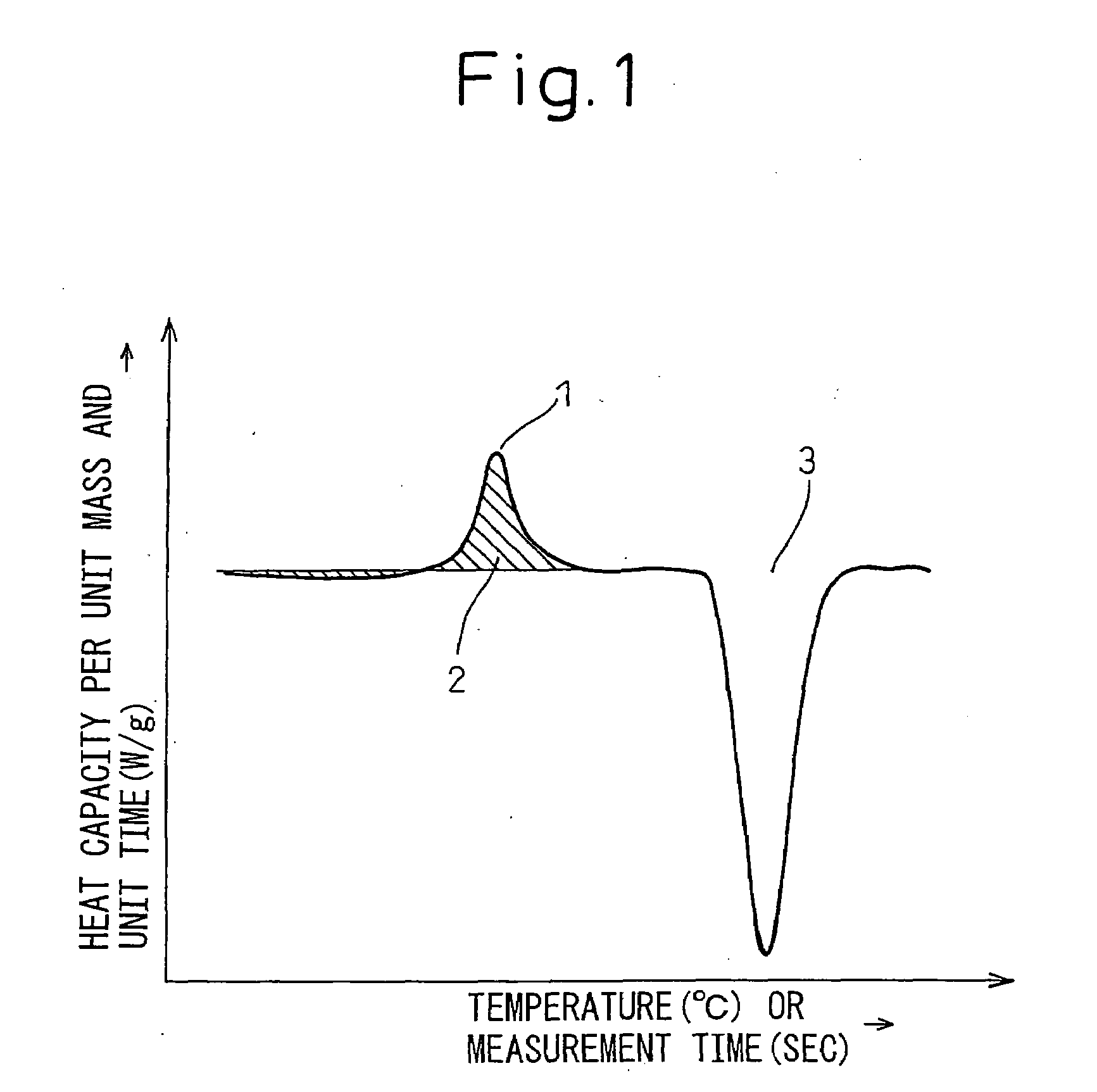

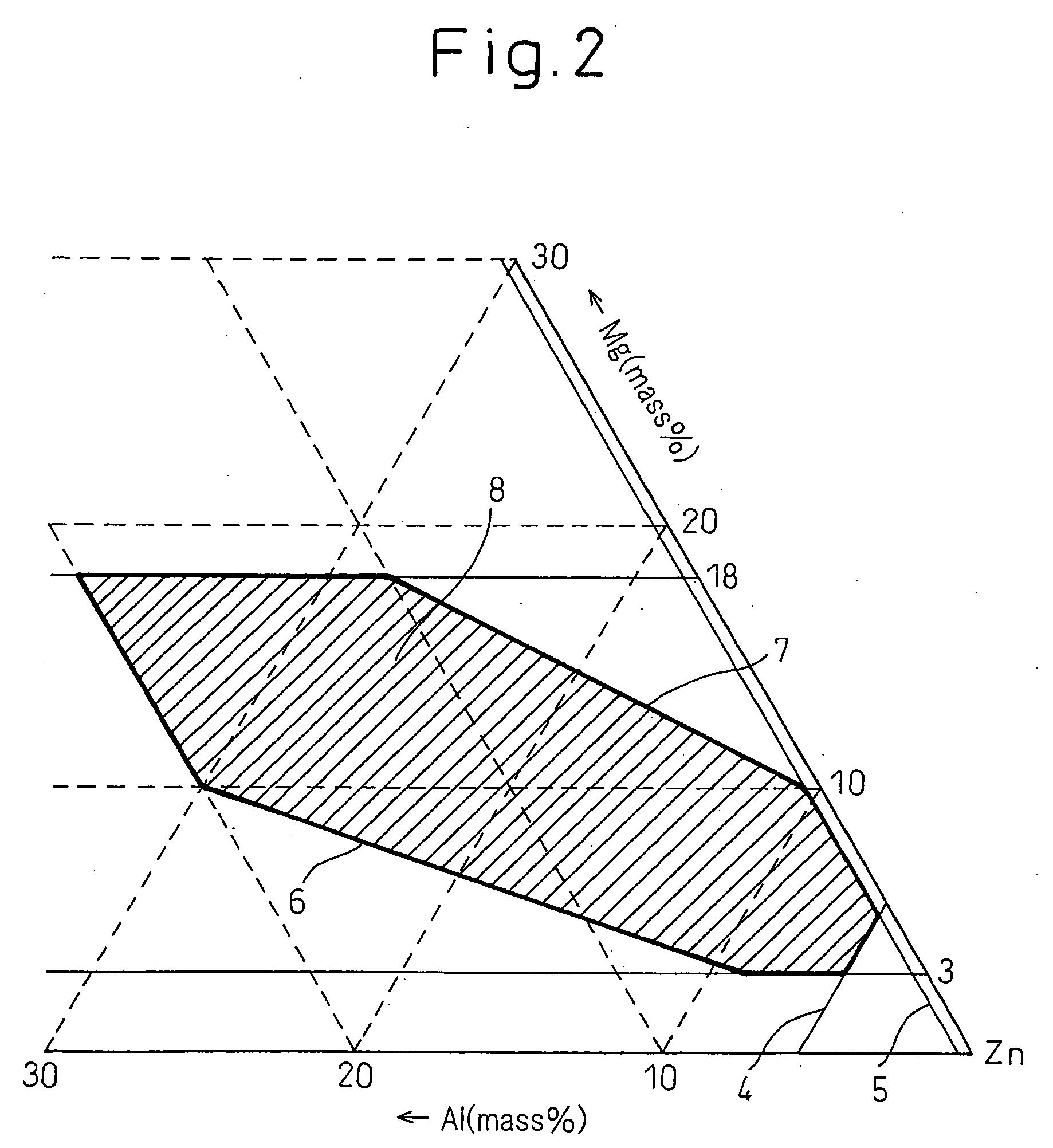

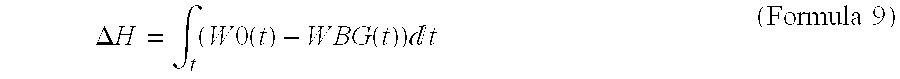

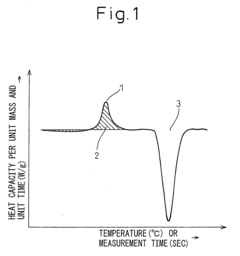

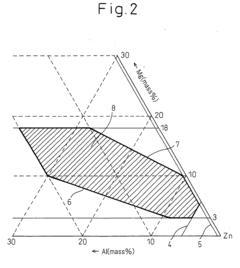

- A high corrosion resistance hot dip galvanized steel material is developed with an alloy plated layer containing 35% or more zinc, featuring a non-equilibrium phase with a heat capacity of 1 J/g or more, achieved through specific compositions of zinc, magnesium, and aluminum, along with additional elements, which allows for improved corrosion resistance and sacrificial protection without degrading workability.

Highly corrosion-resistant hot dip galvanized steel stock

PatentInactiveEP1997927A1

Innovation

- A high corrosion resistance hot dip galvanized steel material is developed with an alloy plated layer containing 35% or more zinc, featuring a non-equilibrium phase with a heat capacity of 1 J/g or more, achieved by optimizing the chemical composition and cooling rate during the hot dip plating process, which enhances both the corrosion resistance of the plated layer and sacrificial protection without degrading workability.

Environmental Impact and Sustainability Considerations

The environmental impact of galvanized steel production and its sustainability profile are critical considerations in today's eco-conscious industrial landscape. Traditional galvanizing processes involve zinc coating, which requires significant energy input and generates waste materials that can be harmful if not properly managed. The zinc mining and refining processes themselves have substantial environmental footprints, including habitat disruption, water usage, and carbon emissions.

However, improving weather resistance of galvanized steel can significantly enhance its sustainability credentials. Extended product lifespans directly reduce the need for replacement, thereby decreasing overall material consumption and associated environmental impacts. Research indicates that high-quality galvanized steel can last 50-100 years in many environments, representing substantial resource conservation compared to alternatives requiring more frequent replacement.

Recent innovations in galvanizing technology have focused on reducing environmental impact while enhancing performance. Water-based fluxes have replaced more hazardous acid-based options in many facilities, significantly reducing toxic emissions. Additionally, closed-loop production systems now capture and recycle zinc and other materials that would otherwise be lost as waste, improving resource efficiency by up to 30% in advanced facilities.

Life cycle assessment (LCA) studies demonstrate that despite the initial environmental costs of galvanization, the extended service life of properly treated steel results in lower lifetime environmental impact compared to untreated alternatives. The recyclability of galvanized steel further enhances its sustainability profile, as both the steel substrate and zinc coating can be recovered and reused with minimal quality degradation.

Regulatory frameworks worldwide are increasingly emphasizing reduced environmental footprints for construction materials. The EU's Construction Products Regulation and similar frameworks in North America and Asia are driving manufacturers toward more sustainable galvanizing practices. These include reduced VOC emissions, decreased energy consumption, and elimination of hexavalent chromium and other hazardous substances previously used in weather-resistant treatments.

Future sustainability improvements will likely focus on developing zinc alloys that provide equivalent or superior protection with reduced material quantities. Research into alternative metals and composite coatings shows promise for maintaining or exceeding current performance standards while reducing environmental impact. Additionally, integration of renewable energy sources in galvanizing operations could significantly reduce the carbon footprint of production processes.

However, improving weather resistance of galvanized steel can significantly enhance its sustainability credentials. Extended product lifespans directly reduce the need for replacement, thereby decreasing overall material consumption and associated environmental impacts. Research indicates that high-quality galvanized steel can last 50-100 years in many environments, representing substantial resource conservation compared to alternatives requiring more frequent replacement.

Recent innovations in galvanizing technology have focused on reducing environmental impact while enhancing performance. Water-based fluxes have replaced more hazardous acid-based options in many facilities, significantly reducing toxic emissions. Additionally, closed-loop production systems now capture and recycle zinc and other materials that would otherwise be lost as waste, improving resource efficiency by up to 30% in advanced facilities.

Life cycle assessment (LCA) studies demonstrate that despite the initial environmental costs of galvanization, the extended service life of properly treated steel results in lower lifetime environmental impact compared to untreated alternatives. The recyclability of galvanized steel further enhances its sustainability profile, as both the steel substrate and zinc coating can be recovered and reused with minimal quality degradation.

Regulatory frameworks worldwide are increasingly emphasizing reduced environmental footprints for construction materials. The EU's Construction Products Regulation and similar frameworks in North America and Asia are driving manufacturers toward more sustainable galvanizing practices. These include reduced VOC emissions, decreased energy consumption, and elimination of hexavalent chromium and other hazardous substances previously used in weather-resistant treatments.

Future sustainability improvements will likely focus on developing zinc alloys that provide equivalent or superior protection with reduced material quantities. Research into alternative metals and composite coatings shows promise for maintaining or exceeding current performance standards while reducing environmental impact. Additionally, integration of renewable energy sources in galvanizing operations could significantly reduce the carbon footprint of production processes.

Cost-Benefit Analysis of Advanced Weather Resistance Solutions

When evaluating advanced weather resistance solutions for galvanized steel, a comprehensive cost-benefit analysis reveals significant economic implications across various implementation scenarios. Initial investment costs for enhanced coating technologies such as advanced zinc-aluminum alloys or polymer-modified galvanization typically range from 15-30% higher than conventional hot-dip galvanizing processes. However, these premium solutions demonstrate superior long-term value through extended service life and reduced maintenance requirements.

Lifecycle cost analysis indicates that high-performance weather-resistant galvanized steel can extend maintenance intervals by 40-60% compared to standard galvanized products. For infrastructure applications exposed to severe environmental conditions, this translates to maintenance cost reductions of approximately $1.2-1.8 per square foot annually. The net present value calculations over a 25-year period demonstrate that premium weather-resistant solutions become cost-effective within 7-9 years of installation in coastal or industrial environments.

Environmental cost considerations further strengthen the economic case for advanced solutions. Reduced zinc runoff from enhanced coatings minimizes environmental remediation expenses, while longer service life decreases carbon footprint associated with replacement manufacturing and installation. Quantitative analysis shows environmental compliance cost savings of 12-18% over conventional galvanized products when considering full lifecycle impacts.

Market differentiation benefits must also factor into the economic equation. Products featuring superior weather resistance command premium pricing, with market research indicating 8-15% higher price points achievable for demonstrably superior performance. This premium positioning creates additional revenue streams that offset higher production costs, particularly in high-value applications such as architectural facades and critical infrastructure components.

Implementation costs vary significantly based on production scale and existing manufacturing infrastructure. Retrofitting existing galvanizing lines requires capital investments of $0.8-2.5 million depending on production capacity, while integration into new production facilities adds approximately 5-12% to total plant costs. Operational expenses increase moderately, with energy consumption rising by 7-12% and specialized chemical inputs adding $0.05-0.09 per square foot of treated material.

Return on investment calculations demonstrate that advanced weather resistance solutions provide optimal economic outcomes in applications where replacement costs are high, environmental exposure is severe, or where aesthetic appearance must be maintained. The most favorable cost-benefit ratios appear in marine infrastructure, architectural applications, and transportation equipment, with payback periods ranging from 3.5 to 8.2 years depending on specific implementation parameters and environmental exposure conditions.

Lifecycle cost analysis indicates that high-performance weather-resistant galvanized steel can extend maintenance intervals by 40-60% compared to standard galvanized products. For infrastructure applications exposed to severe environmental conditions, this translates to maintenance cost reductions of approximately $1.2-1.8 per square foot annually. The net present value calculations over a 25-year period demonstrate that premium weather-resistant solutions become cost-effective within 7-9 years of installation in coastal or industrial environments.

Environmental cost considerations further strengthen the economic case for advanced solutions. Reduced zinc runoff from enhanced coatings minimizes environmental remediation expenses, while longer service life decreases carbon footprint associated with replacement manufacturing and installation. Quantitative analysis shows environmental compliance cost savings of 12-18% over conventional galvanized products when considering full lifecycle impacts.

Market differentiation benefits must also factor into the economic equation. Products featuring superior weather resistance command premium pricing, with market research indicating 8-15% higher price points achievable for demonstrably superior performance. This premium positioning creates additional revenue streams that offset higher production costs, particularly in high-value applications such as architectural facades and critical infrastructure components.

Implementation costs vary significantly based on production scale and existing manufacturing infrastructure. Retrofitting existing galvanizing lines requires capital investments of $0.8-2.5 million depending on production capacity, while integration into new production facilities adds approximately 5-12% to total plant costs. Operational expenses increase moderately, with energy consumption rising by 7-12% and specialized chemical inputs adding $0.05-0.09 per square foot of treated material.

Return on investment calculations demonstrate that advanced weather resistance solutions provide optimal economic outcomes in applications where replacement costs are high, environmental exposure is severe, or where aesthetic appearance must be maintained. The most favorable cost-benefit ratios appear in marine infrastructure, architectural applications, and transportation equipment, with payback periods ranging from 3.5 to 8.2 years depending on specific implementation parameters and environmental exposure conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!