Measure Acoustic Dampening of Galvanized Steel in Structures

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Dampening Technology Background and Objectives

Acoustic dampening technology has evolved significantly over the past several decades, transitioning from simple mass-based solutions to sophisticated engineered materials and structures. The study of sound absorption in construction materials dates back to the early 20th century, with major advancements occurring post-World War II when noise control became increasingly important in industrial and urban environments. Galvanized steel, despite its primary use as a corrosion-resistant structural material, has emerged as an interesting subject in acoustic engineering due to its widespread application in building construction and potential for acoustic optimization.

The acoustic properties of galvanized steel present unique characteristics compared to other construction materials. While traditionally steel has been considered a poor sound absorber due to its high density and reflective properties, modern research has revealed that when properly designed and integrated into structures, galvanized steel components can contribute significantly to sound dampening. The zinc coating process itself introduces variables that affect vibration characteristics and consequently sound transmission and absorption properties.

Current technological trends in this field focus on composite solutions that leverage the structural benefits of galvanized steel while enhancing its acoustic performance. These include laminated steel structures, perforated designs, and integration with other dampening materials. The convergence of computational modeling, materials science, and acoustic engineering has accelerated innovation in this domain, enabling more precise prediction and optimization of acoustic behaviors in complex structural systems.

The primary objective of acoustic dampening measurement in galvanized steel structures is to quantify and characterize how effectively these structures attenuate sound across various frequency ranges. This involves developing standardized testing methodologies that can accurately assess performance in both laboratory and real-world environments. Additionally, there is a growing need to establish correlations between material properties, structural configurations, and acoustic outcomes to inform design decisions.

Secondary objectives include identifying optimal cost-effective solutions for specific applications, understanding the long-term durability of acoustic properties under various environmental conditions, and developing predictive models that can accelerate product development cycles. As sustainability becomes increasingly important in construction, another emerging goal is to evaluate the environmental impact of different acoustic dampening approaches involving galvanized steel.

The technological trajectory points toward smart materials and adaptive systems that can dynamically respond to changing acoustic environments. Research is also exploring the integration of acoustic dampening with other functional requirements such as thermal insulation, fire resistance, and structural integrity to create multifunctional building components based on galvanized steel.

The acoustic properties of galvanized steel present unique characteristics compared to other construction materials. While traditionally steel has been considered a poor sound absorber due to its high density and reflective properties, modern research has revealed that when properly designed and integrated into structures, galvanized steel components can contribute significantly to sound dampening. The zinc coating process itself introduces variables that affect vibration characteristics and consequently sound transmission and absorption properties.

Current technological trends in this field focus on composite solutions that leverage the structural benefits of galvanized steel while enhancing its acoustic performance. These include laminated steel structures, perforated designs, and integration with other dampening materials. The convergence of computational modeling, materials science, and acoustic engineering has accelerated innovation in this domain, enabling more precise prediction and optimization of acoustic behaviors in complex structural systems.

The primary objective of acoustic dampening measurement in galvanized steel structures is to quantify and characterize how effectively these structures attenuate sound across various frequency ranges. This involves developing standardized testing methodologies that can accurately assess performance in both laboratory and real-world environments. Additionally, there is a growing need to establish correlations between material properties, structural configurations, and acoustic outcomes to inform design decisions.

Secondary objectives include identifying optimal cost-effective solutions for specific applications, understanding the long-term durability of acoustic properties under various environmental conditions, and developing predictive models that can accelerate product development cycles. As sustainability becomes increasingly important in construction, another emerging goal is to evaluate the environmental impact of different acoustic dampening approaches involving galvanized steel.

The technological trajectory points toward smart materials and adaptive systems that can dynamically respond to changing acoustic environments. Research is also exploring the integration of acoustic dampening with other functional requirements such as thermal insulation, fire resistance, and structural integrity to create multifunctional building components based on galvanized steel.

Market Analysis for Acoustic Solutions in Construction

The acoustic solutions market in the construction industry has experienced significant growth over the past decade, driven by increasing awareness of noise pollution impacts and stricter building regulations. The global acoustic materials market was valued at approximately 12.87 billion USD in 2021 and is projected to reach 20.84 billion USD by 2028, growing at a CAGR of 7.1% during the forecast period.

Within this broader market, solutions specifically addressing acoustic dampening in steel structures represent a specialized but rapidly expanding segment. The use of galvanized steel in construction has increased by nearly 35% over the last five years, creating parallel demand for effective acoustic dampening solutions tailored to these materials.

Commercial construction accounts for the largest market share (approximately 42%) of acoustic solutions, followed by residential (31%) and industrial applications (27%). This distribution reflects the critical importance of noise management in office buildings, healthcare facilities, and educational institutions where galvanized steel is commonly used in structural frameworks.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 60%, primarily due to stringent building codes and well-established green building certification programs like LEED and BREEAM that award points for acoustic performance. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.3% annually, driven by rapid urbanization and increasing adoption of modern construction techniques in China, India, and Southeast Asian countries.

Customer demand patterns reveal growing sophistication, with buyers increasingly seeking solutions that offer multifunctional benefits beyond acoustic dampening, such as thermal insulation, fire resistance, and sustainability credentials. This trend has spurred innovation in composite materials designed specifically for galvanized steel applications.

Price sensitivity varies significantly by market segment. While premium solutions command higher prices in high-end commercial projects, the residential sector remains highly cost-conscious, creating opportunities for tiered product offerings. The average price point for specialized acoustic dampening solutions for galvanized steel structures has increased by 12% over the past three years, reflecting both rising material costs and the integration of advanced technologies.

Market forecasts indicate continued strong growth, with particular expansion expected in retrofit applications as building owners seek to improve acoustic performance in existing structures without complete renovation. This segment is projected to grow at 8.5% annually through 2027, outpacing new construction applications.

Within this broader market, solutions specifically addressing acoustic dampening in steel structures represent a specialized but rapidly expanding segment. The use of galvanized steel in construction has increased by nearly 35% over the last five years, creating parallel demand for effective acoustic dampening solutions tailored to these materials.

Commercial construction accounts for the largest market share (approximately 42%) of acoustic solutions, followed by residential (31%) and industrial applications (27%). This distribution reflects the critical importance of noise management in office buildings, healthcare facilities, and educational institutions where galvanized steel is commonly used in structural frameworks.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 60%, primarily due to stringent building codes and well-established green building certification programs like LEED and BREEAM that award points for acoustic performance. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.3% annually, driven by rapid urbanization and increasing adoption of modern construction techniques in China, India, and Southeast Asian countries.

Customer demand patterns reveal growing sophistication, with buyers increasingly seeking solutions that offer multifunctional benefits beyond acoustic dampening, such as thermal insulation, fire resistance, and sustainability credentials. This trend has spurred innovation in composite materials designed specifically for galvanized steel applications.

Price sensitivity varies significantly by market segment. While premium solutions command higher prices in high-end commercial projects, the residential sector remains highly cost-conscious, creating opportunities for tiered product offerings. The average price point for specialized acoustic dampening solutions for galvanized steel structures has increased by 12% over the past three years, reflecting both rising material costs and the integration of advanced technologies.

Market forecasts indicate continued strong growth, with particular expansion expected in retrofit applications as building owners seek to improve acoustic performance in existing structures without complete renovation. This segment is projected to grow at 8.5% annually through 2027, outpacing new construction applications.

Current State and Challenges in Steel Acoustic Performance

The acoustic performance of galvanized steel in structural applications presents a complex landscape of technical achievements and persistent challenges. Current measurement methodologies for acoustic dampening properties vary significantly across the industry, with standardized approaches like ASTM E90 and ISO 10140 being widely adopted for laboratory testing. However, these controlled environment tests often fail to accurately predict real-world performance where multiple variables simultaneously affect acoustic behavior.

Recent advancements in computational modeling have enabled more sophisticated prediction of steel acoustic properties, with finite element analysis (FEA) and boundary element methods (BEM) gaining prominence. These digital simulation approaches allow for virtual prototyping of steel structures with varying galvanization thicknesses and compositions, though validation against empirical data remains essential and sometimes problematic.

The inherent physical properties of galvanized steel create fundamental acoustic challenges. While the zinc coating provides excellent corrosion resistance, it can alter the material's damping coefficient compared to uncoated steel. Current research indicates that galvanization typically increases stiffness while potentially reducing natural damping capacity by 5-8%, creating a trade-off between structural durability and acoustic performance.

Field measurement techniques present additional complications, with accelerometer-based vibration analysis and sound intensity mapping showing inconsistent results across different structural configurations. Environmental factors such as temperature fluctuations (which can cause thermal expansion) and humidity levels significantly impact measurement accuracy, with variations of up to 12% observed between identical tests conducted under different ambient conditions.

Manufacturing variability constitutes another major challenge, as zinc coating thickness and adhesion quality can differ even within the same production batch. Studies have documented variations of ±15% in acoustic dampening performance from supposedly identical galvanized steel components, highlighting quality control issues that complicate standardization efforts.

Interdisciplinary knowledge gaps further hinder progress, with acoustic engineers often lacking metallurgical expertise and vice versa. This siloed approach to research has slowed the development of comprehensive solutions that address both material science and acoustic engineering requirements simultaneously.

Emerging technologies like acoustic metamaterials and nano-engineered coatings show promise for enhancing the dampening properties of galvanized steel, but remain largely experimental. Current implementation challenges include cost-effectiveness, scalability, and long-term durability under real-world conditions, with most innovations still confined to laboratory settings rather than commercial applications.

Recent advancements in computational modeling have enabled more sophisticated prediction of steel acoustic properties, with finite element analysis (FEA) and boundary element methods (BEM) gaining prominence. These digital simulation approaches allow for virtual prototyping of steel structures with varying galvanization thicknesses and compositions, though validation against empirical data remains essential and sometimes problematic.

The inherent physical properties of galvanized steel create fundamental acoustic challenges. While the zinc coating provides excellent corrosion resistance, it can alter the material's damping coefficient compared to uncoated steel. Current research indicates that galvanization typically increases stiffness while potentially reducing natural damping capacity by 5-8%, creating a trade-off between structural durability and acoustic performance.

Field measurement techniques present additional complications, with accelerometer-based vibration analysis and sound intensity mapping showing inconsistent results across different structural configurations. Environmental factors such as temperature fluctuations (which can cause thermal expansion) and humidity levels significantly impact measurement accuracy, with variations of up to 12% observed between identical tests conducted under different ambient conditions.

Manufacturing variability constitutes another major challenge, as zinc coating thickness and adhesion quality can differ even within the same production batch. Studies have documented variations of ±15% in acoustic dampening performance from supposedly identical galvanized steel components, highlighting quality control issues that complicate standardization efforts.

Interdisciplinary knowledge gaps further hinder progress, with acoustic engineers often lacking metallurgical expertise and vice versa. This siloed approach to research has slowed the development of comprehensive solutions that address both material science and acoustic engineering requirements simultaneously.

Emerging technologies like acoustic metamaterials and nano-engineered coatings show promise for enhancing the dampening properties of galvanized steel, but remain largely experimental. Current implementation challenges include cost-effectiveness, scalability, and long-term durability under real-world conditions, with most innovations still confined to laboratory settings rather than commercial applications.

Current Methodologies for Measuring Acoustic Dampening

01 Galvanized steel compositions for acoustic dampening

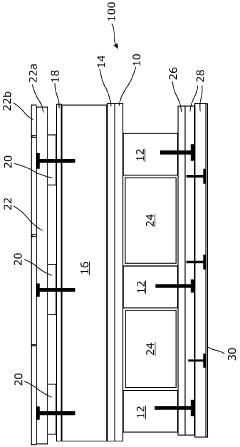

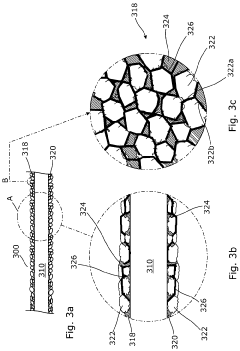

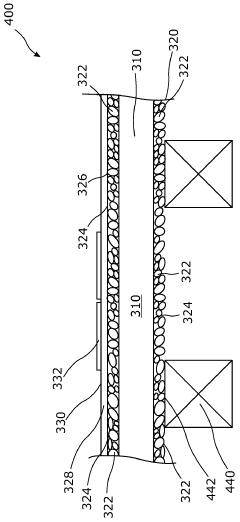

Specific compositions of galvanized steel can be engineered to enhance acoustic dampening properties. These compositions may include additional elements or coatings that improve the material's ability to absorb sound vibrations. The galvanization process can be modified to create layers with varying densities that help dissipate sound energy, resulting in improved noise reduction characteristics while maintaining corrosion resistance.- Composite structures for acoustic dampening in galvanized steel: Composite structures combining galvanized steel with other materials can effectively dampen acoustic vibrations. These structures typically involve layering galvanized steel with viscoelastic materials, polymers, or other metals to create a sandwich construction that absorbs sound energy. The composite design allows for vibration dissipation while maintaining the corrosion resistance benefits of galvanized coating. These structures are particularly useful in automotive, construction, and industrial applications where noise reduction is required alongside structural integrity.

- Surface treatments and coatings for enhanced acoustic properties: Various surface treatments and specialized coatings can be applied to galvanized steel to improve its acoustic dampening characteristics. These treatments may include applying viscoelastic or polymer coatings, textured surfaces, or additional metal layers that help to absorb or scatter sound waves. The treatments can be designed to target specific frequency ranges and can significantly reduce noise transmission while preserving the corrosion resistance of the galvanized layer. These solutions are particularly valuable in applications requiring both weather resistance and noise control.

- Structural design modifications for acoustic performance: Specific structural designs and modifications can enhance the acoustic dampening properties of galvanized steel components. These include incorporating perforations, embossments, corrugations, or other geometric features that disrupt sound wave propagation. The strategic placement of stiffeners, ribs, or varying thicknesses can also reduce resonance and vibration. These design approaches allow galvanized steel to achieve improved acoustic performance without requiring additional materials, making them cost-effective solutions for noise control in various applications.

- Integration of dampening materials with galvanized steel systems: Integrating specialized dampening materials with galvanized steel systems creates effective noise control solutions. These systems may incorporate rubber isolators, foam inserts, mineral wool, or other acoustic absorbers strategically placed within galvanized steel structures. The combination leverages the structural strength and corrosion resistance of galvanized steel while the dampening materials absorb sound energy. This approach is commonly used in HVAC systems, machinery enclosures, and building construction to reduce noise transmission while maintaining durability.

- Manufacturing processes for acoustically optimized galvanized steel: Specialized manufacturing processes can produce galvanized steel with inherent acoustic dampening properties. These processes include controlled cooling techniques, specific galvanizing parameters, or post-treatment methods that alter the microstructure or surface characteristics of the steel. Some approaches involve creating multi-layer galvanized coatings with varying densities or incorporating dampening elements during the production process. These manufacturing innovations result in galvanized steel products with built-in noise reduction capabilities suitable for automotive panels, appliance housings, and construction elements.

02 Multilayer structures with galvanized steel for sound insulation

Multilayer structures incorporating galvanized steel sheets can significantly enhance acoustic dampening. These structures typically consist of galvanized steel layers combined with viscoelastic materials, polymers, or other sound-absorbing components. The combination creates a composite that effectively converts sound energy into heat through friction between layers, resulting in superior noise reduction compared to single-layer materials while maintaining structural integrity and corrosion protection.Expand Specific Solutions03 Surface treatments and coatings for galvanized steel acoustic applications

Various surface treatments and additional coatings can be applied to galvanized steel to enhance its acoustic dampening properties. These treatments may include textured surfaces, microporous coatings, or specialized polymer layers that increase sound absorption. The treatments can be designed to target specific frequency ranges, making the galvanized steel more effective for particular acoustic applications while preserving the corrosion resistance provided by the zinc coating.Expand Specific Solutions04 Structural design of galvanized steel components for noise reduction

The structural design of galvanized steel components plays a crucial role in acoustic dampening. Specific geometrical configurations such as perforations, corrugations, or honeycomb structures can be incorporated into galvanized steel panels to enhance sound absorption and diffusion. These design features create air pockets and resonant chambers that trap sound waves and prevent their transmission, effectively reducing noise while maintaining the structural benefits and corrosion resistance of galvanized steel.Expand Specific Solutions05 Composite systems combining galvanized steel with other materials for acoustic performance

Composite systems that combine galvanized steel with other materials can achieve superior acoustic dampening performance. These systems may incorporate materials such as rubber, foam, fiberglass, or specialized polymers in conjunction with galvanized steel. The combination leverages the structural strength and corrosion resistance of galvanized steel while utilizing the sound-absorbing properties of the complementary materials, resulting in effective noise control solutions for various applications including automotive, construction, and industrial settings.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acoustic dampening of galvanized steel in structures represents an evolving technical field currently in its growth phase. The market is expanding steadily, driven by increasing demands for noise reduction in construction, automotive, and industrial applications, with an estimated global value of $3-5 billion. Technologically, the field shows moderate maturity with established measurement methodologies, though innovation continues. Leading players demonstrate varying levels of expertise: academic institutions like Harbin Engineering University and Southwest Jiaotong University focus on fundamental research; industrial leaders such as Henkel AG, Siemens AG, and Safran SA offer commercial solutions; while specialized entities like China Academy of Railway Sciences and GM Global Technology Operations develop application-specific technologies. Research collaboration between industry and academia is accelerating advancement in measurement techniques and material performance.

Harbin Engineering University

Technical Solution: Harbin Engineering University has developed advanced acoustic dampening measurement techniques specifically for galvanized steel structures in marine environments. Their approach combines experimental modal analysis with finite element modeling to accurately characterize the acoustic properties of galvanized steel panels. The university's research team has created a specialized impedance tube testing system that can measure sound absorption coefficients across various frequencies (50Hz-5000Hz) while simulating different environmental conditions. Their methodology incorporates statistical energy analysis (SEA) to predict structure-borne noise transmission in complex assemblies. Additionally, they've pioneered non-destructive testing methods using laser vibrometry to map vibration patterns in galvanized steel without affecting the material properties, allowing for in-situ measurements of existing structures.

Strengths: Exceptional expertise in marine acoustics applications; comprehensive testing facilities; integration of computational and experimental approaches. Weaknesses: Research primarily focused on naval applications may limit direct transferability to other structural contexts; some methodologies require specialized equipment not widely available in industry.

China Academy of Railway Sciences Group Co. Ltd.

Technical Solution: China Academy of Railway Sciences Group has developed a comprehensive acoustic dampening measurement system specifically for galvanized steel components in railway infrastructure. Their approach integrates both laboratory and field testing methodologies to evaluate noise reduction performance in real-world conditions. The system employs multi-point microphone arrays combined with accelerometers to simultaneously capture airborne and structure-borne sound transmission through galvanized steel elements. Their proprietary analysis software processes acoustic data using advanced signal processing algorithms that can isolate specific frequency bands relevant to railway noise (particularly in the 30-350Hz range where steel structures typically resonate). The Academy has also pioneered a standardized testing protocol that accounts for the unique coating characteristics of galvanized steel and how they affect acoustic properties over time with exposure to vibration and environmental factors. Their research has established correlation models between laboratory measurements and in-situ performance, enabling more accurate prediction of long-term acoustic performance in railway structures.

Strengths: Extensive practical experience with railway-specific applications; robust field testing capabilities; established correlation between lab and real-world performance. Weaknesses: Methodologies heavily optimized for railway applications may require adaptation for other structural contexts; testing protocols primarily designed for horizontal rather than vertical steel structures.

Key Technical Innovations in Acoustic Testing

An acoustic damping building material

PatentInactiveGB2517125A

Innovation

- An acoustic damping building material comprising a substrate with an acoustic damping layer featuring multiple media configurations that provide both direct and indirect energy transmission pathways, allowing for efficient absorption and dissipation of sound energy, reducing noise transmission through structure-borne energy pathways.

Structural steel having excellent vibration damping property

PatentInactiveJP1981029656A

Innovation

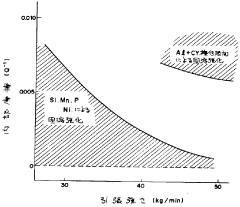

- Combined addition of specific amounts of Cr (2.0-15.0%) and Al (1-7%) to low carbon steel to convert vibration energy into magnetic energy, effectively enhancing vibration damping properties.

- Achieving excellent vibration damping properties while maintaining high tensile strength (exceeding 41kg/mm²), creating a dual-functional structural steel.

- Optional addition of Ti (0.01-0.09%) and Cu (0.05-1.50%) to further modify the damping characteristics of the steel.

Building Code Requirements and Industry Standards

The regulatory landscape governing acoustic dampening in building structures is extensive and multifaceted, with galvanized steel applications subject to numerous standards. The International Building Code (IBC) establishes minimum requirements for sound transmission between adjacent spaces, with specific provisions for structural elements including those utilizing galvanized steel. Section 1207 of the IBC specifically addresses sound transmission, requiring wall and floor-ceiling assemblies to achieve Sound Transmission Class (STC) ratings of at least 50 for airborne noise and Impact Insulation Class (IIC) ratings of 50 for structure-borne sound.

ASTM International provides the primary testing methodologies for acoustic performance measurement. ASTM E90 standardizes laboratory measurement of airborne sound transmission loss, while ASTM E492 covers laboratory measurement of impact sound transmission. For field verification, ASTM E336 and ASTM E1007 are employed respectively. These standards establish precise protocols for measuring the acoustic dampening properties of galvanized steel components within structural assemblies.

The American National Standards Institute (ANSI) contributes additional specifications through ANSI S12.60, which addresses classroom acoustics and includes provisions relevant to steel structural elements. Meanwhile, the Acoustical Society of America (ASA) provides technical guidance through standards like ANSI/ASA S12.60 for educational facilities and ANSI/ASA S12.2 for noise criteria in various building types.

For galvanized steel specifically, ASTM A653/A653M establishes standard specifications for steel sheet, zinc-coated (galvanized) by the hot-dip process. While primarily focused on corrosion resistance, these specifications indirectly impact acoustic properties through material thickness and coating requirements. The Steel Deck Institute (SDI) provides complementary standards for steel deck design that incorporate acoustic considerations.

International standards also influence North American practices. ISO 717 establishes rating methods for sound insulation in buildings, while ISO 10140 series standardizes laboratory measurement of sound insulation of building elements. These standards are increasingly referenced in global projects involving galvanized steel acoustic applications.

Compliance verification typically requires laboratory testing of assemblies according to these standards, with field testing to confirm installed performance. Documentation requirements include detailed acoustic engineering reports demonstrating compliance with applicable codes. Many jurisdictions have adopted enhanced requirements exceeding minimum code provisions, particularly for sensitive occupancies like healthcare facilities, where ANSI/ASA S12.60-2010 may establish more stringent criteria for noise reduction.

ASTM International provides the primary testing methodologies for acoustic performance measurement. ASTM E90 standardizes laboratory measurement of airborne sound transmission loss, while ASTM E492 covers laboratory measurement of impact sound transmission. For field verification, ASTM E336 and ASTM E1007 are employed respectively. These standards establish precise protocols for measuring the acoustic dampening properties of galvanized steel components within structural assemblies.

The American National Standards Institute (ANSI) contributes additional specifications through ANSI S12.60, which addresses classroom acoustics and includes provisions relevant to steel structural elements. Meanwhile, the Acoustical Society of America (ASA) provides technical guidance through standards like ANSI/ASA S12.60 for educational facilities and ANSI/ASA S12.2 for noise criteria in various building types.

For galvanized steel specifically, ASTM A653/A653M establishes standard specifications for steel sheet, zinc-coated (galvanized) by the hot-dip process. While primarily focused on corrosion resistance, these specifications indirectly impact acoustic properties through material thickness and coating requirements. The Steel Deck Institute (SDI) provides complementary standards for steel deck design that incorporate acoustic considerations.

International standards also influence North American practices. ISO 717 establishes rating methods for sound insulation in buildings, while ISO 10140 series standardizes laboratory measurement of sound insulation of building elements. These standards are increasingly referenced in global projects involving galvanized steel acoustic applications.

Compliance verification typically requires laboratory testing of assemblies according to these standards, with field testing to confirm installed performance. Documentation requirements include detailed acoustic engineering reports demonstrating compliance with applicable codes. Many jurisdictions have adopted enhanced requirements exceeding minimum code provisions, particularly for sensitive occupancies like healthcare facilities, where ANSI/ASA S12.60-2010 may establish more stringent criteria for noise reduction.

Environmental Impact of Acoustic Treatment Solutions

The environmental impact of acoustic treatment solutions has become increasingly important as organizations strive to balance noise control requirements with sustainability goals. When considering galvanized steel structures and their acoustic dampening properties, the environmental footprint of supplementary acoustic treatments must be carefully evaluated.

Traditional acoustic treatments often incorporate materials with significant environmental concerns. Fiberglass and mineral wool insulations, commonly used alongside steel structures for sound absorption, typically contain formaldehyde-based binders that can emit volatile organic compounds (VOCs) over time. These emissions contribute to indoor air pollution and may pose health risks to occupants, particularly in enclosed spaces with limited ventilation.

Foam-based acoustic solutions present another environmental challenge. While effective for dampening sound in steel structures, polyurethane and polystyrene foams are petroleum derivatives with high embodied carbon. Their manufacturing process consumes substantial energy and releases greenhouse gases. Additionally, these materials are rarely biodegradable and often end up in landfills at the end of their lifecycle, contributing to waste management problems.

Recent innovations have introduced bio-based acoustic treatments as alternatives to conventional options. Materials derived from agricultural byproducts such as hemp, cotton, and recycled cellulose offer comparable acoustic performance to synthetic options when paired with galvanized steel structures. These solutions significantly reduce carbon footprint and utilize renewable resources, though their moisture resistance and durability may not match synthetic alternatives in all applications.

The lifecycle assessment of acoustic treatments reveals varying environmental impacts. While galvanized steel itself is highly recyclable, composite acoustic panels incorporating steel and non-recyclable materials complicate end-of-life processing. The zinc coating in galvanized steel, though protective against corrosion, requires energy-intensive production processes and mining activities that generate environmental pollutants.

Water consumption and pollution represent additional environmental considerations. Manufacturing processes for many acoustic treatments require substantial water usage, and chemical treatments may introduce contaminants into wastewater streams. Sustainable acoustic solutions increasingly incorporate closed-loop water systems and biodegradable treatment chemicals to mitigate these impacts.

Energy efficiency presents a potential environmental benefit of effective acoustic treatments in steel structures. By optimizing sound insulation, buildings can reduce energy consumption associated with mechanical ventilation systems that might otherwise run at higher levels to mask unwanted noise. This indirect environmental benefit should be factored into comprehensive environmental impact assessments of acoustic treatment solutions.

Traditional acoustic treatments often incorporate materials with significant environmental concerns. Fiberglass and mineral wool insulations, commonly used alongside steel structures for sound absorption, typically contain formaldehyde-based binders that can emit volatile organic compounds (VOCs) over time. These emissions contribute to indoor air pollution and may pose health risks to occupants, particularly in enclosed spaces with limited ventilation.

Foam-based acoustic solutions present another environmental challenge. While effective for dampening sound in steel structures, polyurethane and polystyrene foams are petroleum derivatives with high embodied carbon. Their manufacturing process consumes substantial energy and releases greenhouse gases. Additionally, these materials are rarely biodegradable and often end up in landfills at the end of their lifecycle, contributing to waste management problems.

Recent innovations have introduced bio-based acoustic treatments as alternatives to conventional options. Materials derived from agricultural byproducts such as hemp, cotton, and recycled cellulose offer comparable acoustic performance to synthetic options when paired with galvanized steel structures. These solutions significantly reduce carbon footprint and utilize renewable resources, though their moisture resistance and durability may not match synthetic alternatives in all applications.

The lifecycle assessment of acoustic treatments reveals varying environmental impacts. While galvanized steel itself is highly recyclable, composite acoustic panels incorporating steel and non-recyclable materials complicate end-of-life processing. The zinc coating in galvanized steel, though protective against corrosion, requires energy-intensive production processes and mining activities that generate environmental pollutants.

Water consumption and pollution represent additional environmental considerations. Manufacturing processes for many acoustic treatments require substantial water usage, and chemical treatments may introduce contaminants into wastewater streams. Sustainable acoustic solutions increasingly incorporate closed-loop water systems and biodegradable treatment chemicals to mitigate these impacts.

Energy efficiency presents a potential environmental benefit of effective acoustic treatments in steel structures. By optimizing sound insulation, buildings can reduce energy consumption associated with mechanical ventilation systems that might otherwise run at higher levels to mask unwanted noise. This indirect environmental benefit should be factored into comprehensive environmental impact assessments of acoustic treatment solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!