How to Design with Galvanized Steel for Earthquake Resistance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Seismic Design Background and Objectives

Galvanized steel has emerged as a critical material in seismic-resistant construction over the past several decades. The evolution of this technology can be traced back to the mid-20th century when engineers began recognizing the importance of both structural integrity and corrosion resistance in earthquake-prone regions. The convergence of galvanization technology with structural engineering principles has created a robust solution for buildings that must withstand significant seismic events while maintaining long-term durability.

The technical progression in this field has been marked by significant advancements in hot-dip galvanizing processes, which have enhanced the bond between zinc coating and steel substrates. This evolution has been driven by catastrophic seismic events that exposed weaknesses in traditional construction materials, particularly in coastal regions where corrosion accelerates structural degradation.

Current research focuses on optimizing the performance of galvanized steel under dynamic loading conditions typical during earthquakes. The primary technical objective is to develop design methodologies that maximize the ductility and energy dissipation capabilities of galvanized steel structural systems while maintaining their corrosion resistance properties throughout the building's lifecycle.

Another critical goal is to establish comprehensive design standards specifically addressing the unique behavior of galvanized steel connections during seismic events. This includes understanding how the zinc coating affects the friction coefficients at bolted connections and the performance of welded joints under cyclic loading conditions.

The integration of galvanized steel into modern seismic design codes represents a significant technical challenge. Engineers must balance multiple performance criteria including strength, ductility, corrosion resistance, and economic feasibility. The target is to develop design approaches that can be readily implemented by structural engineers without requiring specialized knowledge of metallurgical processes.

Recent technological trends indicate a growing interest in dual-performance galvanized steel systems that combine enhanced corrosion protection with improved seismic response characteristics. These innovations aim to extend building lifespans in seismically active regions while reducing maintenance costs and improving safety margins during major earthquakes.

The ultimate technical objective remains the development of a unified design framework that quantifies the relationship between galvanization parameters and seismic performance metrics. This would enable engineers to specify optimal galvanization processes based on specific seismic design requirements, creating a more integrated approach to earthquake-resistant construction using galvanized steel components.

The technical progression in this field has been marked by significant advancements in hot-dip galvanizing processes, which have enhanced the bond between zinc coating and steel substrates. This evolution has been driven by catastrophic seismic events that exposed weaknesses in traditional construction materials, particularly in coastal regions where corrosion accelerates structural degradation.

Current research focuses on optimizing the performance of galvanized steel under dynamic loading conditions typical during earthquakes. The primary technical objective is to develop design methodologies that maximize the ductility and energy dissipation capabilities of galvanized steel structural systems while maintaining their corrosion resistance properties throughout the building's lifecycle.

Another critical goal is to establish comprehensive design standards specifically addressing the unique behavior of galvanized steel connections during seismic events. This includes understanding how the zinc coating affects the friction coefficients at bolted connections and the performance of welded joints under cyclic loading conditions.

The integration of galvanized steel into modern seismic design codes represents a significant technical challenge. Engineers must balance multiple performance criteria including strength, ductility, corrosion resistance, and economic feasibility. The target is to develop design approaches that can be readily implemented by structural engineers without requiring specialized knowledge of metallurgical processes.

Recent technological trends indicate a growing interest in dual-performance galvanized steel systems that combine enhanced corrosion protection with improved seismic response characteristics. These innovations aim to extend building lifespans in seismically active regions while reducing maintenance costs and improving safety margins during major earthquakes.

The ultimate technical objective remains the development of a unified design framework that quantifies the relationship between galvanization parameters and seismic performance metrics. This would enable engineers to specify optimal galvanization processes based on specific seismic design requirements, creating a more integrated approach to earthquake-resistant construction using galvanized steel components.

Market Analysis for Earthquake-Resistant Steel Structures

The global market for earthquake-resistant steel structures has experienced significant growth over the past decade, driven by increasing urbanization in seismic zones and heightened awareness of structural safety requirements. Currently valued at approximately $9.8 billion, this market segment is projected to grow at a compound annual growth rate of 6.2% through 2028, reaching an estimated $14.7 billion.

Galvanized steel solutions specifically have captured about 23% of this market, with their share steadily increasing due to superior corrosion resistance combined with structural integrity. This growth is particularly pronounced in coastal seismic regions where structures face dual threats of earthquake damage and salt-air corrosion.

Regionally, the Asia-Pacific market dominates with 42% of global demand, led by Japan, China, and New Zealand, all countries with stringent seismic building codes. North America follows at 28%, with particular concentration in the western United States and Mexico. Europe accounts for 19%, with Italy, Turkey, and Greece representing the primary markets due to their seismic activity profiles.

Market segmentation reveals that commercial buildings represent the largest application sector (37%), followed by residential structures (29%), infrastructure projects (22%), and industrial facilities (12%). The residential sector is showing the fastest growth rate at 7.8% annually, driven by increasing housing development in urban seismic zones and retrofitting of existing structures.

Key market drivers include increasingly stringent building codes in seismic regions, growing insurance industry pressure for resilient construction, and the overall cost-effectiveness of preventative design compared to post-disaster reconstruction. The economic impact of recent major earthquakes has significantly influenced market growth, with post-disaster analyses consistently demonstrating superior performance of properly designed galvanized steel structures.

Customer demand patterns show increasing preference for integrated solutions that combine earthquake resistance with sustainability features. This has created a premium market segment where galvanized steel has competitive advantages due to its recyclability and long service life. Price sensitivity varies significantly by region, with developed markets focusing more on total lifecycle costs while developing markets remain more sensitive to initial construction expenses.

Supply chain analysis indicates potential constraints in raw material availability, with zinc supplies for galvanization potentially facing pressure as demand increases. This has prompted innovation in more efficient galvanization processes and exploration of alternative coating technologies that maintain or enhance seismic performance characteristics.

Galvanized steel solutions specifically have captured about 23% of this market, with their share steadily increasing due to superior corrosion resistance combined with structural integrity. This growth is particularly pronounced in coastal seismic regions where structures face dual threats of earthquake damage and salt-air corrosion.

Regionally, the Asia-Pacific market dominates with 42% of global demand, led by Japan, China, and New Zealand, all countries with stringent seismic building codes. North America follows at 28%, with particular concentration in the western United States and Mexico. Europe accounts for 19%, with Italy, Turkey, and Greece representing the primary markets due to their seismic activity profiles.

Market segmentation reveals that commercial buildings represent the largest application sector (37%), followed by residential structures (29%), infrastructure projects (22%), and industrial facilities (12%). The residential sector is showing the fastest growth rate at 7.8% annually, driven by increasing housing development in urban seismic zones and retrofitting of existing structures.

Key market drivers include increasingly stringent building codes in seismic regions, growing insurance industry pressure for resilient construction, and the overall cost-effectiveness of preventative design compared to post-disaster reconstruction. The economic impact of recent major earthquakes has significantly influenced market growth, with post-disaster analyses consistently demonstrating superior performance of properly designed galvanized steel structures.

Customer demand patterns show increasing preference for integrated solutions that combine earthquake resistance with sustainability features. This has created a premium market segment where galvanized steel has competitive advantages due to its recyclability and long service life. Price sensitivity varies significantly by region, with developed markets focusing more on total lifecycle costs while developing markets remain more sensitive to initial construction expenses.

Supply chain analysis indicates potential constraints in raw material availability, with zinc supplies for galvanization potentially facing pressure as demand increases. This has prompted innovation in more efficient galvanization processes and exploration of alternative coating technologies that maintain or enhance seismic performance characteristics.

Current Challenges in Galvanized Steel Seismic Applications

Despite the widespread use of galvanized steel in seismic-resistant structures, several significant challenges persist in its application for earthquake resistance. The primary concern involves the behavior of zinc coating during high-strain seismic events. Under extreme lateral forces, the zinc layer may experience micro-cracking or delamination, potentially compromising the corrosion protection that represents one of galvanized steel's key advantages. This phenomenon becomes particularly problematic in connections and joints where stress concentration occurs during seismic loading.

Another substantial challenge lies in the welding processes for galvanized steel in seismic applications. The zinc coating vaporizes at temperatures lower than steel's melting point, creating potential weld defects including porosity and incomplete fusion. These defects can significantly reduce the ductility and energy absorption capacity of connections—properties that are crucial for earthquake resistance. Current welding protocols often require additional preparation steps and specialized techniques, increasing construction complexity and costs.

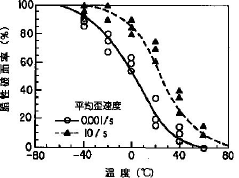

The long-term performance prediction of galvanized steel under repeated seismic events presents another technical hurdle. While single-event testing is relatively common, the cumulative effect of multiple seismic events on galvanized connections remains inadequately characterized. This knowledge gap complicates the development of reliable life-cycle models for structures in high-seismic zones, where buildings may experience numerous moderate earthquakes throughout their service life.

Design code limitations further constrain galvanized steel applications in seismic zones. Many international building codes contain insufficient provisions specifically addressing galvanized steel in seismic design, forcing engineers to apply general steel provisions that may not account for the unique properties of galvanized materials. This regulatory gap creates uncertainty in design processes and may lead to either overly conservative or potentially unsafe designs.

The cost-benefit analysis of galvanized steel in seismic applications remains challenging due to the difficulty in quantifying long-term benefits against higher initial costs. While galvanized steel offers superior corrosion resistance—particularly valuable in coastal seismic regions—the premium cost compared to traditional steel solutions creates adoption barriers, especially in developing economies where seismic risk is often high but construction budgets are limited.

Environmental considerations add another layer of complexity, as the galvanization process involves chemicals and energy consumption that must be balanced against the sustainability benefits of longer structural lifespans. Finding this balance while maintaining optimal seismic performance represents an ongoing challenge for the industry.

Another substantial challenge lies in the welding processes for galvanized steel in seismic applications. The zinc coating vaporizes at temperatures lower than steel's melting point, creating potential weld defects including porosity and incomplete fusion. These defects can significantly reduce the ductility and energy absorption capacity of connections—properties that are crucial for earthquake resistance. Current welding protocols often require additional preparation steps and specialized techniques, increasing construction complexity and costs.

The long-term performance prediction of galvanized steel under repeated seismic events presents another technical hurdle. While single-event testing is relatively common, the cumulative effect of multiple seismic events on galvanized connections remains inadequately characterized. This knowledge gap complicates the development of reliable life-cycle models for structures in high-seismic zones, where buildings may experience numerous moderate earthquakes throughout their service life.

Design code limitations further constrain galvanized steel applications in seismic zones. Many international building codes contain insufficient provisions specifically addressing galvanized steel in seismic design, forcing engineers to apply general steel provisions that may not account for the unique properties of galvanized materials. This regulatory gap creates uncertainty in design processes and may lead to either overly conservative or potentially unsafe designs.

The cost-benefit analysis of galvanized steel in seismic applications remains challenging due to the difficulty in quantifying long-term benefits against higher initial costs. While galvanized steel offers superior corrosion resistance—particularly valuable in coastal seismic regions—the premium cost compared to traditional steel solutions creates adoption barriers, especially in developing economies where seismic risk is often high but construction budgets are limited.

Environmental considerations add another layer of complexity, as the galvanization process involves chemicals and energy consumption that must be balanced against the sustainability benefits of longer structural lifespans. Finding this balance while maintaining optimal seismic performance represents an ongoing challenge for the industry.

Prevalent Galvanized Steel Seismic Design Methodologies

01 Galvanized steel structural components for earthquake resistance

Galvanized steel is used in various structural components designed specifically for earthquake resistance. These components include frames, columns, beams, and connectors that form the backbone of earthquake-resistant buildings. The galvanization process provides corrosion protection while maintaining the structural integrity needed to withstand seismic forces. These components are engineered to absorb and dissipate energy during earthquakes, preventing catastrophic failures.- Galvanized steel structural components for earthquake resistance: Galvanized steel components are used in building structures to enhance earthquake resistance. These components include beams, columns, and bracing systems that are designed to withstand seismic forces. The galvanization process provides corrosion protection while maintaining the structural integrity needed for earthquake resistance. These components are engineered to absorb and dissipate seismic energy, preventing catastrophic failure during earthquakes.

- Specialized coatings and treatments for galvanized steel in seismic applications: Advanced coatings and treatments are applied to galvanized steel to enhance its performance in earthquake-prone areas. These treatments improve ductility, fatigue resistance, and energy absorption capabilities of the steel. Some coatings provide additional corrosion protection beyond standard galvanization, which is crucial for maintaining structural integrity in seismic zones where structures may be exposed to harsh environmental conditions. These specialized treatments help extend the service life of earthquake-resistant structures.

- Connection systems for galvanized steel in seismic design: Innovative connection systems are developed specifically for galvanized steel structures in seismic zones. These connections are designed to maintain structural integrity during ground movement while preventing brittle failure. The connections allow for controlled deformation and energy dissipation during earthquakes. Special attention is given to the design of bolted and welded connections to ensure they can withstand cyclic loading without compromising the galvanized coating or the structural performance.

- Composite systems combining galvanized steel with other materials: Composite structural systems that combine galvanized steel with other materials like concrete, timber, or advanced composites enhance earthquake resistance. These hybrid systems leverage the strengths of different materials to create structures with superior seismic performance. The galvanized steel components provide ductility and tensile strength, while the complementary materials contribute to damping, compression resistance, or other beneficial properties. These composite systems are engineered to work together to absorb and dissipate seismic energy effectively.

- Testing and performance evaluation methods for galvanized steel in seismic conditions: Specialized testing methodologies are developed to evaluate the performance of galvanized steel structures under seismic conditions. These include cyclic loading tests, shake table experiments, and computer simulations that predict how galvanized steel components will behave during earthquakes. The testing protocols assess factors such as ductility, energy dissipation capacity, and the integrity of the galvanized coating after repeated stress cycles. These evaluation methods help engineers design safer structures and develop improved galvanizing techniques specifically for earthquake-resistant applications.

02 Enhanced coating technologies for seismic performance

Advanced coating technologies are applied to steel to enhance its performance during seismic events. These coatings not only provide galvanic protection but also improve the steel's ability to withstand repeated stress cycles during earthquakes. Special formulations may include zinc-aluminum alloys or composite coatings that offer superior adhesion and flexibility. These enhanced coatings help prevent brittle fractures and maintain structural integrity even after multiple seismic events.Expand Specific Solutions03 Connection systems for galvanized steel in seismic zones

Specialized connection systems are developed for galvanized steel structures in earthquake-prone areas. These connections are designed to allow controlled movement during seismic events while maintaining structural integrity. Innovations include flexible joints, energy-dissipating connectors, and slip-critical connections that prevent catastrophic failures. The galvanization process ensures these critical connection points remain protected from corrosion, maintaining their performance capabilities throughout the structure's lifetime.Expand Specific Solutions04 Manufacturing processes for earthquake-resistant galvanized steel

Specific manufacturing processes are employed to produce galvanized steel with enhanced earthquake resistance properties. These processes include controlled cooling, microstructure optimization, and precise alloying to achieve the desired combination of strength and ductility. The galvanization process is carefully controlled to ensure uniform coating thickness and adhesion, which is critical for seismic performance. Post-galvanizing treatments may also be applied to further enhance the steel's ability to withstand cyclic loading during earthquakes.Expand Specific Solutions05 Testing and performance standards for earthquake-resistant galvanized steel

Comprehensive testing methodologies and performance standards have been developed specifically for evaluating galvanized steel's earthquake resistance. These include cyclic loading tests, fatigue resistance evaluations, and full-scale structural simulations. The standards ensure that galvanized steel structures can maintain their integrity during and after seismic events. Testing protocols also assess the long-term performance of galvanized coatings under repeated stress conditions, ensuring that corrosion protection remains effective even after earthquake damage.Expand Specific Solutions

Leading Manufacturers and Researchers in Seismic Steel Solutions

The earthquake-resistant galvanized steel design market is currently in a growth phase, with increasing adoption driven by urbanization in seismic zones and stricter building codes. The global market for earthquake-resistant construction materials is projected to reach $40 billion by 2025. Leading steel manufacturers like NIPPON STEEL, POSCO Holdings, and JFE Steel have developed advanced galvanized steel products with enhanced ductility and strength-to-weight ratios specifically for seismic applications. Construction companies such as Takenaka Corp. and Sumitomo Mitsui Construction are implementing these technologies in practical applications, while research institutions including Tsinghua University and the University of Washington are advancing innovative connection designs and composite systems that optimize galvanized steel's performance under seismic loads.

JFE Steel Corp.

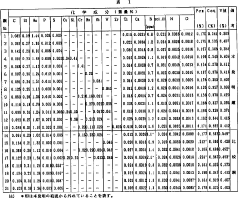

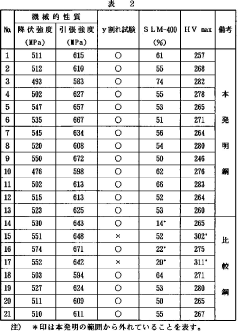

Technical Solution: JFE Steel has pioneered earthquake-resistant galvanized steel design through their JFE Seismic Resistance System, which integrates high-performance galvanized steel with innovative structural configurations. Their approach centers on developing steel with optimal combinations of strength and ductility specifically for seismic applications. JFE's galvanized steel products for earthquake resistance feature zinc coatings applied through continuous hot-dip galvanizing, achieving coating weights of 60-180 g/m² while maintaining excellent formability[3]. Their earthquake design methodology incorporates energy dissipation mechanisms through specially designed structural fuses that concentrate deformation in predetermined locations, protecting critical structural components. JFE has developed proprietary HBLTM (High-Performance Building Material with Low Yield Point) galvanized steel that exhibits controlled yielding behavior ideal for seismic energy absorption[4]. Their system includes comprehensive connection details that maintain structural integrity during extreme lateral loading, with particular attention to preventing galvanized coating damage at connection points through innovative fastening techniques.

Strengths: Excellent balance between corrosion protection and seismic performance, with specialized steel grades designed specifically for energy dissipation in earthquakes. Their structural fuse approach effectively protects primary structural elements. Weaknesses: More complex design requirements may increase engineering costs, and the specialized steel grades may have limited availability in some markets compared to standard galvanized products.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed comprehensive earthquake-resistant galvanized steel solutions through their PosSeismic system, which leverages high-performance galvanized steel in innovative structural configurations. Their approach focuses on creating structures with enhanced energy absorption capabilities while maintaining long-term durability through galvanization. POSCO's earthquake-resistant galvanized steel features zinc coatings with thickness ranges of 20-275 g/m² depending on application requirements, applied through advanced continuous galvanizing lines that ensure coating uniformity[5]. Their seismic design methodology incorporates specially designed structural elements with controlled yielding zones that absorb earthquake energy while protecting critical connections. POSCO has developed proprietary POSMAC® galvanized steel with magnesium and aluminum additions to the zinc coating, providing superior corrosion resistance in seismic applications where coating damage might occur during deformation[6]. Their system includes detailed guidelines for welding and connection design that preserve coating integrity while ensuring structural performance, addressing one of the key challenges in using galvanized steel for seismic applications.

Strengths: Advanced coating technology provides superior long-term performance in corrosive environments while maintaining excellent seismic response. Their comprehensive design guidelines simplify implementation for engineers. Weaknesses: Premium coating technologies increase material costs, and some specialized connection details may require additional fabrication steps compared to conventional steel construction.

Key Technical Innovations in Earthquake-Resistant Steel Connections

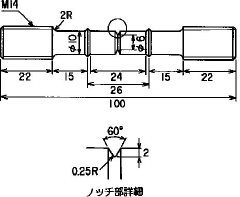

Heat treated type earthquake-proof steel product excellent in hot-dip galvanizing crack resistance

PatentInactiveJP1998204584A

Innovation

- A tempered steel composition with controlled alloying elements and a specific Pcm and Y value, combined with a notched tensile test to ensure a minimum reduction of area, enhances weldability, galvanization crack resistance, and brittle fracture resistance under high-speed deformation.

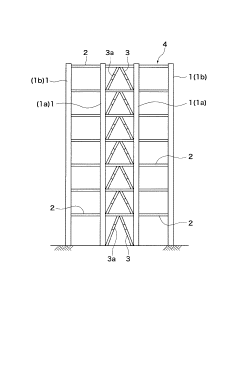

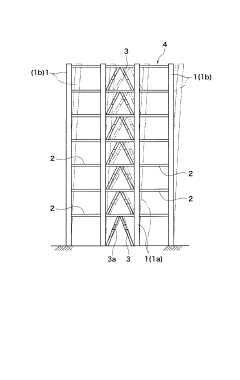

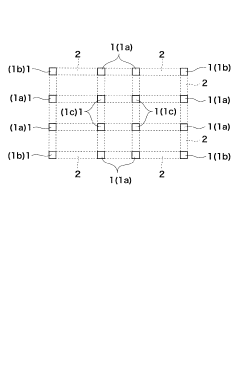

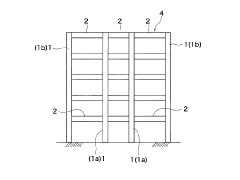

Earthquake-resistant steel structure and its design method

PatentActiveJPWO2010103801A1

Innovation

- A steel frame structure design where side pillars have a yield strength of at least 400 N/mm² with a beam-to-column yield strength ratio of 1.5 to 3.0, and corner pillars have a yield strength of at least 400 N/mm² with a beam-to-column yield strength ratio of 1.7 to 3.5, using the same steel composition for all pillars to enhance weldability and reduce construction costs.

Corrosion Resistance Benefits in Seismic Applications

Galvanized steel offers significant corrosion resistance benefits that are particularly valuable in seismic applications. When structures are designed to withstand earthquake forces, the long-term durability of the structural components becomes a critical consideration. The zinc coating applied during the galvanization process creates a sacrificial barrier that protects the underlying steel from oxidation and corrosion, even when exposed to moisture, soil, or atmospheric contaminants.

In seismic zones, structures are frequently subjected to ground moisture, especially in coastal regions where saltwater exposure accelerates corrosion. Galvanized steel maintains its structural integrity over time, ensuring that the designed earthquake resistance capabilities remain intact throughout the building's lifecycle. Research indicates that properly galvanized steel can provide corrosion protection for 50-100 years in many environments, significantly extending the service life of seismic-resistant structures.

The uniform zinc coating penetrates all surfaces, including hard-to-reach areas such as joints, connections, and threaded components. This comprehensive protection is particularly important for seismic applications, as these connection points often experience the highest stress concentrations during earthquakes and would be most vulnerable to corrosion-induced failures.

Post-earthquake functionality is another critical benefit. After seismic events, structures may develop minor cracks or damage that expose steel elements to moisture. Galvanized steel continues to provide corrosion protection even when scratched or slightly damaged, as the zinc coating offers cathodic protection by sacrificially corroding to protect the exposed steel. This self-healing property ensures that the structure maintains its designed seismic resistance even after experiencing earthquake damage.

From a lifecycle cost perspective, the initial investment in galvanized steel pays dividends through reduced maintenance requirements and extended service life. In seismic regions, where inspection and repair access may be challenging, this maintenance reduction is particularly valuable. Studies have shown that galvanized steel structures can reduce lifetime maintenance costs by up to 40% compared to structures using unprotected steel, while simultaneously ensuring consistent seismic performance throughout the building's service life.

The environmental benefits of galvanized steel also align with sustainable seismic design principles. The extended service life reduces the need for replacement and reconstruction after earthquakes, minimizing embodied carbon impacts. Additionally, galvanized steel is 100% recyclable at the end of its service life, supporting circular economy principles in earthquake-resistant construction.

In seismic zones, structures are frequently subjected to ground moisture, especially in coastal regions where saltwater exposure accelerates corrosion. Galvanized steel maintains its structural integrity over time, ensuring that the designed earthquake resistance capabilities remain intact throughout the building's lifecycle. Research indicates that properly galvanized steel can provide corrosion protection for 50-100 years in many environments, significantly extending the service life of seismic-resistant structures.

The uniform zinc coating penetrates all surfaces, including hard-to-reach areas such as joints, connections, and threaded components. This comprehensive protection is particularly important for seismic applications, as these connection points often experience the highest stress concentrations during earthquakes and would be most vulnerable to corrosion-induced failures.

Post-earthquake functionality is another critical benefit. After seismic events, structures may develop minor cracks or damage that expose steel elements to moisture. Galvanized steel continues to provide corrosion protection even when scratched or slightly damaged, as the zinc coating offers cathodic protection by sacrificially corroding to protect the exposed steel. This self-healing property ensures that the structure maintains its designed seismic resistance even after experiencing earthquake damage.

From a lifecycle cost perspective, the initial investment in galvanized steel pays dividends through reduced maintenance requirements and extended service life. In seismic regions, where inspection and repair access may be challenging, this maintenance reduction is particularly valuable. Studies have shown that galvanized steel structures can reduce lifetime maintenance costs by up to 40% compared to structures using unprotected steel, while simultaneously ensuring consistent seismic performance throughout the building's service life.

The environmental benefits of galvanized steel also align with sustainable seismic design principles. The extended service life reduces the need for replacement and reconstruction after earthquakes, minimizing embodied carbon impacts. Additionally, galvanized steel is 100% recyclable at the end of its service life, supporting circular economy principles in earthquake-resistant construction.

Cost-Benefit Analysis of Galvanized vs. Alternative Materials

When evaluating galvanized steel for earthquake-resistant construction, cost considerations must be balanced against performance benefits. Initial material costs for galvanized steel typically exceed those of traditional uncoated steel by 15-25%, representing a significant upfront investment. However, this premium is offset by substantial long-term savings in maintenance and replacement costs, particularly in seismic zones where structural integrity is paramount.

The lifecycle cost analysis reveals that galvanized steel structures can achieve cost savings of 30-40% over a 50-year period compared to uncoated steel alternatives that require periodic painting and maintenance. In high-corrosion environments such as coastal seismic regions, these savings can increase to 45-60% due to galvanized steel's superior corrosion resistance, which maintains structural ductility essential for seismic performance.

Alternative materials like stainless steel offer comparable corrosion resistance but at significantly higher initial costs—typically 3-4 times that of galvanized steel. Fiber-reinforced polymers (FRPs) present another alternative with excellent corrosion resistance but lack the proven long-term performance history in seismic applications and come with higher material costs and specialized installation requirements.

Concrete-encased steel provides another option, combining corrosion protection with fire resistance. However, this approach increases structural weight, potentially amplifying seismic forces, and complicates inspection and retrofit operations. The additional concrete also increases overall project costs by approximately 20-30% compared to exposed galvanized steel solutions.

Environmental cost-benefit analysis further favors galvanized steel, as hot-dip galvanizing is a relatively low-energy process compared to stainless steel production. Additionally, galvanized steel is 100% recyclable without loss of properties, reducing its environmental footprint. Life cycle assessment studies indicate that galvanized steel structures generate 15-20% lower carbon emissions over their lifetime compared to alternatives requiring frequent maintenance or replacement.

Installation efficiency also factors into the cost equation. Galvanized components can be fabricated off-site and rapidly assembled, reducing construction time by up to 20% compared to cast-in-place concrete alternatives. This time efficiency translates to earlier occupancy and revenue generation, particularly valuable in commercial construction projects in seismic zones.

Insurance premiums represent another economic consideration, with galvanized steel structures in seismic zones typically qualifying for 5-15% lower premiums due to their proven performance record and durability. These ongoing savings contribute significantly to the favorable long-term economic profile of galvanized steel in earthquake-resistant design.

The lifecycle cost analysis reveals that galvanized steel structures can achieve cost savings of 30-40% over a 50-year period compared to uncoated steel alternatives that require periodic painting and maintenance. In high-corrosion environments such as coastal seismic regions, these savings can increase to 45-60% due to galvanized steel's superior corrosion resistance, which maintains structural ductility essential for seismic performance.

Alternative materials like stainless steel offer comparable corrosion resistance but at significantly higher initial costs—typically 3-4 times that of galvanized steel. Fiber-reinforced polymers (FRPs) present another alternative with excellent corrosion resistance but lack the proven long-term performance history in seismic applications and come with higher material costs and specialized installation requirements.

Concrete-encased steel provides another option, combining corrosion protection with fire resistance. However, this approach increases structural weight, potentially amplifying seismic forces, and complicates inspection and retrofit operations. The additional concrete also increases overall project costs by approximately 20-30% compared to exposed galvanized steel solutions.

Environmental cost-benefit analysis further favors galvanized steel, as hot-dip galvanizing is a relatively low-energy process compared to stainless steel production. Additionally, galvanized steel is 100% recyclable without loss of properties, reducing its environmental footprint. Life cycle assessment studies indicate that galvanized steel structures generate 15-20% lower carbon emissions over their lifetime compared to alternatives requiring frequent maintenance or replacement.

Installation efficiency also factors into the cost equation. Galvanized components can be fabricated off-site and rapidly assembled, reducing construction time by up to 20% compared to cast-in-place concrete alternatives. This time efficiency translates to earlier occupancy and revenue generation, particularly valuable in commercial construction projects in seismic zones.

Insurance premiums represent another economic consideration, with galvanized steel structures in seismic zones typically qualifying for 5-15% lower premiums due to their proven performance record and durability. These ongoing savings contribute significantly to the favorable long-term economic profile of galvanized steel in earthquake-resistant design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!