Measure Galvanized Steel's Coating Weight Using Gravimetric Method

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Coating Weight Measurement Background and Objectives

Galvanized steel coating has evolved significantly since its commercial introduction in the early 19th century. Initially developed as a protective measure against corrosion, the process of applying zinc coatings to steel substrates has become a cornerstone technology in construction, automotive, and manufacturing industries. The evolution of galvanization techniques has progressed from rudimentary hot-dip methods to sophisticated continuous galvanizing lines capable of precise coating weight control.

The gravimetric method for measuring galvanized coating weight represents one of the fundamental analytical techniques in this field. This method, based on determining the mass difference before and after coating removal, has remained relevant despite technological advancements in measurement technologies. Its importance lies in its role as a reference standard against which other measurement techniques are calibrated.

Current industry trends indicate a growing demand for more precise coating weight control, driven by economic considerations and performance requirements. Excessive coating represents unnecessary material costs, while insufficient coating compromises corrosion protection. This delicate balance underscores the critical importance of accurate measurement methodologies.

The primary objective of this technical research is to comprehensively evaluate the gravimetric method for measuring galvanized steel coating weight. This includes assessing its accuracy, repeatability, and practical implementation challenges in both laboratory and production environments. Additionally, we aim to identify potential improvements to the standard methodology that could enhance measurement precision or operational efficiency.

Secondary objectives include comparing the gravimetric method with alternative measurement technologies such as X-ray fluorescence, magnetic methods, and coulometric techniques. This comparative analysis will provide insights into the relative strengths and limitations of each approach across different application scenarios.

The research also seeks to address emerging challenges in coating weight measurement, particularly for advanced galvanized products featuring zinc alloys or thin organic coatings. These newer materials often present unique measurement challenges that may require modifications to traditional gravimetric protocols.

Finally, this investigation aims to establish a forward-looking perspective on coating weight measurement technologies, identifying potential technological innovations that could supplement or eventually replace gravimetric methods. This includes exploring non-destructive testing methods that could enable real-time, in-line measurement capabilities while maintaining the reference-grade accuracy currently provided by gravimetric analysis.

The gravimetric method for measuring galvanized coating weight represents one of the fundamental analytical techniques in this field. This method, based on determining the mass difference before and after coating removal, has remained relevant despite technological advancements in measurement technologies. Its importance lies in its role as a reference standard against which other measurement techniques are calibrated.

Current industry trends indicate a growing demand for more precise coating weight control, driven by economic considerations and performance requirements. Excessive coating represents unnecessary material costs, while insufficient coating compromises corrosion protection. This delicate balance underscores the critical importance of accurate measurement methodologies.

The primary objective of this technical research is to comprehensively evaluate the gravimetric method for measuring galvanized steel coating weight. This includes assessing its accuracy, repeatability, and practical implementation challenges in both laboratory and production environments. Additionally, we aim to identify potential improvements to the standard methodology that could enhance measurement precision or operational efficiency.

Secondary objectives include comparing the gravimetric method with alternative measurement technologies such as X-ray fluorescence, magnetic methods, and coulometric techniques. This comparative analysis will provide insights into the relative strengths and limitations of each approach across different application scenarios.

The research also seeks to address emerging challenges in coating weight measurement, particularly for advanced galvanized products featuring zinc alloys or thin organic coatings. These newer materials often present unique measurement challenges that may require modifications to traditional gravimetric protocols.

Finally, this investigation aims to establish a forward-looking perspective on coating weight measurement technologies, identifying potential technological innovations that could supplement or eventually replace gravimetric methods. This includes exploring non-destructive testing methods that could enable real-time, in-line measurement capabilities while maintaining the reference-grade accuracy currently provided by gravimetric analysis.

Market Demand Analysis for Precise Coating Weight Measurement

The global market for galvanized steel coating weight measurement technologies has experienced significant growth in recent years, driven by increasing quality control requirements across multiple industries. The automotive sector represents the largest market segment, with approximately 35% of the demand, as manufacturers require precise zinc coating measurements to ensure corrosion resistance in vehicle components. Construction follows closely at 30%, where galvanized steel is extensively used in infrastructure projects requiring strict adherence to coating specifications.

The gravimetric method for measuring coating weight has seen renewed interest despite being a traditional technique. This resurgence is attributed to its high accuracy and reliability when properly implemented. Market research indicates that industries are willing to invest in improved gravimetric testing equipment that offers enhanced precision, faster processing times, and better integration with digital quality management systems.

Regional analysis reveals that Asia-Pacific dominates the market with over 40% share, primarily due to the massive steel production in China, India, and Japan. North America and Europe collectively account for approximately 45% of the market, with these regions focusing on high-precision measurement technologies for specialized applications in aerospace, defense, and premium automotive segments.

The market for coating weight measurement solutions is projected to grow at a compound annual growth rate of 5.8% through 2028, reaching a value exceeding $1.2 billion. This growth is fueled by stringent regulatory standards for corrosion protection in critical infrastructure and transportation applications, as well as the expanding use of galvanized steel in renewable energy installations such as solar mounting systems and wind turbine components.

Customer needs analysis reveals several key requirements driving market demand: increased measurement accuracy (within ±1% tolerance), faster testing procedures to support high-volume production environments, non-destructive testing options that complement traditional gravimetric methods, and integrated data management capabilities for quality assurance documentation and traceability.

Industry surveys indicate that while newer technologies like X-ray fluorescence and electromagnetic methods are gaining popularity for inline measurements, the gravimetric method remains the reference standard for calibration and verification purposes. This has created a specialized market segment for high-precision gravimetric testing equipment with enhanced features such as automated sample preparation, advanced weighing technologies, and sophisticated data analysis software.

The market also shows increasing demand for training and certification programs related to coating weight measurement techniques, as manufacturers seek to ensure proper implementation of testing protocols and accurate interpretation of results.

The gravimetric method for measuring coating weight has seen renewed interest despite being a traditional technique. This resurgence is attributed to its high accuracy and reliability when properly implemented. Market research indicates that industries are willing to invest in improved gravimetric testing equipment that offers enhanced precision, faster processing times, and better integration with digital quality management systems.

Regional analysis reveals that Asia-Pacific dominates the market with over 40% share, primarily due to the massive steel production in China, India, and Japan. North America and Europe collectively account for approximately 45% of the market, with these regions focusing on high-precision measurement technologies for specialized applications in aerospace, defense, and premium automotive segments.

The market for coating weight measurement solutions is projected to grow at a compound annual growth rate of 5.8% through 2028, reaching a value exceeding $1.2 billion. This growth is fueled by stringent regulatory standards for corrosion protection in critical infrastructure and transportation applications, as well as the expanding use of galvanized steel in renewable energy installations such as solar mounting systems and wind turbine components.

Customer needs analysis reveals several key requirements driving market demand: increased measurement accuracy (within ±1% tolerance), faster testing procedures to support high-volume production environments, non-destructive testing options that complement traditional gravimetric methods, and integrated data management capabilities for quality assurance documentation and traceability.

Industry surveys indicate that while newer technologies like X-ray fluorescence and electromagnetic methods are gaining popularity for inline measurements, the gravimetric method remains the reference standard for calibration and verification purposes. This has created a specialized market segment for high-precision gravimetric testing equipment with enhanced features such as automated sample preparation, advanced weighing technologies, and sophisticated data analysis software.

The market also shows increasing demand for training and certification programs related to coating weight measurement techniques, as manufacturers seek to ensure proper implementation of testing protocols and accurate interpretation of results.

Current Gravimetric Method Status and Technical Challenges

The gravimetric method for measuring galvanized steel coating weight represents one of the most established and standardized techniques in the steel industry. Currently, this method is widely adopted globally and is referenced in key international standards such as ASTM A90/A90M, ISO 1460, and JIS H 0401. These standards provide detailed protocols for determining zinc coating mass through precise weight differential measurements before and after chemical stripping.

Despite its widespread acceptance, the current implementation of the gravimetric method faces several significant technical challenges. The process requires destructive testing, meaning that tested samples cannot be used in final products, resulting in material waste and additional production costs. This limitation makes it unsuitable for 100% quality control inspection in high-volume manufacturing environments.

Precision and accuracy concerns persist in practical applications. The method is highly sensitive to procedural variations, with factors such as stripping solution concentration, temperature, and immersion time significantly affecting measurement outcomes. Studies have shown that even minor deviations in these parameters can lead to measurement uncertainties of 3-5%, which may exceed acceptable tolerances in high-precision applications.

Sample preparation represents another critical challenge. The method requires careful specimen cutting, degreasing, and handling to avoid contamination or damage to the coating. Edge effects from sample cutting can introduce systematic errors, as zinc coating at cut edges may be thicker or thinner than the representative area, potentially skewing results.

Time efficiency remains a substantial limitation. The complete procedure typically requires 30-60 minutes per sample, including preparation, stripping, washing, drying, and weighing steps. This extended processing time creates bottlenecks in quality control workflows and delays production feedback loops, particularly problematic in just-in-time manufacturing systems.

Environmental and safety concerns have also emerged as significant challenges. The stripping solutions commonly used contain hazardous chemicals such as hydrochloric acid, chromic acid, or antimony trioxide, which pose workplace safety risks and environmental disposal challenges. Regulatory pressures are increasingly restricting the use of such chemicals, necessitating the development of alternative approaches.

Measurement variability between different laboratories and operators continues to be problematic. Interlaboratory studies have revealed discrepancies of up to 8% for identical samples, highlighting the method's dependence on operator skill and environmental conditions. This variability complicates quality assurance across global supply chains where testing may occur at multiple facilities.

Despite its widespread acceptance, the current implementation of the gravimetric method faces several significant technical challenges. The process requires destructive testing, meaning that tested samples cannot be used in final products, resulting in material waste and additional production costs. This limitation makes it unsuitable for 100% quality control inspection in high-volume manufacturing environments.

Precision and accuracy concerns persist in practical applications. The method is highly sensitive to procedural variations, with factors such as stripping solution concentration, temperature, and immersion time significantly affecting measurement outcomes. Studies have shown that even minor deviations in these parameters can lead to measurement uncertainties of 3-5%, which may exceed acceptable tolerances in high-precision applications.

Sample preparation represents another critical challenge. The method requires careful specimen cutting, degreasing, and handling to avoid contamination or damage to the coating. Edge effects from sample cutting can introduce systematic errors, as zinc coating at cut edges may be thicker or thinner than the representative area, potentially skewing results.

Time efficiency remains a substantial limitation. The complete procedure typically requires 30-60 minutes per sample, including preparation, stripping, washing, drying, and weighing steps. This extended processing time creates bottlenecks in quality control workflows and delays production feedback loops, particularly problematic in just-in-time manufacturing systems.

Environmental and safety concerns have also emerged as significant challenges. The stripping solutions commonly used contain hazardous chemicals such as hydrochloric acid, chromic acid, or antimony trioxide, which pose workplace safety risks and environmental disposal challenges. Regulatory pressures are increasingly restricting the use of such chemicals, necessitating the development of alternative approaches.

Measurement variability between different laboratories and operators continues to be problematic. Interlaboratory studies have revealed discrepancies of up to 8% for identical samples, highlighting the method's dependence on operator skill and environmental conditions. This variability complicates quality assurance across global supply chains where testing may occur at multiple facilities.

Current Gravimetric Method Implementation Protocols

01 Coating weight control methods for galvanized steel

Various methods are employed to control the coating weight of galvanized steel, including air knife systems, mechanical wiping, and roll coating techniques. These methods help achieve precise coating thickness distribution across the steel surface. The coating weight can be adjusted by controlling parameters such as air pressure, distance between nozzles and strip, and wiping force, resulting in optimized zinc consumption and product quality.- Coating weight control methods for galvanized steel: Various methods are employed to control the coating weight of galvanized steel, including air knife systems, gas wiping techniques, and mechanical wiping processes. These methods help to regulate the thickness of the zinc coating applied to the steel substrate, ensuring consistent quality and performance. The coating weight can be adjusted by controlling parameters such as air pressure, distance between nozzles and strip, and wiping angle to meet specific industry standards and application requirements.

- Zinc alloy compositions for optimized coating weight: Specific zinc alloy compositions are developed to optimize the coating weight and performance of galvanized steel. These alloys may include elements such as aluminum, magnesium, silicon, and other metals that enhance corrosion resistance, adhesion, and surface appearance. The composition of the zinc bath affects the coating weight, microstructure, and overall quality of the galvanized layer, allowing manufacturers to tailor the coating properties for different applications and environments.

- Measurement and testing techniques for coating weight: Advanced measurement and testing techniques are utilized to accurately determine and monitor the coating weight of galvanized steel. These include X-ray fluorescence, magnetic methods, gravimetric analysis, and optical systems that provide real-time feedback during production. Quality control processes ensure that the coating weight meets specified standards and remains uniform across the steel surface, which is critical for product performance and durability in various applications.

- Coating weight standards and specifications: Industry standards and specifications define the required coating weights for different grades and applications of galvanized steel. These standards, established by organizations like ASTM, ISO, and JIS, specify minimum coating weights based on intended use, environmental exposure, and performance requirements. Manufacturers must adhere to these specifications to ensure their products meet market demands and regulatory requirements, with coating weights typically measured in grams per square meter (g/m²) or ounces per square foot (oz/ft²).

- Innovative coating technologies for weight optimization: Innovative coating technologies are being developed to optimize the weight and performance of galvanized steel coatings. These include pulse electroplating, vapor deposition techniques, pre-treatment processes, and multi-layer coating systems. These advanced methods allow for more precise control of coating thickness and distribution, resulting in improved corrosion protection with potentially lower zinc consumption. Such technologies help manufacturers balance cost efficiency with performance requirements while meeting environmental regulations.

02 Zinc alloy compositions for galvanized coatings

Specific zinc alloy compositions are developed to enhance the properties of galvanized steel coatings. These alloys typically include elements such as aluminum, magnesium, silicon, and other metals in controlled proportions. The addition of these alloying elements can improve corrosion resistance, adhesion, formability, and surface appearance of the galvanized coating while maintaining optimal coating weight distribution.Expand Specific Solutions03 Measurement and testing of galvanized coating weight

Advanced techniques for measuring and testing galvanized coating weight include X-ray fluorescence, electromagnetic methods, and optical systems. These non-destructive testing methods provide real-time monitoring of coating weight during production, allowing for immediate adjustments to maintain specifications. Quality control procedures ensure consistent coating weight across the steel substrate, which is critical for meeting industry standards and customer requirements.Expand Specific Solutions04 Surface preparation techniques for optimal coating weight

Proper surface preparation of steel substrates is essential for achieving uniform galvanized coating weight. Techniques include degreasing, pickling, fluxing, and pre-treatment processes that remove contaminants and create an optimal surface for zinc adhesion. These preparation methods significantly impact the final coating weight distribution and quality, ensuring better corrosion protection and extending the service life of galvanized products.Expand Specific Solutions05 Post-treatment processes for galvanized coatings

Various post-treatment processes are applied to galvanized steel to enhance coating properties while maintaining optimal weight. These include passivation treatments, chromate conversion coatings, organic sealers, and heat treatments. Post-treatments can improve corrosion resistance, adhesion for subsequent painting, and surface appearance without significantly altering the coating weight, thereby extending product durability in various environmental conditions.Expand Specific Solutions

Key Industry Players in Galvanized Steel Testing

The gravimetric method for measuring galvanized steel coating weight represents a mature technology in a well-established market dominated by major steel producers. The global galvanized steel market is in a growth phase, valued at approximately $200 billion with steady annual expansion driven by construction, automotive, and infrastructure sectors. Leading companies like NIPPON STEEL, JFE Steel, POSCO Holdings, and Tata Steel have developed sophisticated quality control processes incorporating gravimetric testing as standard practice. European manufacturers such as thyssenkrupp Steel Europe and Chinese producers including HBIS and Baoshan Iron & Steel have invested in advanced coating measurement technologies to meet increasingly stringent international standards. The competitive landscape features both traditional steel giants and specialized testing equipment providers like Rigaku Corp., creating a diverse ecosystem of established players with deep technical expertise.

JFE Steel Corp.

Technical Solution: JFE Steel has developed a comprehensive gravimetric method for measuring galvanized steel coating weight that involves precise sample preparation, chemical stripping, and weight differential analysis. Their approach utilizes a standardized acid dissolution technique where samples of specific dimensions (typically 100mm × 100mm) are carefully weighed before and after the zinc coating is removed using inhibited hydrochloric acid solution. JFE's method incorporates temperature control (20-25°C) during the stripping process to ensure consistent dissolution rates without affecting the base steel. The company has refined this technique to achieve measurement accuracy within ±2g/m² for regular galvanized products and ±1.5g/m² for automotive-grade coatings. Their process includes specialized sample handling protocols to prevent contamination and oxidation that could affect weight measurements. JFE has integrated this method into their quality control systems across multiple production facilities, establishing it as their reference method against which other faster techniques are calibrated.

Strengths: High accuracy and precision with well-established protocols that serve as reference standards. Their method includes specialized contamination prevention techniques that improve reliability. Weaknesses: Time-consuming process requiring skilled technicians and laboratory conditions, making it unsuitable for real-time production monitoring. The destructive nature of testing means tested samples cannot be used in final products.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has engineered an advanced gravimetric measurement system for galvanized coating weight determination that combines traditional chemical dissolution with digital precision weighing technology. Their method employs a multi-stage process beginning with standardized sample preparation (typically 50cm² specimens) followed by careful degreasing using non-reactive solvents. The zinc coating is then selectively dissolved using their proprietary inhibited acid solution formulation that minimizes base metal attack while ensuring complete zinc removal. NIPPON STEEL's innovation includes a specialized rinsing and drying protocol that eliminates residual solution effects on weight measurements. Their system incorporates analytical balances with 0.1mg precision housed in vibration-isolated environments to maximize measurement accuracy. The company has documented repeatability of ±1.8g/m² across their production range and has established correlation factors between their gravimetric results and online measurement systems. This method serves as their definitive reference standard for calibrating production equipment and validating coating specifications for critical applications in automotive and construction sectors.

Strengths: Exceptional measurement precision with proprietary inhibited acid formulations that prevent base metal attack. Their system includes environmental controls that minimize external factors affecting measurement accuracy. Weaknesses: Laboratory-based process with significant time requirements (typically 30-45 minutes per sample). The method requires hazardous chemicals handling and generates waste that requires proper disposal protocols.

Critical Technical Innovations in Coating Weight Measurement

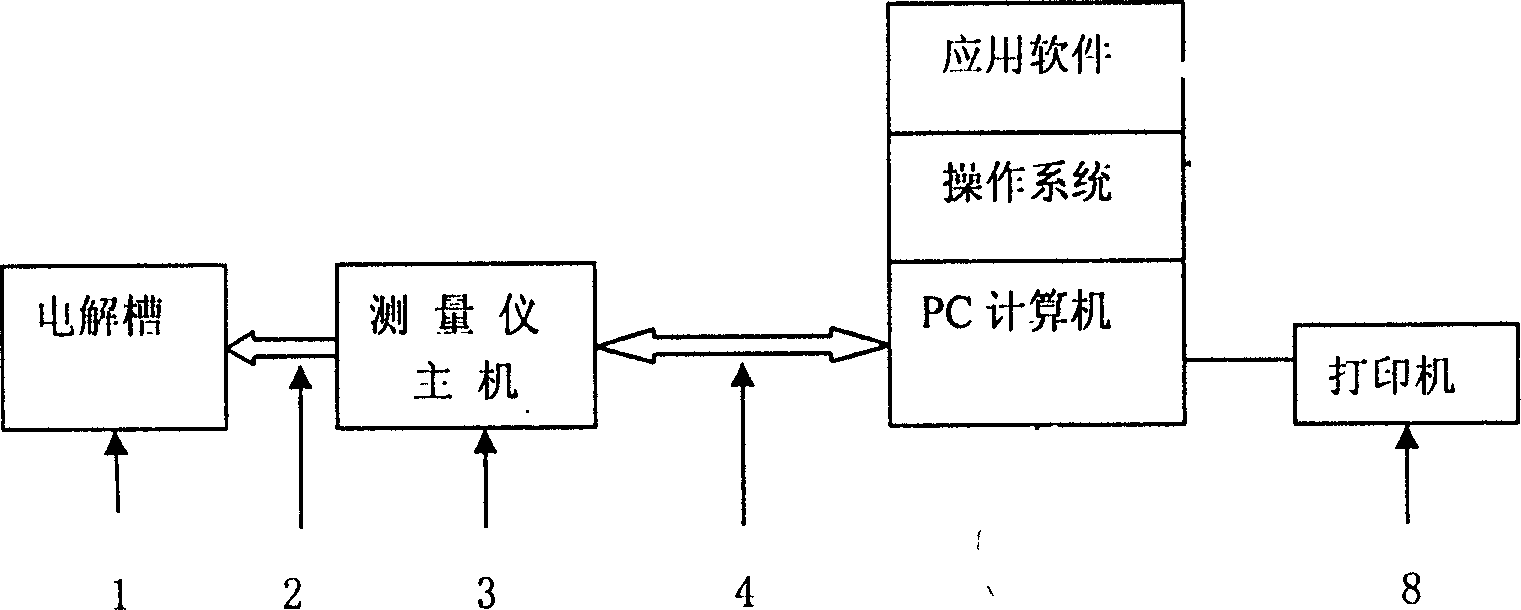

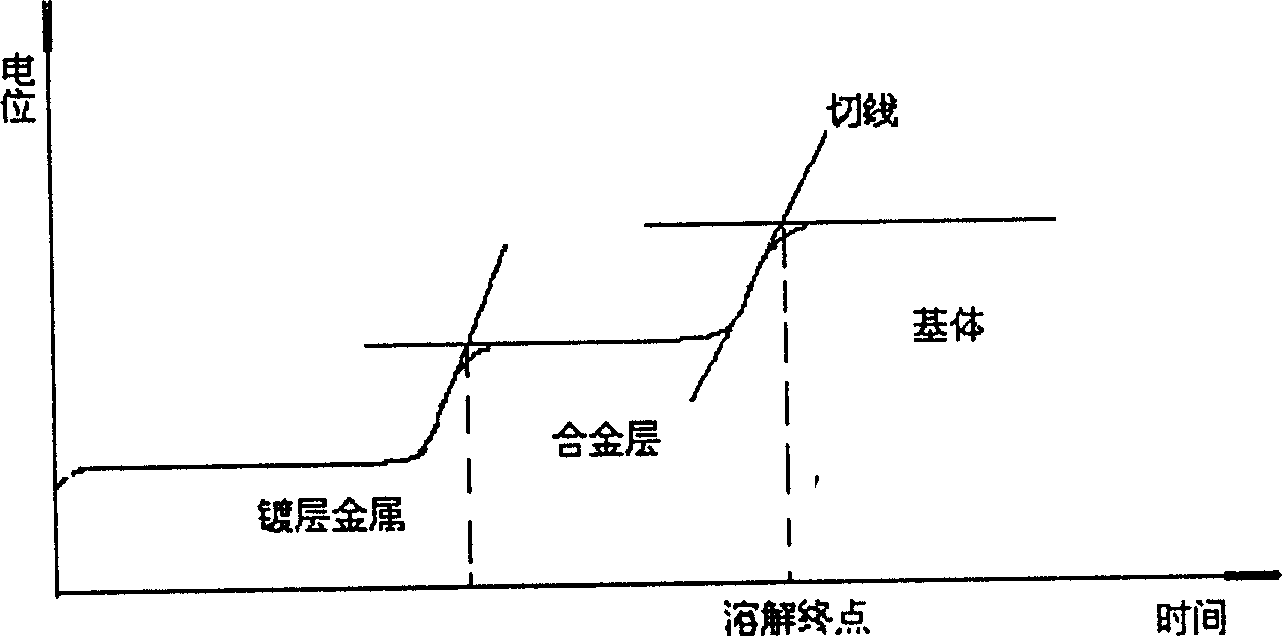

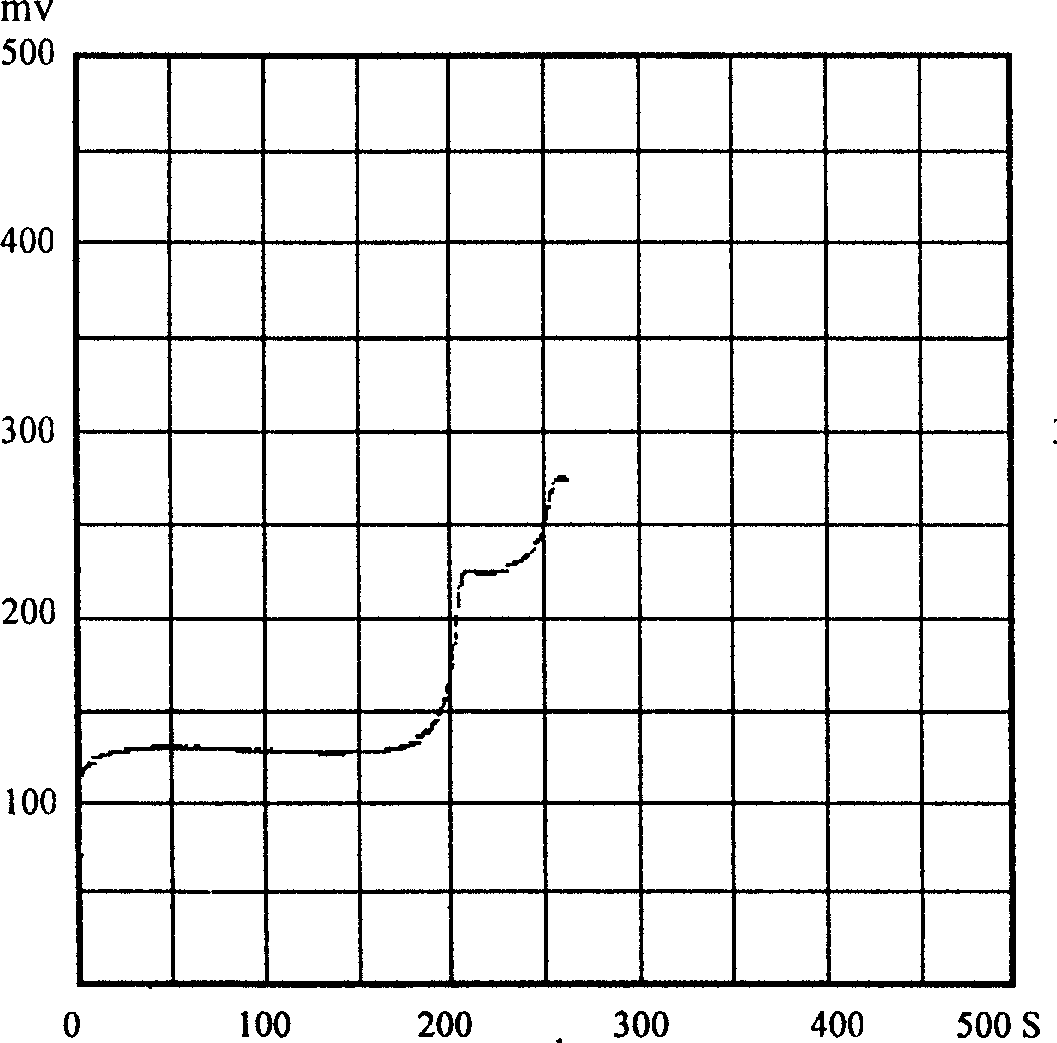

Method for measuring plate coating metal weight

PatentInactiveCN1173164C

Innovation

- The coulomb method is used for electrochemical dissolution. The end point of dissolution is determined by recording the potential change curve and the inflection point of the curve to ensure that the coating is completely dissolved. The thickness of the coating is calculated based on the weight difference before and after electrolysis and the area of the fixture.

Method of manufacturing a galvannealed steel strip product for hot press forming, method of manufacturing a hot-pressed steel component, and galvannealed steel strip product

PatentWO2015007723A1

Innovation

- A method involving galvanizing a steel strip with zinc or zinc alloy, coiling, and batch annealing in a furnace to achieve an iron-zinc solid solution phase with high iron content, reducing zinc evaporation and oxidation, and enabling quicker heating processes for hot press forming.

Quality Control Standards and Compliance Requirements

The gravimetric method for measuring galvanized steel coating weight operates within a framework of stringent quality control standards and compliance requirements that ensure consistency, reliability, and market acceptability of the final product. ASTM A90/A90M stands as the primary international standard governing this testing methodology, providing detailed specifications for sample preparation, testing procedures, and result interpretation. This standard ensures that measurements across different facilities maintain comparable accuracy and precision, establishing a universal benchmark for quality assurance.

In addition to ASTM standards, ISO 1460 offers complementary guidelines specifically addressing hot-dip galvanized coatings on ferrous materials. These standards collectively define acceptable coating weight ranges for various applications, with automotive-grade galvanized steel typically requiring 45-100 g/m² and construction applications demanding 180-600 g/m² depending on environmental exposure conditions.

Quality control protocols mandate regular calibration of analytical balances used in gravimetric testing, with verification against certified reference materials at least quarterly. Statistical process control methods are commonly implemented to monitor measurement stability, with control charts tracking both accuracy and precision metrics. Most standards require measurement uncertainty to remain below ±3% for compliance, with some premium applications demanding even tighter tolerances of ±1.5%.

Documentation requirements constitute another critical compliance aspect, with test reports needing to include sample identification, testing conditions, individual measurements, statistical analysis, and traceability information. Many regulatory frameworks, particularly in automotive and construction sectors, require retention of these records for a minimum of five years.

Regional variations in compliance requirements exist, with European standards under EN 10346 emphasizing environmental considerations in testing procedures, while North American standards focus more on performance metrics. The Japanese Industrial Standards (JIS) incorporate additional corrosion resistance parameters alongside coating weight measurements.

For manufacturers seeking certification, regular third-party audits verify adherence to these standards, with certification bodies like TÜV, SGS, and Bureau Veritas providing independent verification. These certifications often serve as prerequisites for market access in regulated industries and form an integral part of supplier qualification processes for major manufacturers.

In addition to ASTM standards, ISO 1460 offers complementary guidelines specifically addressing hot-dip galvanized coatings on ferrous materials. These standards collectively define acceptable coating weight ranges for various applications, with automotive-grade galvanized steel typically requiring 45-100 g/m² and construction applications demanding 180-600 g/m² depending on environmental exposure conditions.

Quality control protocols mandate regular calibration of analytical balances used in gravimetric testing, with verification against certified reference materials at least quarterly. Statistical process control methods are commonly implemented to monitor measurement stability, with control charts tracking both accuracy and precision metrics. Most standards require measurement uncertainty to remain below ±3% for compliance, with some premium applications demanding even tighter tolerances of ±1.5%.

Documentation requirements constitute another critical compliance aspect, with test reports needing to include sample identification, testing conditions, individual measurements, statistical analysis, and traceability information. Many regulatory frameworks, particularly in automotive and construction sectors, require retention of these records for a minimum of five years.

Regional variations in compliance requirements exist, with European standards under EN 10346 emphasizing environmental considerations in testing procedures, while North American standards focus more on performance metrics. The Japanese Industrial Standards (JIS) incorporate additional corrosion resistance parameters alongside coating weight measurements.

For manufacturers seeking certification, regular third-party audits verify adherence to these standards, with certification bodies like TÜV, SGS, and Bureau Veritas providing independent verification. These certifications often serve as prerequisites for market access in regulated industries and form an integral part of supplier qualification processes for major manufacturers.

Environmental Impact of Gravimetric Testing Procedures

The gravimetric method for measuring galvanized steel coating weight, while effective and widely accepted as a standard procedure, presents several environmental concerns that merit careful consideration. The process involves chemical stripping using acidic or alkaline solutions, which generates hazardous waste streams containing dissolved zinc, iron compounds, and spent chemical reagents.

Primary environmental impacts stem from the disposal of these chemical solutions. Hydrochloric acid, sulfuric acid, and alkaline strippers used in the testing process can contribute to soil acidification and water pollution if improperly managed. The dissolved zinc and other heavy metals present in the waste stream pose particular ecological risks, as these elements can bioaccumulate in aquatic organisms and disrupt ecosystem functions.

Water consumption represents another significant environmental consideration. The gravimetric method requires substantial volumes of water for rinsing specimens before and after stripping, as well as for diluting chemical solutions. In regions facing water scarcity, this resource demand may contribute to broader environmental stresses.

Energy requirements for the gravimetric testing process, while not as substantial as some industrial processes, still contribute to the overall environmental footprint. This includes energy for heating solutions to optimal stripping temperatures, operating ventilation systems, and powering analytical equipment such as precision balances.

Laboratory air quality and worker safety concerns intersect with environmental impacts. Volatile compounds released during the stripping process require proper ventilation systems, which themselves consume energy and potentially release pollutants to the external environment.

Regulatory frameworks worldwide increasingly address these environmental aspects of testing procedures. The EU's REACH regulations, the US EPA guidelines, and similar frameworks in other jurisdictions impose specific requirements for handling, documenting, and disposing of hazardous materials used in testing procedures like the gravimetric method.

Industry best practices have evolved to mitigate these environmental impacts. These include implementing closed-loop recycling systems for chemical solutions, utilizing less hazardous alternative stripping agents where feasible, optimizing solution concentrations to reduce chemical usage, and employing waste treatment processes to neutralize and recover metals before disposal.

Comparative lifecycle assessments indicate that while gravimetric testing has significant environmental impacts per test, its overall contribution remains relatively small within the broader environmental footprint of galvanized steel production. Nevertheless, as testing volumes increase with growing quality control requirements, the cumulative environmental impact becomes increasingly significant.

Primary environmental impacts stem from the disposal of these chemical solutions. Hydrochloric acid, sulfuric acid, and alkaline strippers used in the testing process can contribute to soil acidification and water pollution if improperly managed. The dissolved zinc and other heavy metals present in the waste stream pose particular ecological risks, as these elements can bioaccumulate in aquatic organisms and disrupt ecosystem functions.

Water consumption represents another significant environmental consideration. The gravimetric method requires substantial volumes of water for rinsing specimens before and after stripping, as well as for diluting chemical solutions. In regions facing water scarcity, this resource demand may contribute to broader environmental stresses.

Energy requirements for the gravimetric testing process, while not as substantial as some industrial processes, still contribute to the overall environmental footprint. This includes energy for heating solutions to optimal stripping temperatures, operating ventilation systems, and powering analytical equipment such as precision balances.

Laboratory air quality and worker safety concerns intersect with environmental impacts. Volatile compounds released during the stripping process require proper ventilation systems, which themselves consume energy and potentially release pollutants to the external environment.

Regulatory frameworks worldwide increasingly address these environmental aspects of testing procedures. The EU's REACH regulations, the US EPA guidelines, and similar frameworks in other jurisdictions impose specific requirements for handling, documenting, and disposing of hazardous materials used in testing procedures like the gravimetric method.

Industry best practices have evolved to mitigate these environmental impacts. These include implementing closed-loop recycling systems for chemical solutions, utilizing less hazardous alternative stripping agents where feasible, optimizing solution concentrations to reduce chemical usage, and employing waste treatment processes to neutralize and recover metals before disposal.

Comparative lifecycle assessments indicate that while gravimetric testing has significant environmental impacts per test, its overall contribution remains relatively small within the broader environmental footprint of galvanized steel production. Nevertheless, as testing volumes increase with growing quality control requirements, the cumulative environmental impact becomes increasingly significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!