Galvanized Steel vs Cast Iron: Load-Bearing Capacity

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Background and Performance Objectives

The evolution of load-bearing materials in construction and manufacturing has witnessed significant advancements over centuries, with cast iron and galvanized steel emerging as two prominent materials with distinct historical trajectories. Cast iron, dating back to 5th century BCE China, gained widespread industrial application during the 18th century Industrial Revolution, valued for its excellent compression strength and casting versatility. Galvanized steel, a more recent innovation from the 19th century, combines the tensile strength of steel with corrosion resistance through zinc coating, representing the evolution of ferrous metallurgy.

The fundamental performance objectives when comparing these materials center on their load-bearing capacity under various structural conditions. This technical assessment aims to establish comprehensive metrics for evaluating how each material responds to static loads, dynamic forces, and environmental stressors in both construction and industrial applications. The primary goal is to determine optimal material selection criteria based on specific load requirements, environmental exposure conditions, and economic considerations.

For galvanized steel, key performance objectives include quantifying its superior tensile strength (typically 250-400 MPa), evaluating its weight-to-strength ratio, and assessing its corrosion resistance in diverse environments. Additionally, we seek to establish its fatigue resistance under cyclic loading conditions and long-term structural integrity when exposed to varying temperature ranges and chemical environments.

For cast iron, performance objectives focus on measuring its exceptional compression strength (600-1400 MPa), thermal stability under high-temperature applications, vibration dampening properties, and wear resistance. We also aim to evaluate its brittleness limitations and fracture behavior under sudden impact or stress concentration scenarios.

This technical investigation will establish standardized testing protocols to generate comparable data sets for both materials across identical loading scenarios. The research will incorporate finite element analysis modeling to predict material behavior under complex loading conditions beyond standard testing capabilities. Performance objectives also include developing cost-efficiency metrics that account for material acquisition, fabrication complexity, installation requirements, and lifecycle maintenance considerations.

The ultimate goal of this technical assessment is to develop a decision framework that enables engineers and designers to make evidence-based material selections optimized for specific applications. This framework will consider not only immediate load-bearing requirements but also long-term performance factors including fatigue resistance, environmental durability, and total lifecycle costs, thereby supporting more informed engineering decisions in structural applications.

The fundamental performance objectives when comparing these materials center on their load-bearing capacity under various structural conditions. This technical assessment aims to establish comprehensive metrics for evaluating how each material responds to static loads, dynamic forces, and environmental stressors in both construction and industrial applications. The primary goal is to determine optimal material selection criteria based on specific load requirements, environmental exposure conditions, and economic considerations.

For galvanized steel, key performance objectives include quantifying its superior tensile strength (typically 250-400 MPa), evaluating its weight-to-strength ratio, and assessing its corrosion resistance in diverse environments. Additionally, we seek to establish its fatigue resistance under cyclic loading conditions and long-term structural integrity when exposed to varying temperature ranges and chemical environments.

For cast iron, performance objectives focus on measuring its exceptional compression strength (600-1400 MPa), thermal stability under high-temperature applications, vibration dampening properties, and wear resistance. We also aim to evaluate its brittleness limitations and fracture behavior under sudden impact or stress concentration scenarios.

This technical investigation will establish standardized testing protocols to generate comparable data sets for both materials across identical loading scenarios. The research will incorporate finite element analysis modeling to predict material behavior under complex loading conditions beyond standard testing capabilities. Performance objectives also include developing cost-efficiency metrics that account for material acquisition, fabrication complexity, installation requirements, and lifecycle maintenance considerations.

The ultimate goal of this technical assessment is to develop a decision framework that enables engineers and designers to make evidence-based material selections optimized for specific applications. This framework will consider not only immediate load-bearing requirements but also long-term performance factors including fatigue resistance, environmental durability, and total lifecycle costs, thereby supporting more informed engineering decisions in structural applications.

Market Demand Analysis for Structural Materials

The global structural materials market has witnessed significant shifts in demand patterns, with galvanized steel and cast iron remaining key players in load-bearing applications. Current market analysis indicates the structural materials sector is valued at approximately $180 billion, with annual growth rates between 3.5-4.2% projected through 2028. This growth is primarily driven by expanding construction activities in emerging economies and infrastructure renewal projects in developed nations.

The construction industry represents the largest demand segment for load-bearing materials, accounting for roughly 65% of total consumption. Within this segment, commercial and industrial construction projects demonstrate the strongest preference for galvanized steel due to its superior strength-to-weight ratio and corrosion resistance. Residential construction maintains a more balanced usage pattern between both materials, with regional variations based on building codes and climate considerations.

Infrastructure development constitutes the second-largest market segment, where cast iron maintains significant market share in specific applications such as underground piping systems, bridge components, and heavy machinery foundations. Government infrastructure spending initiatives across North America, Europe, and Asia have created sustained demand for high-capacity load-bearing materials, with particular emphasis on longevity and lifecycle cost considerations.

Market research indicates a growing preference for galvanized steel in modern structural applications, with annual market share increases of approximately 2.3% at the expense of traditional cast iron solutions. This trend is particularly pronounced in regions with aggressive environmental conditions where corrosion resistance delivers significant lifecycle advantages. However, cast iron maintains strong demand in specialized applications requiring vibration dampening, compression strength, and thermal stability.

Price sensitivity analysis reveals that material selection decisions are increasingly influenced by total cost of ownership calculations rather than initial acquisition costs. While galvanized steel typically commands a 15-22% price premium over comparable cast iron components, its reduced maintenance requirements and extended service life often result in favorable long-term economics, particularly in exposed or corrosive environments.

Sustainability considerations are reshaping market demand patterns, with increasing preference for materials offering reduced environmental impact. Galvanized steel's recyclability and lower production energy requirements compared to cast iron have strengthened its position in markets with stringent environmental regulations or green building certification requirements. This trend is expected to accelerate as carbon pricing mechanisms and environmental performance metrics gain broader adoption across global markets.

The construction industry represents the largest demand segment for load-bearing materials, accounting for roughly 65% of total consumption. Within this segment, commercial and industrial construction projects demonstrate the strongest preference for galvanized steel due to its superior strength-to-weight ratio and corrosion resistance. Residential construction maintains a more balanced usage pattern between both materials, with regional variations based on building codes and climate considerations.

Infrastructure development constitutes the second-largest market segment, where cast iron maintains significant market share in specific applications such as underground piping systems, bridge components, and heavy machinery foundations. Government infrastructure spending initiatives across North America, Europe, and Asia have created sustained demand for high-capacity load-bearing materials, with particular emphasis on longevity and lifecycle cost considerations.

Market research indicates a growing preference for galvanized steel in modern structural applications, with annual market share increases of approximately 2.3% at the expense of traditional cast iron solutions. This trend is particularly pronounced in regions with aggressive environmental conditions where corrosion resistance delivers significant lifecycle advantages. However, cast iron maintains strong demand in specialized applications requiring vibration dampening, compression strength, and thermal stability.

Price sensitivity analysis reveals that material selection decisions are increasingly influenced by total cost of ownership calculations rather than initial acquisition costs. While galvanized steel typically commands a 15-22% price premium over comparable cast iron components, its reduced maintenance requirements and extended service life often result in favorable long-term economics, particularly in exposed or corrosive environments.

Sustainability considerations are reshaping market demand patterns, with increasing preference for materials offering reduced environmental impact. Galvanized steel's recyclability and lower production energy requirements compared to cast iron have strengthened its position in markets with stringent environmental regulations or green building certification requirements. This trend is expected to accelerate as carbon pricing mechanisms and environmental performance metrics gain broader adoption across global markets.

Current Technical Limitations and Challenges

The comparative load-bearing capacity between galvanized steel and cast iron presents significant technical challenges that continue to influence material selection in structural engineering applications. Current testing methodologies often fail to accurately represent real-world conditions, particularly when evaluating long-term performance under variable loads. Standard testing protocols typically focus on static load scenarios, whereas actual applications frequently involve dynamic loading, thermal cycling, and environmental exposure that can dramatically alter performance characteristics over time.

Material inconsistency remains a persistent challenge, especially for cast iron, where variations in carbon content, cooling rates during manufacturing, and the presence of impurities can lead to unpredictable mechanical properties. Even within the same production batch, cast iron components may exhibit up to 15% variation in load-bearing capacity, complicating reliable engineering calculations and safety factor determinations.

For galvanized steel, the zinc coating process introduces its own set of technical limitations. The galvanization process can potentially alter the base steel's microstructure, particularly in high-strength steel variants, leading to hydrogen embrittlement or reduced ductility. These metallurgical changes can compromise load-bearing capacity in ways that are difficult to predict using conventional testing methods.

Corrosion resistance versus structural integrity presents another significant technical challenge. While galvanized steel offers superior corrosion protection compared to untreated steel, the relationship between coating thickness and structural performance creates a technical trade-off. Thicker zinc coatings provide enhanced corrosion protection but may affect dimensional tolerances and joint integrity in complex assemblies.

Connection points and joining methods represent critical weak links in both materials' load-bearing systems. Welding galvanized steel requires special considerations due to zinc volatilization, which can create porosity and compromise joint strength. Cast iron's limited weldability necessitates mechanical joining methods that may introduce stress concentration points, reducing overall structural capacity.

Computational modeling limitations further complicate accurate performance prediction. Current finite element analysis (FEA) models struggle to fully account for the anisotropic properties of cast iron or the complex interface behavior between zinc coating and steel substrate under various loading conditions. This modeling gap creates uncertainty in predicting failure modes, particularly in complex geometries or under combined loading scenarios.

Cost-performance optimization remains challenging as material prices fluctuate. The economic viability of galvanized steel versus cast iron solutions shifts with raw material costs, energy prices, and manufacturing technologies, creating a moving target for engineers seeking optimal load-bearing solutions within budget constraints.

Material inconsistency remains a persistent challenge, especially for cast iron, where variations in carbon content, cooling rates during manufacturing, and the presence of impurities can lead to unpredictable mechanical properties. Even within the same production batch, cast iron components may exhibit up to 15% variation in load-bearing capacity, complicating reliable engineering calculations and safety factor determinations.

For galvanized steel, the zinc coating process introduces its own set of technical limitations. The galvanization process can potentially alter the base steel's microstructure, particularly in high-strength steel variants, leading to hydrogen embrittlement or reduced ductility. These metallurgical changes can compromise load-bearing capacity in ways that are difficult to predict using conventional testing methods.

Corrosion resistance versus structural integrity presents another significant technical challenge. While galvanized steel offers superior corrosion protection compared to untreated steel, the relationship between coating thickness and structural performance creates a technical trade-off. Thicker zinc coatings provide enhanced corrosion protection but may affect dimensional tolerances and joint integrity in complex assemblies.

Connection points and joining methods represent critical weak links in both materials' load-bearing systems. Welding galvanized steel requires special considerations due to zinc volatilization, which can create porosity and compromise joint strength. Cast iron's limited weldability necessitates mechanical joining methods that may introduce stress concentration points, reducing overall structural capacity.

Computational modeling limitations further complicate accurate performance prediction. Current finite element analysis (FEA) models struggle to fully account for the anisotropic properties of cast iron or the complex interface behavior between zinc coating and steel substrate under various loading conditions. This modeling gap creates uncertainty in predicting failure modes, particularly in complex geometries or under combined loading scenarios.

Cost-performance optimization remains challenging as material prices fluctuate. The economic viability of galvanized steel versus cast iron solutions shifts with raw material costs, energy prices, and manufacturing technologies, creating a moving target for engineers seeking optimal load-bearing solutions within budget constraints.

Comparative Analysis of Galvanized Steel and Cast Iron Solutions

01 Comparative load-bearing properties of galvanized steel and cast iron

Galvanized steel and cast iron exhibit different load-bearing capacities due to their inherent material properties. Galvanized steel typically offers higher tensile strength and better resistance to bending forces, while cast iron provides superior compression strength. The zinc coating on galvanized steel enhances corrosion resistance without significantly affecting its load-bearing capacity, whereas cast iron's graphite flakes contribute to its brittleness under tension but excellent performance under compression loads.- Comparative load-bearing properties of galvanized steel versus cast iron: Galvanized steel and cast iron exhibit different load-bearing capacities due to their inherent material properties. Galvanized steel typically offers higher tensile strength and better weight-to-strength ratio, making it suitable for applications requiring high load capacity with reduced weight. Cast iron, while heavier, provides excellent compression strength and durability under static loads. The galvanization process enhances steel's corrosion resistance without significantly affecting its load-bearing capacity, whereas cast iron's graphite structure contributes to its compressive strength characteristics.

- Structural applications combining galvanized steel and cast iron components: Hybrid structural systems that combine galvanized steel and cast iron components leverage the advantageous properties of both materials. Galvanized steel is often used for tension members and framework, while cast iron components are utilized for compression elements and nodes. This combination optimizes load distribution in structural applications such as building frameworks, industrial equipment, and infrastructure projects. The interface between these dissimilar metals requires special consideration to prevent galvanic corrosion while maintaining structural integrity and load transfer efficiency.

- Surface treatment effects on load-bearing capacity: Surface treatments significantly impact the load-bearing capacity of both galvanized steel and cast iron. Hot-dip galvanization creates a zinc coating that protects steel from corrosion while maintaining its structural integrity. For cast iron, various surface treatments including specialized coatings and heat treatments can enhance its load-bearing performance by reducing surface defects and improving wear resistance. The thickness and quality of galvanized coatings affect the overall performance of steel structures under load, while proper surface preparation of cast iron components ensures optimal stress distribution and prevents premature failure.

- Connection methods for load-bearing applications: Various connection methods are employed to join galvanized steel and cast iron components in load-bearing applications. Bolted connections are commonly used for both materials, with special consideration for galvanized steel to prevent coating damage. Welding techniques for galvanized steel require removal of the zinc coating at the weld area, while cast iron typically relies on mechanical fastening or specialized welding procedures. The design of connection points significantly influences the overall load-bearing capacity of structures incorporating these materials, with proper engineering ensuring effective load transfer while accommodating the different thermal expansion properties of galvanized steel and cast iron.

- Environmental factors affecting load-bearing durability: Environmental conditions significantly impact the long-term load-bearing capacity of galvanized steel and cast iron structures. Galvanized steel offers superior performance in corrosive environments due to its sacrificial zinc coating, maintaining structural integrity even when exposed to moisture and chemicals. Cast iron, while naturally resistant to compression and wear, is more susceptible to corrosion that can compromise its load-bearing capacity over time. Temperature fluctuations affect both materials differently, with cast iron being more brittle in cold environments and galvanized steel maintaining more consistent performance across temperature ranges. Proper material selection based on environmental exposure is crucial for ensuring optimal load-bearing performance throughout the service life of structural components.

02 Structural applications combining galvanized steel and cast iron

Hybrid structural systems utilizing both galvanized steel and cast iron leverage the complementary properties of each material. Galvanized steel components are often used for tension-bearing elements like beams and supports, while cast iron components are employed for compression-bearing elements such as columns and bases. This combination optimizes load distribution in structural frameworks, particularly in construction applications where different types of loads must be accommodated while maintaining corrosion resistance.Expand Specific Solutions03 Surface treatment effects on load-bearing capacity

Surface treatments significantly impact the load-bearing capacity of both galvanized steel and cast iron. Hot-dip galvanization creates a metallurgically bonded zinc coating that protects steel without compromising its structural integrity, while various treatments for cast iron, such as graphitization or surface hardening, can enhance its load-bearing performance. The thickness and quality of galvanized coatings affect durability under load, particularly in environments where corrosion might otherwise compromise structural integrity.Expand Specific Solutions04 Environmental factors affecting load-bearing durability

Environmental conditions significantly impact the long-term load-bearing capacity of both galvanized steel and cast iron structures. Galvanized steel maintains its structural integrity in corrosive environments due to its sacrificial zinc coating, while cast iron may experience graphitic corrosion in certain conditions, potentially reducing its load-bearing capacity over time. Temperature fluctuations, humidity levels, and exposure to chemicals can accelerate degradation processes, necessitating specific design considerations for maintaining load-bearing performance throughout the intended service life.Expand Specific Solutions05 Innovative connection methods for load transfer

Advanced connection techniques between galvanized steel and cast iron components are crucial for effective load transfer in composite structures. Specialized fastening systems, welding protocols adapted for dissimilar metals, and interface treatments help prevent galvanic corrosion while maintaining structural integrity. These connection methods must accommodate the different thermal expansion properties of the materials while ensuring that loads are distributed optimally across the structure, preventing stress concentration that could lead to premature failure.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The galvanized steel versus cast iron load-bearing capacity market is in a mature growth phase, with an estimated global market size exceeding $150 billion. Major steel manufacturers like NIPPON STEEL, POSCO Holdings, JFE Steel, and Baoshan Iron & Steel dominate the galvanized steel segment, leveraging advanced coating technologies and continuous production innovations. Cast iron technology remains well-established, with companies such as Hyundai Steel, JSW Steel, and Wuhan Iron & Steel maintaining significant market share through specialized high-strength applications. The competitive landscape shows increasing technical differentiation, with companies like Bekaert and Riken Corp developing specialized coatings and alloys to enhance load-bearing properties while reducing weight and improving corrosion resistance, driving incremental innovation in this established market.

JFE Steel Corp.

Technical Solution: JFE Steel has developed advanced high-strength galvanized steel products specifically engineered for load-bearing applications. Their proprietary hot-dip galvanizing process creates a zinc coating that bonds metallurgically with the steel substrate, providing superior corrosion resistance while maintaining structural integrity. JFE's galvanized steel achieves tensile strengths exceeding 780 MPa while maintaining excellent formability. Their research has demonstrated that their high-strength galvanized steel can achieve comparable load-bearing capacity to cast iron while being up to 30% lighter. JFE has also pioneered dual-phase galvanized steel structures that combine high strength with enhanced ductility, making them suitable for applications requiring both load-bearing capacity and impact resistance.

Strengths: Superior strength-to-weight ratio compared to cast iron, excellent corrosion resistance, and good formability. Weaknesses: Higher initial cost than standard galvanized steel, potential for galvanic corrosion when in contact with certain metals, and lower heat resistance compared to cast iron.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed SuperDyma®, an advanced galvanized steel product with significantly enhanced load-bearing capacity. This technology incorporates aluminum, magnesium, and silicon into the zinc coating, creating a product that offers up to 10-20 times the corrosion resistance of conventional galvanized steel while maintaining structural integrity. Their research shows that properly designed galvanized steel structures can achieve load capacities comparable to cast iron in many applications while reducing weight by 25-40%. NIPPON STEEL's high-tensile galvanized products achieve yield strengths of 550-980 MPa, approaching the compressive strength advantages of cast iron but with superior tensile properties. Their galvanized steel solutions incorporate specialized coating thickness control technology that ensures uniform protection without compromising mechanical properties.

Strengths: Excellent corrosion resistance even in harsh environments, significant weight reduction compared to cast iron, and superior tensile strength properties. Weaknesses: Lower thermal stability than cast iron, higher production costs for specialized coatings, and potential for coating damage during installation that can compromise load-bearing capacity.

Critical Material Properties and Engineering Considerations

Galvanized steel having good weldabity and method for manufacturing the same

PatentActiveKR1020150066366A

Innovation

- A galvanized steel sheet with a controlled Ni pretreatment layer, an Fe-Al-Zn or Fe-Mn-Al-Zn interfacial suppression layer, and an Fe-Mn-Zn alloy layer is formed to increase the melting point of the plating layer, preventing it from melting and penetrating into the grain boundary during welding.

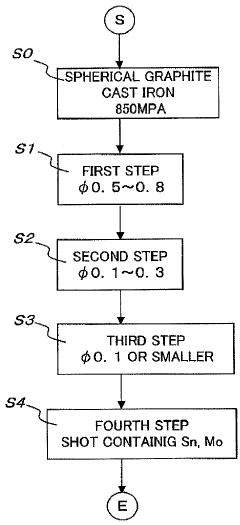

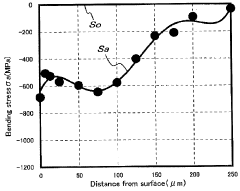

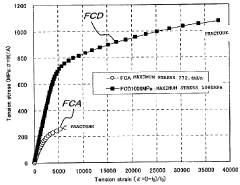

Method for improving fatigue strength of cast iron material

PatentInactiveUS9340846B2

Innovation

- A method involving multiple shot peening treatments with specific hardness and particle size shots, followed by normalization heat treatment, to enhance the fatigue strength of spherical graphite cast iron to match that of carburized and hardened steel materials, without the need for carburizing and hardening processes.

Corrosion Resistance and Environmental Factors

Corrosion resistance represents a critical factor in the comparative analysis of galvanized steel and cast iron for load-bearing applications. Galvanized steel, featuring a protective zinc coating, demonstrates superior corrosion resistance in most environmental conditions. The zinc layer creates a sacrificial barrier that corrodes preferentially, protecting the underlying steel structure even when the coating sustains minor damage. This galvanic protection mechanism extends the material's service life significantly in outdoor and humid environments.

Cast iron, conversely, forms a natural oxide layer that provides some inherent protection, but remains more vulnerable to progressive corrosion, particularly in high-moisture settings. The corrosion behavior of cast iron typically manifests as surface rusting that, while initially slow-progressing, can accelerate over time and compromise structural integrity in load-bearing applications.

Environmental exposure conditions dramatically influence the performance differential between these materials. In coastal environments with high salt content, galvanized steel outperforms cast iron substantially, maintaining its load-bearing capacity for extended periods despite aggressive chloride exposure. However, in highly acidic industrial environments, both materials face accelerated degradation, though galvanized steel generally maintains its structural advantage longer.

Temperature fluctuations also affect corrosion resistance differently across these materials. Cast iron demonstrates better stability across temperature ranges, with minimal expansion and contraction that could compromise protective layers. Galvanized steel, while generally resilient, may experience accelerated zinc coating deterioration under extreme temperature cycling conditions.

Soil contact represents another critical environmental factor, particularly for buried or ground-contact load-bearing components. Galvanized steel performs exceptionally well in neutral soils but may experience accelerated corrosion in highly acidic or alkaline soil conditions. Cast iron typically exhibits more consistent, albeit generally slower, corrosion rates across varying soil compositions.

The environmental sustainability aspects cannot be overlooked in contemporary engineering assessments. Galvanized steel offers advantages through its recyclability and the relatively lower environmental impact of zinc coating processes compared to traditional cast iron production. However, cast iron's exceptional longevity in certain applications and its complete recyclability present counterbalancing environmental benefits that merit consideration in lifecycle assessments of load-bearing structures.

Cast iron, conversely, forms a natural oxide layer that provides some inherent protection, but remains more vulnerable to progressive corrosion, particularly in high-moisture settings. The corrosion behavior of cast iron typically manifests as surface rusting that, while initially slow-progressing, can accelerate over time and compromise structural integrity in load-bearing applications.

Environmental exposure conditions dramatically influence the performance differential between these materials. In coastal environments with high salt content, galvanized steel outperforms cast iron substantially, maintaining its load-bearing capacity for extended periods despite aggressive chloride exposure. However, in highly acidic industrial environments, both materials face accelerated degradation, though galvanized steel generally maintains its structural advantage longer.

Temperature fluctuations also affect corrosion resistance differently across these materials. Cast iron demonstrates better stability across temperature ranges, with minimal expansion and contraction that could compromise protective layers. Galvanized steel, while generally resilient, may experience accelerated zinc coating deterioration under extreme temperature cycling conditions.

Soil contact represents another critical environmental factor, particularly for buried or ground-contact load-bearing components. Galvanized steel performs exceptionally well in neutral soils but may experience accelerated corrosion in highly acidic or alkaline soil conditions. Cast iron typically exhibits more consistent, albeit generally slower, corrosion rates across varying soil compositions.

The environmental sustainability aspects cannot be overlooked in contemporary engineering assessments. Galvanized steel offers advantages through its recyclability and the relatively lower environmental impact of zinc coating processes compared to traditional cast iron production. However, cast iron's exceptional longevity in certain applications and its complete recyclability present counterbalancing environmental benefits that merit consideration in lifecycle assessments of load-bearing structures.

Cost-Benefit Analysis and Implementation Strategies

When evaluating galvanized steel versus cast iron for load-bearing applications, cost-benefit analysis reveals significant economic implications across the material lifecycle. Initial acquisition costs typically favor galvanized steel, which is approximately 15-30% less expensive than comparable cast iron components. This price advantage stems from more efficient manufacturing processes and lower raw material costs. However, the total cost of ownership extends beyond purchase price to include installation, maintenance, and replacement considerations.

Installation costs for galvanized steel structures generally run 10-20% lower than cast iron due to the material's lighter weight, which reduces transportation expenses and simplifies handling during construction. This weight differential translates to approximately 40-60% savings in labor hours for typical installation projects, particularly in applications where manual handling is required.

Maintenance requirements present a notable divergence between these materials. Galvanized steel's zinc coating provides corrosion protection that can last 20-50 years depending on environmental exposure, requiring minimal maintenance during this period. Cast iron, while naturally resistant to surface corrosion through its oxide layer formation, may require more frequent inspection and treatment in certain environments, particularly where moisture is persistent.

Implementation strategies should consider application-specific factors that influence optimal material selection. For structures requiring frequent disassembly or modification, galvanized steel offers superior flexibility and lower labor costs during reconfiguration. Conversely, cast iron may prove more economical in applications with extreme cyclic loading or where vibration dampening is critical, as its replacement frequency would be lower despite higher initial costs.

Risk assessment must factor into implementation planning, with galvanized steel presenting lower catastrophic failure risks but potentially higher gradual degradation concerns in certain environments. Cast iron's brittle failure mode requires more conservative safety factors but offers more predictable performance under consistent loading conditions.

Lifecycle analysis indicates that while galvanized steel typically offers better short to medium-term economics, cast iron may provide superior long-term value in applications exceeding 50 years of service life, particularly in stable loading conditions with minimal environmental exposure. Organizations should develop implementation timelines that account for these lifecycle differences, potentially phasing material selection based on immediate budget constraints versus long-term performance requirements.

Installation costs for galvanized steel structures generally run 10-20% lower than cast iron due to the material's lighter weight, which reduces transportation expenses and simplifies handling during construction. This weight differential translates to approximately 40-60% savings in labor hours for typical installation projects, particularly in applications where manual handling is required.

Maintenance requirements present a notable divergence between these materials. Galvanized steel's zinc coating provides corrosion protection that can last 20-50 years depending on environmental exposure, requiring minimal maintenance during this period. Cast iron, while naturally resistant to surface corrosion through its oxide layer formation, may require more frequent inspection and treatment in certain environments, particularly where moisture is persistent.

Implementation strategies should consider application-specific factors that influence optimal material selection. For structures requiring frequent disassembly or modification, galvanized steel offers superior flexibility and lower labor costs during reconfiguration. Conversely, cast iron may prove more economical in applications with extreme cyclic loading or where vibration dampening is critical, as its replacement frequency would be lower despite higher initial costs.

Risk assessment must factor into implementation planning, with galvanized steel presenting lower catastrophic failure risks but potentially higher gradual degradation concerns in certain environments. Cast iron's brittle failure mode requires more conservative safety factors but offers more predictable performance under consistent loading conditions.

Lifecycle analysis indicates that while galvanized steel typically offers better short to medium-term economics, cast iron may provide superior long-term value in applications exceeding 50 years of service life, particularly in stable loading conditions with minimal environmental exposure. Organizations should develop implementation timelines that account for these lifecycle differences, potentially phasing material selection based on immediate budget constraints versus long-term performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!