How to Apply a Topcoat on Galvanized Steel for Added Protection

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Coating Background and Objectives

Galvanized steel has been a cornerstone material in various industries since its commercial development in the 19th century. The process of galvanization, which involves coating steel with a protective layer of zinc, was first patented in 1837 by French engineer Stanislas Sorel. This innovation marked a significant advancement in metal protection technology, providing steel with enhanced corrosion resistance while maintaining its structural integrity.

The evolution of galvanized steel coating technologies has progressed through several key phases. Initially, hot-dip galvanizing dominated the market, where steel is immersed in molten zinc. This was followed by the development of electrogalvanizing in the mid-20th century, offering more precise coating control. Recent decades have seen the emergence of zinc-aluminum coatings and various alloy combinations, each pushing the boundaries of protection capabilities.

Despite these advancements, galvanized steel still faces limitations in extreme environments or specialized applications where aesthetic considerations are paramount. The zinc coating, while effective against corrosion, can develop white rust or lose its appearance over time, particularly when exposed to harsh conditions or certain chemicals.

The primary objective of topcoat application on galvanized steel is to extend the material's service life by providing an additional barrier against environmental factors. This dual-protection system aims to combine the sacrificial protection of zinc with the barrier protection of organic coatings, creating a synergistic effect that significantly outperforms either method alone.

Secondary objectives include enhancing the aesthetic appeal of galvanized surfaces, which is particularly important in architectural and consumer product applications. Additionally, specialized topcoats can provide supplementary properties such as chemical resistance, UV protection, or specific friction characteristics that pure galvanized surfaces cannot offer.

Current market trends indicate growing demand for environmentally friendly coating solutions with reduced volatile organic compounds (VOCs) and elimination of heavy metals. This shift is driven by increasingly stringent environmental regulations worldwide and growing consumer awareness of sustainability issues.

The technical trajectory is moving toward smart coatings that can self-heal minor damage, indicate corrosion before visible failure, or adapt to changing environmental conditions. Research is also focused on developing coating systems that can be applied more efficiently, with faster curing times and reduced energy requirements during application.

Understanding this historical context and current trajectory is essential for developing effective topcoating strategies that align with both market demands and technological possibilities in the protective coating sector.

The evolution of galvanized steel coating technologies has progressed through several key phases. Initially, hot-dip galvanizing dominated the market, where steel is immersed in molten zinc. This was followed by the development of electrogalvanizing in the mid-20th century, offering more precise coating control. Recent decades have seen the emergence of zinc-aluminum coatings and various alloy combinations, each pushing the boundaries of protection capabilities.

Despite these advancements, galvanized steel still faces limitations in extreme environments or specialized applications where aesthetic considerations are paramount. The zinc coating, while effective against corrosion, can develop white rust or lose its appearance over time, particularly when exposed to harsh conditions or certain chemicals.

The primary objective of topcoat application on galvanized steel is to extend the material's service life by providing an additional barrier against environmental factors. This dual-protection system aims to combine the sacrificial protection of zinc with the barrier protection of organic coatings, creating a synergistic effect that significantly outperforms either method alone.

Secondary objectives include enhancing the aesthetic appeal of galvanized surfaces, which is particularly important in architectural and consumer product applications. Additionally, specialized topcoats can provide supplementary properties such as chemical resistance, UV protection, or specific friction characteristics that pure galvanized surfaces cannot offer.

Current market trends indicate growing demand for environmentally friendly coating solutions with reduced volatile organic compounds (VOCs) and elimination of heavy metals. This shift is driven by increasingly stringent environmental regulations worldwide and growing consumer awareness of sustainability issues.

The technical trajectory is moving toward smart coatings that can self-heal minor damage, indicate corrosion before visible failure, or adapt to changing environmental conditions. Research is also focused on developing coating systems that can be applied more efficiently, with faster curing times and reduced energy requirements during application.

Understanding this historical context and current trajectory is essential for developing effective topcoating strategies that align with both market demands and technological possibilities in the protective coating sector.

Market Analysis for Enhanced Corrosion Protection Solutions

The global market for enhanced corrosion protection solutions for galvanized steel continues to expand significantly, driven by increasing infrastructure development and growing awareness of lifecycle cost benefits. Currently valued at approximately 7.2 billion USD, this market segment is projected to grow at a compound annual growth rate of 5.8% through 2028, according to recent industry analyses.

The construction sector remains the largest consumer of galvanized steel with topcoat applications, accounting for roughly 42% of market share. This dominance stems from the dual protection requirements in both residential and commercial buildings, particularly in coastal and high-humidity regions where corrosion risks are elevated. Infrastructure projects, including bridges, highways, and utility structures, constitute the second-largest market segment at 27%.

Regional market distribution shows notable variations, with Asia-Pacific leading consumption at 38% of global demand, primarily driven by China and India's rapid industrialization and infrastructure development. North America follows at 24%, with particular emphasis on premium protection systems for critical infrastructure. Europe accounts for 22% of the market, where stringent environmental regulations have accelerated the adoption of eco-friendly topcoat solutions.

Customer demand patterns reveal a clear shift toward integrated protection systems that offer extended service life guarantees. End-users increasingly prioritize total cost of ownership over initial application costs, creating market opportunities for premium solutions that can demonstrate superior long-term performance metrics. Market research indicates that products offering 25+ years of protection without maintenance can command price premiums of 30-40% over standard solutions.

Environmental regulations continue to reshape market dynamics, with VOC-compliant and chromate-free systems gaining significant market share. Water-based topcoat systems have seen a 34% increase in adoption over the past five years, despite performance limitations in certain applications. This trend is expected to accelerate as regulatory frameworks become more stringent globally.

Emerging market opportunities exist in specialized sectors such as renewable energy infrastructure, where the combination of galvanized steel with advanced topcoat systems addresses the unique challenges of solar mounting structures and wind turbine components. These applications require exceptional UV resistance alongside traditional corrosion protection, creating a premium market segment growing at nearly twice the rate of the overall market.

Customer feedback analysis indicates that ease of application and field repairability are becoming increasingly important selection criteria, particularly for maintenance-intensive industries. Solutions that can be effectively applied in field conditions without specialized equipment are gaining market share, especially in the utilities and telecommunications sectors.

The construction sector remains the largest consumer of galvanized steel with topcoat applications, accounting for roughly 42% of market share. This dominance stems from the dual protection requirements in both residential and commercial buildings, particularly in coastal and high-humidity regions where corrosion risks are elevated. Infrastructure projects, including bridges, highways, and utility structures, constitute the second-largest market segment at 27%.

Regional market distribution shows notable variations, with Asia-Pacific leading consumption at 38% of global demand, primarily driven by China and India's rapid industrialization and infrastructure development. North America follows at 24%, with particular emphasis on premium protection systems for critical infrastructure. Europe accounts for 22% of the market, where stringent environmental regulations have accelerated the adoption of eco-friendly topcoat solutions.

Customer demand patterns reveal a clear shift toward integrated protection systems that offer extended service life guarantees. End-users increasingly prioritize total cost of ownership over initial application costs, creating market opportunities for premium solutions that can demonstrate superior long-term performance metrics. Market research indicates that products offering 25+ years of protection without maintenance can command price premiums of 30-40% over standard solutions.

Environmental regulations continue to reshape market dynamics, with VOC-compliant and chromate-free systems gaining significant market share. Water-based topcoat systems have seen a 34% increase in adoption over the past five years, despite performance limitations in certain applications. This trend is expected to accelerate as regulatory frameworks become more stringent globally.

Emerging market opportunities exist in specialized sectors such as renewable energy infrastructure, where the combination of galvanized steel with advanced topcoat systems addresses the unique challenges of solar mounting structures and wind turbine components. These applications require exceptional UV resistance alongside traditional corrosion protection, creating a premium market segment growing at nearly twice the rate of the overall market.

Customer feedback analysis indicates that ease of application and field repairability are becoming increasingly important selection criteria, particularly for maintenance-intensive industries. Solutions that can be effectively applied in field conditions without specialized equipment are gaining market share, especially in the utilities and telecommunications sectors.

Current Topcoat Technologies and Technical Barriers

The current landscape of topcoat technologies for galvanized steel protection encompasses several established systems with varying performance characteristics. Liquid-based coating systems remain dominant, including polyurethane, epoxy, and acrylic formulations. Polyurethane coatings offer excellent UV resistance and color retention, making them suitable for exterior applications where aesthetic longevity is crucial. Epoxy systems provide superior chemical and abrasion resistance but tend to chalk when exposed to prolonged UV radiation. Acrylic coatings balance cost-effectiveness with decent performance characteristics, particularly in less demanding environments.

Powder coating technology has gained significant market share due to its environmental benefits and durability. These solvent-free systems create a uniform, thick protective layer through electrostatic application and thermal curing. Advanced powder formulations now incorporate zinc-rich primers specifically designed to complement galvanized substrates, enhancing the overall corrosion protection system.

Nano-enhanced coatings represent the cutting edge of topcoat technology, incorporating particles at the nanoscale to dramatically improve performance properties. These formulations can self-heal minor scratches, repel water more effectively, and provide enhanced UV protection without increasing coating thickness.

Despite these advancements, significant technical barriers persist in topcoat application on galvanized steel. Surface preparation remains the foremost challenge, as zinc surfaces develop passivation layers that can compromise coating adhesion. Traditional mechanical preparation methods risk damaging the galvanized layer, while chemical treatments must be precisely controlled to avoid over-etching.

Compatibility issues between coating chemistries and zinc substrates continue to challenge manufacturers. Certain coating systems can react with zinc to produce hydrogen gas, creating bubbles and adhesion failures. This chemical incompatibility necessitates specialized primer systems, adding complexity and cost to the protection system.

Environmental regulations present evolving constraints on coating formulations. VOC restrictions have accelerated the shift toward water-based and powder systems, but these alternatives sometimes deliver inferior performance in harsh environments compared to traditional solvent-based coatings. The industry faces the ongoing challenge of developing environmentally compliant formulations that maintain or exceed performance standards.

Application process control presents another significant barrier. Galvanized steel's thermal properties differ from standard steel, requiring precise temperature management during curing to prevent coating defects. Humidity control during application is also critical, as moisture interaction with zinc surfaces can compromise coating integrity before curing completes.

Quality assurance remains challenging due to the complex interaction between the galvanized substrate and topcoat. Non-destructive testing methods for adhesion and coverage uniformity are still evolving, making quality control more reliant on destructive testing and visual inspection than ideal for high-reliability applications.

Powder coating technology has gained significant market share due to its environmental benefits and durability. These solvent-free systems create a uniform, thick protective layer through electrostatic application and thermal curing. Advanced powder formulations now incorporate zinc-rich primers specifically designed to complement galvanized substrates, enhancing the overall corrosion protection system.

Nano-enhanced coatings represent the cutting edge of topcoat technology, incorporating particles at the nanoscale to dramatically improve performance properties. These formulations can self-heal minor scratches, repel water more effectively, and provide enhanced UV protection without increasing coating thickness.

Despite these advancements, significant technical barriers persist in topcoat application on galvanized steel. Surface preparation remains the foremost challenge, as zinc surfaces develop passivation layers that can compromise coating adhesion. Traditional mechanical preparation methods risk damaging the galvanized layer, while chemical treatments must be precisely controlled to avoid over-etching.

Compatibility issues between coating chemistries and zinc substrates continue to challenge manufacturers. Certain coating systems can react with zinc to produce hydrogen gas, creating bubbles and adhesion failures. This chemical incompatibility necessitates specialized primer systems, adding complexity and cost to the protection system.

Environmental regulations present evolving constraints on coating formulations. VOC restrictions have accelerated the shift toward water-based and powder systems, but these alternatives sometimes deliver inferior performance in harsh environments compared to traditional solvent-based coatings. The industry faces the ongoing challenge of developing environmentally compliant formulations that maintain or exceed performance standards.

Application process control presents another significant barrier. Galvanized steel's thermal properties differ from standard steel, requiring precise temperature management during curing to prevent coating defects. Humidity control during application is also critical, as moisture interaction with zinc surfaces can compromise coating integrity before curing completes.

Quality assurance remains challenging due to the complex interaction between the galvanized substrate and topcoat. Non-destructive testing methods for adhesion and coverage uniformity are still evolving, making quality control more reliant on destructive testing and visual inspection than ideal for high-reliability applications.

Established Topcoat Application Methodologies

01 Polymer-based protective topcoats

Polymer-based coatings provide excellent protection for galvanized steel surfaces. These formulations typically include acrylic, polyurethane, or epoxy polymers that form a durable barrier against environmental factors. The polymer matrix creates a flexible yet strong film that adheres well to the galvanized substrate while offering resistance to UV radiation, moisture, and chemical exposure. These coatings can be formulated with various additives to enhance specific protective properties while maintaining good adhesion to the zinc surface.- Polymer-based protective topcoats for galvanized steel: Polymer-based coatings provide excellent protection for galvanized steel surfaces. These formulations typically include acrylic, polyurethane, or epoxy polymers that form a durable barrier against corrosion and environmental damage. The polymers create a flexible yet tough film that adheres well to the zinc surface while offering resistance to UV radiation, moisture, and chemical exposure. These coatings can be formulated with various additives to enhance specific protective properties.

- Chromate-free corrosion inhibitors for galvanized steel protection: Environmental concerns have driven the development of chromate-free corrosion inhibitors for galvanized steel protection. These alternative formulations utilize compounds such as phosphates, silicates, molybdates, and organic inhibitors to provide effective corrosion resistance without the toxicity associated with hexavalent chromium. These inhibitors work by forming protective films on the zinc surface or by neutralizing corrosive agents. The topcoats incorporating these inhibitors offer comparable or superior protection while meeting stringent environmental regulations.

- Nano-enhanced protective coatings for galvanized steel: Nanotechnology has enabled the development of advanced protective coatings for galvanized steel. These formulations incorporate nanoparticles such as nano-silica, nano-zinc oxide, or carbon nanotubes to enhance barrier properties, mechanical strength, and corrosion resistance. The nanoparticles fill microscopic voids in the coating matrix, creating a more impermeable barrier against corrosive elements. Additionally, some nanoparticles provide self-healing capabilities or active corrosion inhibition, significantly extending the service life of the galvanized steel substrate.

- Water-based eco-friendly topcoat systems: Water-based topcoat systems offer environmentally friendly protection for galvanized steel surfaces. These formulations replace traditional solvent-based systems with water as the primary carrier, significantly reducing VOC emissions and improving workplace safety. Advanced water-based technologies incorporate specialized dispersants, surfactants, and coalescence agents to ensure proper film formation and adhesion to the galvanized substrate. These coatings provide effective protection against corrosion, UV degradation, and physical damage while meeting increasingly stringent environmental regulations.

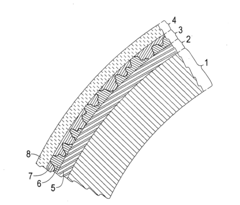

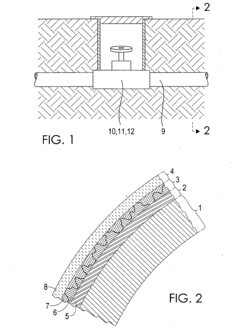

- Multi-layer protective coating systems for severe environments: Multi-layer coating systems provide enhanced protection for galvanized steel in severe environments. These systems typically consist of a primer specifically formulated for adhesion to the zinc surface, intermediate layers containing corrosion inhibitors, and a topcoat designed for resistance to the specific environmental challenges. The combination of layers creates a synergistic protective effect, with each layer serving specific functions such as adhesion promotion, barrier protection, corrosion inhibition, and UV resistance. This approach is particularly effective for galvanized steel exposed to marine environments, industrial atmospheres, or extreme weather conditions.

02 Corrosion inhibitor additives

Specialized corrosion inhibitors can be incorporated into topcoat formulations to provide enhanced protection for galvanized steel. These additives work by forming protective complexes with metal ions or creating passive layers that prevent corrosive agents from reaching the substrate. Common inhibitors include phosphates, silicates, and organic compounds that selectively bind to zinc surfaces. When properly formulated in the topcoat system, these inhibitors significantly extend the service life of galvanized steel structures even in harsh environments.Expand Specific Solutions03 Multi-layer coating systems

Multi-layer coating systems provide comprehensive protection for galvanized steel through complementary protective mechanisms. These systems typically consist of a primer directly applied to the galvanized surface, followed by one or more topcoat layers. The primer ensures excellent adhesion to the zinc substrate while providing initial corrosion resistance. Intermediate layers may add barrier properties, while the final topcoat delivers weather resistance, color stability, and aesthetic finish. This layered approach creates redundant protection that significantly outperforms single-layer systems.Expand Specific Solutions04 Nano-enhanced protective coatings

Nano-enhanced coatings represent an advanced approach to galvanized steel protection. These formulations incorporate nanoscale materials such as silica, zinc oxide, or carbon nanotubes to dramatically improve protective properties. The nanomaterials create a dense, impermeable barrier that prevents moisture and corrosive agents from reaching the substrate. Additionally, some nano-additives provide self-healing capabilities or photocatalytic properties that actively combat degradation. These coatings typically offer superior durability with thinner application layers compared to conventional systems.Expand Specific Solutions05 Environmentally-friendly protective solutions

Environmentally-friendly topcoat solutions for galvanized steel have been developed to reduce VOC emissions and eliminate toxic components while maintaining protective performance. These formulations typically use water-based systems, high-solids technologies, or powder coating approaches instead of traditional solvent-based coatings. Bio-based resins derived from renewable resources may replace petroleum-based polymers. These eco-friendly coatings are formulated to provide comparable or superior protection to conventional systems while meeting increasingly stringent environmental regulations.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The galvanized steel topcoat protection market is in a growth phase, driven by increasing demand for corrosion-resistant materials across construction, automotive, and industrial sectors. The global market size is estimated at $2.5-3 billion annually with projected 5-7% CAGR through 2028. Technology maturity varies across application methods, with established players like Henkel AG, Kansai Paint, and Nippon Steel offering conventional solutions, while innovative companies such as Oerlikon Metco and Tata Steel are developing advanced nano-coatings and environmentally friendly alternatives. The competitive landscape features traditional coating manufacturers competing with specialized surface treatment companies and steel producers integrating downstream coating capabilities, creating a fragmented market with opportunities for technological differentiation in durability, environmental compliance, and application efficiency.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced topcoat systems specifically designed for galvanized steel protection, featuring their Bonderite two-step process. This technology first applies a zinc phosphate conversion coating that chemically bonds with the galvanized surface, creating an ideal foundation for subsequent coating adhesion. Following this, Henkel's proprietary epoxy-polyester hybrid topcoats are applied, which contain specialized corrosion inhibitors and UV stabilizers. Their formulations incorporate self-healing polymer technology that can repair minor surface damage through molecular rearrangement when exposed to heat[1]. Henkel's coatings achieve salt spray resistance exceeding 1,000 hours in ASTM B117 testing, significantly outperforming conventional systems. The company has also pioneered water-based topcoat formulations with VOC levels below 100 g/L while maintaining performance comparable to solvent-based alternatives[3].

Strengths: Superior adhesion to galvanized surfaces through specialized chemical bonding; exceptional corrosion resistance; environmentally compliant formulations with low VOC emissions; self-healing capabilities for extended service life. Weaknesses: Higher initial application cost compared to conventional systems; requires precise application parameters; some formulations have limited color options; may require specialized equipment for optimal application.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has engineered their ZINCTECT topcoat system specifically for galvanized steel protection. This multi-layer approach begins with their proprietary etching primer containing modified phosphoric acid derivatives that create microscopic anchoring points on the zinc surface without damaging the galvanization. The intermediate layer utilizes their patented "ion-exchange resin technology" that actively neutralizes corrosive elements that penetrate the coating system[2]. The final topcoat incorporates nano-ceramic particles dispersed throughout a modified polyurethane matrix, creating a dense barrier with exceptional scratch and chemical resistance. Laboratory testing demonstrates these coatings maintain gloss retention above 80% after 5,000 hours of QUV accelerated weathering tests, and corrosion protection exceeding 2,000 hours in salt spray environments[4]. Kansai's system also features "edge retention" technology that prevents coating thinning at sharp edges - a common failure point in galvanized steel structures.

Strengths: Exceptional long-term durability in harsh environments; superior edge protection; excellent color and gloss retention; active corrosion inhibition through ion-exchange technology. Weaknesses: Complex multi-step application process increases labor costs; requires specialized training for proper application; higher material cost compared to standard industrial coatings; some formulations have extended cure times that may impact production schedules.

Key Technical Innovations in Galvanized Steel Protection

Coating composition that cannot be wetted by liquid zinc

PatentWO2024213634A1

Innovation

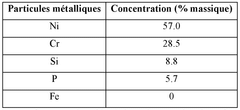

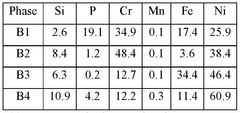

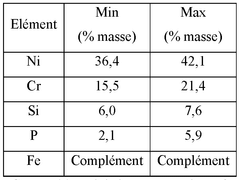

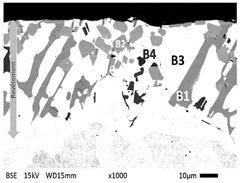

- A coating composition comprising nickel, chromium, silicon, phosphorus, and optionally boron, applied via a suspension followed by high-temperature heat treatment, which creates a non-wettable and corrosion-resistant surface for steel parts, reducing zinc adhesion and extending part lifespan.

Anti-corrosive coating for metal surfaces

PatentActiveUS20090252986A1

Innovation

- A coated metal surface comprising a metallic layer of anodic metal and a composite layer with a dielectric material, where the second anodic metal is electrically connected to the substrate, optionally with a topcoat for additional barrier protection, applied using advanced spraying techniques for rapid and cost-effective application.

Environmental Compliance and Sustainability Factors

The application of topcoats on galvanized steel must align with increasingly stringent environmental regulations across global markets. VOC (Volatile Organic Compound) emissions from traditional coating systems have become a critical concern, with regulations such as the EU's VOC Directive, the US EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP), and China's Air Pollution Prevention and Control Law imposing strict limitations on coating formulations. Manufacturers must carefully select topcoat systems that comply with these regional requirements to avoid penalties and operational restrictions.

Water-based coating technologies have emerged as a leading environmentally compliant solution, offering VOC reductions of up to 80% compared to conventional solvent-based systems. These formulations maintain protective performance while significantly reducing environmental impact during application processes. Powder coating systems represent another sustainable alternative, achieving near-zero VOC emissions through their solvent-free composition and high material utilization rates exceeding 95%.

Life cycle assessment (LCA) has become an essential tool for evaluating the environmental footprint of galvanized steel coating systems. Recent industry analyses indicate that properly selected topcoat systems can extend service life by 15-25 years, substantially reducing the environmental impact associated with premature replacement and maintenance. This longevity factor must be balanced against the immediate environmental impacts of coating production and application.

The recyclability of coated galvanized steel presents another sustainability consideration. Topcoat systems must be designed to maintain the recyclability of the base material, avoiding contaminants that might compromise end-of-life recovery processes. Several coating manufacturers have developed systems specifically engineered to maintain full recyclability while providing enhanced protection.

Energy consumption during topcoat curing represents a significant environmental factor. Traditional thermal curing processes can consume 3-5 kWh per square meter of coated surface. Advanced UV-curing and ambient-temperature curing systems have demonstrated energy reductions of 40-60%, with corresponding decreases in carbon emissions. These technologies are gaining market share despite higher initial material costs due to their operational efficiency and reduced environmental impact.

Corporate sustainability initiatives increasingly influence coating selection decisions beyond regulatory compliance. Many steel processors and end-users have established environmental performance targets that exceed regulatory requirements, driving innovation in coating technologies with improved sustainability profiles. This market-driven approach complements regulatory frameworks in accelerating the adoption of environmentally preferable coating solutions.

Water-based coating technologies have emerged as a leading environmentally compliant solution, offering VOC reductions of up to 80% compared to conventional solvent-based systems. These formulations maintain protective performance while significantly reducing environmental impact during application processes. Powder coating systems represent another sustainable alternative, achieving near-zero VOC emissions through their solvent-free composition and high material utilization rates exceeding 95%.

Life cycle assessment (LCA) has become an essential tool for evaluating the environmental footprint of galvanized steel coating systems. Recent industry analyses indicate that properly selected topcoat systems can extend service life by 15-25 years, substantially reducing the environmental impact associated with premature replacement and maintenance. This longevity factor must be balanced against the immediate environmental impacts of coating production and application.

The recyclability of coated galvanized steel presents another sustainability consideration. Topcoat systems must be designed to maintain the recyclability of the base material, avoiding contaminants that might compromise end-of-life recovery processes. Several coating manufacturers have developed systems specifically engineered to maintain full recyclability while providing enhanced protection.

Energy consumption during topcoat curing represents a significant environmental factor. Traditional thermal curing processes can consume 3-5 kWh per square meter of coated surface. Advanced UV-curing and ambient-temperature curing systems have demonstrated energy reductions of 40-60%, with corresponding decreases in carbon emissions. These technologies are gaining market share despite higher initial material costs due to their operational efficiency and reduced environmental impact.

Corporate sustainability initiatives increasingly influence coating selection decisions beyond regulatory compliance. Many steel processors and end-users have established environmental performance targets that exceed regulatory requirements, driving innovation in coating technologies with improved sustainability profiles. This market-driven approach complements regulatory frameworks in accelerating the adoption of environmentally preferable coating solutions.

Performance Testing and Quality Assurance Protocols

Performance testing and quality assurance protocols are essential components in the application of topcoats on galvanized steel. These protocols ensure that the coating system provides the intended protection and meets industry standards for durability and performance. The testing regimen typically begins with adhesion testing, which evaluates the bond strength between the topcoat and the galvanized substrate using methods such as cross-cut, pull-off, or tape tests according to ASTM D3359 or ISO 2409 standards.

Corrosion resistance testing forms a critical aspect of performance evaluation, commonly conducted through salt spray testing (ASTM B117) or cyclic corrosion testing (ASTM D5894). These accelerated weathering tests simulate harsh environmental conditions to predict long-term performance. The duration of testing varies based on the intended application environment, ranging from 500 hours for moderate exposure to 3000+ hours for severe industrial or marine environments.

Impact and flexibility testing assess the coating's ability to withstand physical stress without cracking or delamination. Standard tests include impact resistance (ASTM D2794) and mandrel bend testing (ASTM D522), which evaluate the coating's ability to maintain integrity when the substrate is deformed. These tests are particularly important for applications where the coated steel may experience physical impacts or temperature-induced expansion and contraction.

Chemical resistance testing evaluates the topcoat's ability to withstand exposure to various substances it might encounter during service life. This includes resistance to acids, alkalis, solvents, and other chemicals specific to the intended application environment. ASTM D1308 provides standardized procedures for chemical spot testing, while immersion tests may be used for more severe exposure scenarios.

Quality assurance protocols should include comprehensive documentation systems that track batch numbers, application parameters, environmental conditions during application, and test results. Regular calibration of testing equipment ensures accuracy and repeatability of results. Statistical process control methods help identify trends that might indicate potential quality issues before they become significant problems.

Non-destructive testing techniques such as dry film thickness measurement (using magnetic gauges per ASTM D7091) provide critical quality control data without damaging the coating. Visual inspection protocols should be standardized with acceptance criteria for defects such as pinholes, runs, sags, and other application imperfections.

Field testing complements laboratory evaluations by assessing performance under actual service conditions. This may include periodic inspections, adhesion testing of field samples, and documentation of coating performance over time. The correlation between accelerated laboratory testing and actual field performance should be continuously evaluated to improve predictive models and testing protocols.

Corrosion resistance testing forms a critical aspect of performance evaluation, commonly conducted through salt spray testing (ASTM B117) or cyclic corrosion testing (ASTM D5894). These accelerated weathering tests simulate harsh environmental conditions to predict long-term performance. The duration of testing varies based on the intended application environment, ranging from 500 hours for moderate exposure to 3000+ hours for severe industrial or marine environments.

Impact and flexibility testing assess the coating's ability to withstand physical stress without cracking or delamination. Standard tests include impact resistance (ASTM D2794) and mandrel bend testing (ASTM D522), which evaluate the coating's ability to maintain integrity when the substrate is deformed. These tests are particularly important for applications where the coated steel may experience physical impacts or temperature-induced expansion and contraction.

Chemical resistance testing evaluates the topcoat's ability to withstand exposure to various substances it might encounter during service life. This includes resistance to acids, alkalis, solvents, and other chemicals specific to the intended application environment. ASTM D1308 provides standardized procedures for chemical spot testing, while immersion tests may be used for more severe exposure scenarios.

Quality assurance protocols should include comprehensive documentation systems that track batch numbers, application parameters, environmental conditions during application, and test results. Regular calibration of testing equipment ensures accuracy and repeatability of results. Statistical process control methods help identify trends that might indicate potential quality issues before they become significant problems.

Non-destructive testing techniques such as dry film thickness measurement (using magnetic gauges per ASTM D7091) provide critical quality control data without damaging the coating. Visual inspection protocols should be standardized with acceptance criteria for defects such as pinholes, runs, sags, and other application imperfections.

Field testing complements laboratory evaluations by assessing performance under actual service conditions. This may include periodic inspections, adhesion testing of field samples, and documentation of coating performance over time. The correlation between accelerated laboratory testing and actual field performance should be continuously evaluated to improve predictive models and testing protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!