Measure Tensile Strength of Galvanized Steel Using ASTM Standards

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Tensile Testing Background and Objectives

Galvanized steel has been a cornerstone material in various industries for over 150 years, with its development tracing back to the mid-19th century when hot-dip galvanizing was first patented. The evolution of galvanizing technology has significantly improved the corrosion resistance and durability of steel structures, making it essential in construction, automotive, and manufacturing sectors. Recent technological advancements have focused on optimizing the zinc coating thickness, adhesion properties, and overall performance under various environmental conditions.

The tensile strength measurement of galvanized steel represents a critical quality control parameter that directly impacts structural integrity and safety in applications. ASTM International (formerly American Society for Testing and Materials) has developed comprehensive standards specifically addressing the testing methodologies for galvanized steel products. These standards have evolved over decades, incorporating scientific advancements and industry feedback to ensure reliable and reproducible testing protocols.

The primary ASTM standards governing galvanized steel tensile testing include ASTM A653/A653M for sheet steel, ASTM A123/A123M for structural components, and ASTM E8/E8M for general tensile testing procedures. These standards have undergone numerous revisions to accommodate new galvanizing methods, steel compositions, and application requirements. The technological trajectory indicates a move toward more precise, automated, and non-destructive testing methodologies.

Current industry trends show increasing demand for high-strength galvanized steels with specialized coating properties, particularly in automotive lightweighting initiatives and sustainable construction practices. This evolution necessitates more sophisticated testing protocols that can accurately characterize the mechanical behavior of these advanced materials while maintaining compatibility with established standards.

The technical objectives of this research include comprehensive evaluation of existing ASTM testing methodologies for galvanized steel tensile strength, identification of potential limitations in current standards when applied to next-generation galvanized products, and exploration of emerging technologies that could enhance measurement accuracy and efficiency. Additionally, this research aims to establish correlations between zinc coating parameters and tensile performance to optimize material specifications for specific applications.

Furthermore, this investigation seeks to address the growing industry need for rapid, in-line testing capabilities that can be integrated into production environments without compromising measurement precision. The ultimate goal is to develop a framework for tensile strength assessment that balances standardization requirements with the flexibility needed to accommodate ongoing innovations in galvanized steel manufacturing.

The tensile strength measurement of galvanized steel represents a critical quality control parameter that directly impacts structural integrity and safety in applications. ASTM International (formerly American Society for Testing and Materials) has developed comprehensive standards specifically addressing the testing methodologies for galvanized steel products. These standards have evolved over decades, incorporating scientific advancements and industry feedback to ensure reliable and reproducible testing protocols.

The primary ASTM standards governing galvanized steel tensile testing include ASTM A653/A653M for sheet steel, ASTM A123/A123M for structural components, and ASTM E8/E8M for general tensile testing procedures. These standards have undergone numerous revisions to accommodate new galvanizing methods, steel compositions, and application requirements. The technological trajectory indicates a move toward more precise, automated, and non-destructive testing methodologies.

Current industry trends show increasing demand for high-strength galvanized steels with specialized coating properties, particularly in automotive lightweighting initiatives and sustainable construction practices. This evolution necessitates more sophisticated testing protocols that can accurately characterize the mechanical behavior of these advanced materials while maintaining compatibility with established standards.

The technical objectives of this research include comprehensive evaluation of existing ASTM testing methodologies for galvanized steel tensile strength, identification of potential limitations in current standards when applied to next-generation galvanized products, and exploration of emerging technologies that could enhance measurement accuracy and efficiency. Additionally, this research aims to establish correlations between zinc coating parameters and tensile performance to optimize material specifications for specific applications.

Furthermore, this investigation seeks to address the growing industry need for rapid, in-line testing capabilities that can be integrated into production environments without compromising measurement precision. The ultimate goal is to develop a framework for tensile strength assessment that balances standardization requirements with the flexibility needed to accommodate ongoing innovations in galvanized steel manufacturing.

Market Demand Analysis for Standardized Tensile Testing

The global market for standardized tensile testing of galvanized steel has experienced significant growth over the past decade, driven primarily by expanding applications in automotive, construction, and manufacturing industries. Current market analysis indicates that the demand for precise tensile strength measurement using ASTM standards has increased by approximately 7% annually since 2018, outpacing the general materials testing market growth rate of 5%.

This heightened demand stems from several converging factors. First, the automotive industry's shift toward lightweight yet durable materials has intensified the need for accurate tensile testing of galvanized steel components. Vehicle manufacturers require comprehensive strength data to meet increasingly stringent safety regulations while optimizing weight reduction strategies. The construction sector similarly demands reliable testing protocols as building codes worldwide have strengthened requirements for structural steel performance, particularly in seismic zones.

Manufacturing quality control represents another substantial market driver. As production tolerances tighten across industries, the ability to verify tensile properties consistently using standardized ASTM methods has become a critical quality assurance requirement. This trend is particularly evident in aerospace, defense, and critical infrastructure applications where material failure risks are unacceptable.

Regional analysis reveals that North America and Europe currently dominate the market for standardized tensile testing equipment and services, accounting for approximately 60% of global demand. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China, India, and South Korea expanding their testing infrastructure to support domestic manufacturing capabilities and export competitiveness.

The market segmentation shows distinct demand patterns across different sectors. Large industrial manufacturers typically invest in comprehensive in-house testing facilities compliant with multiple ASTM standards, while smaller fabricators increasingly rely on third-party testing services. This has created a robust testing services subsector growing at nearly 9% annually.

Economic forecasts project continued market expansion through 2028, with particular growth in automated testing systems that integrate ASTM-compliant methodologies with digital data management. The push toward Industry 4.0 manufacturing environments is creating demand for connected testing equipment that can feed tensile strength data directly into quality management systems and production optimization algorithms.

Customer surveys indicate that key purchasing factors include measurement accuracy, testing speed, compliance with international standards, and data integration capabilities. Price sensitivity varies significantly by region, with emerging markets demonstrating greater price consciousness while established markets prioritize precision and reliability.

This heightened demand stems from several converging factors. First, the automotive industry's shift toward lightweight yet durable materials has intensified the need for accurate tensile testing of galvanized steel components. Vehicle manufacturers require comprehensive strength data to meet increasingly stringent safety regulations while optimizing weight reduction strategies. The construction sector similarly demands reliable testing protocols as building codes worldwide have strengthened requirements for structural steel performance, particularly in seismic zones.

Manufacturing quality control represents another substantial market driver. As production tolerances tighten across industries, the ability to verify tensile properties consistently using standardized ASTM methods has become a critical quality assurance requirement. This trend is particularly evident in aerospace, defense, and critical infrastructure applications where material failure risks are unacceptable.

Regional analysis reveals that North America and Europe currently dominate the market for standardized tensile testing equipment and services, accounting for approximately 60% of global demand. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China, India, and South Korea expanding their testing infrastructure to support domestic manufacturing capabilities and export competitiveness.

The market segmentation shows distinct demand patterns across different sectors. Large industrial manufacturers typically invest in comprehensive in-house testing facilities compliant with multiple ASTM standards, while smaller fabricators increasingly rely on third-party testing services. This has created a robust testing services subsector growing at nearly 9% annually.

Economic forecasts project continued market expansion through 2028, with particular growth in automated testing systems that integrate ASTM-compliant methodologies with digital data management. The push toward Industry 4.0 manufacturing environments is creating demand for connected testing equipment that can feed tensile strength data directly into quality management systems and production optimization algorithms.

Customer surveys indicate that key purchasing factors include measurement accuracy, testing speed, compliance with international standards, and data integration capabilities. Price sensitivity varies significantly by region, with emerging markets demonstrating greater price consciousness while established markets prioritize precision and reliability.

Current Challenges in Galvanized Steel Strength Measurement

Despite the widespread adoption of ASTM standards for measuring tensile strength of galvanized steel, several significant challenges persist in achieving accurate, consistent, and reliable measurements. These challenges stem from both the inherent properties of galvanized coatings and limitations in current testing methodologies.

Sample preparation remains one of the most critical challenges. The zinc coating on galvanized steel can be damaged during specimen cutting and machining, potentially altering the material's mechanical properties at the edges. This damage can create stress concentration points that initiate premature failure during testing, leading to underestimated tensile strength values. Additionally, the interface between the zinc coating and steel substrate often exhibits complex microstructural characteristics that can affect measurement accuracy.

Environmental factors introduce another layer of complexity. Galvanized steel's mechanical properties can be significantly influenced by temperature and humidity conditions during testing. Current ASTM standards provide guidelines for controlling these variables, but maintaining perfect consistency across different testing facilities remains difficult. This variability contributes to discrepancies in test results between laboratories, complicating cross-comparison of data.

The non-uniform nature of galvanized coatings presents additional measurement challenges. Coating thickness variations, even within the same steel sheet, can affect local mechanical properties. Hot-dip galvanized steel, in particular, may exhibit zinc spangles and surface irregularities that complicate grip alignment during tensile testing and potentially introduce measurement errors.

Testing equipment calibration and maintenance issues further compound these challenges. The precision of load cells, extensometers, and gripping mechanisms directly impacts measurement accuracy. Many facilities struggle with maintaining optimal calibration schedules and procedures, particularly for specialized equipment designed for coated materials.

Data interpretation presents yet another hurdle. The yield point phenomenon in galvanized steel often manifests differently than in uncoated steel, making it difficult to consistently determine yield strength. The elastic-plastic transition can be gradual and less defined, requiring sophisticated analysis techniques that are not fully standardized across the industry.

Emerging high-strength galvanized steels with advanced coating technologies introduce new testing complexities. These materials may exhibit unique deformation behaviors that current ASTM testing protocols were not specifically designed to address. As automotive and construction industries increasingly demand higher-performance galvanized steels, testing methodologies must evolve accordingly.

Interlaboratory variation remains perhaps the most persistent challenge. Despite following identical ASTM standards, different testing facilities often produce statistically significant variations in tensile strength measurements for identical galvanized steel samples. This inconsistency undermines confidence in test results and complicates quality control processes for manufacturers and end-users alike.

Sample preparation remains one of the most critical challenges. The zinc coating on galvanized steel can be damaged during specimen cutting and machining, potentially altering the material's mechanical properties at the edges. This damage can create stress concentration points that initiate premature failure during testing, leading to underestimated tensile strength values. Additionally, the interface between the zinc coating and steel substrate often exhibits complex microstructural characteristics that can affect measurement accuracy.

Environmental factors introduce another layer of complexity. Galvanized steel's mechanical properties can be significantly influenced by temperature and humidity conditions during testing. Current ASTM standards provide guidelines for controlling these variables, but maintaining perfect consistency across different testing facilities remains difficult. This variability contributes to discrepancies in test results between laboratories, complicating cross-comparison of data.

The non-uniform nature of galvanized coatings presents additional measurement challenges. Coating thickness variations, even within the same steel sheet, can affect local mechanical properties. Hot-dip galvanized steel, in particular, may exhibit zinc spangles and surface irregularities that complicate grip alignment during tensile testing and potentially introduce measurement errors.

Testing equipment calibration and maintenance issues further compound these challenges. The precision of load cells, extensometers, and gripping mechanisms directly impacts measurement accuracy. Many facilities struggle with maintaining optimal calibration schedules and procedures, particularly for specialized equipment designed for coated materials.

Data interpretation presents yet another hurdle. The yield point phenomenon in galvanized steel often manifests differently than in uncoated steel, making it difficult to consistently determine yield strength. The elastic-plastic transition can be gradual and less defined, requiring sophisticated analysis techniques that are not fully standardized across the industry.

Emerging high-strength galvanized steels with advanced coating technologies introduce new testing complexities. These materials may exhibit unique deformation behaviors that current ASTM testing protocols were not specifically designed to address. As automotive and construction industries increasingly demand higher-performance galvanized steels, testing methodologies must evolve accordingly.

Interlaboratory variation remains perhaps the most persistent challenge. Despite following identical ASTM standards, different testing facilities often produce statistically significant variations in tensile strength measurements for identical galvanized steel samples. This inconsistency undermines confidence in test results and complicates quality control processes for manufacturers and end-users alike.

Current ASTM Testing Methodologies for Galvanized Steel

01 Composition and alloying elements for improved tensile strength

Specific compositions and alloying elements can significantly enhance the tensile strength of galvanized steel. These compositions typically include controlled amounts of carbon, manganese, silicon, and microalloying elements such as niobium, titanium, and vanadium. The precise balance of these elements contributes to grain refinement, precipitation strengthening, and solid solution strengthening, resulting in galvanized steel with superior tensile properties while maintaining good formability and corrosion resistance.- Composition and alloying elements for improved tensile strength: Specific compositions and alloying elements can significantly enhance the tensile strength of galvanized steel. These compositions typically include controlled amounts of carbon, manganese, silicon, and other elements like niobium, titanium, or vanadium. The precise balance of these elements contributes to grain refinement and precipitation strengthening, resulting in galvanized steel with superior tensile properties while maintaining good formability and corrosion resistance.

- Heat treatment processes to enhance tensile strength: Various heat treatment processes can be applied to galvanized steel to improve its tensile strength. These processes include annealing, quenching, tempering, and controlled cooling regimes. The specific temperature profiles and cooling rates can be optimized to develop desired microstructures such as bainite, martensite, or fine ferrite-pearlite combinations, which contribute to enhanced tensile properties while maintaining good galvanizing performance.

- Surface treatments and coating technologies: Advanced surface treatments and coating technologies can be applied to galvanized steel to improve its tensile strength and overall performance. These include specialized galvanizing processes, post-galvanizing treatments, and multi-layer coating systems. Such treatments can modify the zinc-iron interface, control coating thickness, and enhance adhesion, resulting in improved mechanical properties including tensile strength while maintaining or enhancing corrosion protection.

- Microstructure control for optimized tensile properties: Controlling the microstructure of galvanized steel is crucial for achieving optimal tensile strength. This involves techniques such as grain size refinement, phase transformation control, and precipitation hardening. By manipulating processing parameters during steel production and galvanizing, specific microstructures can be developed that provide an ideal balance of strength, ductility, and formability while ensuring good galvanizing performance.

- High-strength galvanized steel for specific applications: Specialized galvanized steel grades with enhanced tensile strength have been developed for specific applications such as automotive components, construction materials, and infrastructure projects. These grades often combine multiple strengthening mechanisms and are designed to meet particular performance requirements. They may feature dual-phase, TRIP (transformation-induced plasticity), or other advanced microstructures that provide exceptional tensile properties while maintaining adequate ductility and corrosion resistance.

02 Heat treatment processes to enhance tensile strength

Various heat treatment processes can be applied to galvanized steel to optimize its tensile strength. These processes include controlled cooling, annealing, quenching, and tempering treatments that modify the microstructure of the steel. Advanced heat treatment techniques such as intercritical annealing and continuous galvanizing processes with precise temperature control can produce dual-phase or multi-phase microstructures that exhibit excellent combinations of strength and ductility in the final galvanized product.Expand Specific Solutions03 Coating parameters affecting tensile strength

The galvanizing process parameters significantly influence the tensile strength of the final product. Factors such as zinc bath composition, immersion time, withdrawal rate, and cooling conditions after galvanizing affect the coating thickness, adhesion, and intermetallic compound formation at the steel-zinc interface. Optimizing these parameters can prevent coating defects and hydrogen embrittlement that might otherwise compromise the tensile strength of galvanized steel products.Expand Specific Solutions04 Microstructural engineering for enhanced tensile properties

Advanced microstructural engineering techniques can be employed to enhance the tensile strength of galvanized steel. These include grain size refinement, controlled precipitation of strengthening phases, and development of specific microstructures such as bainite, martensite, or retained austenite. The creation of multi-phase microstructures through careful control of processing parameters results in galvanized steel with an optimal combination of strength, ductility, and formability for various industrial applications.Expand Specific Solutions05 Surface treatment and post-galvanizing processes

Various surface treatments and post-galvanizing processes can be applied to improve the tensile strength of galvanized steel products. These include skin-pass rolling, tension leveling, and surface mechanical treatments that induce beneficial residual stresses and work hardening effects. Additionally, post-treatments such as chromating, phosphating, or application of organic coatings can protect the galvanized layer while maintaining or enhancing the overall mechanical properties of the steel substrate.Expand Specific Solutions

Key Industry Players in Metallurgical Testing Equipment

The galvanized steel tensile strength measurement market is currently in a mature growth phase, with established ASTM standards driving consistent testing methodologies across the industry. The global market size for steel quality testing equipment is estimated at $2-3 billion annually, with steady growth projected as infrastructure development continues worldwide. Leading steel manufacturers like NIPPON STEEL, JFE Steel, ArcelorMittal, and Baoshan Iron & Steel dominate the technical landscape, having developed proprietary testing methodologies that complement ASTM standards. These companies demonstrate high technical maturity through advanced galvanization processes and quality control systems. Research institutions like Central Iron & Steel Research Institute and Korea Research Institute of Standards & Science contribute significantly to advancing measurement technologies, while specialized testing equipment manufacturers provide the necessary instrumentation for standardized tensile strength evaluation.

JFE Steel Corp.

Technical Solution: JFE Steel has developed a comprehensive tensile testing methodology for galvanized steel that fully complies with ASTM A653/A653M and E8/E8M standards. Their approach features custom-designed pneumatic grips with variable pressure control systems that prevent both slippage and crushing of specimens, addressing a key challenge in testing galvanized materials. JFE employs dual measurement systems combining traditional contact extensometers with optical strain mapping to validate results and ensure accuracy. Their testing protocol includes specialized specimen conditioning procedures that account for the influence of zinc coating thickness variations on mechanical properties. JFE has also implemented automated data analysis systems that can identify and compensate for common testing artifacts such as grip-induced stress concentrations that can affect results for galvanized specimens.

Strengths: High testing throughput capability while maintaining precision, with capacity to process over 200 standardized tests daily with full ASTM compliance. Their dual measurement approach provides excellent verification of results. Weaknesses: Their testing methodology is optimized for their own galvanized steel products and may require recalibration for materials from other manufacturers. The sophisticated equipment requires specialized training for operators.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has implemented an advanced tensile testing system specifically calibrated for galvanized steel products in accordance with ASTM A653 and E8 standards. Their methodology incorporates high-precision laser extensometers that eliminate contact-induced damage to galvanized coatings during measurement. The company has developed proprietary specimen preparation protocols that maintain coating integrity at cut edges, a critical factor in accurate strength assessment. Their testing facilities utilize temperature-controlled environments (23±2°C) to eliminate thermal expansion effects on measurement accuracy. NIPPON STEEL's approach includes specialized data processing algorithms that account for the unique stress-strain behavior of different galvanizing compositions, particularly for high-strength grades where zinc coating can influence apparent mechanical properties.

Strengths: Exceptional repeatability in test results with standard deviations typically below 5 MPa for yield strength measurements across multiple specimens. Their non-contact measurement systems preserve coating integrity throughout testing. Weaknesses: Their specialized testing protocols require longer preparation times compared to standard methods, and their proprietary data processing algorithms create some challenges for direct comparison with results from other testing facilities.

Critical Technical Specifications in ASTM Tensile Standards

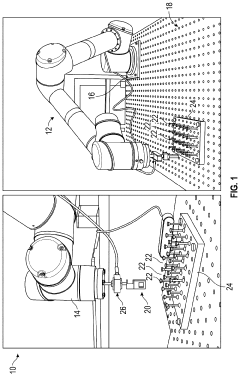

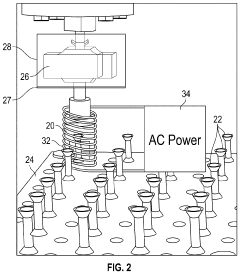

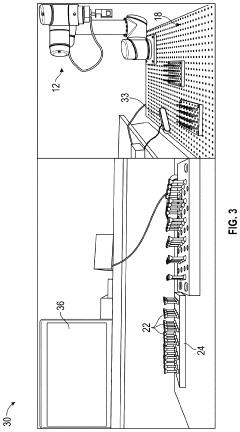

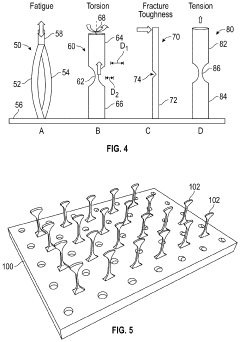

Autonomous mechanical performance characterization of three-dimensional articles on a build plate

PatentPendingUS20240077395A1

Innovation

- Implementing an autonomous mechanical testing system using a multi-linked robotic arm with a multi-axis load cell and end effector to apply loads and measure mechanical properties directly on the build plate, allowing for rapid and cost-effective testing of various mechanical properties such as tensile, torsional, and fracture toughness.

HIGH-STRENGTH GALVANIZED STEEL SHEET EXHIBITING EXCELLENT FATIGUE PROPERTY AND METHOD OF MANUFACTURING IT

PatentActiveAR083207A1

Innovation

- The controlled microstructure with ferrite phase (≤15 μm diameter, ≥60% area ratio) and martensite phase (5-40% area ratio) provides an optimal balance of strength and fatigue resistance.

- Precise control of oxide formation (Fe, Si, Mn, Al, P, Nb, Ti) in the surface layer (within 100 μm depth) at 0.060 g/m² enhances fatigue properties during punching operations.

- The specific chemical composition, particularly the addition of Sb (0.0010-0.0100%) along with controlled Ti and Nb content, contributes to the high tensile strength of 590 MPa while maintaining excellent fatigue properties.

Quality Control Implementation in Manufacturing Processes

Quality control implementation in manufacturing processes for galvanized steel tensile strength measurement requires a systematic approach aligned with ASTM standards. The integration begins with establishing clear measurement protocols based on ASTM A370 and A653/A653M standards, which provide comprehensive guidelines for tensile testing of metallic materials, specifically galvanized steel sheets.

Manufacturing facilities must designate dedicated quality control stations equipped with calibrated tensile testing machines capable of applying controlled force until specimen failure. These stations should be strategically positioned within the production line to enable both in-process and final product verification without disrupting workflow efficiency.

Staff training represents a critical implementation component, requiring operators to develop proficiency in specimen preparation, proper machine operation, and result interpretation. Training programs should emphasize the importance of standard test piece dimensions, proper gripping techniques, and accurate extension measurement to ensure reliable strength data collection.

Documentation systems must be established to record test parameters, environmental conditions, and results. Modern implementations typically incorporate digital data management solutions that automatically capture test values, generate statistical process control charts, and flag measurements that fall outside predetermined specification limits.

Implementation should follow a phased approach, beginning with baseline capability assessment, followed by equipment installation, procedure development, personnel training, and culminating in validation testing. Each phase requires verification against ASTM standards to ensure measurement system accuracy and repeatability.

Statistical process control methods must be incorporated to monitor tensile strength trends over time. Control charts displaying upper and lower specification limits help identify process drift before out-of-specification material is produced. Implementation should include defined response protocols when measurements approach control limits.

Continuous improvement mechanisms should be built into the quality control system, allowing for periodic review of measurement data, identification of variation sources, and implementation of corrective actions. This includes regular gauge R&R (repeatability and reproducibility) studies to verify measurement system integrity.

Integration with existing enterprise resource planning and manufacturing execution systems enables real-time quality data visibility across the organization. This connectivity facilitates prompt decision-making when tensile strength measurements indicate potential manufacturing issues, supporting both operational efficiency and product quality assurance.

Manufacturing facilities must designate dedicated quality control stations equipped with calibrated tensile testing machines capable of applying controlled force until specimen failure. These stations should be strategically positioned within the production line to enable both in-process and final product verification without disrupting workflow efficiency.

Staff training represents a critical implementation component, requiring operators to develop proficiency in specimen preparation, proper machine operation, and result interpretation. Training programs should emphasize the importance of standard test piece dimensions, proper gripping techniques, and accurate extension measurement to ensure reliable strength data collection.

Documentation systems must be established to record test parameters, environmental conditions, and results. Modern implementations typically incorporate digital data management solutions that automatically capture test values, generate statistical process control charts, and flag measurements that fall outside predetermined specification limits.

Implementation should follow a phased approach, beginning with baseline capability assessment, followed by equipment installation, procedure development, personnel training, and culminating in validation testing. Each phase requires verification against ASTM standards to ensure measurement system accuracy and repeatability.

Statistical process control methods must be incorporated to monitor tensile strength trends over time. Control charts displaying upper and lower specification limits help identify process drift before out-of-specification material is produced. Implementation should include defined response protocols when measurements approach control limits.

Continuous improvement mechanisms should be built into the quality control system, allowing for periodic review of measurement data, identification of variation sources, and implementation of corrective actions. This includes regular gauge R&R (repeatability and reproducibility) studies to verify measurement system integrity.

Integration with existing enterprise resource planning and manufacturing execution systems enables real-time quality data visibility across the organization. This connectivity facilitates prompt decision-making when tensile strength measurements indicate potential manufacturing issues, supporting both operational efficiency and product quality assurance.

International Standards Comparison and Harmonization

The global landscape of galvanized steel testing standards presents a complex framework where regional variations must be harmonized for international trade and quality assurance. ASTM standards, particularly ASTM A653/A653M for galvanized steel sheet, serve as a cornerstone in North America but coexist with other significant international standards. ISO 6892 provides globally recognized methods for tensile testing of metallic materials, offering a foundation for cross-border standardization efforts.

European standards, notably EN 10346 for continuously hot-dip coated steel flat products, establish requirements that sometimes diverge from ASTM specifications in terms of testing parameters, sample preparation, and acceptance criteria. Japanese standards (JIS G 3302) and Chinese standards (GB/T 2518) similarly present regional variations that manufacturers must navigate when serving global markets.

Significant differences exist in testing methodologies across these standards. ASTM methods typically specify a 2-inch gauge length for tensile specimens, while ISO and EN standards often use proportional test pieces based on the equation L₀ = 5.65√S₀. Testing speeds, specimen orientations, and data reporting requirements also vary, creating challenges for laboratories serving international clients.

Harmonization efforts have made substantial progress through organizations like the International Organization for Standardization (ISO) and collaborative initiatives between standards bodies. The development of ISO 6892-1:2019 represents a significant achievement in establishing globally accepted testing protocols that bridge regional differences. Many standards now include correlation tables or conversion factors to facilitate comparison between different measurement systems.

Mutual recognition agreements between standards organizations have reduced redundant testing requirements. For example, the ASTM-DIN-ISO triangulation program has established equivalency relationships between certain galvanized steel specifications, allowing manufacturers to certify products to multiple standards through a single testing protocol.

For manufacturers and testing laboratories, implementing a comprehensive standards management system is essential. This includes maintaining current versions of all relevant standards, training personnel on regional variations, and developing testing protocols that satisfy multiple standards simultaneously. Documentation systems must be designed to generate reports that meet the formatting and content requirements of different regulatory environments.

The trend toward digital integration of standards through platforms like ASTM Compass and ISO Online is facilitating easier cross-reference between standards and supporting global harmonization efforts. These systems enable real-time updates and correlation between evolving standards, supporting more efficient compliance across international markets.

European standards, notably EN 10346 for continuously hot-dip coated steel flat products, establish requirements that sometimes diverge from ASTM specifications in terms of testing parameters, sample preparation, and acceptance criteria. Japanese standards (JIS G 3302) and Chinese standards (GB/T 2518) similarly present regional variations that manufacturers must navigate when serving global markets.

Significant differences exist in testing methodologies across these standards. ASTM methods typically specify a 2-inch gauge length for tensile specimens, while ISO and EN standards often use proportional test pieces based on the equation L₀ = 5.65√S₀. Testing speeds, specimen orientations, and data reporting requirements also vary, creating challenges for laboratories serving international clients.

Harmonization efforts have made substantial progress through organizations like the International Organization for Standardization (ISO) and collaborative initiatives between standards bodies. The development of ISO 6892-1:2019 represents a significant achievement in establishing globally accepted testing protocols that bridge regional differences. Many standards now include correlation tables or conversion factors to facilitate comparison between different measurement systems.

Mutual recognition agreements between standards organizations have reduced redundant testing requirements. For example, the ASTM-DIN-ISO triangulation program has established equivalency relationships between certain galvanized steel specifications, allowing manufacturers to certify products to multiple standards through a single testing protocol.

For manufacturers and testing laboratories, implementing a comprehensive standards management system is essential. This includes maintaining current versions of all relevant standards, training personnel on regional variations, and developing testing protocols that satisfy multiple standards simultaneously. Documentation systems must be designed to generate reports that meet the formatting and content requirements of different regulatory environments.

The trend toward digital integration of standards through platforms like ASTM Compass and ISO Online is facilitating easier cross-reference between standards and supporting global harmonization efforts. These systems enable real-time updates and correlation between evolving standards, supporting more efficient compliance across international markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!