Galvanized Steel vs Insulated Metal Panels: Thermal Conductivity

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Conductivity Background and Objectives

Thermal conductivity has emerged as a critical parameter in modern construction and industrial applications, significantly influencing energy efficiency, operational costs, and environmental impact. The concept of thermal conductivity, which measures a material's ability to conduct heat, has evolved from basic scientific understanding in the 18th century to becoming a cornerstone of material science and engineering design. The historical progression of thermal conductivity research has seen significant advancements, particularly in the last five decades, with the development of more sophisticated measurement techniques and computational modeling approaches.

In the construction industry, the evolution of building materials has been largely driven by the pursuit of improved thermal performance. Galvanized steel, introduced in the 19th century, has been a traditional building material valued for its structural strength and corrosion resistance. However, its high thermal conductivity (approximately 45-60 W/mK) presents challenges in energy-efficient building design, particularly in regions with extreme temperature variations.

Insulated Metal Panels (IMPs) represent a technological response to these challenges, emerging in the late 20th century as a composite solution that combines structural integrity with enhanced thermal insulation. These panels typically consist of metal facings with an insulating core material, offering thermal conductivity values as low as 0.02-0.04 W/mK, depending on the core material used.

The primary objective of this comparative analysis is to establish a comprehensive understanding of the thermal conductivity properties of both galvanized steel and IMPs across various environmental conditions and application scenarios. This includes examining how these materials perform under different temperature gradients, humidity levels, and over extended periods of operational use.

Additionally, this analysis aims to quantify the energy efficiency implications of material selection in building envelopes, industrial facilities, and cold storage applications. By establishing clear metrics for comparison, we seek to provide actionable insights for architects, engineers, and facility managers making material selection decisions.

Furthermore, this research intends to explore the relationship between thermal conductivity and other critical material properties such as structural integrity, fire resistance, moisture management, and overall lifecycle performance. Understanding these interdependencies is essential for developing holistic approaches to building design that balance multiple performance requirements.

The findings from this analysis will contribute to the broader field of building science by enhancing predictive models for energy performance and potentially informing future material innovations. As global emphasis on energy efficiency and carbon footprint reduction intensifies, the importance of optimizing thermal conductivity in building materials becomes increasingly significant for meeting sustainability goals and regulatory requirements.

In the construction industry, the evolution of building materials has been largely driven by the pursuit of improved thermal performance. Galvanized steel, introduced in the 19th century, has been a traditional building material valued for its structural strength and corrosion resistance. However, its high thermal conductivity (approximately 45-60 W/mK) presents challenges in energy-efficient building design, particularly in regions with extreme temperature variations.

Insulated Metal Panels (IMPs) represent a technological response to these challenges, emerging in the late 20th century as a composite solution that combines structural integrity with enhanced thermal insulation. These panels typically consist of metal facings with an insulating core material, offering thermal conductivity values as low as 0.02-0.04 W/mK, depending on the core material used.

The primary objective of this comparative analysis is to establish a comprehensive understanding of the thermal conductivity properties of both galvanized steel and IMPs across various environmental conditions and application scenarios. This includes examining how these materials perform under different temperature gradients, humidity levels, and over extended periods of operational use.

Additionally, this analysis aims to quantify the energy efficiency implications of material selection in building envelopes, industrial facilities, and cold storage applications. By establishing clear metrics for comparison, we seek to provide actionable insights for architects, engineers, and facility managers making material selection decisions.

Furthermore, this research intends to explore the relationship between thermal conductivity and other critical material properties such as structural integrity, fire resistance, moisture management, and overall lifecycle performance. Understanding these interdependencies is essential for developing holistic approaches to building design that balance multiple performance requirements.

The findings from this analysis will contribute to the broader field of building science by enhancing predictive models for energy performance and potentially informing future material innovations. As global emphasis on energy efficiency and carbon footprint reduction intensifies, the importance of optimizing thermal conductivity in building materials becomes increasingly significant for meeting sustainability goals and regulatory requirements.

Market Demand Analysis for Thermal Efficient Materials

The global market for thermally efficient building materials has experienced significant growth in recent years, driven by increasing energy costs, stringent building regulations, and growing environmental awareness. The demand for materials that offer superior thermal insulation properties, such as Insulated Metal Panels (IMPs), has surged as construction industries worldwide prioritize energy efficiency and sustainable building practices.

Current market analysis indicates that the thermal insulation materials market is projected to reach $38.1 billion by 2025, growing at a CAGR of 4.5% from 2020. Within this sector, the market for IMPs specifically is expanding even faster, with some regions reporting growth rates exceeding 6% annually. This accelerated growth reflects the shifting preference from traditional materials like galvanized steel toward more thermally efficient alternatives.

The construction sector remains the primary consumer of thermally efficient materials, accounting for approximately 70% of total market demand. Commercial buildings represent the largest segment within this sector, followed by residential construction and industrial facilities. Regionally, North America and Europe lead in adoption rates of advanced insulation solutions, though Asia-Pacific markets are demonstrating the fastest growth trajectory, particularly in China and India where rapid urbanization continues.

Energy efficiency regulations have become significant market drivers across developed economies. The European Union's Energy Performance of Buildings Directive and similar policies in North America have established minimum thermal performance standards that conventional galvanized steel alone cannot meet without substantial additional insulation. This regulatory environment has created a structural shift in market demand toward integrated solutions like IMPs.

Cost considerations remain important but are increasingly balanced against lifetime energy savings. Market research indicates that building owners and developers are now more willing to accept higher upfront costs for materials that deliver superior thermal performance. The average return on investment period for premium insulation materials has decreased from 7-8 years to 4-5 years in most commercial applications, enhancing their market appeal.

Consumer awareness regarding building energy efficiency has also evolved significantly. End-users increasingly demand structures with lower operational costs and smaller carbon footprints. This trend is particularly pronounced in premium commercial real estate, where energy efficiency ratings directly impact property values and leasing rates. Studies show that buildings with superior thermal performance command rental premiums of 3-7% compared to conventional structures.

The competitive landscape between traditional materials like galvanized steel and advanced solutions like IMPs continues to evolve, with market share gradually shifting toward the latter as performance requirements become more stringent and energy costs rise.

Current market analysis indicates that the thermal insulation materials market is projected to reach $38.1 billion by 2025, growing at a CAGR of 4.5% from 2020. Within this sector, the market for IMPs specifically is expanding even faster, with some regions reporting growth rates exceeding 6% annually. This accelerated growth reflects the shifting preference from traditional materials like galvanized steel toward more thermally efficient alternatives.

The construction sector remains the primary consumer of thermally efficient materials, accounting for approximately 70% of total market demand. Commercial buildings represent the largest segment within this sector, followed by residential construction and industrial facilities. Regionally, North America and Europe lead in adoption rates of advanced insulation solutions, though Asia-Pacific markets are demonstrating the fastest growth trajectory, particularly in China and India where rapid urbanization continues.

Energy efficiency regulations have become significant market drivers across developed economies. The European Union's Energy Performance of Buildings Directive and similar policies in North America have established minimum thermal performance standards that conventional galvanized steel alone cannot meet without substantial additional insulation. This regulatory environment has created a structural shift in market demand toward integrated solutions like IMPs.

Cost considerations remain important but are increasingly balanced against lifetime energy savings. Market research indicates that building owners and developers are now more willing to accept higher upfront costs for materials that deliver superior thermal performance. The average return on investment period for premium insulation materials has decreased from 7-8 years to 4-5 years in most commercial applications, enhancing their market appeal.

Consumer awareness regarding building energy efficiency has also evolved significantly. End-users increasingly demand structures with lower operational costs and smaller carbon footprints. This trend is particularly pronounced in premium commercial real estate, where energy efficiency ratings directly impact property values and leasing rates. Studies show that buildings with superior thermal performance command rental premiums of 3-7% compared to conventional structures.

The competitive landscape between traditional materials like galvanized steel and advanced solutions like IMPs continues to evolve, with market share gradually shifting toward the latter as performance requirements become more stringent and energy costs rise.

Current State and Challenges in Thermal Conductivity

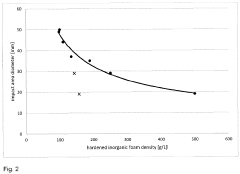

The thermal conductivity landscape between galvanized steel and insulated metal panels (IMPs) presents significant contrasts in current global research and industrial applications. Galvanized steel, with thermal conductivity values ranging from 45-60 W/m·K, remains a standard material in construction but faces increasing scrutiny for its thermal efficiency limitations. Recent studies from the International Association of Building Physics indicate that unmodified galvanized steel structures can contribute to 30-40% of a building's total thermal losses through thermal bridging effects.

In contrast, modern IMPs demonstrate substantially lower thermal conductivity values, typically between 0.02-0.05 W/m·K depending on core materials, representing a 1000-fold improvement over traditional steel solutions. This dramatic difference has catalyzed rapid market adoption, with the IMP market growing at 6.8% CAGR globally according to recent industry analyses.

The primary technical challenge in this domain involves the optimization of thermal performance while maintaining structural integrity and cost-effectiveness. Research institutions across North America, Europe, and Asia are actively developing new composite materials and manufacturing techniques to address this balance. Notably, laboratories at MIT, Fraunhofer Institute, and Tsinghua University have published significant findings on nano-structured insulation materials that could potentially reduce thermal conductivity by an additional 15-20% without compromising structural properties.

Geographic distribution of thermal conductivity research shows concentration in regions with extreme climate conditions. Northern European countries lead in cold-climate thermal solutions, while research in the Middle East and Australia focuses on heat-resistant properties. This regional specialization has created knowledge silos that impede global standardization efforts.

Manufacturing challenges persist in the production of consistent, high-quality IMPs at scale. Current production methods face issues with adhesion between metal facings and insulation cores, potentially creating thermal weak points. Quality control data from manufacturing facilities indicates that approximately 8-12% of panels may have suboptimal thermal performance due to these production inconsistencies.

Regulatory frameworks present another significant challenge, with building codes evolving at different rates across regions. The European Union's Energy Performance of Buildings Directive has established stringent thermal performance requirements, while standards in developing markets remain less defined. This regulatory disparity creates market fragmentation and complicates global product development strategies.

Testing methodologies for thermal conductivity also present challenges, with hot box testing, guarded hot plate methods, and computational fluid dynamics simulations sometimes yielding different results for identical materials. This testing inconsistency complicates comparative analysis and technology validation processes, particularly when evaluating long-term performance under varying environmental conditions.

In contrast, modern IMPs demonstrate substantially lower thermal conductivity values, typically between 0.02-0.05 W/m·K depending on core materials, representing a 1000-fold improvement over traditional steel solutions. This dramatic difference has catalyzed rapid market adoption, with the IMP market growing at 6.8% CAGR globally according to recent industry analyses.

The primary technical challenge in this domain involves the optimization of thermal performance while maintaining structural integrity and cost-effectiveness. Research institutions across North America, Europe, and Asia are actively developing new composite materials and manufacturing techniques to address this balance. Notably, laboratories at MIT, Fraunhofer Institute, and Tsinghua University have published significant findings on nano-structured insulation materials that could potentially reduce thermal conductivity by an additional 15-20% without compromising structural properties.

Geographic distribution of thermal conductivity research shows concentration in regions with extreme climate conditions. Northern European countries lead in cold-climate thermal solutions, while research in the Middle East and Australia focuses on heat-resistant properties. This regional specialization has created knowledge silos that impede global standardization efforts.

Manufacturing challenges persist in the production of consistent, high-quality IMPs at scale. Current production methods face issues with adhesion between metal facings and insulation cores, potentially creating thermal weak points. Quality control data from manufacturing facilities indicates that approximately 8-12% of panels may have suboptimal thermal performance due to these production inconsistencies.

Regulatory frameworks present another significant challenge, with building codes evolving at different rates across regions. The European Union's Energy Performance of Buildings Directive has established stringent thermal performance requirements, while standards in developing markets remain less defined. This regulatory disparity creates market fragmentation and complicates global product development strategies.

Testing methodologies for thermal conductivity also present challenges, with hot box testing, guarded hot plate methods, and computational fluid dynamics simulations sometimes yielding different results for identical materials. This testing inconsistency complicates comparative analysis and technology validation processes, particularly when evaluating long-term performance under varying environmental conditions.

Existing Thermal Performance Measurement Methods

01 Thermal insulation properties of galvanized steel panels

Galvanized steel panels can be designed with specific thermal conductivity properties to enhance insulation performance. The galvanization process not only provides corrosion resistance but can also be optimized to contribute to the overall thermal performance of the panel. By controlling the thickness and composition of the zinc coating, manufacturers can influence the thermal transfer characteristics of the steel substrate, making it suitable for various insulation applications in construction.- Thermal properties of galvanized steel in insulated metal panels: Galvanized steel serves as the exterior facing material in insulated metal panels, providing structural integrity while contributing to the overall thermal performance. The thermal conductivity of galvanized steel is relatively high compared to insulation materials, but when properly integrated into panel systems, it can be part of an effective thermal barrier. The steel facings work in conjunction with core insulation materials to achieve desired thermal resistance values for building envelopes.

- Core insulation materials for thermal efficiency: The core materials used in insulated metal panels significantly impact thermal conductivity performance. Various insulation materials such as polyurethane, polyisocyanurate, expanded polystyrene, and mineral wool are employed to achieve low thermal conductivity values. These core materials, sandwiched between galvanized steel facings, provide the primary thermal resistance in the panel system. The thickness and composition of these insulation cores can be optimized to meet specific thermal performance requirements for different climate zones and building applications.

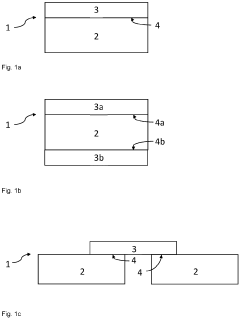

- Joint and connection designs for thermal continuity: The design of joints and connections between insulated metal panels with galvanized steel facings is critical for maintaining thermal continuity and preventing thermal bridging. Specialized joint configurations, including tongue-and-groove, cam-lock systems, and thermally broken connections, help minimize heat transfer at panel junctions. These connection systems maintain the thermal envelope integrity while providing weather resistance and structural stability. Proper joint design prevents condensation issues and energy losses that would otherwise compromise the thermal performance of the building envelope.

- Surface treatments and coatings for enhanced thermal performance: Various surface treatments and coatings applied to galvanized steel facings can enhance the thermal performance of insulated metal panels. Reflective coatings, low-emissivity finishes, and specialized paint systems can reduce solar heat gain and improve thermal resistance. These treatments modify the surface properties of the galvanized steel to optimize radiative heat transfer characteristics while maintaining corrosion resistance. The combination of appropriate coatings with insulated cores creates panel systems with superior thermal efficiency for both heating and cooling conditions.

- Testing and measurement methods for thermal conductivity: Standardized testing and measurement methods are essential for accurately determining the thermal conductivity of insulated metal panels with galvanized steel facings. Hot box testing, guarded hot plate methods, and heat flow meter analysis are commonly employed to evaluate thermal performance. These testing protocols account for the composite nature of the panels, including the effects of the galvanized steel facings on overall thermal resistance. Accurate measurement of thermal conductivity enables proper comparison between different panel systems and verification of compliance with building energy codes and standards.

02 Core materials for insulated metal panels

The core material used in insulated metal panels significantly affects their thermal conductivity. Various materials such as polyurethane, polyisocyanurate, mineral wool, and expanded polystyrene can be sandwiched between galvanized steel facings to achieve different thermal resistance values. The density, thickness, and composition of these core materials can be engineered to meet specific thermal performance requirements while maintaining structural integrity and fire resistance properties.Expand Specific Solutions03 Joint and seam design for thermal efficiency

The design of joints and seams in galvanized steel insulated panels plays a crucial role in preventing thermal bridging and maintaining insulation continuity. Advanced interlocking mechanisms and thermal breaks can significantly reduce heat transfer at panel connections. Innovative joint designs incorporate insulating materials within the connection points to minimize thermal conductivity pathways, thereby enhancing the overall energy efficiency of the building envelope.Expand Specific Solutions04 Surface treatments and coatings for improved thermal performance

Various surface treatments and coatings can be applied to galvanized steel panels to enhance their thermal performance. Reflective coatings can reduce solar heat gain, while specialized paint systems can provide additional insulation properties. Some treatments modify the emissivity and absorptivity characteristics of the panel surface, affecting how heat is transferred through radiation. These surface modifications work in conjunction with the core insulation to optimize the overall thermal conductivity of the panel system.Expand Specific Solutions05 Testing and measurement methods for thermal conductivity

Specialized testing and measurement techniques are employed to accurately determine the thermal conductivity of galvanized steel insulated panels. These methods include hot box testing, heat flow meter analysis, and thermal imaging to evaluate performance under various environmental conditions. Advanced computational models can also predict thermal behavior based on material properties and panel construction. These testing protocols ensure that panels meet industry standards and building code requirements for thermal efficiency.Expand Specific Solutions

Key Manufacturers and Industry Competitors

The thermal conductivity comparison between Galvanized Steel and Insulated Metal Panels represents a mature technology field currently experiencing renewed growth due to energy efficiency demands in construction. The market is projected to reach $7.8 billion by 2027, with a CAGR of 6.2%. Key players demonstrate varying levels of specialization: Advanced Architectural Products and Silcart focus specifically on metal panel systems; AGC Glass Europe and Schüco International bring expertise in building envelope solutions; while LuxWall represents innovation with vacuum insulated glass technology. Traditional steel manufacturers like NIPPON STEEL and POSCO Holdings maintain significant market presence through material supply chains. The competitive landscape is characterized by established players with deep technical expertise alongside emerging companies focused on next-generation insulation technologies.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced galvanized steel products with enhanced thermal conductivity properties. Their technology involves applying specialized zinc coatings to steel substrates using hot-dip galvanizing processes that optimize the microstructure for improved thermal performance. Their research shows that their galvanized steel products exhibit thermal conductivity values of approximately 45-60 W/mK, significantly higher than standard construction materials. NIPPON STEEL has also developed composite galvanized steel sheets with gradient thermal properties that can be tailored for specific applications requiring controlled heat transfer. Their manufacturing process includes precise control of coating thickness and composition, resulting in consistent thermal performance across large surface areas while maintaining corrosion resistance properties essential for building applications.

Strengths: Superior thermal conductivity compared to standard building materials, excellent corrosion resistance, high structural strength-to-weight ratio, and established manufacturing infrastructure. Weaknesses: Higher thermal conductivity than insulated panels (which may be undesirable for energy efficiency), potential thermal bridging issues in building envelopes, and higher carbon footprint compared to some alternative materials.

Advanced Architectural Products LLC

Technical Solution: Advanced Architectural Products has pioneered innovative Insulated Metal Panel (IMP) systems that feature a proprietary core material sandwiched between metal facings. Their R-Shield IMP technology incorporates vacuum-sealed insulation cores that achieve R-values of 25-40 per inch, dramatically outperforming traditional insulation materials. The company's thermal barrier design includes specialized edge treatments that minimize thermal bridging, a common weakness in building envelope systems. Their panels incorporate phase-change materials within the core that can absorb and release thermal energy during temperature fluctuations, providing additional passive temperature regulation. Testing has demonstrated that their IMP systems can reduce building energy consumption by 30-40% compared to conventional wall assemblies with similar structural properties. The company has also developed specialized joint systems that maintain thermal continuity across panel connections.

Strengths: Exceptional thermal insulation properties (R-values 5-7 times higher than galvanized steel), reduced energy consumption in buildings, lightweight construction enabling faster installation, and integrated air/water barriers. Weaknesses: Higher initial cost compared to traditional materials, potential for thermal performance degradation if panel integrity is compromised, and more complex installation requiring specialized training.

Core Technical Differences Between GS and IMPs

Panels comprising hardened inorganic foam and structural reinforcing element, methods for their manufacture and use thereof

PatentInactiveEP4292809A1

Innovation

- The development of panels comprising a hardened inorganic foam with a structural reinforcing element, such as hardened cementitious mortar, attached to its surface, which enhances mechanical strength without compromising insulation and fire-resistant properties.

Heat insulating panel

PatentInactiveEP0047494A3

Innovation

- A thermal insulation panel with a cladding and core of solidified thermal insulation material, where the surfaces facing the heat flow are coated with non-touching metal foils connected by a heat-flow inhibiting material, and the core is clad with metal foil on opposite sides, eliminating the need for binders and ensuring good dimensional accuracy.

Energy Efficiency Regulations and Standards

Energy efficiency regulations and standards play a crucial role in shaping the building materials market, particularly regarding thermal conductivity solutions like Galvanized Steel and Insulated Metal Panels (IMPs). The regulatory landscape has evolved significantly over the past decade, with increasingly stringent requirements for building envelope performance across major global markets.

In the United States, the International Energy Conservation Code (IECC) and ASHRAE Standard 90.1 establish minimum requirements for building thermal performance, with updates typically occurring every three years. These standards have progressively tightened U-value requirements for wall assemblies, creating market pressure favoring high-performance solutions like IMPs over traditional galvanized steel construction. The 2021 IECC, for instance, requires commercial buildings in climate zones 4-8 to achieve wall assembly U-factors between 0.051-0.079 W/m²K, values difficult to achieve with standard galvanized steel systems without substantial additional insulation.

The European Union's Energy Performance of Buildings Directive (EPBD) has established even more ambitious targets, requiring all new buildings to be nearly zero-energy buildings (nZEB) from 2021. This directive has accelerated the adoption of high-performance building envelope solutions, with many EU member states implementing national building codes that effectively mandate insulated panel systems for most commercial applications.

Certification systems like LEED, BREEAM, and Passive House have further influenced market dynamics by rewarding superior thermal performance beyond code minimums. These voluntary standards often serve as precursors to future mandatory requirements and create premium market segments where IMPs demonstrate significant advantages over traditional galvanized steel construction.

Compliance methodologies vary across jurisdictions, with prescriptive paths specifying minimum R-values for building components, and performance paths allowing trade-offs between systems while meeting overall building energy targets. The trend toward performance-based compliance has generally benefited integrated solutions like IMPs, which can deliver predictable thermal performance with fewer thermal bridges compared to field-assembled systems using galvanized steel.

Looking forward, regulatory roadmaps in major economies indicate continued tightening of energy efficiency requirements. The EU's "Renovation Wave" strategy aims to double renovation rates in the next decade, while various U.S. states have established climate action plans with aggressive decarbonization targets for the building sector. These regulatory trends suggest that the comparative advantage of IMPs over galvanized steel in thermal conductivity performance will likely translate into growing market share as compliance with energy codes becomes increasingly challenging for traditional construction methods.

In the United States, the International Energy Conservation Code (IECC) and ASHRAE Standard 90.1 establish minimum requirements for building thermal performance, with updates typically occurring every three years. These standards have progressively tightened U-value requirements for wall assemblies, creating market pressure favoring high-performance solutions like IMPs over traditional galvanized steel construction. The 2021 IECC, for instance, requires commercial buildings in climate zones 4-8 to achieve wall assembly U-factors between 0.051-0.079 W/m²K, values difficult to achieve with standard galvanized steel systems without substantial additional insulation.

The European Union's Energy Performance of Buildings Directive (EPBD) has established even more ambitious targets, requiring all new buildings to be nearly zero-energy buildings (nZEB) from 2021. This directive has accelerated the adoption of high-performance building envelope solutions, with many EU member states implementing national building codes that effectively mandate insulated panel systems for most commercial applications.

Certification systems like LEED, BREEAM, and Passive House have further influenced market dynamics by rewarding superior thermal performance beyond code minimums. These voluntary standards often serve as precursors to future mandatory requirements and create premium market segments where IMPs demonstrate significant advantages over traditional galvanized steel construction.

Compliance methodologies vary across jurisdictions, with prescriptive paths specifying minimum R-values for building components, and performance paths allowing trade-offs between systems while meeting overall building energy targets. The trend toward performance-based compliance has generally benefited integrated solutions like IMPs, which can deliver predictable thermal performance with fewer thermal bridges compared to field-assembled systems using galvanized steel.

Looking forward, regulatory roadmaps in major economies indicate continued tightening of energy efficiency requirements. The EU's "Renovation Wave" strategy aims to double renovation rates in the next decade, while various U.S. states have established climate action plans with aggressive decarbonization targets for the building sector. These regulatory trends suggest that the comparative advantage of IMPs over galvanized steel in thermal conductivity performance will likely translate into growing market share as compliance with energy codes becomes increasingly challenging for traditional construction methods.

Life Cycle Assessment of Thermal Materials

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of thermal materials throughout their entire existence. When comparing galvanized steel and insulated metal panels (IMPs), LCA reveals significant differences in their environmental footprints across production, use, and end-of-life phases.

The production phase of galvanized steel involves energy-intensive processes including mining iron ore, coal extraction, steel manufacturing, and zinc coating. These processes generate substantial greenhouse gas emissions, primarily CO2, and require considerable water usage. Conversely, IMPs production encompasses multiple components - steel facings and insulating core materials (typically polyurethane, polyisocyanurate, or mineral wool). While the steel facings share similar environmental impacts with galvanized steel, the insulation core manufacturing introduces additional environmental considerations, including potential use of blowing agents with high global warming potential.

During the use phase, the thermal conductivity differences become paramount. Galvanized steel exhibits high thermal conductivity (approximately 45-60 W/mK), creating significant thermal bridging issues in building envelopes. This results in increased energy consumption for heating and cooling throughout the building's operational life. IMPs, with their integrated insulation cores, demonstrate substantially lower thermal conductivity values (typically 0.02-0.04 W/mK), dramatically reducing energy transfer and associated operational emissions.

End-of-life considerations further differentiate these materials. Galvanized steel offers excellent recyclability, with recovery rates exceeding 90% in many developed markets, reducing the environmental impact of raw material extraction for new production. IMPs present more complex recycling challenges due to their composite nature, often requiring separation of the steel facings from the insulation core. The insulation materials may have limited recycling options, particularly for foam-based cores, potentially leading to landfill disposal.

Economic analysis across the life cycle reveals that while galvanized steel typically has lower initial costs, the superior thermal performance of IMPs often results in substantial operational savings through reduced energy consumption. Studies indicate that buildings utilizing IMPs can achieve energy savings of 30-40% compared to conventional steel construction, potentially offsetting the higher initial investment within 5-10 years depending on climate conditions and energy prices.

Environmental impact assessments demonstrate that despite the potentially higher embodied carbon in IMPs production, their superior thermal performance typically results in lower overall carbon emissions across the full life cycle in most climate zones where heating or cooling demands are significant.

The production phase of galvanized steel involves energy-intensive processes including mining iron ore, coal extraction, steel manufacturing, and zinc coating. These processes generate substantial greenhouse gas emissions, primarily CO2, and require considerable water usage. Conversely, IMPs production encompasses multiple components - steel facings and insulating core materials (typically polyurethane, polyisocyanurate, or mineral wool). While the steel facings share similar environmental impacts with galvanized steel, the insulation core manufacturing introduces additional environmental considerations, including potential use of blowing agents with high global warming potential.

During the use phase, the thermal conductivity differences become paramount. Galvanized steel exhibits high thermal conductivity (approximately 45-60 W/mK), creating significant thermal bridging issues in building envelopes. This results in increased energy consumption for heating and cooling throughout the building's operational life. IMPs, with their integrated insulation cores, demonstrate substantially lower thermal conductivity values (typically 0.02-0.04 W/mK), dramatically reducing energy transfer and associated operational emissions.

End-of-life considerations further differentiate these materials. Galvanized steel offers excellent recyclability, with recovery rates exceeding 90% in many developed markets, reducing the environmental impact of raw material extraction for new production. IMPs present more complex recycling challenges due to their composite nature, often requiring separation of the steel facings from the insulation core. The insulation materials may have limited recycling options, particularly for foam-based cores, potentially leading to landfill disposal.

Economic analysis across the life cycle reveals that while galvanized steel typically has lower initial costs, the superior thermal performance of IMPs often results in substantial operational savings through reduced energy consumption. Studies indicate that buildings utilizing IMPs can achieve energy savings of 30-40% compared to conventional steel construction, potentially offsetting the higher initial investment within 5-10 years depending on climate conditions and energy prices.

Environmental impact assessments demonstrate that despite the potentially higher embodied carbon in IMPs production, their superior thermal performance typically results in lower overall carbon emissions across the full life cycle in most climate zones where heating or cooling demands are significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!