Optimize Galvanized Steel Resistance in Marine Environments

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Corrosion Background and Objectives

Marine corrosion represents one of the most significant challenges in materials engineering, particularly for galvanized steel structures deployed in coastal and offshore environments. The historical development of corrosion protection technologies dates back to the 18th century when Sir Humphry Davy first demonstrated cathodic protection principles. Since then, galvanization has evolved as a primary method for protecting steel against aggressive marine conditions, with hot-dip galvanizing becoming commercially viable in the mid-19th century.

The marine environment presents uniquely harsh conditions due to the combination of high chloride content, varying oxygen levels, fluctuating temperatures, and biological activity. These factors accelerate corrosion processes at rates significantly higher than those observed in non-marine settings. Traditional galvanized coatings, while effective in many applications, have shown limitations in long-term performance under severe marine exposure, particularly in splash zones and tidal regions where corrosion rates can be 10-15 times higher than in atmospheric conditions.

Recent technological advancements have focused on enhancing the durability of galvanized steel through modified zinc alloys, multi-layer protection systems, and surface treatments. The integration of aluminum, magnesium, and other elements into zinc coatings has demonstrated promising results in laboratory testing, showing potential to extend service life by 30-50% compared to conventional galvanized systems.

The primary objective of optimizing galvanized steel resistance in marine environments is to develop cost-effective solutions that can maintain structural integrity for 25+ years while minimizing maintenance requirements. This involves addressing several technical challenges, including the mitigation of galvanic corrosion between dissimilar metals, prevention of zinc coating degradation in high-chloride environments, and development of self-healing capabilities to address coating damage.

Current research trends indicate a shift toward environmentally sustainable protection systems that eliminate toxic components while maintaining or improving performance characteristics. This aligns with global regulatory frameworks increasingly restricting the use of certain corrosion inhibitors and heavy metals in marine applications.

The economic implications of enhanced corrosion resistance are substantial, with potential savings in maintenance and replacement costs estimated at $2.5 trillion annually worldwide. For marine infrastructure specifically, extending service life by even 5-10 years represents billions in deferred capital expenditure and reduced operational disruptions.

As we advance toward more resilient galvanized steel solutions, the integration of digital monitoring technologies and predictive analytics presents opportunities for real-time corrosion assessment and preventive maintenance strategies, further optimizing lifecycle performance in challenging marine environments.

The marine environment presents uniquely harsh conditions due to the combination of high chloride content, varying oxygen levels, fluctuating temperatures, and biological activity. These factors accelerate corrosion processes at rates significantly higher than those observed in non-marine settings. Traditional galvanized coatings, while effective in many applications, have shown limitations in long-term performance under severe marine exposure, particularly in splash zones and tidal regions where corrosion rates can be 10-15 times higher than in atmospheric conditions.

Recent technological advancements have focused on enhancing the durability of galvanized steel through modified zinc alloys, multi-layer protection systems, and surface treatments. The integration of aluminum, magnesium, and other elements into zinc coatings has demonstrated promising results in laboratory testing, showing potential to extend service life by 30-50% compared to conventional galvanized systems.

The primary objective of optimizing galvanized steel resistance in marine environments is to develop cost-effective solutions that can maintain structural integrity for 25+ years while minimizing maintenance requirements. This involves addressing several technical challenges, including the mitigation of galvanic corrosion between dissimilar metals, prevention of zinc coating degradation in high-chloride environments, and development of self-healing capabilities to address coating damage.

Current research trends indicate a shift toward environmentally sustainable protection systems that eliminate toxic components while maintaining or improving performance characteristics. This aligns with global regulatory frameworks increasingly restricting the use of certain corrosion inhibitors and heavy metals in marine applications.

The economic implications of enhanced corrosion resistance are substantial, with potential savings in maintenance and replacement costs estimated at $2.5 trillion annually worldwide. For marine infrastructure specifically, extending service life by even 5-10 years represents billions in deferred capital expenditure and reduced operational disruptions.

As we advance toward more resilient galvanized steel solutions, the integration of digital monitoring technologies and predictive analytics presents opportunities for real-time corrosion assessment and preventive maintenance strategies, further optimizing lifecycle performance in challenging marine environments.

Market Demand Analysis for Marine-Grade Galvanized Steel

The global market for marine-grade galvanized steel continues to experience robust growth, driven primarily by expanding maritime infrastructure development and increasing offshore activities. Current market valuations indicate the marine-grade steel sector represents approximately 18% of the specialized steel market, with annual growth rates consistently outpacing general construction steel by 3-4 percentage points. This premium segment is projected to reach $47 billion by 2028, reflecting the increasing demand for corrosion-resistant materials in harsh marine environments.

Shipbuilding remains the largest application segment, accounting for nearly 40% of marine-grade galvanized steel consumption. The global shipbuilding industry's recovery post-pandemic has accelerated demand, particularly in Asian markets where shipyard activity has increased by 22% year-over-year. China, South Korea, and Japan collectively represent over 75% of global shipbuilding capacity, creating significant regional demand concentration.

Offshore structures constitute the second-largest market segment, with oil and gas platforms, wind farms, and tidal energy installations driving consumption. The offshore wind sector alone has seen 34% annual growth in steel requirements, with projections indicating this trend will continue as renewable energy investments accelerate globally. The North Sea, South China Sea, and Gulf of Mexico regions demonstrate particularly strong demand growth trajectories.

Port infrastructure development represents another significant market driver, with over 300 major port expansion or modernization projects currently underway worldwide. These developments require substantial quantities of marine-grade galvanized steel for terminals, piers, and supporting structures. Emerging economies in Southeast Asia and Africa are showing the highest growth rates in this segment, with infrastructure investment increasing by 27% annually.

Customer requirements are evolving toward enhanced performance specifications, with service life expectations increasing from the traditional 15-20 years to 30+ years for critical marine applications. This shift has created premium market segments for advanced galvanizing technologies that can deliver superior corrosion resistance in aggressive saltwater environments. Surveys indicate that 78% of marine engineering firms are willing to pay 15-20% price premiums for materials that can demonstrate extended service life guarantees.

Regulatory factors are also influencing market dynamics, with stricter environmental standards and safety regulations driving demand for higher-quality coatings and more durable materials. The International Maritime Organization's regulations on sustainable shipping have created additional market opportunities for advanced galvanized steel products that contribute to reduced maintenance requirements and longer vessel operational lifespans.

Shipbuilding remains the largest application segment, accounting for nearly 40% of marine-grade galvanized steel consumption. The global shipbuilding industry's recovery post-pandemic has accelerated demand, particularly in Asian markets where shipyard activity has increased by 22% year-over-year. China, South Korea, and Japan collectively represent over 75% of global shipbuilding capacity, creating significant regional demand concentration.

Offshore structures constitute the second-largest market segment, with oil and gas platforms, wind farms, and tidal energy installations driving consumption. The offshore wind sector alone has seen 34% annual growth in steel requirements, with projections indicating this trend will continue as renewable energy investments accelerate globally. The North Sea, South China Sea, and Gulf of Mexico regions demonstrate particularly strong demand growth trajectories.

Port infrastructure development represents another significant market driver, with over 300 major port expansion or modernization projects currently underway worldwide. These developments require substantial quantities of marine-grade galvanized steel for terminals, piers, and supporting structures. Emerging economies in Southeast Asia and Africa are showing the highest growth rates in this segment, with infrastructure investment increasing by 27% annually.

Customer requirements are evolving toward enhanced performance specifications, with service life expectations increasing from the traditional 15-20 years to 30+ years for critical marine applications. This shift has created premium market segments for advanced galvanizing technologies that can deliver superior corrosion resistance in aggressive saltwater environments. Surveys indicate that 78% of marine engineering firms are willing to pay 15-20% price premiums for materials that can demonstrate extended service life guarantees.

Regulatory factors are also influencing market dynamics, with stricter environmental standards and safety regulations driving demand for higher-quality coatings and more durable materials. The International Maritime Organization's regulations on sustainable shipping have created additional market opportunities for advanced galvanized steel products that contribute to reduced maintenance requirements and longer vessel operational lifespans.

Current Challenges in Marine Corrosion Protection

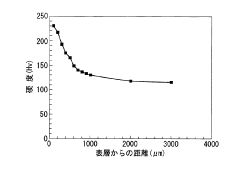

Marine environments present some of the most aggressive conditions for galvanized steel structures, with multiple corrosion mechanisms operating simultaneously. The primary challenge stems from the high chloride content in seawater, which accelerates the degradation of zinc coating through rapid dissolution. Studies indicate that zinc corrosion rates in marine environments can be 10-15 times higher than in rural settings, significantly reducing the protective lifespan of galvanized coatings.

Temperature fluctuations in marine environments create additional stress on protective coatings through thermal expansion and contraction cycles. These physical stresses often lead to microscopic cracks that become entry points for corrosive agents. Research shows that temperature variations of just 20°C can double the rate of certain corrosion reactions, particularly in splash zones where structures experience both atmospheric and immersion conditions.

Biofouling represents another significant challenge, as marine organisms attach to submerged structures and create microenvironments that accelerate localized corrosion. These organisms can create oxygen concentration cells and produce metabolic byproducts that are highly corrosive to both zinc coatings and the underlying steel substrate. Current antifouling solutions often contain environmentally problematic compounds, creating a tension between corrosion protection and environmental compliance.

The varying exposure zones in marine environments (atmospheric, splash, tidal, and submerged) each present unique corrosion mechanisms requiring specialized protection strategies. Particularly challenging is the splash zone, where structures experience cyclic wetting and drying, oxygen saturation, and mechanical impact from waves. Traditional galvanized coatings alone typically provide only 2-5 years of protection in splash zones compared to 15-20 years in atmospheric zones.

Current protective systems face significant limitations in durability and environmental compatibility. Conventional zinc coatings often incorporate heavy metals like cadmium or chromium for enhanced performance, but these face increasing regulatory restrictions worldwide. Alternative formulations using more environmentally acceptable inhibitors frequently demonstrate reduced performance, particularly in high-salinity conditions.

The economic impact of marine corrosion is substantial, with global costs estimated at $2.5 trillion annually, representing approximately 3.4% of global GDP. The marine sector alone accounts for approximately $50-80 billion of these costs. Despite significant research investment, the gap between laboratory performance and real-world durability remains problematic, with many promising solutions failing to deliver expected protection when deployed in actual marine environments.

Temperature fluctuations in marine environments create additional stress on protective coatings through thermal expansion and contraction cycles. These physical stresses often lead to microscopic cracks that become entry points for corrosive agents. Research shows that temperature variations of just 20°C can double the rate of certain corrosion reactions, particularly in splash zones where structures experience both atmospheric and immersion conditions.

Biofouling represents another significant challenge, as marine organisms attach to submerged structures and create microenvironments that accelerate localized corrosion. These organisms can create oxygen concentration cells and produce metabolic byproducts that are highly corrosive to both zinc coatings and the underlying steel substrate. Current antifouling solutions often contain environmentally problematic compounds, creating a tension between corrosion protection and environmental compliance.

The varying exposure zones in marine environments (atmospheric, splash, tidal, and submerged) each present unique corrosion mechanisms requiring specialized protection strategies. Particularly challenging is the splash zone, where structures experience cyclic wetting and drying, oxygen saturation, and mechanical impact from waves. Traditional galvanized coatings alone typically provide only 2-5 years of protection in splash zones compared to 15-20 years in atmospheric zones.

Current protective systems face significant limitations in durability and environmental compatibility. Conventional zinc coatings often incorporate heavy metals like cadmium or chromium for enhanced performance, but these face increasing regulatory restrictions worldwide. Alternative formulations using more environmentally acceptable inhibitors frequently demonstrate reduced performance, particularly in high-salinity conditions.

The economic impact of marine corrosion is substantial, with global costs estimated at $2.5 trillion annually, representing approximately 3.4% of global GDP. The marine sector alone accounts for approximately $50-80 billion of these costs. Despite significant research investment, the gap between laboratory performance and real-world durability remains problematic, with many promising solutions failing to deliver expected protection when deployed in actual marine environments.

Existing Galvanized Steel Protection Solutions

01 Corrosion resistance enhancement in galvanized steel

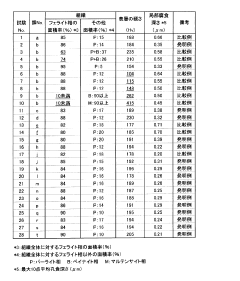

Various methods can be employed to enhance the corrosion resistance of galvanized steel. These include the application of specialized coatings, incorporation of corrosion inhibitors, and modification of the galvanization process. By improving the corrosion resistance, the overall durability and lifespan of galvanized steel products can be significantly increased, particularly in harsh environmental conditions.- Corrosion resistance enhancement in galvanized steel: Various methods and compositions can be used to enhance the corrosion resistance of galvanized steel. These include specialized coating formulations, surface treatments, and the addition of specific alloying elements to the zinc coating. These approaches create protective barriers that prevent oxidation and extend the service life of galvanized steel products in corrosive environments.

- Mechanical resistance improvement techniques: Techniques to improve the mechanical resistance properties of galvanized steel include controlled heat treatments, microstructure optimization, and specific processing methods. These approaches enhance properties such as tensile strength, hardness, and wear resistance while maintaining the corrosion protection provided by the zinc coating. The resulting materials offer improved performance in structural and high-stress applications.

- Zinc coating composition modifications: Modifications to the zinc coating composition can significantly impact the resistance properties of galvanized steel. By incorporating specific elements such as aluminum, magnesium, or rare earth metals into the zinc bath, enhanced corrosion resistance and mechanical properties can be achieved. These modified coatings provide superior protection in aggressive environments while maintaining good formability and adhesion characteristics.

- Surface treatment processes for improved resistance: Various surface treatment processes can be applied to galvanized steel to improve its resistance properties. These include chemical passivation, phosphating, chromating, and the application of organic coatings. Such treatments create additional protective layers that enhance corrosion resistance, adhesion properties, and overall durability of galvanized steel products in challenging environments.

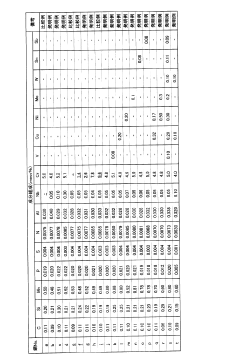

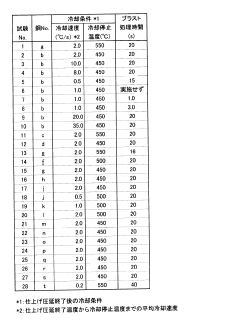

- Heat treatment effects on galvanized steel resistance: Heat treatment processes significantly influence the resistance properties of galvanized steel. Controlled heating and cooling cycles can optimize the microstructure, improve the zinc-iron intermetallic layer formation, and enhance both mechanical and corrosion resistance. These thermal processes can be tailored to specific applications, balancing corrosion protection with mechanical performance requirements.

02 Composition modifications for improved resistance properties

The resistance properties of galvanized steel can be improved by modifying the composition of the zinc coating or the base steel. Adding elements such as aluminum, magnesium, or silicon to the zinc bath can enhance various resistance properties. These compositional modifications can lead to improved corrosion resistance, better adhesion between the zinc coating and steel substrate, and enhanced mechanical properties of the galvanized product.Expand Specific Solutions03 Heat treatment effects on galvanized steel resistance

Heat treatment processes applied to galvanized steel can significantly affect its resistance properties. Controlled heating and cooling cycles can optimize the microstructure of both the zinc coating and the steel substrate, leading to improved mechanical resistance, better corrosion protection, and enhanced durability. Various heat treatment parameters including temperature, duration, and cooling rate can be adjusted to achieve specific resistance properties for different applications.Expand Specific Solutions04 Surface treatment techniques for resistance improvement

Various surface treatment techniques can be applied to galvanized steel to improve its resistance properties. These include chemical passivation, application of conversion coatings, surface texturing, and post-galvanizing treatments. Such treatments can enhance corrosion resistance, wear resistance, and adhesion properties of subsequent coatings. The selection of appropriate surface treatment depends on the specific application requirements and environmental exposure conditions.Expand Specific Solutions05 Testing and measurement methods for galvanized steel resistance

Various testing and measurement methods are employed to evaluate the resistance properties of galvanized steel. These include accelerated corrosion tests, electrochemical impedance spectroscopy, salt spray testing, and mechanical resistance tests. These methods help in quantifying the performance of galvanized steel under different conditions and enable the comparison of different galvanizing processes or treatments. Standardized testing protocols ensure consistency and reliability in resistance evaluation.Expand Specific Solutions

Key Industry Players in Marine Corrosion Protection

The marine galvanized steel protection market is currently in a growth phase, driven by expanding maritime infrastructure and increasing awareness of corrosion challenges. The global market for marine corrosion protection is estimated at $7-9 billion annually, with steady growth projected at 4-5% CAGR. Technologically, solutions range from traditional hot-dip galvanizing to advanced multi-layer protection systems. Industry leaders like POSCO Holdings, NIPPON STEEL, and Baoshan Iron & Steel are developing proprietary marine-grade galvanized steel with enhanced salt resistance, while Kobe Steel and JFE Steel focus on specialized coatings for extreme environments. Research partnerships between companies and institutions like University of Science & Technology Beijing and Northwestern University are advancing nano-coating technologies and environmentally friendly protection methods, positioning galvanized steel optimization as a critical focus area for maritime applications.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baosteel has developed B-ZAM® (Baosteel Zinc-Aluminum-Magnesium) coating technology specifically designed to enhance galvanized steel resistance in marine environments. This innovative coating system incorporates approximately 5% aluminum, 3% magnesium, and trace elements into the zinc coating, creating a complex protective barrier against saltwater corrosion. Baosteel's research has demonstrated that their coating forms stable corrosion products including zinc-aluminum-magnesium hydroxides and simonkolleite when exposed to marine conditions, which effectively seal the surface and inhibit further corrosion progression. Their manufacturing process employs precise temperature control during hot-dip galvanizing, followed by a controlled cooling regimen that optimizes the microstructure of the coating. Laboratory testing shows that B-ZAM® exhibits 4-6 times greater corrosion resistance than conventional galvanized steel in salt spray tests. Additionally, Baosteel has developed specialized edge protection technologies to address the vulnerability of cut edges in marine applications, applying additional protective compounds to these areas to prevent accelerated corrosion.

Strengths: Significantly improved corrosion resistance in marine environments compared to conventional galvanized steel; cost-effective solution for extending service life in coastal applications; compatible with existing fabrication processes. Weaknesses: Relatively newer technology with less long-term performance data compared to some competitors; potential challenges with coating uniformity in complex geometries; may require specialized welding techniques.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed the KOBEMAG® galvanized steel system specifically engineered for marine environment applications. This advanced coating technology incorporates a zinc-aluminum-magnesium alloy with approximately 6% aluminum, 3% magnesium, and trace amounts of silicon and other elements. The coating forms a complex protective layer featuring a unique microstructure that significantly enhances corrosion resistance in saltwater environments. Kobe's research has demonstrated that their coating technology creates a stable barrier of zinc-aluminum-magnesium hydroxycarbonates when exposed to marine conditions, which effectively inhibits the cathodic reaction that drives corrosion. Their manufacturing process employs precise temperature control during the hot-dip galvanizing process, followed by a specialized cooling regimen that optimizes the crystalline structure of the coating. Kobe Steel has also developed proprietary edge protection technologies to address the vulnerability of cut edges and has implemented specialized surface preparation techniques to enhance coating adhesion and uniformity across the steel substrate.

Strengths: Exceptional corrosion resistance in marine environments; specialized edge protection technology; comprehensive quality control systems ensuring consistent performance. Weaknesses: Higher manufacturing costs compared to conventional galvanizing; requires specialized equipment and expertise; potential challenges with welding and joining techniques compared to uncoated steel.

Advanced Coating Technologies Analysis

Steel material excellent in sea-water corrosion resistance

PatentInactiveJP2011225918A

Innovation

- A steel composition with controlled chromium content (2.0% to 9.0%) and a ferrite phase structure, combined with elements like niobium and strain-induced refinement of carbides, to enhance general and localized corrosion resistance, minimizing maintenance and improving life cycle costs.

Weathering steel used in marine environment

PatentActiveCN107488818A

Innovation

- Weathering steel containing specific alloy elements is used, which is treated by alloy solid solution, water quenching, and annealing. After pickling, chromate conversion treatment is used to form a protective film. The surface is then sprayed with mixed hot aluminum powder containing rare earth elements to form a high temperature Rare earth ions are implanted into the surface of the steel to form a metallurgical phase to improve hardness and corrosion resistance.

Environmental Impact Assessment

The environmental impact of galvanized steel in marine environments extends beyond its primary function of corrosion protection. When considering optimization strategies, a comprehensive assessment of ecological consequences becomes essential for sustainable implementation. Galvanized coatings primarily consist of zinc, which can gradually leach into surrounding ecosystems through weathering and corrosion processes in marine settings.

Marine environments present particularly challenging conditions where zinc ions may be released into seawater, potentially affecting aquatic organisms. Studies have shown that elevated zinc concentrations can impact marine biodiversity, particularly affecting filter-feeding organisms and larval stages of various species. The bioaccumulation potential of zinc in marine food chains requires careful monitoring when deploying galvanized steel structures in sensitive coastal ecosystems.

The production processes for enhanced galvanized coatings also carry environmental considerations. Traditional hot-dip galvanizing involves energy-intensive heating processes and chemical treatments that generate emissions and waste products. Advanced coating technologies may incorporate additional elements like aluminum, magnesium, or rare earth metals, which have their own environmental extraction and processing footprints.

Lifecycle assessment data indicates that optimizing galvanized steel for marine applications can yield positive environmental outcomes when considering the full product lifecycle. Extended service life reduces the frequency of replacement, thereby decreasing the cumulative environmental impact associated with manufacturing, transportation, and installation of steel structures. Research suggests that doubling the service life of marine steel structures can reduce overall environmental impact by approximately 40-45%.

Waste management considerations are equally important, as end-of-life galvanized steel components require proper recycling protocols. While steel itself is highly recyclable, specialized coatings may complicate the recycling process or introduce contaminants into the recycling stream. Developing coating systems that maintain compatibility with existing recycling infrastructure represents an important optimization goal.

Regulatory frameworks worldwide are increasingly incorporating environmental impact criteria for marine construction materials. The European Union's Marine Strategy Framework Directive and similar regulations in other regions establish thresholds for zinc and other metal releases into marine environments. Compliance with these evolving standards necessitates continuous improvement in coating technologies that balance corrosion resistance with minimal environmental footprint.

Marine environments present particularly challenging conditions where zinc ions may be released into seawater, potentially affecting aquatic organisms. Studies have shown that elevated zinc concentrations can impact marine biodiversity, particularly affecting filter-feeding organisms and larval stages of various species. The bioaccumulation potential of zinc in marine food chains requires careful monitoring when deploying galvanized steel structures in sensitive coastal ecosystems.

The production processes for enhanced galvanized coatings also carry environmental considerations. Traditional hot-dip galvanizing involves energy-intensive heating processes and chemical treatments that generate emissions and waste products. Advanced coating technologies may incorporate additional elements like aluminum, magnesium, or rare earth metals, which have their own environmental extraction and processing footprints.

Lifecycle assessment data indicates that optimizing galvanized steel for marine applications can yield positive environmental outcomes when considering the full product lifecycle. Extended service life reduces the frequency of replacement, thereby decreasing the cumulative environmental impact associated with manufacturing, transportation, and installation of steel structures. Research suggests that doubling the service life of marine steel structures can reduce overall environmental impact by approximately 40-45%.

Waste management considerations are equally important, as end-of-life galvanized steel components require proper recycling protocols. While steel itself is highly recyclable, specialized coatings may complicate the recycling process or introduce contaminants into the recycling stream. Developing coating systems that maintain compatibility with existing recycling infrastructure represents an important optimization goal.

Regulatory frameworks worldwide are increasingly incorporating environmental impact criteria for marine construction materials. The European Union's Marine Strategy Framework Directive and similar regulations in other regions establish thresholds for zinc and other metal releases into marine environments. Compliance with these evolving standards necessitates continuous improvement in coating technologies that balance corrosion resistance with minimal environmental footprint.

Cost-Benefit Analysis of Protection Methods

When evaluating protection methods for galvanized steel in marine environments, financial considerations play a crucial role in decision-making processes. Initial implementation costs vary significantly across different protection systems, with traditional hot-dip galvanizing representing a moderate investment compared to specialized marine-grade coatings which can cost 30-40% more upfront. However, these premium solutions typically offer extended service life that may justify the higher initial expenditure.

Maintenance expenses constitute a substantial portion of the total cost of ownership. Standard galvanized steel may require maintenance interventions every 5-7 years in aggressive marine settings, while advanced protection systems incorporating zinc-aluminum alloys can extend maintenance intervals to 12-15 years. This reduction in maintenance frequency translates to significant operational savings, particularly for difficult-to-access structures where scaffolding and specialized equipment deployment costs can exceed the material expenses.

Lifecycle analysis reveals that despite higher initial costs, premium protection methods often deliver superior return on investment. For example, thermal spray zinc coatings with sealed polymer topcoats may cost 45-60% more than basic galvanization but can extend service life by 2.5-3 times in splash zones. When factoring in the avoided costs of structural failure, business interruption, and emergency repairs, these advanced solutions demonstrate compelling economic advantages.

Environmental compliance costs represent an increasingly important consideration. Traditional protection methods may involve chemicals that face regulatory restrictions in certain jurisdictions, potentially incurring disposal fees and environmental remediation expenses. Newer, environmentally-optimized protection systems may command premium pricing but mitigate regulatory risks and associated penalties.

Opportunity costs must also be evaluated when comparing protection strategies. Structures with inadequate corrosion resistance may require premature replacement, creating significant disruption to operations. For critical infrastructure such as offshore platforms or port facilities, the economic impact of downtime can dwarf the direct costs of corrosion protection, making high-performance systems economically justified despite higher upfront investments.

Risk-adjusted cost models indicate that hybrid protection systems combining galvanization with supplementary treatments offer the most balanced cost-benefit profile for most marine applications. These approaches typically provide 85-90% of the performance of premium solutions at 60-70% of the cost, representing an optimal compromise between immediate budget constraints and long-term asset preservation objectives.

Maintenance expenses constitute a substantial portion of the total cost of ownership. Standard galvanized steel may require maintenance interventions every 5-7 years in aggressive marine settings, while advanced protection systems incorporating zinc-aluminum alloys can extend maintenance intervals to 12-15 years. This reduction in maintenance frequency translates to significant operational savings, particularly for difficult-to-access structures where scaffolding and specialized equipment deployment costs can exceed the material expenses.

Lifecycle analysis reveals that despite higher initial costs, premium protection methods often deliver superior return on investment. For example, thermal spray zinc coatings with sealed polymer topcoats may cost 45-60% more than basic galvanization but can extend service life by 2.5-3 times in splash zones. When factoring in the avoided costs of structural failure, business interruption, and emergency repairs, these advanced solutions demonstrate compelling economic advantages.

Environmental compliance costs represent an increasingly important consideration. Traditional protection methods may involve chemicals that face regulatory restrictions in certain jurisdictions, potentially incurring disposal fees and environmental remediation expenses. Newer, environmentally-optimized protection systems may command premium pricing but mitigate regulatory risks and associated penalties.

Opportunity costs must also be evaluated when comparing protection strategies. Structures with inadequate corrosion resistance may require premature replacement, creating significant disruption to operations. For critical infrastructure such as offshore platforms or port facilities, the economic impact of downtime can dwarf the direct costs of corrosion protection, making high-performance systems economically justified despite higher upfront investments.

Risk-adjusted cost models indicate that hybrid protection systems combining galvanization with supplementary treatments offer the most balanced cost-benefit profile for most marine applications. These approaches typically provide 85-90% of the performance of premium solutions at 60-70% of the cost, representing an optimal compromise between immediate budget constraints and long-term asset preservation objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!