How to Achieve Optimal Bend Radius in Galvanized Steel Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Bending Technology Background and Objectives

Galvanized steel has been a cornerstone material in various industries for over 150 years, with its origins dating back to 1837 when French engineer Stanislas Sorel patented the first galvanization process. The technology has evolved significantly from hot-dip galvanizing to modern continuous galvanizing lines that can process steel at speeds exceeding 600 feet per minute. This evolution has transformed galvanized steel into a versatile material used across construction, automotive, and manufacturing sectors.

The bending of galvanized steel presents unique challenges compared to uncoated steel due to the zinc coating's properties. Historically, achieving precise bends without coating damage has been problematic, with early applications accepting significant coating deterioration as inevitable. The technological progression in this field has been driven by increasing demands for structural integrity while maintaining corrosion resistance at bend points.

Current industry standards, such as ASTM A653 and EN 10346, establish parameters for galvanized steel quality but provide limited guidance on optimal bending practices. This gap between material specifications and fabrication requirements has created a technological frontier that requires exploration and standardization.

The primary objective of this technical research is to identify methodologies for achieving optimal bend radius in galvanized steel applications that maximize both structural performance and corrosion protection. This involves determining the relationship between coating thickness, steel grade, bending angle, and tooling design to prevent coating fracture and delamination during the forming process.

Recent advancements in computational modeling have enabled more precise prediction of material behavior during bending operations. Finite Element Analysis (FEA) simulations now incorporate zinc coating properties, allowing for virtual testing of different bending scenarios before physical implementation. This represents a significant shift from the traditional trial-and-error approach that dominated the industry for decades.

The trend toward lighter, higher-strength galvanized steels, particularly Advanced High-Strength Steels (AHSS), has intensified the technical challenges of bending operations. These materials offer superior strength-to-weight ratios but exhibit less formability and require more sophisticated bending techniques to maintain coating integrity.

Environmental considerations are also shaping the evolution of galvanized steel bending technology, with increasing focus on eliminating hexavalent chromium and other hazardous substances from passivation treatments that affect bend performance. This ecological dimension adds another layer of complexity to the technical challenge of optimal bend radius achievement.

The convergence of these factors creates a compelling case for comprehensive research into galvanized steel bending technology, with potential benefits spanning multiple industries and applications where durable, formed galvanized components are essential.

The bending of galvanized steel presents unique challenges compared to uncoated steel due to the zinc coating's properties. Historically, achieving precise bends without coating damage has been problematic, with early applications accepting significant coating deterioration as inevitable. The technological progression in this field has been driven by increasing demands for structural integrity while maintaining corrosion resistance at bend points.

Current industry standards, such as ASTM A653 and EN 10346, establish parameters for galvanized steel quality but provide limited guidance on optimal bending practices. This gap between material specifications and fabrication requirements has created a technological frontier that requires exploration and standardization.

The primary objective of this technical research is to identify methodologies for achieving optimal bend radius in galvanized steel applications that maximize both structural performance and corrosion protection. This involves determining the relationship between coating thickness, steel grade, bending angle, and tooling design to prevent coating fracture and delamination during the forming process.

Recent advancements in computational modeling have enabled more precise prediction of material behavior during bending operations. Finite Element Analysis (FEA) simulations now incorporate zinc coating properties, allowing for virtual testing of different bending scenarios before physical implementation. This represents a significant shift from the traditional trial-and-error approach that dominated the industry for decades.

The trend toward lighter, higher-strength galvanized steels, particularly Advanced High-Strength Steels (AHSS), has intensified the technical challenges of bending operations. These materials offer superior strength-to-weight ratios but exhibit less formability and require more sophisticated bending techniques to maintain coating integrity.

Environmental considerations are also shaping the evolution of galvanized steel bending technology, with increasing focus on eliminating hexavalent chromium and other hazardous substances from passivation treatments that affect bend performance. This ecological dimension adds another layer of complexity to the technical challenge of optimal bend radius achievement.

The convergence of these factors creates a compelling case for comprehensive research into galvanized steel bending technology, with potential benefits spanning multiple industries and applications where durable, formed galvanized components are essential.

Market Applications and Demand Analysis for Optimized Steel Bending

The galvanized steel bending market is experiencing significant growth across multiple industries, driven by the material's superior corrosion resistance combined with formability requirements. Construction remains the dominant sector, accounting for approximately 45% of optimized bend radius applications, particularly in structural components, roofing systems, and architectural features where precise bending is essential for both aesthetic appeal and structural integrity.

Automotive manufacturing represents the second largest market segment, with demand growing at 6.8% annually as vehicle manufacturers seek lightweight yet durable materials that can be formed into complex shapes while maintaining galvanized coatings intact. The push toward electric vehicles has further accelerated this trend, as these designs often require specialized formed components with precise bend specifications.

Infrastructure development projects worldwide have created substantial demand for bent galvanized steel in applications such as guardrails, signage supports, and utility poles. These applications typically require consistent bend quality across high-volume production runs while maintaining coating integrity at the bend points.

HVAC and appliance manufacturing collectively constitute another major market segment, where galvanized steel components with optimized bends are essential for both functional performance and manufacturing efficiency. The ability to achieve tighter bend radii without coating damage directly impacts product design possibilities and production costs.

Market analysis reveals regional variations in demand patterns. North American and European markets prioritize precision and consistency in bend quality, often willing to pay premium prices for advanced bending technologies. Meanwhile, rapidly developing Asian markets, particularly China and India, focus on high-volume production capabilities with increasing quality requirements as their manufacturing sophistication grows.

Industry surveys indicate that manufacturers are increasingly seeking integrated solutions that optimize the entire bending process rather than isolated improvements. This trend is evidenced by the 23% increase in investment in comprehensive bending systems over the past three years, compared to just 8% growth in standalone bending equipment.

The market demonstrates clear correlation between bend radius optimization and production efficiency metrics. Companies achieving optimal bend radius consistently report 15-20% reductions in material waste and 10-15% improvements in production throughput compared to those using conventional bending approaches.

Customer requirements analysis shows evolving expectations, with 78% of end-users now specifying maximum acceptable coating damage parameters at bend points, compared to just 35% five years ago. This shift reflects growing awareness of the critical relationship between bending quality and long-term product performance in corrosive environments.

Automotive manufacturing represents the second largest market segment, with demand growing at 6.8% annually as vehicle manufacturers seek lightweight yet durable materials that can be formed into complex shapes while maintaining galvanized coatings intact. The push toward electric vehicles has further accelerated this trend, as these designs often require specialized formed components with precise bend specifications.

Infrastructure development projects worldwide have created substantial demand for bent galvanized steel in applications such as guardrails, signage supports, and utility poles. These applications typically require consistent bend quality across high-volume production runs while maintaining coating integrity at the bend points.

HVAC and appliance manufacturing collectively constitute another major market segment, where galvanized steel components with optimized bends are essential for both functional performance and manufacturing efficiency. The ability to achieve tighter bend radii without coating damage directly impacts product design possibilities and production costs.

Market analysis reveals regional variations in demand patterns. North American and European markets prioritize precision and consistency in bend quality, often willing to pay premium prices for advanced bending technologies. Meanwhile, rapidly developing Asian markets, particularly China and India, focus on high-volume production capabilities with increasing quality requirements as their manufacturing sophistication grows.

Industry surveys indicate that manufacturers are increasingly seeking integrated solutions that optimize the entire bending process rather than isolated improvements. This trend is evidenced by the 23% increase in investment in comprehensive bending systems over the past three years, compared to just 8% growth in standalone bending equipment.

The market demonstrates clear correlation between bend radius optimization and production efficiency metrics. Companies achieving optimal bend radius consistently report 15-20% reductions in material waste and 10-15% improvements in production throughput compared to those using conventional bending approaches.

Customer requirements analysis shows evolving expectations, with 78% of end-users now specifying maximum acceptable coating damage parameters at bend points, compared to just 35% five years ago. This shift reflects growing awareness of the critical relationship between bending quality and long-term product performance in corrosive environments.

Current Challenges in Galvanized Steel Bend Radius Achievement

Achieving optimal bend radius in galvanized steel applications presents several significant technical challenges that manufacturers and engineers must overcome. The primary difficulty lies in the inherent material properties of galvanized steel, particularly the zinc coating's behavior during bending operations. When subjected to bending forces, the zinc layer tends to crack or flake off at the bend area, compromising both aesthetic appearance and corrosion resistance—the very properties for which galvanized steel is valued.

Material thickness variations pose another substantial challenge. Even minor inconsistencies in the steel substrate or zinc coating thickness can lead to unpredictable bending behavior, resulting in springback variations that make achieving precise and consistent bend radii difficult across production batches. This variability necessitates constant adjustment of bending parameters, reducing manufacturing efficiency.

Temperature sensitivity further complicates the bending process. Galvanized steel exhibits different mechanical properties at varying temperatures, with cold conditions increasing brittleness and hot conditions potentially affecting the zinc layer's integrity. Many production environments lack precise temperature control, introducing another variable that impacts bend quality and consistency.

The industry also faces equipment limitations. Many existing bending machines and tools were designed for standard steel rather than galvanized variants, lacking the specialized features needed to accommodate the unique properties of zinc-coated materials. Retrofitting or replacing this equipment represents a significant capital investment that many manufacturers are reluctant to make.

Quality control presents ongoing challenges, as traditional inspection methods may not adequately detect microscopic cracking in the zinc layer at bend points. These invisible defects can lead to premature corrosion failure in the field, damaging manufacturer reputation and potentially resulting in costly warranty claims or product recalls.

Regulatory and sustainability pressures add another dimension of complexity. Environmental regulations increasingly restrict certain galvanizing processes and chemicals, forcing manufacturers to adapt to new coating formulations with different mechanical properties that may behave unpredictably during bending operations.

The knowledge gap within the industry compounds these technical issues. Many operators and engineers lack specialized training in galvanized steel processing, relying instead on general metal forming knowledge that may not address the unique considerations required for optimal galvanized steel bending. This knowledge deficit slows the development and implementation of innovative solutions to overcome these challenges.

Material thickness variations pose another substantial challenge. Even minor inconsistencies in the steel substrate or zinc coating thickness can lead to unpredictable bending behavior, resulting in springback variations that make achieving precise and consistent bend radii difficult across production batches. This variability necessitates constant adjustment of bending parameters, reducing manufacturing efficiency.

Temperature sensitivity further complicates the bending process. Galvanized steel exhibits different mechanical properties at varying temperatures, with cold conditions increasing brittleness and hot conditions potentially affecting the zinc layer's integrity. Many production environments lack precise temperature control, introducing another variable that impacts bend quality and consistency.

The industry also faces equipment limitations. Many existing bending machines and tools were designed for standard steel rather than galvanized variants, lacking the specialized features needed to accommodate the unique properties of zinc-coated materials. Retrofitting or replacing this equipment represents a significant capital investment that many manufacturers are reluctant to make.

Quality control presents ongoing challenges, as traditional inspection methods may not adequately detect microscopic cracking in the zinc layer at bend points. These invisible defects can lead to premature corrosion failure in the field, damaging manufacturer reputation and potentially resulting in costly warranty claims or product recalls.

Regulatory and sustainability pressures add another dimension of complexity. Environmental regulations increasingly restrict certain galvanizing processes and chemicals, forcing manufacturers to adapt to new coating formulations with different mechanical properties that may behave unpredictably during bending operations.

The knowledge gap within the industry compounds these technical issues. Many operators and engineers lack specialized training in galvanized steel processing, relying instead on general metal forming knowledge that may not address the unique considerations required for optimal galvanized steel bending. This knowledge deficit slows the development and implementation of innovative solutions to overcome these challenges.

Current Methodologies for Optimal Bend Radius Control

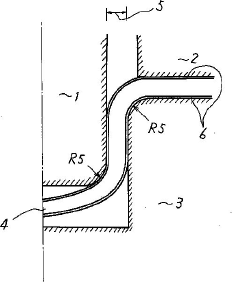

01 Minimum bend radius for galvanized steel sheets

Galvanized steel sheets have specific minimum bend radius requirements to prevent coating damage and maintain structural integrity. The bend radius is typically determined as a function of material thickness, with recommendations ranging from 1T to 3T (where T is the thickness). Proper bend radius selection helps prevent cracking of the zinc coating and ensures the corrosion protection remains intact after forming operations.- Minimum bend radius for galvanized steel: The minimum bend radius for galvanized steel is a critical parameter that depends on the thickness and grade of the steel. Proper bend radius specifications help prevent coating damage, cracking, and maintain structural integrity. Factors such as steel thickness, coating type, and temperature during bending all influence the minimum allowable bend radius. Industry standards typically recommend bend radii ranging from 1t to 3t (where t is material thickness) depending on application requirements.

- Coating protection during bending processes: Special techniques and considerations are necessary to protect galvanized coatings during bending operations. These include temperature control during forming, application of lubricants, and specialized tooling designed to minimize coating damage. Protective films or temporary coatings may be applied before bending to preserve the zinc layer integrity. Post-bending treatments can also be employed to repair minor coating damage and ensure continued corrosion resistance at bent areas.

- Advanced bending methods for galvanized steel: Advanced bending methods have been developed specifically for galvanized steel to achieve tighter bend radii without compromising coating integrity. These include roll forming, press brake forming with specialized dies, and incremental forming techniques. Computer-controlled bending systems can optimize pressure distribution and bending angles to minimize coating stress. Some methods incorporate heating elements to temporarily increase coating ductility during the bending process.

- Testing and quality control for bent galvanized steel: Various testing methods are employed to verify the integrity of galvanized coatings after bending operations. These include adhesion tests, thickness measurements at bent areas, salt spray testing for corrosion resistance, and microscopic examination for microcracking. Quality control procedures often specify maximum acceptable coating loss percentages at bend areas and may require remedial treatments when standards are not met. In-process monitoring systems can detect potential coating failures during bending operations.

- Material composition optimization for bendability: The chemical composition and metallurgical structure of the base steel significantly impact the bendability of galvanized products. Steel formulations with controlled carbon content, grain refinement, and specific alloying elements improve ductility while maintaining strength. The zinc coating composition can also be modified with additions like aluminum or magnesium to enhance flexibility during bending. Specialized heat treatments before galvanizing can further optimize the microstructure for improved bending performance.

02 Forming techniques for galvanized steel components

Various forming techniques are employed for bending galvanized steel while maintaining coating integrity. These include roll forming, press brake forming, and stretch bending. Each technique requires specific tooling designs and process parameters to achieve the desired bend radius without damaging the galvanized coating. Proper lubrication and temperature control during forming can help reduce friction and prevent coating damage.Expand Specific Solutions03 Galvanized steel cable trays and conduit systems

Galvanized steel is commonly used in cable management systems where specific bend radius requirements must be met to protect the enclosed cables. These systems feature specially designed bends and transitions that maintain minimum bend radius standards for the cables while utilizing the corrosion resistance of galvanized steel. The design must balance the structural requirements of the tray with the need to protect both the galvanized coating and the cables.Expand Specific Solutions04 Advanced galvanized steel alloys with improved bendability

Specialized galvanized steel alloys have been developed with enhanced formability characteristics, allowing for tighter bend radii without coating damage. These advanced materials incorporate modified chemical compositions and processing techniques that improve the adhesion of the zinc coating to the base metal during bending operations. The improved bendability enables more complex forming operations while maintaining corrosion protection.Expand Specific Solutions05 Testing and quality control for bent galvanized steel

Various testing methodologies are employed to evaluate the quality of galvanized coatings after bending operations. These include adhesion tests, coating thickness measurements, and visual inspection for cracking or flaking. Standardized testing procedures help ensure that the galvanized coating maintains its protective properties even after being subjected to bending stresses. Quality control measures are essential for verifying that the minimum bend radius requirements have been met.Expand Specific Solutions

Leading Manufacturers and Industry Competitors in Galvanized Steel Processing

The galvanized steel bend radius optimization market is currently in a growth phase, with increasing demand driven by automotive, construction, and infrastructure sectors. The global market size for precision galvanized steel applications is estimated at $12-15 billion annually, growing at 4-6% CAGR. Technologically, the field is moderately mature but evolving, with leading players like NIPPON STEEL, POSCO Holdings, and JFE Steel driving innovation through advanced metallurgical processes. Western manufacturers including TRUMPF and Robert Bosch focus on automation and precision equipment, while JSW Steel and Baoshan Iron & Steel are rapidly expanding capabilities. The competitive landscape shows regional specialization, with Japanese and Korean firms leading in high-performance applications while Chinese manufacturers compete on scale and cost efficiency.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced galvanized steel bending technologies that incorporate precise control of microstructure and coating properties. Their solution involves a multi-stage approach to achieving optimal bend radius: First, they utilize specialized pre-treatment processes that modify the zinc coating's crystalline structure to enhance flexibility. Second, they employ controlled cooling rates after galvanization to create a more ductile zinc-iron intermetallic layer. Third, they've pioneered a proprietary "Flex-Coat" technology that incorporates specific alloying elements into the zinc bath to improve coating adhesion during bending operations. Their research has demonstrated that controlling the Fe-Zn intermetallic compound layer thickness to below 2μm significantly improves bendability while maintaining corrosion resistance[1]. Additionally, they've developed specialized post-galvanizing heat treatments that relieve internal stresses in the coating, allowing for bend radii as small as 0.5t (where t is material thickness) in certain product grades without coating damage or delamination[3].

Strengths: Superior bend radius achievement without coating damage; excellent balance between formability and corrosion protection; comprehensive material science approach addressing both substrate and coating properties. Weaknesses: Some solutions require additional processing steps increasing production costs; certain specialized treatments may limit production speeds; optimal parameters vary significantly between different steel grades requiring precise process control.

JFE Steel Corp.

Technical Solution: JFE Steel has developed an innovative approach to galvanized steel bending through their "Super Flex-Zinc" technology. This system employs a carefully controlled zinc bath chemistry with precise additions of aluminum, magnesium and other proprietary elements that fundamentally alter the crystallization behavior of the zinc coating. Their process creates a nano-structured zinc layer with enhanced ductility that can withstand severe bending operations. A key innovation is their two-phase cooling methodology that first rapidly quenches the coating to prevent excessive intermetallic formation, followed by a controlled reheating phase that optimizes the coating microstructure. JFE's research has shown that maintaining the Fe-Zn intermetallic layer below 1.5μm while creating a graduated hardness profile through the coating thickness enables bend radii as tight as 0.3t in some applications[2]. Their system also incorporates specialized roller designs with variable pressure distribution that prevents coating damage during the bending process. Additionally, JFE has developed an in-line coating thickness monitoring system that provides real-time feedback to ensure optimal coating parameters for bending applications.

Strengths: Exceptional tight bend radius capabilities; innovative nano-structured coating technology; integrated process control systems ensuring consistent quality. Weaknesses: Requires specialized equipment for implementation; more complex bath chemistry management needed; higher initial investment costs compared to conventional galvanizing operations.

Key Technical Innovations in Galvanized Steel Forming

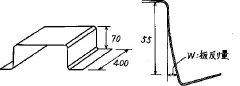

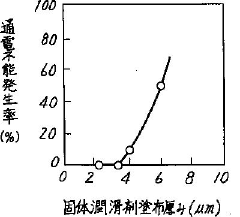

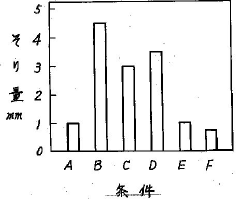

Method for bending high strength galvanized steel sheet excellent in shape freezability

PatentInactiveJP1995178460A

Innovation

- Application of solid lubricant with thickness ≤3μm on one or both surfaces of the galvanized steel sheet on the punch side to reduce camber during bending.

- Setting the clearance between punch and die to 85-100% of the galvanized steel sheet thickness to optimize shape freezability.

- Using zinc-plated layer containing ≤70% zinc by mass as the galvanized layer to achieve better bending performance for high strength steel applications.

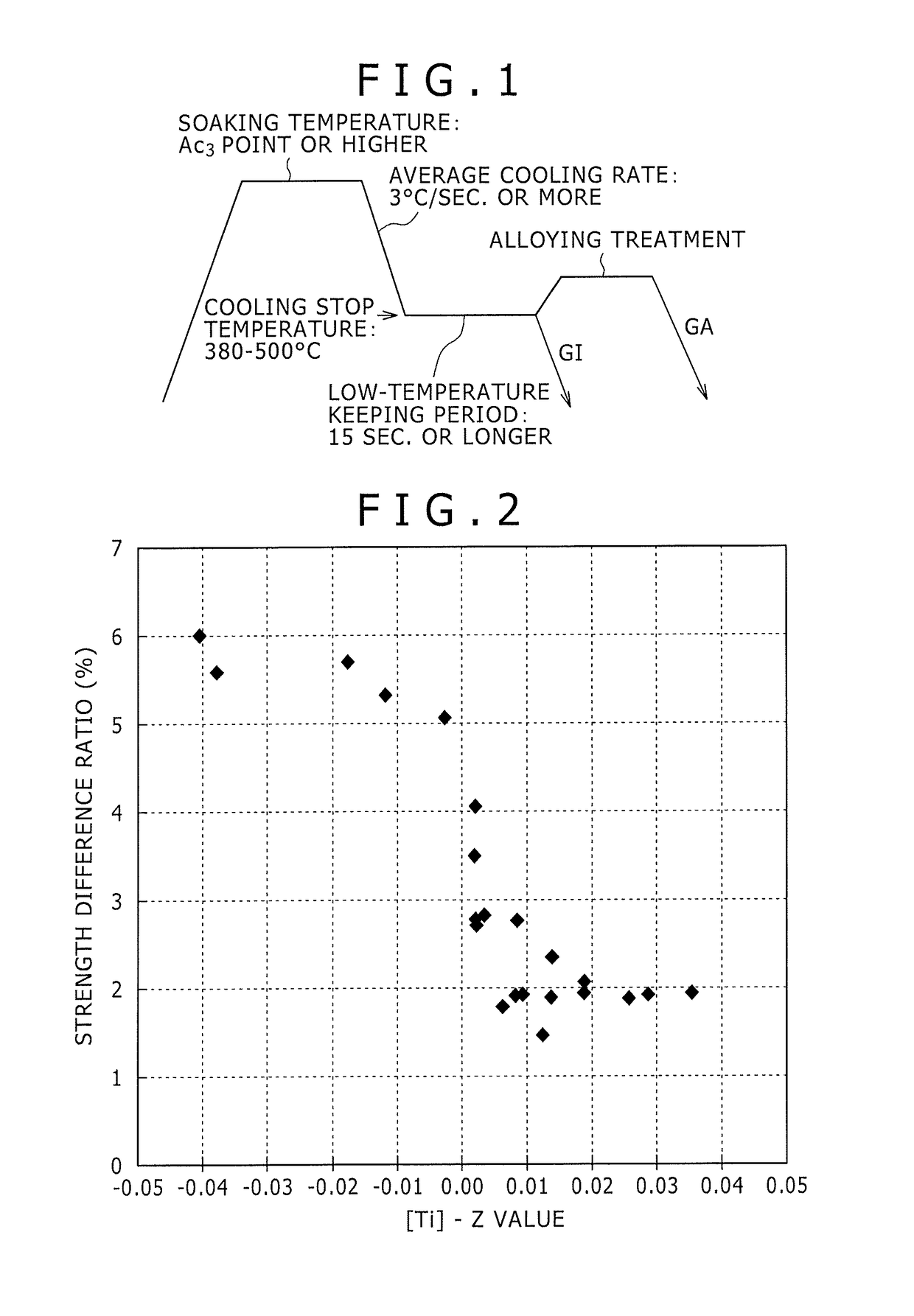

High-strength hot-dip galvanized steel sheet and high-strength alloyed hot-dip galvanized steel sheet having excellent bending workability and minimal strength difference between center part and end parts in sheet width direction, and method for manufacturing same

PatentInactiveUS20190078188A1

Innovation

- A high-strength hot-dip galvanized steel sheet with a metallic microstructure comprising 50% or more martensite, 15-50% bainite, and 5% or less ferrite, along with specific compositions of elements like Mn, B, and Ti, is produced through controlled soaking and cooling processes to minimize strength differences and enhance bending workability.

Material Science Considerations for Galvanized Steel Formability

The fundamental properties of galvanized steel significantly influence its formability and bend radius capabilities. The microstructure of the base steel substrate plays a critical role, with fine-grained steels typically exhibiting superior formability compared to coarse-grained variants. The grain size distribution directly affects the material's ability to deform plastically without fracture, which is essential when achieving tight bend radii in manufacturing processes.

The zinc coating applied during galvanization introduces additional complexity to formability considerations. The coating thickness, typically ranging from 7-100 μm depending on application requirements, creates a composite material system with mechanical properties distinct from the base steel. This zinc layer, while providing corrosion protection, possesses different elastic-plastic behavior than the substrate, leading to potential stress concentrations at the interface during bending operations.

Crystallographic texture within both the steel substrate and zinc coating significantly impacts formability. Preferred crystallographic orientations can either facilitate or impede dislocation movement during plastic deformation. Materials with favorable textures can achieve smaller bend radii without coating damage or substrate failure. Modern galvanized steel production often incorporates texture control technologies to optimize formability characteristics.

The adhesion quality between the zinc coating and steel substrate represents another critical factor. Poor interfacial bonding can lead to coating delamination during bending, particularly at tight radii. The formation of intermetallic compounds at this interface, such as Fe-Zn phases, influences both adhesion strength and mechanical behavior during deformation processes.

Temperature effects must also be considered, as galvanized steel exhibits temperature-dependent formability. The ductile-to-brittle transition temperature of the zinc coating differs from that of the steel substrate, creating a processing window that manufacturers must carefully manage. Cold-working operations may require specific temperature controls to prevent coating cracking when achieving optimal bend radii.

Strain rate sensitivity further complicates formability predictions, as both the steel substrate and zinc coating respond differently to varying deformation speeds. High-speed forming operations may require different minimum bend radius specifications compared to slower processes. Advanced material models incorporating strain rate effects have become essential tools for predicting formability limits across diverse manufacturing conditions.

The zinc coating applied during galvanization introduces additional complexity to formability considerations. The coating thickness, typically ranging from 7-100 μm depending on application requirements, creates a composite material system with mechanical properties distinct from the base steel. This zinc layer, while providing corrosion protection, possesses different elastic-plastic behavior than the substrate, leading to potential stress concentrations at the interface during bending operations.

Crystallographic texture within both the steel substrate and zinc coating significantly impacts formability. Preferred crystallographic orientations can either facilitate or impede dislocation movement during plastic deformation. Materials with favorable textures can achieve smaller bend radii without coating damage or substrate failure. Modern galvanized steel production often incorporates texture control technologies to optimize formability characteristics.

The adhesion quality between the zinc coating and steel substrate represents another critical factor. Poor interfacial bonding can lead to coating delamination during bending, particularly at tight radii. The formation of intermetallic compounds at this interface, such as Fe-Zn phases, influences both adhesion strength and mechanical behavior during deformation processes.

Temperature effects must also be considered, as galvanized steel exhibits temperature-dependent formability. The ductile-to-brittle transition temperature of the zinc coating differs from that of the steel substrate, creating a processing window that manufacturers must carefully manage. Cold-working operations may require specific temperature controls to prevent coating cracking when achieving optimal bend radii.

Strain rate sensitivity further complicates formability predictions, as both the steel substrate and zinc coating respond differently to varying deformation speeds. High-speed forming operations may require different minimum bend radius specifications compared to slower processes. Advanced material models incorporating strain rate effects have become essential tools for predicting formability limits across diverse manufacturing conditions.

Quality Control Standards and Testing Protocols for Bent Galvanized Components

Quality control standards and testing protocols are essential components in ensuring the reliability and performance of bent galvanized steel components. The manufacturing industry has established comprehensive frameworks that govern the evaluation of these components, particularly focusing on bend radius specifications.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have developed specific standards such as ASTM A653 and ISO 1461 that outline the requirements for galvanized steel products. These standards include detailed specifications for bend testing, coating adhesion after bending, and surface quality assessment.

Visual inspection represents the first line of quality control, where trained inspectors examine bent components for coating cracks, flaking, or peeling. This process is often supplemented by digital imaging systems that can detect microscopic defects invisible to the human eye. Modern facilities employ automated optical inspection systems with machine learning algorithms to identify deviations from acceptable bend parameters.

Mechanical testing forms the core of bend quality assessment. The mandrel bend test, as specified in ASTM E290, evaluates the ductility and coating adhesion by bending samples around mandrels of specified diameters. The T-bend test quantifies the formability of galvanized coatings, with results expressed as T-values (0T, 1T, 2T, etc.), where lower values indicate superior flexibility.

Coating adhesion after bending is typically evaluated using tape tests (ASTM D3359) or impact tests (ASTM D2794). These procedures assess whether the zinc coating remains firmly bonded to the steel substrate after deformation. Microhardness testing along the bend area provides valuable data on potential work hardening effects that might influence component performance.

Advanced analytical techniques include scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) to characterize the microstructure and chemical composition of the coating at bend areas. These methods can identify zinc layer thinning, microcracks, or intermetallic compound formations that might compromise corrosion protection.

Statistical process control (SPC) methodologies are increasingly implemented to monitor bend quality over time. Key performance indicators such as bend consistency, coating thickness variation, and defect rates are tracked using control charts to identify process drift before it results in non-conforming products.

Documentation and traceability systems ensure that all testing results are properly recorded and linked to specific production batches. This enables manufacturers to demonstrate compliance with industry standards and customer specifications while facilitating continuous improvement initiatives through data analysis.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have developed specific standards such as ASTM A653 and ISO 1461 that outline the requirements for galvanized steel products. These standards include detailed specifications for bend testing, coating adhesion after bending, and surface quality assessment.

Visual inspection represents the first line of quality control, where trained inspectors examine bent components for coating cracks, flaking, or peeling. This process is often supplemented by digital imaging systems that can detect microscopic defects invisible to the human eye. Modern facilities employ automated optical inspection systems with machine learning algorithms to identify deviations from acceptable bend parameters.

Mechanical testing forms the core of bend quality assessment. The mandrel bend test, as specified in ASTM E290, evaluates the ductility and coating adhesion by bending samples around mandrels of specified diameters. The T-bend test quantifies the formability of galvanized coatings, with results expressed as T-values (0T, 1T, 2T, etc.), where lower values indicate superior flexibility.

Coating adhesion after bending is typically evaluated using tape tests (ASTM D3359) or impact tests (ASTM D2794). These procedures assess whether the zinc coating remains firmly bonded to the steel substrate after deformation. Microhardness testing along the bend area provides valuable data on potential work hardening effects that might influence component performance.

Advanced analytical techniques include scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) to characterize the microstructure and chemical composition of the coating at bend areas. These methods can identify zinc layer thinning, microcracks, or intermetallic compound formations that might compromise corrosion protection.

Statistical process control (SPC) methodologies are increasingly implemented to monitor bend quality over time. Key performance indicators such as bend consistency, coating thickness variation, and defect rates are tracked using control charts to identify process drift before it results in non-conforming products.

Documentation and traceability systems ensure that all testing results are properly recorded and linked to specific production batches. This enables manufacturers to demonstrate compliance with industry standards and customer specifications while facilitating continuous improvement initiatives through data analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!