How to Assess Galvanized Steel's Recyclability Potential

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Recyclability Background and Objectives

Galvanized steel has been a cornerstone material in various industries for over 150 years, with its development tracing back to 1837 when Stanislas Sorel patented the first galvanization process. The technology has evolved significantly from early hot-dip galvanizing methods to modern continuous galvanizing lines that can process steel at remarkable speeds. This evolution reflects the growing importance of corrosion protection in extending the lifespan of steel products while maintaining their structural integrity.

The global focus on sustainability and circular economy principles has brought renewed attention to galvanized steel's end-of-life management. Historically, recycling considerations were secondary to performance characteristics, but environmental regulations and resource scarcity have elevated recyclability to a primary concern in material selection and design. The zinc coating that provides corrosion resistance presents both challenges and opportunities in the recycling process.

Current technical objectives in assessing galvanized steel recyclability include developing standardized methodologies for quantifying recyclability potential, understanding the behavior of zinc during the steel recycling process, and optimizing separation technologies. These objectives align with broader sustainability goals of reducing primary resource consumption and minimizing environmental impacts associated with steel production.

The technical evolution trajectory shows a clear trend toward more sophisticated coating compositions and application methods, with recent innovations focusing on reducing coating thickness while maintaining or improving performance. This trend has implications for recyclability assessment, as thinner coatings may alter the zinc-to-steel ratio and consequently affect recycling economics and environmental impacts.

Market demands are increasingly driving research into galvanized steel's circular economy performance, with automotive, construction, and appliance manufacturers seeking materials that can demonstrate high recyclability rates to meet corporate sustainability targets and comply with emerging extended producer responsibility regulations.

The assessment of galvanized steel recyclability must consider multiple technical factors, including coating thickness variability, alloy composition of both substrate and coating, presence of contaminants, and the efficiency of existing recycling infrastructure. These factors interact in complex ways that influence the technical and economic feasibility of different recycling pathways.

The ultimate goal of recyclability assessment is to develop a comprehensive framework that enables producers and users of galvanized steel to make informed decisions about material selection, design, and end-of-life management strategies that maximize resource recovery while minimizing environmental impacts throughout the material's lifecycle.

The global focus on sustainability and circular economy principles has brought renewed attention to galvanized steel's end-of-life management. Historically, recycling considerations were secondary to performance characteristics, but environmental regulations and resource scarcity have elevated recyclability to a primary concern in material selection and design. The zinc coating that provides corrosion resistance presents both challenges and opportunities in the recycling process.

Current technical objectives in assessing galvanized steel recyclability include developing standardized methodologies for quantifying recyclability potential, understanding the behavior of zinc during the steel recycling process, and optimizing separation technologies. These objectives align with broader sustainability goals of reducing primary resource consumption and minimizing environmental impacts associated with steel production.

The technical evolution trajectory shows a clear trend toward more sophisticated coating compositions and application methods, with recent innovations focusing on reducing coating thickness while maintaining or improving performance. This trend has implications for recyclability assessment, as thinner coatings may alter the zinc-to-steel ratio and consequently affect recycling economics and environmental impacts.

Market demands are increasingly driving research into galvanized steel's circular economy performance, with automotive, construction, and appliance manufacturers seeking materials that can demonstrate high recyclability rates to meet corporate sustainability targets and comply with emerging extended producer responsibility regulations.

The assessment of galvanized steel recyclability must consider multiple technical factors, including coating thickness variability, alloy composition of both substrate and coating, presence of contaminants, and the efficiency of existing recycling infrastructure. These factors interact in complex ways that influence the technical and economic feasibility of different recycling pathways.

The ultimate goal of recyclability assessment is to develop a comprehensive framework that enables producers and users of galvanized steel to make informed decisions about material selection, design, and end-of-life management strategies that maximize resource recovery while minimizing environmental impacts throughout the material's lifecycle.

Market Demand Analysis for Recycled Galvanized Steel

The global market for recycled galvanized steel has been experiencing significant growth in recent years, driven by increasing environmental regulations, sustainability initiatives, and economic incentives. Current market analysis indicates that the recycling rate for galvanized steel varies considerably across regions, with developed economies achieving rates between 70-85%, while developing nations often struggle to exceed 40-50%. This disparity represents both a challenge and an opportunity for market expansion.

Consumer demand for sustainable products has created a robust downstream market for recycled galvanized steel. Industries such as automotive, construction, and consumer appliances are increasingly specifying recycled content requirements in their procurement policies. This trend is particularly evident in Europe, where circular economy regulations have established minimum recycled content thresholds for various steel applications.

The economic value proposition of recycled galvanized steel is compelling. Market research shows that properly processed recycled galvanized steel can retain up to 95% of the value of virgin material while requiring only 30-40% of the energy input. This favorable energy-to-value ratio has attracted significant investment in recycling infrastructure, particularly in regions with high energy costs.

Supply chain dynamics present both opportunities and constraints for market growth. The collection and sorting infrastructure for galvanized steel remains underdeveloped in many regions, creating bottlenecks in the recycling process. Additionally, the presence of zinc coating presents technical challenges that impact market efficiency. These challenges have created price premiums for properly processed recycled galvanized steel in certain applications.

Market forecasts project continued growth in demand for recycled galvanized steel, with compound annual growth rates expected to exceed general steel market growth by 3-5 percentage points through 2030. This growth is being fueled by several factors, including tightening environmental regulations, corporate sustainability commitments, and the increasing cost-competitiveness of recycled materials as processing technologies improve.

Regional market analysis reveals significant variations in demand patterns. European markets show the highest premium for recycled content, driven by regulatory frameworks and consumer preferences. North American markets demonstrate strong growth in specific sectors, particularly automotive and construction. Asian markets, while currently less developed for recycled galvanized steel, show the highest potential growth rates as environmental regulations strengthen and manufacturing sectors expand their sustainability initiatives.

The market structure is evolving from a traditional linear model toward a more circular ecosystem. This transition is creating new business opportunities for specialized processors who can effectively separate zinc coatings from steel substrates while preserving the value of both materials. These specialized processors are becoming increasingly important intermediaries in the supply chain.

Consumer demand for sustainable products has created a robust downstream market for recycled galvanized steel. Industries such as automotive, construction, and consumer appliances are increasingly specifying recycled content requirements in their procurement policies. This trend is particularly evident in Europe, where circular economy regulations have established minimum recycled content thresholds for various steel applications.

The economic value proposition of recycled galvanized steel is compelling. Market research shows that properly processed recycled galvanized steel can retain up to 95% of the value of virgin material while requiring only 30-40% of the energy input. This favorable energy-to-value ratio has attracted significant investment in recycling infrastructure, particularly in regions with high energy costs.

Supply chain dynamics present both opportunities and constraints for market growth. The collection and sorting infrastructure for galvanized steel remains underdeveloped in many regions, creating bottlenecks in the recycling process. Additionally, the presence of zinc coating presents technical challenges that impact market efficiency. These challenges have created price premiums for properly processed recycled galvanized steel in certain applications.

Market forecasts project continued growth in demand for recycled galvanized steel, with compound annual growth rates expected to exceed general steel market growth by 3-5 percentage points through 2030. This growth is being fueled by several factors, including tightening environmental regulations, corporate sustainability commitments, and the increasing cost-competitiveness of recycled materials as processing technologies improve.

Regional market analysis reveals significant variations in demand patterns. European markets show the highest premium for recycled content, driven by regulatory frameworks and consumer preferences. North American markets demonstrate strong growth in specific sectors, particularly automotive and construction. Asian markets, while currently less developed for recycled galvanized steel, show the highest potential growth rates as environmental regulations strengthen and manufacturing sectors expand their sustainability initiatives.

The market structure is evolving from a traditional linear model toward a more circular ecosystem. This transition is creating new business opportunities for specialized processors who can effectively separate zinc coatings from steel substrates while preserving the value of both materials. These specialized processors are becoming increasingly important intermediaries in the supply chain.

Current Challenges in Galvanized Steel Recycling

Despite significant advancements in steel recycling technologies, galvanized steel presents unique challenges that impede its efficient recycling. The primary obstacle stems from the zinc coating applied to protect steel from corrosion. During the recycling process, this zinc volatilizes at high temperatures, creating zinc-rich dust that requires specialized collection systems to prevent environmental contamination and workplace hazards. Many recycling facilities lack these advanced filtration systems, limiting their ability to process galvanized steel effectively.

The heterogeneous nature of galvanized steel products further complicates recycling efforts. Various zinc coating thicknesses, alloy compositions, and additional treatments create inconsistencies in the recycling feedstock. This variability makes it difficult to establish standardized recycling protocols and affects the quality of the recycled output, potentially limiting its applications in high-grade steel production.

Energy consumption represents another significant challenge. The additional processing required to handle zinc coatings increases the overall energy footprint of galvanized steel recycling compared to uncoated steel. This higher energy requirement impacts both the economic viability and environmental sustainability of the recycling process, creating a paradoxical situation where recycling efforts might generate greater carbon emissions than anticipated.

Contamination issues extend beyond zinc to include other materials commonly attached to galvanized steel products. Paints, adhesives, and composite assemblies often require pre-treatment or separation before recycling, adding complexity and cost to the process. The presence of these contaminants can compromise the metallurgical properties of the recycled steel if not properly managed.

Market dynamics also present obstacles to galvanized steel recycling. Price fluctuations in both steel and zinc markets affect the economic incentives for recycling. When virgin material prices are low, the cost-benefit ratio of recycling diminishes, reducing industry motivation to invest in advanced recycling technologies specifically designed for galvanized steel.

Regulatory frameworks across different regions lack harmonization regarding galvanized steel recycling standards. This inconsistency creates compliance challenges for global supply chains and recycling operations. Some regions have stringent emissions controls that increase recycling costs, while others have minimal regulations, creating an uneven playing field in the global recycling market.

Technical knowledge gaps persist regarding optimal methods for zinc recovery during the recycling process. While technologies exist to separate and recover zinc, their implementation at commercial scale remains limited. Research continues to explore more efficient separation techniques, but widespread adoption awaits further technological maturation and economic validation.

The heterogeneous nature of galvanized steel products further complicates recycling efforts. Various zinc coating thicknesses, alloy compositions, and additional treatments create inconsistencies in the recycling feedstock. This variability makes it difficult to establish standardized recycling protocols and affects the quality of the recycled output, potentially limiting its applications in high-grade steel production.

Energy consumption represents another significant challenge. The additional processing required to handle zinc coatings increases the overall energy footprint of galvanized steel recycling compared to uncoated steel. This higher energy requirement impacts both the economic viability and environmental sustainability of the recycling process, creating a paradoxical situation where recycling efforts might generate greater carbon emissions than anticipated.

Contamination issues extend beyond zinc to include other materials commonly attached to galvanized steel products. Paints, adhesives, and composite assemblies often require pre-treatment or separation before recycling, adding complexity and cost to the process. The presence of these contaminants can compromise the metallurgical properties of the recycled steel if not properly managed.

Market dynamics also present obstacles to galvanized steel recycling. Price fluctuations in both steel and zinc markets affect the economic incentives for recycling. When virgin material prices are low, the cost-benefit ratio of recycling diminishes, reducing industry motivation to invest in advanced recycling technologies specifically designed for galvanized steel.

Regulatory frameworks across different regions lack harmonization regarding galvanized steel recycling standards. This inconsistency creates compliance challenges for global supply chains and recycling operations. Some regions have stringent emissions controls that increase recycling costs, while others have minimal regulations, creating an uneven playing field in the global recycling market.

Technical knowledge gaps persist regarding optimal methods for zinc recovery during the recycling process. While technologies exist to separate and recover zinc, their implementation at commercial scale remains limited. Research continues to explore more efficient separation techniques, but widespread adoption awaits further technological maturation and economic validation.

Existing Assessment Methodologies for Recyclability

01 Zinc recovery from galvanized steel scrap

Various methods have been developed to recover zinc from galvanized steel scrap during the recycling process. These techniques include chemical leaching, electrolytic processes, and thermal treatments that separate zinc coating from the steel substrate. The recovered zinc can be reused in new galvanizing processes, reducing the need for primary zinc resources and minimizing environmental impact while improving the economic value of steel recycling operations.- Zinc recovery methods from galvanized steel scrap: Various methods have been developed to recover zinc from galvanized steel during recycling processes. These techniques include chemical leaching, thermal treatments, and electrochemical processes that selectively remove the zinc coating before steel recycling. Efficient zinc recovery not only improves the recyclability of galvanized steel but also provides valuable zinc as a secondary raw material, contributing to circular economy principles.

- Pre-treatment processes for galvanized steel recycling: Pre-treatment processes are essential for enhancing the recyclability potential of galvanized steel. These include mechanical removal of coatings, chemical stripping, and sorting technologies that prepare galvanized steel for efficient recycling. Advanced pre-treatment methods can significantly reduce impurities in the recycled material, leading to higher quality recycled steel and improved resource efficiency in steel production.

- Environmental impact reduction in galvanized steel recycling: Innovations focused on reducing the environmental footprint of galvanized steel recycling include energy-efficient processing methods, waste minimization techniques, and emissions control systems. These technologies address concerns related to air pollution, waste generation, and energy consumption during recycling operations, making galvanized steel recycling more sustainable and environmentally friendly.

- Advanced sorting and separation technologies: Advanced technologies for sorting and separating galvanized steel from mixed waste streams enhance recycling efficiency. These include automated sorting systems using sensors, magnetic separation techniques, and density-based separation methods. Improved sorting technologies increase the purity of recovered materials and enable higher recycling rates for galvanized steel products.

- Innovative galvanized coating designs for improved recyclability: Research has led to the development of innovative galvanized coating formulations and application methods designed with recyclability in mind. These include thinner zinc coatings, alternative alloy compositions, and removable protective layers that maintain corrosion resistance while facilitating easier separation during recycling. Such designs represent a proactive approach to improving the end-of-life management of galvanized steel products.

02 Pre-treatment processes for galvanized steel recycling

Pre-treatment processes are essential for effective recycling of galvanized steel. These include mechanical removal of contaminants, chemical treatments to remove coatings, and sorting technologies to separate different types of galvanized materials. Advanced pre-treatment methods improve the quality of recycled steel by reducing impurities and ensuring more efficient removal of zinc coating, which leads to higher quality recycled products and reduced energy consumption in subsequent processing steps.Expand Specific Solutions03 Environmental impact reduction in galvanized steel recycling

Innovative approaches have been developed to minimize the environmental footprint of galvanized steel recycling. These include closed-loop recycling systems, emission control technologies, and waste minimization strategies. By implementing these environmentally friendly processes, the recycling industry can reduce air and water pollution, decrease energy consumption, and minimize the generation of hazardous byproducts, making galvanized steel recycling more sustainable and aligned with circular economy principles.Expand Specific Solutions04 Advanced melting and refining technologies

Advanced melting and refining technologies have been developed specifically for processing recycled galvanized steel. These include specialized furnace designs, temperature control systems, and slag management techniques that can handle the challenges posed by zinc content in the scrap. These technologies enable more efficient removal of zinc and other impurities during the melting process, resulting in higher quality recycled steel with properties comparable to virgin materials while reducing energy consumption and emissions.Expand Specific Solutions05 Quality improvement of recycled galvanized steel

Various methods have been developed to enhance the quality of recycled galvanized steel products. These include alloying techniques, microstructure control processes, and surface treatment methods that improve the mechanical properties and corrosion resistance of recycled steel. By implementing these quality improvement strategies, recycled galvanized steel can meet stringent performance requirements for high-value applications, expanding its market potential and increasing its economic value in the circular economy.Expand Specific Solutions

Key Industry Players in Galvanized Steel Recycling

The galvanized steel recyclability market is currently in a growth phase, with increasing focus on circular economy principles driving innovation. The global market for steel recycling is substantial, estimated at over $100 billion annually, with galvanized steel representing a significant segment. Leading steel manufacturers like JFE Steel, Nucor, JSW Steel, and Kobe Steel are advancing recycling technologies to address zinc coating challenges. Companies such as Zincovery Process Technologies are developing specialized solutions for zinc recovery, while research institutions including Central South University and University of Canterbury contribute significant academic advancements. The technology maturity varies, with established mechanical recycling methods complemented by emerging chemical and thermal separation techniques being developed by voestalpine and DuPont, indicating a dynamic competitive landscape with both traditional players and innovative startups.

JFE Steel Corp.

Technical Solution: JFE Steel has developed an advanced galvanized steel recycling system that focuses on zinc recovery through their proprietary Multi-Step Zinc Separation Process. This technology employs a combination of mechanical pre-treatment and hydrometallurgical processes to separate zinc coating from steel substrate. Their system first uses precision grinding to remove the zinc layer, followed by chemical leaching with optimized pH levels to extract remaining zinc compounds. The recovered zinc is then purified through electrolysis, achieving purity levels exceeding 99.5%. JFE's approach minimizes energy consumption by operating at lower temperatures compared to pyrometallurgical alternatives, reducing CO2 emissions by approximately 60%. Their closed-loop water system recirculates process water, minimizing waste discharge while recovering valuable zinc for reuse in new galvanizing operations. The company has implemented this technology at scale, processing over 100,000 tons of galvanized steel scrap annually with zinc recovery rates of 92-95%.

Strengths: High zinc recovery efficiency (92-95%), significantly reduced energy consumption and CO2 emissions compared to traditional methods, closed-loop water system minimizing environmental impact. Weaknesses: Requires substantial initial capital investment, process complexity demands specialized technical expertise, and economic viability depends on zinc market prices.

Nucor Corp.

Technical Solution: Nucor has pioneered the Direct Sheet Plant (DSP) technology specifically designed to enhance galvanized steel recyclability. Their approach integrates recycling considerations directly into the production process, creating what they term "recycling-optimized galvanized steel." The technology employs a specialized coating composition that maintains corrosion resistance while being more easily separated during recycling. Nucor's process utilizes thin-film galvanizing technology that reduces zinc usage by up to 30% compared to conventional hot-dip processes while maintaining equivalent corrosion protection. Their patented zinc recovery system employs selective dissolution techniques that allow for zinc reclamation without contaminating the base steel. This system achieves zinc recovery rates of approximately 88-92% while preserving the quality of the steel substrate for direct reuse in electric arc furnace (EAF) steelmaking. Nucor has also developed specialized sorting technologies that can rapidly identify and segregate different types of galvanized steel scrap, optimizing the recycling stream and reducing cross-contamination of alloying elements.

Strengths: Integrated approach that considers recyclability from the production stage, reduced zinc usage while maintaining performance, high zinc recovery rates with minimal steel quality degradation. Weaknesses: Technology primarily optimized for their own production ecosystem, requires specialized equipment for maximum efficiency, and economic benefits are partially dependent on scale.

Critical Technologies for Zinc Recovery from Galvanized Steel

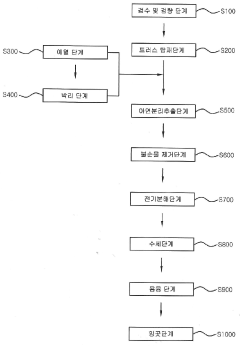

Creating a method for creating a high value-added galvanized scrap for recycling

PatentInactiveKR1020170094571A

Innovation

- A method involving inspection, calibration, chemical separation using sulfuric acid or hydrochloric acid, electrolysis, impurity removal, and electrolyte composition to extract pure zinc from galvanized steel sheet and electro-galvanized steel sheet scrap, followed by melting and shaping into ingots.

Method for recycling galvanized steel scrap comprises immersing the scrap in an alkaline solution, removing the zinc layer from the scrap in the solution to form an alkaline solution containing zinc ions and further processing

PatentActiveDE102008009352A1

Innovation

- A method combining the recycling of galvanized steel scrap with primary zinc production by using an alkaline solution to dissolve zinc, followed by roasting to form zinc oxide, dissolving it in sulfuric acid, and precipitating zinc hydroxide, which is then processed to omit the final electrolysis step and enhance zinc recovery.

Environmental Impact Assessment of Recycling Processes

The recycling of galvanized steel involves several processes that generate varying environmental impacts. When assessing these impacts, it is crucial to consider the entire lifecycle of recycling operations, from collection and sorting to processing and remanufacturing.

The energy consumption during galvanized steel recycling represents a significant environmental factor. Compared to primary steel production, recycling typically requires 60-70% less energy, resulting in substantial carbon emission reductions. However, the removal of zinc coating during recycling necessitates additional processing steps that consume energy and potentially release harmful substances if not properly managed.

Water usage and pollution present another critical environmental concern. The de-zincing process often involves chemical treatments that generate wastewater containing zinc, iron, and other heavy metals. Advanced treatment systems can recover up to 98% of these metals, but implementation varies globally based on regulatory requirements and technological capabilities.

Air emissions during galvanized steel recycling primarily occur during melting operations. These emissions may include particulate matter, volatile organic compounds (VOCs), and metal fumes. Modern recycling facilities employ filtration systems and scrubbers that can capture over 95% of particulates, though older facilities may achieve significantly lower capture rates.

Solid waste generation represents another environmental impact category. The recycling process produces slag, dust, and other residues that require proper disposal or further processing. These by-products contain varying concentrations of zinc and other metals that could potentially leach into soil and groundwater if improperly managed.

Land use impacts of recycling facilities are generally less severe than those of primary steel production. However, the concentration of recycling operations in certain geographic areas can lead to localized environmental degradation if not properly regulated and monitored.

The transportation of galvanized steel scrap to recycling facilities generates additional environmental impacts through fuel consumption and associated emissions. Studies indicate that transportation typically accounts for 5-15% of the total carbon footprint of steel recycling, depending on distance and transport mode.

Life Cycle Assessment (LCA) methodologies provide comprehensive frameworks for quantifying these environmental impacts. Recent LCA studies demonstrate that despite the additional processing requirements, recycling galvanized steel typically results in net environmental benefits compared to primary production, with greenhouse gas emission reductions of 1.5-2.5 tons CO2-equivalent per ton of recycled steel.

The energy consumption during galvanized steel recycling represents a significant environmental factor. Compared to primary steel production, recycling typically requires 60-70% less energy, resulting in substantial carbon emission reductions. However, the removal of zinc coating during recycling necessitates additional processing steps that consume energy and potentially release harmful substances if not properly managed.

Water usage and pollution present another critical environmental concern. The de-zincing process often involves chemical treatments that generate wastewater containing zinc, iron, and other heavy metals. Advanced treatment systems can recover up to 98% of these metals, but implementation varies globally based on regulatory requirements and technological capabilities.

Air emissions during galvanized steel recycling primarily occur during melting operations. These emissions may include particulate matter, volatile organic compounds (VOCs), and metal fumes. Modern recycling facilities employ filtration systems and scrubbers that can capture over 95% of particulates, though older facilities may achieve significantly lower capture rates.

Solid waste generation represents another environmental impact category. The recycling process produces slag, dust, and other residues that require proper disposal or further processing. These by-products contain varying concentrations of zinc and other metals that could potentially leach into soil and groundwater if improperly managed.

Land use impacts of recycling facilities are generally less severe than those of primary steel production. However, the concentration of recycling operations in certain geographic areas can lead to localized environmental degradation if not properly regulated and monitored.

The transportation of galvanized steel scrap to recycling facilities generates additional environmental impacts through fuel consumption and associated emissions. Studies indicate that transportation typically accounts for 5-15% of the total carbon footprint of steel recycling, depending on distance and transport mode.

Life Cycle Assessment (LCA) methodologies provide comprehensive frameworks for quantifying these environmental impacts. Recent LCA studies demonstrate that despite the additional processing requirements, recycling galvanized steel typically results in net environmental benefits compared to primary production, with greenhouse gas emission reductions of 1.5-2.5 tons CO2-equivalent per ton of recycled steel.

Circular Economy Integration Strategies

Integrating galvanized steel recycling into circular economy frameworks requires systematic approaches that maximize resource efficiency while minimizing environmental impacts. Companies can implement closed-loop systems where end-of-life galvanized steel products are collected, processed, and reintroduced into manufacturing cycles. This strategy reduces primary resource extraction and energy consumption associated with virgin steel production.

Material passports represent an innovative strategy for tracking galvanized steel throughout its lifecycle. These digital records document the steel's composition, coating specifications, and recycling parameters, enabling more efficient sorting and processing at end-of-life. When combined with blockchain technology, material passports can create transparent supply chains that incentivize proper recycling practices and verify sustainability claims.

Design for disassembly principles should be incorporated into product development to facilitate the separation of galvanized components from composite products. This approach involves using standardized connections, avoiding permanent adhesives with incompatible materials, and clearly marking different steel grades and coating types. Such design considerations significantly enhance recyclability potential and material recovery rates.

Industrial symbiosis networks offer another integration pathway, where waste streams from one company become valuable inputs for another. Galvanizing facilities can partner with steel mills to create closed material loops, with zinc recovery operations serving as intermediaries in this ecosystem. These collaborative networks reduce waste while creating economic opportunities across multiple sectors.

Policy engagement represents a critical strategy for businesses seeking to enhance galvanized steel recyclability. Companies can advocate for extended producer responsibility programs, recycled content mandates, and standardized labeling systems that facilitate proper end-of-life management. By participating in industry coalitions and policy development, businesses can shape regulatory frameworks that support circular economy transitions.

Consumer education initiatives complement these strategies by raising awareness about the recyclability of galvanized products and proper disposal methods. Clear labeling, take-back programs, and incentive schemes can encourage consumers to return products to appropriate collection points, ensuring higher recovery rates and cleaner material streams for recycling operations.

Digital technologies including IoT sensors, AI-powered sorting systems, and predictive analytics can optimize recycling processes specifically for galvanized steel. These technologies enable more precise identification of coating compositions, more efficient separation techniques, and better quality control in recycled material streams.

Material passports represent an innovative strategy for tracking galvanized steel throughout its lifecycle. These digital records document the steel's composition, coating specifications, and recycling parameters, enabling more efficient sorting and processing at end-of-life. When combined with blockchain technology, material passports can create transparent supply chains that incentivize proper recycling practices and verify sustainability claims.

Design for disassembly principles should be incorporated into product development to facilitate the separation of galvanized components from composite products. This approach involves using standardized connections, avoiding permanent adhesives with incompatible materials, and clearly marking different steel grades and coating types. Such design considerations significantly enhance recyclability potential and material recovery rates.

Industrial symbiosis networks offer another integration pathway, where waste streams from one company become valuable inputs for another. Galvanizing facilities can partner with steel mills to create closed material loops, with zinc recovery operations serving as intermediaries in this ecosystem. These collaborative networks reduce waste while creating economic opportunities across multiple sectors.

Policy engagement represents a critical strategy for businesses seeking to enhance galvanized steel recyclability. Companies can advocate for extended producer responsibility programs, recycled content mandates, and standardized labeling systems that facilitate proper end-of-life management. By participating in industry coalitions and policy development, businesses can shape regulatory frameworks that support circular economy transitions.

Consumer education initiatives complement these strategies by raising awareness about the recyclability of galvanized products and proper disposal methods. Clear labeling, take-back programs, and incentive schemes can encourage consumers to return products to appropriate collection points, ensuring higher recovery rates and cleaner material streams for recycling operations.

Digital technologies including IoT sensors, AI-powered sorting systems, and predictive analytics can optimize recycling processes specifically for galvanized steel. These technologies enable more precise identification of coating compositions, more efficient separation techniques, and better quality control in recycled material streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!