Optimize Galvanized Steel for Earthquake-Prone Areas

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Seismic-Resistant Galvanized Steel Background and Objectives

Galvanized steel has evolved significantly since its initial development in the 18th century, with major technological advancements occurring in the mid-20th century through the implementation of continuous hot-dip galvanizing processes. This protective zinc coating technology has become fundamental in construction, particularly in regions prone to seismic activity where structural integrity under dynamic loads is paramount. The evolution of galvanized steel has been driven by the need for materials that combine corrosion resistance with mechanical strength—properties essential for earthquake resilience.

Recent decades have witnessed accelerated innovation in galvanized steel technology, focusing on optimizing zinc adhesion, coating uniformity, and the development of specialized alloy additions to enhance performance characteristics. The emergence of high-strength, low-alloy (HSLA) galvanized steels represents a significant milestone, offering superior strength-to-weight ratios while maintaining excellent formability and weldability—critical factors for seismic applications.

The technical objective of seismic-resistant galvanized steel development centers on creating materials that can withstand the complex loading patterns experienced during earthquakes. This includes enhancing ductility to absorb seismic energy, improving fatigue resistance for structures subjected to repeated stress cycles, and maintaining structural integrity under extreme displacement conditions. Additionally, there is a focus on developing connection technologies that preserve the galvanic protection at joints—traditionally vulnerable points in seismic events.

Current research trajectories indicate a shift toward nano-engineered zinc coatings that offer superior bonding with the steel substrate and potentially self-healing properties when damaged. Computational modeling and simulation have become instrumental in predicting galvanized steel behavior under various seismic scenarios, allowing for more targeted material development. The integration of these advanced modeling techniques with experimental validation represents a promising approach to accelerating innovation in this field.

The global push toward sustainable construction has also influenced galvanized steel development, with increasing emphasis on reducing zinc consumption while maintaining or improving protective qualities. This has led to the exploration of alternative coating compositions and application methods that minimize environmental impact while enhancing seismic performance.

The ultimate technical goal remains the development of galvanized steel systems that can withstand severe seismic events with minimal structural damage, thereby protecting human life and reducing economic losses associated with earthquake damage. This requires a multidisciplinary approach combining metallurgy, structural engineering, and seismic science to create next-generation materials specifically optimized for earthquake-prone regions.

Recent decades have witnessed accelerated innovation in galvanized steel technology, focusing on optimizing zinc adhesion, coating uniformity, and the development of specialized alloy additions to enhance performance characteristics. The emergence of high-strength, low-alloy (HSLA) galvanized steels represents a significant milestone, offering superior strength-to-weight ratios while maintaining excellent formability and weldability—critical factors for seismic applications.

The technical objective of seismic-resistant galvanized steel development centers on creating materials that can withstand the complex loading patterns experienced during earthquakes. This includes enhancing ductility to absorb seismic energy, improving fatigue resistance for structures subjected to repeated stress cycles, and maintaining structural integrity under extreme displacement conditions. Additionally, there is a focus on developing connection technologies that preserve the galvanic protection at joints—traditionally vulnerable points in seismic events.

Current research trajectories indicate a shift toward nano-engineered zinc coatings that offer superior bonding with the steel substrate and potentially self-healing properties when damaged. Computational modeling and simulation have become instrumental in predicting galvanized steel behavior under various seismic scenarios, allowing for more targeted material development. The integration of these advanced modeling techniques with experimental validation represents a promising approach to accelerating innovation in this field.

The global push toward sustainable construction has also influenced galvanized steel development, with increasing emphasis on reducing zinc consumption while maintaining or improving protective qualities. This has led to the exploration of alternative coating compositions and application methods that minimize environmental impact while enhancing seismic performance.

The ultimate technical goal remains the development of galvanized steel systems that can withstand severe seismic events with minimal structural damage, thereby protecting human life and reducing economic losses associated with earthquake damage. This requires a multidisciplinary approach combining metallurgy, structural engineering, and seismic science to create next-generation materials specifically optimized for earthquake-prone regions.

Market Analysis for Earthquake-Resistant Construction Materials

The global market for earthquake-resistant construction materials has experienced significant growth in recent years, driven by increasing urbanization in seismic zones and growing awareness of disaster resilience. The market value for specialized earthquake-resistant building materials reached approximately $25.6 billion in 2022, with projections indicating growth to $37.8 billion by 2028, representing a compound annual growth rate of 6.7%.

Galvanized steel specifically holds a substantial market share within this sector, valued at roughly $8.3 billion in 2022. This material's popularity stems from its dual benefits of corrosion resistance and structural integrity, making it particularly suitable for regions with both seismic activity and varying climate conditions.

Regionally, the Asia-Pacific market dominates demand, accounting for 42% of global consumption of earthquake-resistant construction materials. This concentration aligns with the region's high seismic activity along the Pacific Ring of Fire and rapid infrastructure development in countries like Japan, China, Indonesia, and the Philippines. North America follows at 27% market share, with particular demand in western United States and parts of Canada.

Consumer demand patterns reveal increasing preference for construction materials that offer multi-hazard protection. Building developers and property owners seek materials that not only withstand seismic forces but also provide resistance to fire, extreme weather, and environmental degradation. This trend has pushed manufacturers toward developing optimized galvanized steel products with enhanced ductility and energy absorption capabilities.

Price sensitivity varies significantly by market segment. While government infrastructure projects often prioritize performance specifications over cost considerations, residential construction remains highly price-sensitive. The average premium for earthquake-optimized galvanized steel ranges from 15-22% above standard structural steel, creating market segmentation based on risk perception and regulatory requirements.

Regulatory influences play a crucial role in market development. Countries with stringent building codes like Japan, New Zealand, and parts of the United States drive innovation in high-performance materials. The implementation of performance-based design approaches in building codes has created opportunities for specialized galvanized steel products that can demonstrate superior behavior under simulated seismic conditions.

Future market growth appears concentrated in developing economies experiencing rapid urbanization in seismic zones. India, Turkey, Mexico, and Indonesia represent particularly promising markets, with projected annual growth rates of 8-12% for specialized earthquake-resistant materials through 2030. These regions combine high seismic risk with substantial construction activity, creating ideal conditions for market expansion.

Galvanized steel specifically holds a substantial market share within this sector, valued at roughly $8.3 billion in 2022. This material's popularity stems from its dual benefits of corrosion resistance and structural integrity, making it particularly suitable for regions with both seismic activity and varying climate conditions.

Regionally, the Asia-Pacific market dominates demand, accounting for 42% of global consumption of earthquake-resistant construction materials. This concentration aligns with the region's high seismic activity along the Pacific Ring of Fire and rapid infrastructure development in countries like Japan, China, Indonesia, and the Philippines. North America follows at 27% market share, with particular demand in western United States and parts of Canada.

Consumer demand patterns reveal increasing preference for construction materials that offer multi-hazard protection. Building developers and property owners seek materials that not only withstand seismic forces but also provide resistance to fire, extreme weather, and environmental degradation. This trend has pushed manufacturers toward developing optimized galvanized steel products with enhanced ductility and energy absorption capabilities.

Price sensitivity varies significantly by market segment. While government infrastructure projects often prioritize performance specifications over cost considerations, residential construction remains highly price-sensitive. The average premium for earthquake-optimized galvanized steel ranges from 15-22% above standard structural steel, creating market segmentation based on risk perception and regulatory requirements.

Regulatory influences play a crucial role in market development. Countries with stringent building codes like Japan, New Zealand, and parts of the United States drive innovation in high-performance materials. The implementation of performance-based design approaches in building codes has created opportunities for specialized galvanized steel products that can demonstrate superior behavior under simulated seismic conditions.

Future market growth appears concentrated in developing economies experiencing rapid urbanization in seismic zones. India, Turkey, Mexico, and Indonesia represent particularly promising markets, with projected annual growth rates of 8-12% for specialized earthquake-resistant materials through 2030. These regions combine high seismic risk with substantial construction activity, creating ideal conditions for market expansion.

Current Challenges in Galvanized Steel for Seismic Applications

Galvanized steel structures in seismic zones face significant challenges that limit their optimal performance during earthquakes. The primary concern is the degradation of zinc coating under cyclic loading conditions, which compromises the corrosion resistance that is essential for long-term structural integrity. Research indicates that during seismic events, the repeated deformation of structural elements can cause micro-cracking in the zinc layer, creating pathways for moisture penetration and accelerating corrosion processes.

Another critical challenge is the behavior of welded connections in galvanized steel structures. The heat from welding processes alters the microstructure of both the base steel and the zinc coating near the weld zone, creating heat-affected zones (HAZ) with potentially reduced ductility and fatigue resistance. These zones become vulnerable points during seismic events, where stress concentration can lead to premature failure.

The thickness uniformity of galvanized coatings presents additional complications in seismic applications. Current hot-dip galvanizing processes often result in uneven coating distribution, with thicker accumulations at edges and corners and thinner coverage on flat surfaces. This inconsistency creates variable performance under seismic loading, with some areas more susceptible to damage than others.

Hydrogen embrittlement remains a persistent issue in high-strength galvanized steels used in seismic applications. The galvanizing process can introduce hydrogen into the steel substrate, potentially reducing ductility and toughness—properties crucial for energy absorption during earthquakes. This phenomenon is particularly problematic in high-strength steels with yield strengths exceeding 1000 MPa, which are increasingly used in modern construction.

The interface bonding between the zinc coating and steel substrate presents another significant challenge. Under the extreme deformation experienced during major seismic events, delamination of the zinc layer can occur, compromising both structural integrity and corrosion protection. Current galvanizing technologies struggle to create consistently strong metallurgical bonds that can withstand such extreme conditions.

Environmental factors in seismic regions further complicate the performance of galvanized steel. Coastal seismic zones expose structures to both earthquake forces and aggressive salt environments, accelerating corrosion processes. Similarly, regions with industrial pollution combined with seismic activity create particularly challenging conditions for maintaining long-term structural integrity of galvanized steel components.

The economic constraints of implementing enhanced galvanizing techniques for seismic applications represent a practical challenge. While advanced coating technologies exist, their higher cost often leads to compromises in implementation, resulting in suboptimal performance during seismic events.

Another critical challenge is the behavior of welded connections in galvanized steel structures. The heat from welding processes alters the microstructure of both the base steel and the zinc coating near the weld zone, creating heat-affected zones (HAZ) with potentially reduced ductility and fatigue resistance. These zones become vulnerable points during seismic events, where stress concentration can lead to premature failure.

The thickness uniformity of galvanized coatings presents additional complications in seismic applications. Current hot-dip galvanizing processes often result in uneven coating distribution, with thicker accumulations at edges and corners and thinner coverage on flat surfaces. This inconsistency creates variable performance under seismic loading, with some areas more susceptible to damage than others.

Hydrogen embrittlement remains a persistent issue in high-strength galvanized steels used in seismic applications. The galvanizing process can introduce hydrogen into the steel substrate, potentially reducing ductility and toughness—properties crucial for energy absorption during earthquakes. This phenomenon is particularly problematic in high-strength steels with yield strengths exceeding 1000 MPa, which are increasingly used in modern construction.

The interface bonding between the zinc coating and steel substrate presents another significant challenge. Under the extreme deformation experienced during major seismic events, delamination of the zinc layer can occur, compromising both structural integrity and corrosion protection. Current galvanizing technologies struggle to create consistently strong metallurgical bonds that can withstand such extreme conditions.

Environmental factors in seismic regions further complicate the performance of galvanized steel. Coastal seismic zones expose structures to both earthquake forces and aggressive salt environments, accelerating corrosion processes. Similarly, regions with industrial pollution combined with seismic activity create particularly challenging conditions for maintaining long-term structural integrity of galvanized steel components.

The economic constraints of implementing enhanced galvanizing techniques for seismic applications represent a practical challenge. While advanced coating technologies exist, their higher cost often leads to compromises in implementation, resulting in suboptimal performance during seismic events.

Current Galvanized Steel Optimization Techniques for Seismic Zones

01 Galvanizing process improvements

Various improvements to the galvanizing process for steel, including optimized dipping methods, temperature control, and flux application techniques. These innovations enhance coating uniformity, reduce zinc consumption, and improve the overall quality of galvanized steel products. Advanced process control systems monitor and adjust parameters in real-time to ensure consistent coating thickness and adhesion.- Galvanizing process improvements: Various improvements in the galvanizing process for steel, including optimized dipping methods, temperature control, and flux application techniques. These innovations enhance coating adhesion, uniformity, and corrosion resistance while reducing zinc consumption. Advanced process controls help maintain consistent coating quality and thickness across different steel substrates.

- Zinc alloy coating compositions: Development of specialized zinc alloy compositions for galvanized coatings that incorporate elements such as aluminum, magnesium, silicon, and rare earth metals. These alloy formulations provide enhanced corrosion protection, improved surface appearance, and better adhesion properties compared to traditional zinc coatings, while potentially reducing the overall amount of zinc required.

- Surface treatment and preparation methods: Innovative surface preparation and treatment techniques for steel prior to galvanizing, including chemical pretreatments, mechanical surface modifications, and cleaning processes. These methods improve coating adhesion, reduce defects, and enhance the overall quality and performance of galvanized steel products by ensuring proper interaction between the zinc coating and steel substrate.

- Corrosion resistance enhancement: Methods to enhance the corrosion resistance of galvanized steel through post-treatment processes, passivation layers, and protective sealants. These techniques extend the service life of galvanized products by providing additional barriers against environmental factors and preventing white rust formation, particularly in aggressive environments such as coastal areas or industrial settings.

- Eco-friendly galvanizing technologies: Development of environmentally sustainable galvanizing technologies that reduce energy consumption, minimize waste generation, and lower emissions. These innovations include zinc recovery systems, reduced-temperature processes, and alternative coating methods that maintain or improve performance while decreasing environmental impact and meeting increasingly stringent environmental regulations.

02 Zinc alloy coating compositions

Development of specialized zinc alloy compositions for galvanized steel coatings that provide enhanced corrosion resistance and surface properties. These alloys typically include elements such as aluminum, magnesium, silicon, or rare earth metals in specific proportions to improve coating performance. The modified compositions offer benefits such as improved formability, weldability, and extended service life in harsh environments.Expand Specific Solutions03 Surface treatment methods for galvanized steel

Pre and post-treatment methods for galvanized steel surfaces to enhance adhesion, corrosion resistance, and appearance. These treatments include chemical passivation, chromate-free conversion coatings, phosphating, and organic coatings. Surface preparation techniques ensure optimal zinc adhesion while post-treatments seal the coating and provide additional protective properties for specific applications.Expand Specific Solutions04 High-performance galvanized steel for automotive applications

Specialized galvanized steel products designed specifically for automotive applications, featuring enhanced formability, weldability, and crash resistance. These products combine advanced steel substrates with optimized galvanized coatings to meet the demanding requirements of vehicle manufacturing. The coatings provide corrosion protection while maintaining compatibility with automotive assembly processes including stamping, joining, and painting.Expand Specific Solutions05 Environmental and sustainable galvanizing technologies

Environmentally friendly approaches to galvanizing that reduce waste, emissions, and energy consumption. These technologies include zinc recovery systems, chromium-free passivation treatments, and energy-efficient heating methods. Sustainable galvanizing processes minimize environmental impact while maintaining or improving the performance characteristics of the galvanized steel products, addressing increasing regulatory requirements and market demand for greener manufacturing processes.Expand Specific Solutions

Key Industry Players in Earthquake-Resistant Steel Manufacturing

The galvanized steel market for earthquake-prone areas is currently in a growth phase, driven by increasing urbanization and infrastructure development in seismic regions. The market size is expanding at approximately 5-7% annually, with an estimated global value of $12-15 billion. Technologically, the sector is moderately mature but experiencing innovation in high-performance coatings and structural designs. Leading players include POSCO Holdings and NIPPON STEEL, who have developed advanced earthquake-resistant galvanized steel products, while companies like HBIS and Baoshan Iron & Steel are investing in R&D for seismic-resistant applications. JFE Steel and Hyundai Steel have made significant progress in optimizing galvanization processes specifically for structural applications in high-risk zones, creating products with enhanced ductility and strength-to-weight ratios essential for earthquake resilience.

POSCO Holdings, Inc.

Technical Solution: POSCO has pioneered PosMAC (POSCO Magnesium Alloy Coated) steel technology specifically optimized for seismic applications. This innovative galvanized steel incorporates magnesium and zinc-aluminum alloy coatings that provide superior corrosion resistance while maintaining exceptional ductility during seismic events. Their earthquake-resistant galvanized steel features a specialized microstructure achieved through controlled cooling processes that enhance energy absorption capabilities. POSCO's seismic-grade galvanized steel undergoes proprietary post-treatment processes that improve coating adhesion even under extreme deformation conditions. The company has developed specific grades with varying strength-to-weight ratios optimized for different seismic risk zones, allowing engineers to select the most appropriate material based on local earthquake hazard assessments.

Strengths: Advanced alloy coating technology provides superior corrosion protection even after seismic deformation; excellent ductility-to-strength ratio optimized for energy absorption; comprehensive product range for different seismic requirements. Weaknesses: Premium pricing structure may limit adoption in cost-sensitive markets; requires specialized welding techniques to maintain integrity of the coating system.

JFE Steel Corp.

Technical Solution: JFE Steel has developed HBLC (High-Performance Building Life Cycle) galvanized steel specifically engineered for seismic resilience. Their technology incorporates a multi-layer galvanizing approach with graduated zinc concentrations that optimize both corrosion protection and mechanical performance during earthquakes. JFE's seismic-resistant galvanized steel features controlled grain structure that enhances energy absorption capabilities while preventing brittle fracture under cyclic loading conditions. The company employs advanced computer modeling to simulate seismic performance of their galvanized steel products across various building configurations and earthquake scenarios. JFE's earthquake-optimized galvanized steel undergoes proprietary heat treatment processes that create an optimal balance between strength and ductility, allowing structures to flex without compromising the protective zinc coating integrity.

Strengths: Sophisticated multi-layer galvanizing technology provides excellent performance under cyclic loading; advanced computer modeling capabilities for predicting seismic behavior; strong integration with construction industry for practical implementation. Weaknesses: Complex manufacturing process increases production costs; requires specialized connection details that may necessitate additional engineering expertise.

Critical Patents and Research in Seismic-Resistant Steel Alloys

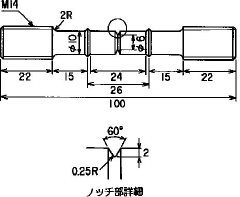

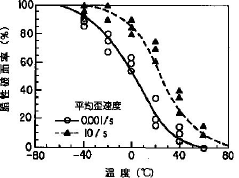

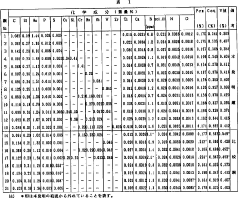

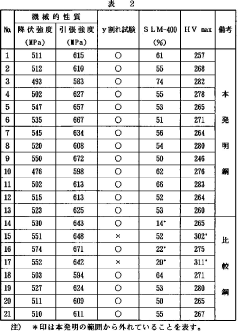

Heat treated type earthquake-proof steel product excellent in hot-dip galvanizing crack resistance

PatentInactiveJP1998204584A

Innovation

- A tempered steel composition with controlled alloying elements and a specific Pcm and Y value, combined with a notched tensile test to ensure a minimum reduction of area, enhances weldability, galvanization crack resistance, and brittle fracture resistance under high-speed deformation.

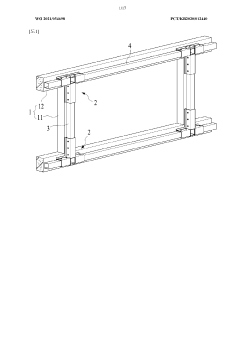

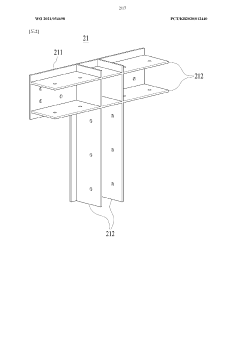

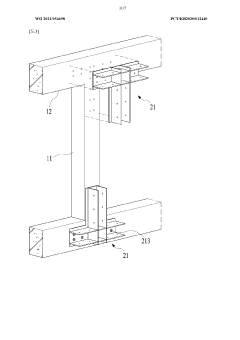

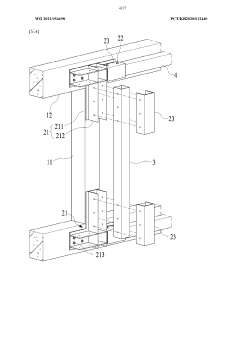

Anti-seismic reinforcement structure using panel zone reinforcing fixtures and construction method therefor

PatentWO2021054698A1

Innovation

- The seismic reinforcement structure and method utilize panel zone reinforcement fixtures that integrate reinforcing columns and beams with the existing frame's panel zone, reducing the need for drilling and ensuring quality through a rib reinforcement system with fastening bolts and fillers, allowing for efficient absorption of measurement errors and improved structural rigidity and ductility.

Building Code Compliance and Certification Standards

Building codes and certification standards play a crucial role in ensuring that galvanized steel structures can withstand seismic events in earthquake-prone regions. The International Building Code (IBC) and its regional adaptations establish minimum requirements for structural integrity during seismic activities, with specific provisions for steel structures that vary based on seismic zone classifications. These codes typically mandate enhanced ductility, connection strength, and overall structural resilience for buildings in high-risk areas.

For galvanized steel specifically, ASTM A123/A123M and ASTM A153/A153M standards govern hot-dip galvanizing processes and quality requirements. These standards ensure proper zinc coating thickness and adhesion, which are essential for maintaining structural integrity during seismic events. In earthquake-prone regions, additional certification requirements often apply, such as those outlined in ASCE 7 (Minimum Design Loads for Buildings and Other Structures), which provides detailed seismic design criteria.

Certification processes for galvanized steel in seismic applications typically involve third-party testing and verification. Organizations like the American Institute of Steel Construction (AISC) offer seismic certification programs that evaluate manufacturers' capabilities to produce components meeting stringent seismic requirements. The Steel Deck Institute (SDI) also provides specific guidelines for steel deck systems in high-seismic regions.

Recent updates to building codes have increasingly focused on performance-based design approaches rather than purely prescriptive requirements. This shift allows for more innovative use of galvanized steel in seismic applications, provided that performance objectives can be demonstrated through testing or advanced analysis. Eurocode 8 (Design of structures for earthquake resistance) and Japanese seismic design codes offer alternative compliance pathways that are gaining international recognition.

Compliance documentation for galvanized steel in seismic applications must include material certifications, coating thickness measurements, and mechanical property verifications. Quality control documentation becomes particularly important, as coating inconsistencies could compromise structural performance during seismic events. Many jurisdictions now require special inspection protocols for steel connections in seismic force-resisting systems.

The certification landscape continues to evolve with new testing methodologies and computational tools for seismic performance assessment. Advanced qualification protocols, such as those developed by the SAC Joint Venture (SEAOC, ATC, and CUREe), provide frameworks for evaluating innovative connection designs that may offer superior performance in earthquake conditions while maintaining the corrosion protection benefits of galvanization.

For galvanized steel specifically, ASTM A123/A123M and ASTM A153/A153M standards govern hot-dip galvanizing processes and quality requirements. These standards ensure proper zinc coating thickness and adhesion, which are essential for maintaining structural integrity during seismic events. In earthquake-prone regions, additional certification requirements often apply, such as those outlined in ASCE 7 (Minimum Design Loads for Buildings and Other Structures), which provides detailed seismic design criteria.

Certification processes for galvanized steel in seismic applications typically involve third-party testing and verification. Organizations like the American Institute of Steel Construction (AISC) offer seismic certification programs that evaluate manufacturers' capabilities to produce components meeting stringent seismic requirements. The Steel Deck Institute (SDI) also provides specific guidelines for steel deck systems in high-seismic regions.

Recent updates to building codes have increasingly focused on performance-based design approaches rather than purely prescriptive requirements. This shift allows for more innovative use of galvanized steel in seismic applications, provided that performance objectives can be demonstrated through testing or advanced analysis. Eurocode 8 (Design of structures for earthquake resistance) and Japanese seismic design codes offer alternative compliance pathways that are gaining international recognition.

Compliance documentation for galvanized steel in seismic applications must include material certifications, coating thickness measurements, and mechanical property verifications. Quality control documentation becomes particularly important, as coating inconsistencies could compromise structural performance during seismic events. Many jurisdictions now require special inspection protocols for steel connections in seismic force-resisting systems.

The certification landscape continues to evolve with new testing methodologies and computational tools for seismic performance assessment. Advanced qualification protocols, such as those developed by the SAC Joint Venture (SEAOC, ATC, and CUREe), provide frameworks for evaluating innovative connection designs that may offer superior performance in earthquake conditions while maintaining the corrosion protection benefits of galvanization.

Life-Cycle Assessment and Sustainability Considerations

The life cycle assessment (LCA) of galvanized steel in earthquake-prone regions reveals significant environmental implications across production, use, and end-of-life phases. Primary production impacts include high energy consumption during galvanization, with approximately 2-3 GJ of energy required per ton of steel processed, and zinc mining contributing to habitat disruption and water pollution. However, galvanized steel's extended service life of 50-75 years in seismic zones—compared to 30-40 years for conventional steel—substantially reduces replacement frequency and associated environmental burdens.

Carbon footprint analysis indicates that optimized galvanized steel structures can reduce lifetime emissions by 15-20% compared to traditional alternatives when considering earthquake resilience. This improvement stems from reduced reconstruction needs following seismic events and decreased material requirements due to enhanced structural efficiency. The embodied carbon in earthquake-optimized galvanized steel averages 1.8-2.2 kg CO2e per kilogram, which represents a favorable life-cycle impact when distributed across its extended service period.

Water consumption presents another critical sustainability consideration, with galvanization processes typically requiring 1.5-2.5 cubic meters of water per ton of steel. Implementation of closed-loop water recycling systems in modern facilities has demonstrated potential reductions of up to 80% in freshwater demand. Additionally, advanced zinc recovery technologies now achieve reclamation rates exceeding 95% from galvanization baths, significantly reducing primary resource requirements.

End-of-life management offers substantial sustainability opportunities, as galvanized steel maintains a recycling rate of approximately 90% in developed markets. The zinc coating, while providing crucial corrosion protection, comprises only 3-5% of the total material weight, minimizing separation challenges during recycling. Emerging technologies for selective zinc recovery before steel recycling further enhance material circularity and reduce environmental impacts.

Sustainability certification systems increasingly recognize the long-term benefits of earthquake-resistant galvanized steel. LEED, BREEAM, and other green building standards award additional points for materials demonstrating extended service life under extreme conditions, creating market incentives for optimized galvanized steel solutions. Recent studies indicate that buildings utilizing earthquake-optimized galvanized steel can achieve 10-15% higher sustainability ratings compared to conventional construction.

The economic dimension of sustainability reveals that while initial costs for optimized galvanized steel may exceed alternatives by 8-12%, life-cycle cost analysis demonstrates net savings of 20-30% when accounting for reduced maintenance, repair, and replacement expenses over a 75-year building lifespan in seismic zones. This favorable economic performance reinforces the triple-bottom-line case for sustainable galvanized steel optimization in earthquake-prone regions.

Carbon footprint analysis indicates that optimized galvanized steel structures can reduce lifetime emissions by 15-20% compared to traditional alternatives when considering earthquake resilience. This improvement stems from reduced reconstruction needs following seismic events and decreased material requirements due to enhanced structural efficiency. The embodied carbon in earthquake-optimized galvanized steel averages 1.8-2.2 kg CO2e per kilogram, which represents a favorable life-cycle impact when distributed across its extended service period.

Water consumption presents another critical sustainability consideration, with galvanization processes typically requiring 1.5-2.5 cubic meters of water per ton of steel. Implementation of closed-loop water recycling systems in modern facilities has demonstrated potential reductions of up to 80% in freshwater demand. Additionally, advanced zinc recovery technologies now achieve reclamation rates exceeding 95% from galvanization baths, significantly reducing primary resource requirements.

End-of-life management offers substantial sustainability opportunities, as galvanized steel maintains a recycling rate of approximately 90% in developed markets. The zinc coating, while providing crucial corrosion protection, comprises only 3-5% of the total material weight, minimizing separation challenges during recycling. Emerging technologies for selective zinc recovery before steel recycling further enhance material circularity and reduce environmental impacts.

Sustainability certification systems increasingly recognize the long-term benefits of earthquake-resistant galvanized steel. LEED, BREEAM, and other green building standards award additional points for materials demonstrating extended service life under extreme conditions, creating market incentives for optimized galvanized steel solutions. Recent studies indicate that buildings utilizing earthquake-optimized galvanized steel can achieve 10-15% higher sustainability ratings compared to conventional construction.

The economic dimension of sustainability reveals that while initial costs for optimized galvanized steel may exceed alternatives by 8-12%, life-cycle cost analysis demonstrates net savings of 20-30% when accounting for reduced maintenance, repair, and replacement expenses over a 75-year building lifespan in seismic zones. This favorable economic performance reinforces the triple-bottom-line case for sustainable galvanized steel optimization in earthquake-prone regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!