Optimize Galvanized Steel Heat Treatment for Strength

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Heat Treatment Background and Objectives

Galvanized steel has been a cornerstone material in various industries for over a century, with its development tracing back to the early 1800s when hot-dip galvanizing was first patented. The technology has evolved significantly from rudimentary coating processes to sophisticated continuous galvanizing lines that operate at industrial scale today. This evolution has been driven by increasing demands for corrosion-resistant materials in construction, automotive, and infrastructure applications.

The heat treatment of galvanized steel represents a critical processing step that directly influences the material's mechanical properties, particularly its strength characteristics. Traditional heat treatment approaches have often resulted in a trade-off between corrosion resistance and mechanical strength, as the zinc coating that provides corrosion protection can be compromised during high-temperature treatments designed to enhance strength.

Recent technological advancements have focused on optimizing this balance, with particular attention to controlling the formation of zinc-iron intermetallic compounds at the coating-substrate interface. These compounds, while contributing to adhesion, can become brittle if not properly managed during the heat treatment process, leading to coating failure under mechanical stress.

The global steel industry has recognized the strategic importance of advanced galvanized steel products, particularly in the context of lightweighting initiatives in automotive manufacturing and sustainable construction practices. This has accelerated research into novel heat treatment methodologies that can simultaneously enhance strength while maintaining or improving corrosion resistance.

The primary objective of optimizing galvanized steel heat treatment is to develop processes that can achieve superior strength characteristics without compromising the protective zinc coating. This involves precise control of heating rates, peak temperatures, holding times, and cooling strategies to manage the microstructural evolution of both the steel substrate and the zinc coating.

Secondary objectives include improving energy efficiency of the heat treatment process, reducing processing times to enhance productivity, and ensuring consistent quality across varying steel compositions and thicknesses. These objectives align with broader industry trends toward sustainable manufacturing and material optimization.

The technological trajectory suggests a move toward more sophisticated, computer-controlled heat treatment systems that can implement complex thermal cycles tailored to specific galvanized steel grades. This includes the integration of real-time monitoring and feedback systems to adjust parameters dynamically during processing, representing a shift from traditional fixed-parameter approaches to adaptive processing methodologies.

The heat treatment of galvanized steel represents a critical processing step that directly influences the material's mechanical properties, particularly its strength characteristics. Traditional heat treatment approaches have often resulted in a trade-off between corrosion resistance and mechanical strength, as the zinc coating that provides corrosion protection can be compromised during high-temperature treatments designed to enhance strength.

Recent technological advancements have focused on optimizing this balance, with particular attention to controlling the formation of zinc-iron intermetallic compounds at the coating-substrate interface. These compounds, while contributing to adhesion, can become brittle if not properly managed during the heat treatment process, leading to coating failure under mechanical stress.

The global steel industry has recognized the strategic importance of advanced galvanized steel products, particularly in the context of lightweighting initiatives in automotive manufacturing and sustainable construction practices. This has accelerated research into novel heat treatment methodologies that can simultaneously enhance strength while maintaining or improving corrosion resistance.

The primary objective of optimizing galvanized steel heat treatment is to develop processes that can achieve superior strength characteristics without compromising the protective zinc coating. This involves precise control of heating rates, peak temperatures, holding times, and cooling strategies to manage the microstructural evolution of both the steel substrate and the zinc coating.

Secondary objectives include improving energy efficiency of the heat treatment process, reducing processing times to enhance productivity, and ensuring consistent quality across varying steel compositions and thicknesses. These objectives align with broader industry trends toward sustainable manufacturing and material optimization.

The technological trajectory suggests a move toward more sophisticated, computer-controlled heat treatment systems that can implement complex thermal cycles tailored to specific galvanized steel grades. This includes the integration of real-time monitoring and feedback systems to adjust parameters dynamically during processing, representing a shift from traditional fixed-parameter approaches to adaptive processing methodologies.

Market Demand Analysis for High-Strength Galvanized Steel

The global market for high-strength galvanized steel has experienced significant growth over the past decade, driven primarily by the automotive and construction industries. This growth trajectory is expected to continue as manufacturers across various sectors seek materials that offer superior strength-to-weight ratios while maintaining corrosion resistance properties.

In the automotive sector, the demand for high-strength galvanized steel has surged due to stringent fuel efficiency standards and safety regulations. Automotive manufacturers are increasingly replacing conventional steel components with high-strength galvanized alternatives to reduce vehicle weight while maintaining or improving crash performance. The trend toward electric vehicles has further accelerated this demand, as manufacturers seek to offset battery weight with lighter structural components.

Construction industry requirements have similarly evolved, with building codes in developed markets increasingly specifying materials that offer both structural integrity and longevity. High-strength galvanized steel meets these requirements by providing enhanced load-bearing capacity while maintaining resistance to environmental degradation. The growing focus on sustainable construction practices has also boosted demand, as high-strength galvanized steel components typically have longer service lives and require less frequent replacement.

Infrastructure development in emerging economies represents another significant market driver. Countries across Asia, particularly China and India, are investing heavily in transportation networks, energy facilities, and urban development projects that require substantial quantities of high-performance steel products. The superior mechanical properties achieved through optimized heat treatment processes make these materials particularly valuable for bridges, high-rise buildings, and other critical infrastructure applications.

Market analysis indicates that the industrial equipment sector is also emerging as a key consumer of high-strength galvanized steel. Manufacturers of heavy machinery, material handling equipment, and industrial storage systems are adopting these materials to develop products with improved performance characteristics and extended operational lifespans.

Regional market dynamics show varying adoption rates, with North America and Europe leading in premium applications where performance requirements justify higher material costs. Meanwhile, Asia-Pacific represents the fastest-growing market segment, driven by rapid industrialization and infrastructure development. The Middle East and Africa regions show increasing demand potential, particularly in oil and gas applications and urban development projects.

Price sensitivity remains a significant factor influencing market penetration. While high-strength galvanized steel commands a premium over conventional alternatives, manufacturers are increasingly recognizing the total cost benefits when considering the entire product lifecycle. Improved processing techniques that optimize heat treatment while maintaining production efficiency will be crucial to expanding market share in price-sensitive applications.

In the automotive sector, the demand for high-strength galvanized steel has surged due to stringent fuel efficiency standards and safety regulations. Automotive manufacturers are increasingly replacing conventional steel components with high-strength galvanized alternatives to reduce vehicle weight while maintaining or improving crash performance. The trend toward electric vehicles has further accelerated this demand, as manufacturers seek to offset battery weight with lighter structural components.

Construction industry requirements have similarly evolved, with building codes in developed markets increasingly specifying materials that offer both structural integrity and longevity. High-strength galvanized steel meets these requirements by providing enhanced load-bearing capacity while maintaining resistance to environmental degradation. The growing focus on sustainable construction practices has also boosted demand, as high-strength galvanized steel components typically have longer service lives and require less frequent replacement.

Infrastructure development in emerging economies represents another significant market driver. Countries across Asia, particularly China and India, are investing heavily in transportation networks, energy facilities, and urban development projects that require substantial quantities of high-performance steel products. The superior mechanical properties achieved through optimized heat treatment processes make these materials particularly valuable for bridges, high-rise buildings, and other critical infrastructure applications.

Market analysis indicates that the industrial equipment sector is also emerging as a key consumer of high-strength galvanized steel. Manufacturers of heavy machinery, material handling equipment, and industrial storage systems are adopting these materials to develop products with improved performance characteristics and extended operational lifespans.

Regional market dynamics show varying adoption rates, with North America and Europe leading in premium applications where performance requirements justify higher material costs. Meanwhile, Asia-Pacific represents the fastest-growing market segment, driven by rapid industrialization and infrastructure development. The Middle East and Africa regions show increasing demand potential, particularly in oil and gas applications and urban development projects.

Price sensitivity remains a significant factor influencing market penetration. While high-strength galvanized steel commands a premium over conventional alternatives, manufacturers are increasingly recognizing the total cost benefits when considering the entire product lifecycle. Improved processing techniques that optimize heat treatment while maintaining production efficiency will be crucial to expanding market share in price-sensitive applications.

Current Challenges in Galvanized Steel Heat Treatment

The heat treatment of galvanized steel presents significant technical challenges that impact product quality, manufacturing efficiency, and material properties. Current heat treatment processes often struggle to achieve optimal strength characteristics while maintaining the integrity of the zinc coating. The primary challenge lies in the narrow temperature window available for heat treatment, as zinc begins to melt at approximately 420°C, while effective steel strengthening typically requires temperatures above 500°C.

Manufacturing facilities face difficulties in precise temperature control during the heat treatment process. Even minor temperature fluctuations can lead to uneven zinc coating distribution, coating defects, or insufficient strengthening of the steel substrate. This challenge is particularly pronounced in continuous galvanizing lines where maintaining consistent temperature profiles across large steel sheets proves technically demanding.

Another significant obstacle is the formation of brittle intermetallic compounds at the steel-zinc interface during heat treatment. These Fe-Zn intermetallic phases, particularly the delta and gamma phases, can compromise the mechanical properties of the final product, reducing ductility and formability while increasing susceptibility to cracking during subsequent forming operations.

Energy efficiency represents a growing concern in galvanized steel heat treatment. Traditional heating methods consume substantial energy, contributing to high operational costs and environmental impact. The industry faces pressure to develop more energy-efficient heat treatment technologies while maintaining or improving product quality and throughput rates.

Cooling rate management after heat treatment presents additional complications. Rapid cooling may enhance steel strength but can induce thermal stresses that affect coating adhesion and uniformity. Conversely, slower cooling rates may preserve coating integrity but potentially sacrifice some strength benefits, creating a difficult balance to achieve consistently.

The variability in steel substrate composition further complicates heat treatment optimization. Different steel grades respond differently to heat treatment parameters, requiring customized approaches that are challenging to implement in high-volume production environments. This is especially problematic for manufacturers processing multiple steel grades on the same production line.

Quality control and process monitoring capabilities remain insufficient in many production facilities. Real-time measurement of temperature distribution, coating thickness, and metallurgical transformations during heat treatment would enable more responsive process control, but current sensor technologies and monitoring systems have limitations in harsh production environments.

Manufacturing facilities face difficulties in precise temperature control during the heat treatment process. Even minor temperature fluctuations can lead to uneven zinc coating distribution, coating defects, or insufficient strengthening of the steel substrate. This challenge is particularly pronounced in continuous galvanizing lines where maintaining consistent temperature profiles across large steel sheets proves technically demanding.

Another significant obstacle is the formation of brittle intermetallic compounds at the steel-zinc interface during heat treatment. These Fe-Zn intermetallic phases, particularly the delta and gamma phases, can compromise the mechanical properties of the final product, reducing ductility and formability while increasing susceptibility to cracking during subsequent forming operations.

Energy efficiency represents a growing concern in galvanized steel heat treatment. Traditional heating methods consume substantial energy, contributing to high operational costs and environmental impact. The industry faces pressure to develop more energy-efficient heat treatment technologies while maintaining or improving product quality and throughput rates.

Cooling rate management after heat treatment presents additional complications. Rapid cooling may enhance steel strength but can induce thermal stresses that affect coating adhesion and uniformity. Conversely, slower cooling rates may preserve coating integrity but potentially sacrifice some strength benefits, creating a difficult balance to achieve consistently.

The variability in steel substrate composition further complicates heat treatment optimization. Different steel grades respond differently to heat treatment parameters, requiring customized approaches that are challenging to implement in high-volume production environments. This is especially problematic for manufacturers processing multiple steel grades on the same production line.

Quality control and process monitoring capabilities remain insufficient in many production facilities. Real-time measurement of temperature distribution, coating thickness, and metallurgical transformations during heat treatment would enable more responsive process control, but current sensor technologies and monitoring systems have limitations in harsh production environments.

Current Heat Treatment Optimization Techniques

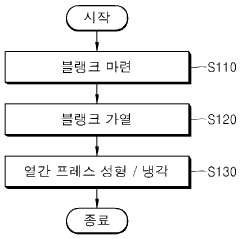

01 Heat treatment processes for galvanized steel strength enhancement

Various heat treatment processes can be applied to galvanized steel to enhance its strength properties. These processes include controlled heating and cooling cycles that modify the microstructure of the steel substrate while maintaining the integrity of the zinc coating. Specific temperature ranges and holding times are critical to achieve optimal strength without compromising the galvanized layer's corrosion protection properties.- Heat treatment processes for enhancing galvanized steel strength: Various heat treatment processes can be applied to galvanized steel to enhance its strength properties. These processes include annealing, tempering, and controlled cooling methods that modify the microstructure of the steel substrate while maintaining the integrity of the zinc coating. The proper selection of temperature ranges and heating durations is critical to achieve optimal strength improvements without compromising the corrosion resistance provided by the galvanized layer.

- Zinc coating composition modifications for improved heat treatment response: The composition of the zinc coating can be modified to better withstand heat treatment processes while contributing to the overall strength of galvanized steel products. By incorporating specific alloying elements such as aluminum, magnesium, or silicon into the zinc bath, the coating forms intermetallic compounds that respond favorably to heat treatment. These modified coatings maintain better adhesion during thermal processing and can contribute to the mechanical properties of the final product.

- Post-galvanizing thermal treatments for strength optimization: After the galvanizing process, specific thermal treatments can be applied to optimize the strength of the coated steel. These post-galvanizing treatments include controlled reheating, quenching, and aging processes that enhance the mechanical properties while preserving the protective zinc layer. The timing and temperature control during these processes are crucial for developing the desired microstructure in the steel substrate without causing coating degradation or delamination.

- Microstructure control during heat treatment of galvanized steel: Controlling the microstructure development during heat treatment is essential for achieving optimal strength in galvanized steel products. This involves precise management of phase transformations, grain refinement, and precipitation hardening mechanisms. Advanced techniques such as intercritical annealing, controlled cooling rates, and isothermal holding can be employed to develop specific microstructures that provide enhanced strength while maintaining compatibility with the zinc coating.

- Protective atmospheres for heat treating galvanized steel: The use of specialized protective atmospheres during heat treatment helps preserve the integrity of the zinc coating while allowing for strength enhancement of the steel substrate. These controlled atmospheres, which may include inert gases, reducing environments, or specific gas mixtures, prevent oxidation and zinc volatilization during high-temperature processing. This approach enables more aggressive heat treatment parameters to be used for strength development without sacrificing the corrosion protection provided by the galvanized coating.

02 Composition modifications for improved heat treatment response

The chemical composition of galvanized steel can be modified to improve its response to heat treatment processes. Addition of specific alloying elements such as manganese, silicon, and boron can enhance hardenability and strength development during heat treatment. These compositional adjustments allow for better control of phase transformations and grain refinement, resulting in superior mechanical properties after the heat treatment of galvanized steel.Expand Specific Solutions03 Coating composition and thickness control for heat treatment compatibility

The composition and thickness of the galvanized coating significantly impact the steel's behavior during heat treatment. Controlling zinc-iron intermetallic phases and coating thickness ensures better adhesion and prevents coating degradation during thermal processing. Advanced coating technologies allow for optimized zinc layers that can withstand heat treatment temperatures while maintaining corrosion resistance and enabling strength improvements in the steel substrate.Expand Specific Solutions04 Post-galvanizing thermal processing techniques

After galvanizing, specific thermal processing techniques can be applied to enhance steel strength without damaging the zinc coating. These include tempering, aging, and specialized annealing processes designed for coated steels. Controlled cooling rates and temperature profiles are employed to achieve desired microstructural changes in the steel substrate while minimizing zinc volatilization or coating deterioration, resulting in improved strength properties.Expand Specific Solutions05 Advanced galvanizing methods for heat-treatable high-strength steels

Innovative galvanizing methods have been developed specifically for heat-treatable high-strength steels. These include modified hot-dip processes, diffusion annealing treatments, and specialized pre-treatment steps that prepare the steel surface for both galvanizing and subsequent heat treatment. These advanced methods create zinc coatings that remain stable during heat treatment while allowing the base steel to achieve maximum strength through proper microstructural development.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The galvanized steel heat treatment optimization market is currently in a growth phase, with increasing demand driven by automotive, construction, and appliance industries requiring higher-strength materials. The global market size for advanced steel treatment technologies is estimated at $15-20 billion annually, with projected 5-7% CAGR through 2028. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established Japanese steelmakers (Nippon Steel, JFE Steel) with advanced heat treatment expertise, Chinese giants (Baoshan Iron & Steel, HBIS) investing heavily in process optimization, and specialized players like JSW Steel Coated Products focusing on high-performance galvanized products. Research collaborations between industry leaders and institutions like Tsinghua University are accelerating technological advancement in strength-optimized galvanized steel production.

JFE Steel Corp.

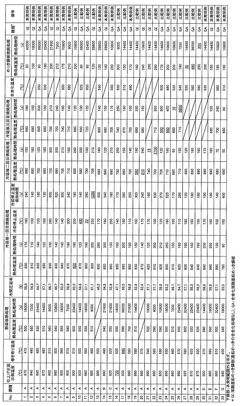

Technical Solution: JFE Steel has pioneered a dual-phase heat treatment technology for galvanized high-strength steel that optimizes both strength and formability. Their process involves precise control of intercritical annealing temperatures (750-830°C) followed by rapid cooling at controlled rates (15-40°C/s) to develop an optimal mixture of ferrite and martensite phases. JFE's innovation includes a specialized post-galvanizing heat treatment that relieves hydrogen embrittlement while maintaining coating integrity. Their "JEFORMA" technology incorporates microalloying with carefully balanced Ti, Nb, and B additions (typically 0.05-0.15%) that form fine precipitates during controlled cooling, significantly enhancing strength without compromising galvanized coating adhesion. The process employs electromagnetic induction heating for precise temperature control across the steel sheet thickness, achieving uniform mechanical properties. JFE has also developed specialized cooling technology that prevents thermal distortion during rapid cooling phases, ensuring dimensional accuracy in the final product.

Strengths: Excellent combination of high strength (up to 1180 MPa) and formability; superior coating adhesion; consistent mechanical properties across varying thicknesses. Weaknesses: Complex process control requirements; higher energy consumption compared to conventional treatments; requires specialized equipment for precise temperature control.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baoshan Iron & Steel (Baosteel) has developed an innovative continuous annealing process for high-strength galvanized steel that optimizes microstructural evolution. Their technology employs a carefully controlled heating profile with specific soaking temperatures (820-880°C) and precise holding times to achieve optimal austenite formation. The process incorporates a stepped cooling approach with multiple temperature plateaus that promote controlled transformation of austenite to bainite and martensite phases. Baosteel's "BaoStrength" technology utilizes micro-alloying elements (Mn, Cr, Mo) in specific ratios (typically 1.5-2.5% Mn, 0.4-0.8% Cr) to enhance hardenability while maintaining good galvanizability. Their process includes a specialized post-galvanizing tempering treatment at 200-350°C that relieves internal stresses while preserving coating integrity. Baosteel has also implemented advanced computer modeling systems that predict mechanical properties based on chemical composition and processing parameters, allowing for real-time adjustments to achieve target strength levels.

Strengths: Cost-effective production of high-strength galvanized steel; good balance of strength and ductility; excellent coating quality with minimal defects. Weaknesses: Somewhat lower maximum strength compared to Japanese competitors; more sensitive to variations in base material composition; requires careful control of cooling rates to prevent coating damage.

Key Patents and Research on Strength Enhancement Methods

Heat treatment hardening type of galvanized steel sheet and manufacturing method of steel products using the same

PatentInactiveKR1020140002272A

Innovation

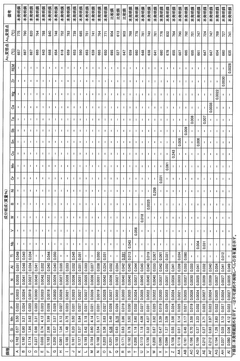

- A heat-treatable galvanized steel sheet with specific alloy compositions, including carbon, manganese, nickel, and vanadium, achieving an A3 transformation temperature of 810°C or less, allowing hot press forming at lower temperatures to maintain the zinc plating layer and prevent springback.

High-strength galvanized steel sheet and method for producing same

PatentWO2021140663A1

Innovation

- A high-strength galvanized steel sheet with a composition of 0.030% to 0.250% C, 2.50% to 8.00% Mn, and specific heat treatment processes involving hot rolling, cold rolling, and galvanizing, which includes maintaining temperatures below and above the transformation point, and pickling treatments to achieve a microstructure with 35% to 80% ferrite, 0.1% to 5.0% quenched martensite, 3.0% to 35% tempered martensite, and 8% or more retained austenite, along with a galvanized layer.

Environmental Impact and Sustainability Considerations

The optimization of galvanized steel heat treatment processes presents significant environmental challenges and sustainability considerations that must be addressed in modern manufacturing contexts. Traditional heat treatment methods consume substantial energy resources, primarily from fossil fuels, contributing to greenhouse gas emissions and climate change impacts. Recent industry assessments indicate that steel heat treatment operations can account for up to 15-20% of a manufacturing facility's total energy consumption, representing a critical area for sustainability improvements.

Water usage in galvanized steel heat treatment processes also raises environmental concerns, particularly regarding the discharge of contaminated cooling water containing metal particulates and treatment chemicals. Advanced closed-loop water systems have demonstrated potential to reduce freshwater consumption by 40-60% compared to conventional methods, while simultaneously minimizing wastewater discharge and associated treatment costs.

Air emissions from heat treatment furnaces, including nitrogen oxides, sulfur dioxide, and particulate matter, require effective mitigation strategies to comply with increasingly stringent environmental regulations. Implementation of low-NOx burners and advanced filtration systems has shown promising results in reducing these emissions by up to 75% in optimized facilities.

Material efficiency represents another critical sustainability dimension. Optimized heat treatment processes can reduce material waste through more precise temperature control and treatment uniformity, extending product lifespan and reducing the need for replacement. Studies indicate that advanced heat treatment protocols can improve galvanized steel durability by 15-30%, significantly reducing lifecycle environmental impacts.

Renewable energy integration offers substantial potential for reducing the carbon footprint of heat treatment operations. Solar thermal systems, biomass heating, and electrification powered by renewable sources are emerging as viable alternatives to conventional fossil fuel-based heating. Early adopters have reported carbon emission reductions of 30-50% through strategic implementation of these technologies.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impacts of galvanized steel production. These assessments reveal that optimized heat treatment processes can reduce overall environmental footprint by 20-35% when considering the entire product lifecycle, from raw material extraction through manufacturing, use, and end-of-life management.

Regulatory compliance and voluntary sustainability certifications are driving innovation in this sector. Companies implementing best practices in environmentally responsible heat treatment are gaining competitive advantages through improved brand reputation, access to environmentally conscious markets, and reduced compliance costs associated with environmental regulations.

Water usage in galvanized steel heat treatment processes also raises environmental concerns, particularly regarding the discharge of contaminated cooling water containing metal particulates and treatment chemicals. Advanced closed-loop water systems have demonstrated potential to reduce freshwater consumption by 40-60% compared to conventional methods, while simultaneously minimizing wastewater discharge and associated treatment costs.

Air emissions from heat treatment furnaces, including nitrogen oxides, sulfur dioxide, and particulate matter, require effective mitigation strategies to comply with increasingly stringent environmental regulations. Implementation of low-NOx burners and advanced filtration systems has shown promising results in reducing these emissions by up to 75% in optimized facilities.

Material efficiency represents another critical sustainability dimension. Optimized heat treatment processes can reduce material waste through more precise temperature control and treatment uniformity, extending product lifespan and reducing the need for replacement. Studies indicate that advanced heat treatment protocols can improve galvanized steel durability by 15-30%, significantly reducing lifecycle environmental impacts.

Renewable energy integration offers substantial potential for reducing the carbon footprint of heat treatment operations. Solar thermal systems, biomass heating, and electrification powered by renewable sources are emerging as viable alternatives to conventional fossil fuel-based heating. Early adopters have reported carbon emission reductions of 30-50% through strategic implementation of these technologies.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impacts of galvanized steel production. These assessments reveal that optimized heat treatment processes can reduce overall environmental footprint by 20-35% when considering the entire product lifecycle, from raw material extraction through manufacturing, use, and end-of-life management.

Regulatory compliance and voluntary sustainability certifications are driving innovation in this sector. Companies implementing best practices in environmentally responsible heat treatment are gaining competitive advantages through improved brand reputation, access to environmentally conscious markets, and reduced compliance costs associated with environmental regulations.

Cost-Benefit Analysis of Advanced Heat Treatment Processes

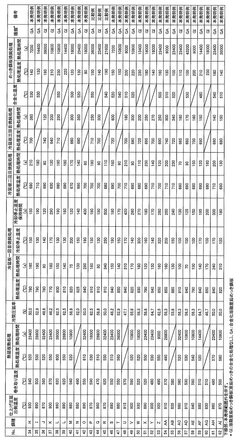

The implementation of advanced heat treatment processes for galvanized steel requires careful financial analysis to determine economic viability. Initial capital expenditures for upgrading existing facilities or installing new equipment represent significant investments, typically ranging from $500,000 to $3 million depending on production scale and technological sophistication. These costs encompass specialized furnaces, precise temperature control systems, and automated handling equipment necessary for optimal treatment parameters.

Operational expenses must be evaluated against potential returns. Energy consumption constitutes a major ongoing cost, with advanced processes often requiring 15-25% more energy than conventional methods. However, this is partially offset by reduced processing times, which can decrease by up to 30% with technologies like induction heating or controlled atmosphere processing.

Labor requirements present another important consideration. While advanced systems typically reduce direct labor needs through automation, they necessitate skilled technicians for operation and maintenance, potentially increasing hourly labor costs by 20-40%. Maintenance expenses for sophisticated equipment generally run 5-8% of capital costs annually.

The benefits side of the equation shows promising returns. Enhanced steel strength properties achieved through optimized heat treatment can command premium pricing, typically 8-15% higher than standard galvanized products. Market analysis indicates growing demand for high-performance galvanized steel in automotive, construction, and infrastructure sectors, with projected annual growth rates of 4-6% over the next five years.

Production efficiency improvements represent another significant benefit. Advanced heat treatment processes can reduce rejection rates by 30-50% and minimize post-treatment rework, resulting in material savings of 3-7%. Additionally, consistent quality outcomes reduce warranty claims and customer returns, providing indirect cost savings estimated at 2-4% of revenue.

Payback periods for investments in advanced heat treatment technologies typically range from 2.5 to 4 years, with ROI calculations showing 18-25% returns over a five-year period. Sensitivity analysis indicates that even with 20% higher than projected energy costs, most advanced processes remain economically viable due to quality and efficiency improvements.

Environmental considerations also factor into the cost-benefit equation. Advanced processes often demonstrate 10-15% lower emissions and reduced waste generation, potentially qualifying for regulatory incentives or avoiding future compliance costs as environmental regulations tighten.

Operational expenses must be evaluated against potential returns. Energy consumption constitutes a major ongoing cost, with advanced processes often requiring 15-25% more energy than conventional methods. However, this is partially offset by reduced processing times, which can decrease by up to 30% with technologies like induction heating or controlled atmosphere processing.

Labor requirements present another important consideration. While advanced systems typically reduce direct labor needs through automation, they necessitate skilled technicians for operation and maintenance, potentially increasing hourly labor costs by 20-40%. Maintenance expenses for sophisticated equipment generally run 5-8% of capital costs annually.

The benefits side of the equation shows promising returns. Enhanced steel strength properties achieved through optimized heat treatment can command premium pricing, typically 8-15% higher than standard galvanized products. Market analysis indicates growing demand for high-performance galvanized steel in automotive, construction, and infrastructure sectors, with projected annual growth rates of 4-6% over the next five years.

Production efficiency improvements represent another significant benefit. Advanced heat treatment processes can reduce rejection rates by 30-50% and minimize post-treatment rework, resulting in material savings of 3-7%. Additionally, consistent quality outcomes reduce warranty claims and customer returns, providing indirect cost savings estimated at 2-4% of revenue.

Payback periods for investments in advanced heat treatment technologies typically range from 2.5 to 4 years, with ROI calculations showing 18-25% returns over a five-year period. Sensitivity analysis indicates that even with 20% higher than projected energy costs, most advanced processes remain economically viable due to quality and efficiency improvements.

Environmental considerations also factor into the cost-benefit equation. Advanced processes often demonstrate 10-15% lower emissions and reduced waste generation, potentially qualifying for regulatory incentives or avoiding future compliance costs as environmental regulations tighten.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!