Measure Coating Integrity of Galvanized Steel Via SEM Analysis

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Galvanized Steel Coating Analysis Background and Objectives

Galvanized steel has been a cornerstone material in various industries for over 150 years, providing essential corrosion protection for steel substrates. The integrity of zinc coatings directly correlates with the service life and performance of galvanized products, making coating analysis a critical quality control parameter. This technical investigation aims to comprehensively evaluate the capabilities of Scanning Electron Microscopy (SEM) as an advanced analytical tool for measuring and characterizing galvanized steel coating integrity.

The evolution of galvanizing technology has progressed from traditional hot-dip processes to include electrogalvanizing, thermal spraying, and various alloy coatings. Each advancement has introduced new challenges in quality assessment and performance prediction. Current industry standards primarily rely on weight-based measurements and accelerated corrosion testing, which provide limited insight into coating microstructure and distribution uniformity—factors increasingly recognized as critical performance indicators.

SEM analysis represents a significant technological advancement in coating evaluation, offering nanometer-scale resolution and the ability to examine cross-sectional morphology, intermetallic phases, and coating defects that remain undetectable through conventional testing methods. This investigation seeks to establish standardized SEM protocols specifically optimized for galvanized coating assessment, addressing the growing demand for more precise quality control in high-performance applications.

The primary technical objectives include developing quantitative metrics for coating integrity based on SEM imaging, correlating microstructural characteristics with corrosion performance, and establishing threshold values for various coating defects. Additionally, we aim to explore the integration of Energy Dispersive X-ray Spectroscopy (EDS) with SEM analysis to provide compositional mapping of zinc coatings and intermetallic layers.

Market trends indicate increasing demand for galvanized steel with enhanced performance specifications in automotive, construction, and renewable energy sectors. These applications require more sophisticated quality assurance methods than currently employed in standard production environments. The development of SEM-based analytical protocols addresses this technological gap while potentially enabling new product differentiation based on verifiable coating quality metrics.

This investigation will also examine the feasibility of implementing SEM analysis in production environments through automated sampling and image processing algorithms. The ultimate goal is to transition from purely laboratory-based analysis to practical quality control tools that can be deployed at various stages of the manufacturing process, providing real-time feedback on coating integrity and enabling process optimization.

The evolution of galvanizing technology has progressed from traditional hot-dip processes to include electrogalvanizing, thermal spraying, and various alloy coatings. Each advancement has introduced new challenges in quality assessment and performance prediction. Current industry standards primarily rely on weight-based measurements and accelerated corrosion testing, which provide limited insight into coating microstructure and distribution uniformity—factors increasingly recognized as critical performance indicators.

SEM analysis represents a significant technological advancement in coating evaluation, offering nanometer-scale resolution and the ability to examine cross-sectional morphology, intermetallic phases, and coating defects that remain undetectable through conventional testing methods. This investigation seeks to establish standardized SEM protocols specifically optimized for galvanized coating assessment, addressing the growing demand for more precise quality control in high-performance applications.

The primary technical objectives include developing quantitative metrics for coating integrity based on SEM imaging, correlating microstructural characteristics with corrosion performance, and establishing threshold values for various coating defects. Additionally, we aim to explore the integration of Energy Dispersive X-ray Spectroscopy (EDS) with SEM analysis to provide compositional mapping of zinc coatings and intermetallic layers.

Market trends indicate increasing demand for galvanized steel with enhanced performance specifications in automotive, construction, and renewable energy sectors. These applications require more sophisticated quality assurance methods than currently employed in standard production environments. The development of SEM-based analytical protocols addresses this technological gap while potentially enabling new product differentiation based on verifiable coating quality metrics.

This investigation will also examine the feasibility of implementing SEM analysis in production environments through automated sampling and image processing algorithms. The ultimate goal is to transition from purely laboratory-based analysis to practical quality control tools that can be deployed at various stages of the manufacturing process, providing real-time feedback on coating integrity and enabling process optimization.

Market Demand for Coating Integrity Assessment

The global market for coating integrity assessment in galvanized steel has experienced significant growth over the past decade, driven primarily by expanding applications in automotive, construction, and infrastructure sectors. The demand for reliable coating evaluation methods has intensified as industries increasingly prioritize corrosion resistance and product longevity in harsh environmental conditions.

In the automotive industry, which consumes approximately 20% of global galvanized steel production, manufacturers require precise coating integrity assessment to ensure vehicle components meet stringent quality standards and corrosion resistance specifications. The construction sector, representing the largest consumer of galvanized steel at roughly 40% of global production, demands effective coating evaluation to guarantee structural longevity in buildings and infrastructure projects.

Market research indicates that the global galvanized steel market reached 180 million tons in 2022, with projected annual growth rates of 4-5% through 2028. This expansion directly correlates with increased demand for advanced coating integrity assessment technologies, particularly non-destructive testing methods like SEM analysis that provide detailed microstructural information without compromising sample integrity.

Regional analysis reveals that Asia-Pacific dominates the market for galvanized steel coating assessment technologies, accounting for over 50% of global demand, followed by Europe and North America. This distribution aligns with regional manufacturing hubs and infrastructure development patterns.

Industry surveys highlight that manufacturers are willing to invest in sophisticated coating assessment technologies that reduce quality control costs and minimize product failures. The economic impact of coating failures in galvanized steel products is substantial, with estimates suggesting that inadequate coating integrity assessment contributes to billions in annual replacement and maintenance costs across industries.

The market specifically for SEM-based coating integrity assessment tools has shown remarkable growth, with specialized equipment sales increasing by approximately 8% annually. This trend reflects the technology's ability to provide nanoscale analysis of coating structure, thickness uniformity, and defect identification that conventional testing methods cannot match.

Regulatory factors further drive market demand, as international standards for corrosion protection become increasingly stringent. Industries subject to safety-critical applications, such as energy and transportation infrastructure, face particularly rigorous compliance requirements that necessitate advanced coating assessment methodologies.

In the automotive industry, which consumes approximately 20% of global galvanized steel production, manufacturers require precise coating integrity assessment to ensure vehicle components meet stringent quality standards and corrosion resistance specifications. The construction sector, representing the largest consumer of galvanized steel at roughly 40% of global production, demands effective coating evaluation to guarantee structural longevity in buildings and infrastructure projects.

Market research indicates that the global galvanized steel market reached 180 million tons in 2022, with projected annual growth rates of 4-5% through 2028. This expansion directly correlates with increased demand for advanced coating integrity assessment technologies, particularly non-destructive testing methods like SEM analysis that provide detailed microstructural information without compromising sample integrity.

Regional analysis reveals that Asia-Pacific dominates the market for galvanized steel coating assessment technologies, accounting for over 50% of global demand, followed by Europe and North America. This distribution aligns with regional manufacturing hubs and infrastructure development patterns.

Industry surveys highlight that manufacturers are willing to invest in sophisticated coating assessment technologies that reduce quality control costs and minimize product failures. The economic impact of coating failures in galvanized steel products is substantial, with estimates suggesting that inadequate coating integrity assessment contributes to billions in annual replacement and maintenance costs across industries.

The market specifically for SEM-based coating integrity assessment tools has shown remarkable growth, with specialized equipment sales increasing by approximately 8% annually. This trend reflects the technology's ability to provide nanoscale analysis of coating structure, thickness uniformity, and defect identification that conventional testing methods cannot match.

Regulatory factors further drive market demand, as international standards for corrosion protection become increasingly stringent. Industries subject to safety-critical applications, such as energy and transportation infrastructure, face particularly rigorous compliance requirements that necessitate advanced coating assessment methodologies.

Current SEM Analysis Techniques and Limitations

Scanning electron microscopy (SEM) has become an indispensable tool for analyzing galvanized steel coating integrity due to its high-resolution imaging capabilities and versatility. Current SEM analysis techniques for galvanized coatings primarily include secondary electron imaging (SEI), backscattered electron imaging (BSE), energy-dispersive X-ray spectroscopy (EDS), and focused ion beam (FIB) cross-sectioning. Each technique offers distinct advantages for coating evaluation but also presents specific limitations.

Secondary electron imaging provides excellent topographical contrast, enabling detailed surface morphology analysis of zinc coatings. This technique effectively reveals surface defects such as cracks, pinholes, and non-uniform coating distribution. However, SEI is limited to surface features and cannot directly provide information about coating thickness or subsurface integrity without supplementary techniques.

Backscattered electron imaging offers compositional contrast based on atomic number differences, making it valuable for distinguishing between zinc coating and steel substrate. BSE can identify coating discontinuities and variations in coating composition but suffers from lower resolution compared to SEI and limited penetration depth in thicker coatings.

Energy-dispersive X-ray spectroscopy has become standard for elemental analysis of galvanized coatings, providing quantitative data on zinc distribution and detecting contaminants or alloying elements. While powerful, EDS has spatial resolution limitations (typically 1-2 μm) that restrict its ability to characterize nanoscale features in modern thin coatings. Additionally, quantification accuracy can be compromised by sample geometry and matrix effects.

Cross-sectional analysis, often prepared using focused ion beam techniques, enables direct measurement of coating thickness and layer structure. This approach reveals interfacial characteristics between coating and substrate but introduces preparation artifacts that may affect interpretation. The destructive nature of cross-sectioning also limits statistical sampling across large areas.

Environmental SEM (ESEM) has emerged as a valuable technique for analyzing non-conductive or moisture-sensitive galvanized coatings without requiring conductive coating preparation. However, ESEM typically operates at lower vacuum levels, which can reduce image resolution and signal-to-noise ratio compared to conventional high-vacuum SEM.

A significant limitation across all SEM techniques is the challenge of representative sampling. Given the heterogeneous nature of industrial galvanized coatings, analyses performed on small areas (typically μm² to mm²) may not accurately represent the entire component. This sampling limitation necessitates multiple measurements across different regions, increasing analysis time and cost.

Advanced quantitative analysis of coating integrity remains challenging, particularly for automated defect detection and classification. Current image analysis algorithms struggle with distinguishing between actual coating defects and normal microstructural features, often requiring significant human interpretation and validation.

Secondary electron imaging provides excellent topographical contrast, enabling detailed surface morphology analysis of zinc coatings. This technique effectively reveals surface defects such as cracks, pinholes, and non-uniform coating distribution. However, SEI is limited to surface features and cannot directly provide information about coating thickness or subsurface integrity without supplementary techniques.

Backscattered electron imaging offers compositional contrast based on atomic number differences, making it valuable for distinguishing between zinc coating and steel substrate. BSE can identify coating discontinuities and variations in coating composition but suffers from lower resolution compared to SEI and limited penetration depth in thicker coatings.

Energy-dispersive X-ray spectroscopy has become standard for elemental analysis of galvanized coatings, providing quantitative data on zinc distribution and detecting contaminants or alloying elements. While powerful, EDS has spatial resolution limitations (typically 1-2 μm) that restrict its ability to characterize nanoscale features in modern thin coatings. Additionally, quantification accuracy can be compromised by sample geometry and matrix effects.

Cross-sectional analysis, often prepared using focused ion beam techniques, enables direct measurement of coating thickness and layer structure. This approach reveals interfacial characteristics between coating and substrate but introduces preparation artifacts that may affect interpretation. The destructive nature of cross-sectioning also limits statistical sampling across large areas.

Environmental SEM (ESEM) has emerged as a valuable technique for analyzing non-conductive or moisture-sensitive galvanized coatings without requiring conductive coating preparation. However, ESEM typically operates at lower vacuum levels, which can reduce image resolution and signal-to-noise ratio compared to conventional high-vacuum SEM.

A significant limitation across all SEM techniques is the challenge of representative sampling. Given the heterogeneous nature of industrial galvanized coatings, analyses performed on small areas (typically μm² to mm²) may not accurately represent the entire component. This sampling limitation necessitates multiple measurements across different regions, increasing analysis time and cost.

Advanced quantitative analysis of coating integrity remains challenging, particularly for automated defect detection and classification. Current image analysis algorithms struggle with distinguishing between actual coating defects and normal microstructural features, often requiring significant human interpretation and validation.

Established SEM Protocols for Galvanized Steel Evaluation

01 Composition of galvanized coatings for improved integrity

Various compositions can be used to enhance the integrity of galvanized steel coatings. These include specific zinc alloys with elements like aluminum, magnesium, and silicon that improve corrosion resistance and adhesion. The precise formulation of these alloys affects the coating's microstructure, resulting in better protection against environmental factors and mechanical damage.- Composition and structure of galvanized coatings: The integrity of galvanized steel coatings depends significantly on their composition and structure. Various alloying elements can be added to zinc coatings to enhance corrosion resistance and mechanical properties. The microstructure of the coating, including the formation of specific zinc-iron intermetallic phases, plays a crucial role in determining coating durability and performance. Controlling the coating thickness and uniformity during the galvanization process ensures optimal protection against environmental factors.

- Surface treatment and preparation methods: Proper surface preparation before galvanizing significantly impacts coating integrity. This includes cleaning processes to remove contaminants, oxides, and oils from the steel surface. Various pretreatment methods such as acid pickling, fluxing, and mechanical cleaning can be employed to ensure optimal zinc adhesion. Post-treatment processes, including passivation treatments and application of sealants, can further enhance the protective properties of galvanized coatings and extend their service life.

- Corrosion resistance enhancement techniques: Various techniques can be employed to enhance the corrosion resistance of galvanized steel coatings. These include the application of conversion coatings, incorporation of corrosion inhibitors, and development of multi-layer protective systems. Advanced coating formulations may include chromate-free passivation treatments that provide environmental benefits while maintaining high levels of protection. Barrier properties can be improved through the use of polymeric top coats or sealers that prevent moisture and aggressive chemicals from reaching the zinc coating.

- Testing and quality control methods: Ensuring galvanized coating integrity requires comprehensive testing and quality control methods. These include thickness measurements using magnetic gauges or microscopic examination, adhesion tests to evaluate coating bonding strength, and accelerated corrosion tests such as salt spray exposure. Surface appearance evaluations can detect defects like bare spots, roughness, or dross inclusions. Advanced analytical techniques including scanning electron microscopy and X-ray diffraction can be used to characterize coating microstructure and composition for quality assurance.

- Environmental factors and coating durability: The durability of galvanized steel coatings is significantly influenced by environmental exposure conditions. Factors affecting coating integrity include atmospheric pollutants, humidity levels, temperature fluctuations, and exposure to chemicals or marine environments. Specialized coating formulations can be developed for specific environmental challenges, such as high-temperature applications or exposure to acidic conditions. Understanding the relationship between environmental factors and coating degradation mechanisms allows for better prediction of service life and development of more resilient protective systems.

02 Surface treatment methods for coating durability

Surface treatment processes applied before or after galvanization significantly impact coating integrity. These include chemical passivation treatments, chromate conversion coatings, and phosphate treatments that enhance adhesion and corrosion resistance. Post-treatment sealing methods can also be employed to close micropores in the coating, further improving durability and protection against environmental factors.Expand Specific Solutions03 Testing and evaluation methods for coating integrity

Various testing methodologies are used to evaluate galvanized coating integrity, including salt spray tests, electrochemical impedance spectroscopy, adhesion tests, and accelerated weathering tests. These methods help assess the coating's resistance to corrosion, mechanical damage, and environmental stressors, ensuring quality control and predicting service life in different applications and environments.Expand Specific Solutions04 Defect prevention and repair techniques

Techniques for preventing and repairing defects in galvanized coatings include controlled cooling after hot-dip galvanizing, proper handling procedures to minimize mechanical damage, and specialized repair methods for damaged areas. These approaches address common issues like coating discontinuities, thickness variations, and mechanical damage that can compromise coating integrity and lead to premature failure.Expand Specific Solutions05 Advanced coating systems for extreme environments

Advanced multi-layer coating systems combine galvanization with additional protective layers for enhanced performance in extreme environments. These systems may include organic topcoats, conversion layers, or specialized sealants that work synergistically with the zinc layer. Such combinations provide superior protection against aggressive chemicals, high humidity, temperature fluctuations, and mechanical stresses that would compromise standard galvanized coatings.Expand Specific Solutions

Leading Players in Coating Analysis Technology

The galvanized steel coating integrity analysis market is currently in a growth phase, with increasing demand driven by automotive, construction, and infrastructure sectors requiring high-performance corrosion-resistant materials. The global market size for advanced steel coating analysis technologies is estimated at $2.5-3 billion, expanding at 5-7% annually. Technologically, SEM analysis for coating integrity assessment has reached moderate maturity, with leading steel manufacturers like NIPPON STEEL, JFE Steel, and Baoshan Iron & Steel driving innovation alongside analytical equipment providers such as Hitachi High-Tech and Applied Materials. These companies are advancing techniques for nanoscale coating evaluation, with recent developments focusing on automated defect detection and AI-enhanced analysis to improve production efficiency and coating performance prediction.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced SEM-based coating integrity analysis techniques for galvanized steel that combine high-resolution imaging with elemental mapping capabilities. Their approach utilizes backscattered electron (BSE) imaging coupled with Energy Dispersive X-ray Spectroscopy (EDS) to simultaneously visualize coating morphology and analyze chemical composition distribution. The company employs cross-sectional SEM analysis at magnifications ranging from 500x to 5000x to precisely measure coating thickness variations and detect microscopic defects such as pinholes, cracks, and delamination. Their proprietary image processing algorithms automatically quantify coating coverage percentage and identify areas of substrate exposure. Additionally, Nippon Steel has integrated focused ion beam (FIB) technology with SEM to create precise cross-sections for examining the zinc-iron intermetallic layers that form during galvanization, allowing for detailed analysis of diffusion zones critical to coating adhesion and corrosion resistance.

Strengths: Superior resolution and detection capabilities for nanoscale defects; comprehensive quantitative analysis of coating uniformity; integrated multi-modal approach combining imaging and spectroscopy. Weaknesses: Equipment-intensive methodology requiring significant capital investment; analysis process can be time-consuming for large sample sets; requires highly trained operators for optimal results.

Hitachi High-Tech America, Inc.

Technical Solution: Hitachi High-Tech has pioneered an integrated SEM analysis platform specifically optimized for galvanized steel coating evaluation. Their system incorporates variable pressure SEM technology that allows for examination of non-conductive samples without additional preparation, significantly reducing analysis time and potential artifacts. The company's proprietary SU7000 series SEMs feature ultra-high resolution capabilities (1.0 nm at 15 kV) coupled with advanced backscattered electron detectors that provide exceptional compositional contrast between zinc coating and steel substrate. Hitachi's solution includes automated stage control for large-area mapping of coating thickness variations across industrial-scale samples, with their Map 3D software enabling three-dimensional reconstruction of coating topography from multiple SEM images. Their technology also incorporates in-situ tensile testing capabilities within the SEM chamber, allowing researchers to observe coating behavior under mechanical stress in real-time - a critical factor for evaluating coating adhesion and crack resistance during forming operations. The system is further enhanced with AI-powered defect recognition algorithms that can automatically classify and quantify various coating imperfections.

Strengths: Industry-leading resolution capabilities; comprehensive software suite for automated analysis; versatile environmental options allowing examination of samples in various states. Weaknesses: Premium pricing positions system at higher cost point than competitors; complex user interface requires extensive training; some specialized modules require separate licensing.

Key Innovations in Coating Microstructure Characterization

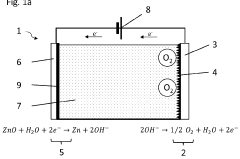

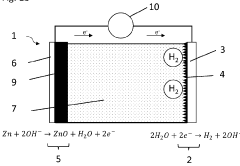

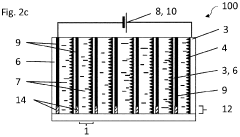

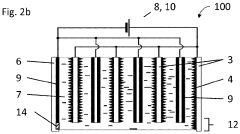

Cell, cell system and method for reversible storage of energy and hydrogen and generation of hydrogen and electricity

PatentWO2024129829A1

Innovation

- A cell system with an alkaline zinc-comprising electrolyte and specific electrode configurations that allow for reversible storage of energy and hydrogen, featuring a compact, adherent zinc layer on the minus electrode, which can be repeatedly deposited and dissolved to generate hydrogen and electricity, using a catalyst-coated plus electrode for efficient gas evolution.

Device having etched feature with shrinkage carryover

PatentInactiveUS7829852B2

Innovation

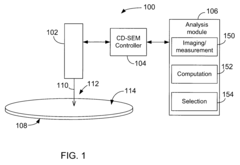

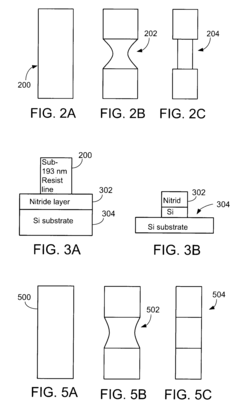

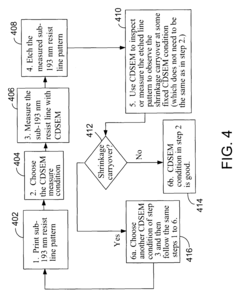

- A technique is developed to characterize and reduce shrinkage carryover by adjusting CD-SEM operating parameters such as beam voltage, probe current, and electron energy dose, and performing multiple measurements under varying conditions to identify optimal settings that minimize shrinkage, ensuring accurate and non-damaging measurements.

Standards and Quality Control Frameworks

The standardization of galvanized steel coating integrity assessment via SEM analysis is governed by several international and industry-specific frameworks. ASTM B117, ISO 9223, and ISO 1461 provide comprehensive guidelines for evaluating corrosion resistance and coating thickness, establishing minimum acceptable thresholds for various industrial applications. These standards define specific parameters for SEM analysis, including magnification ranges, electron beam settings, and sample preparation protocols to ensure consistent and comparable results across different testing facilities.

Quality control frameworks for galvanized steel coating assessment typically implement a multi-tiered approach. The first tier involves routine production line testing using non-destructive methods, while SEM analysis serves as a second-tier verification tool for detailed microstructural examination. ISO/IEC 17025 certification is increasingly becoming mandatory for laboratories conducting these analyses, ensuring adherence to rigorous quality management systems and technical competence in performing SEM-based coating integrity evaluations.

Statistical process control (SPC) methodologies have been integrated into these frameworks to establish control limits and detection thresholds for coating defects. Six Sigma and similar quality management approaches provide structured methodologies for continuous improvement in coating processes, with SEM analysis serving as a critical measurement tool within these systems. The implementation of these statistical frameworks enables manufacturers to maintain consistent coating quality while minimizing variation in production processes.

Industry-specific standards have emerged to address unique requirements in automotive (IATF 16949), construction (EN 10346), and electronics (IPC-4552) sectors. These specialized frameworks incorporate SEM analysis protocols tailored to the particular performance demands and failure modes relevant to each application. For instance, automotive standards emphasize coating adhesion under mechanical stress, while electronics standards focus on solderability and electrical conductivity preservation.

Digital quality management systems are increasingly being integrated with SEM analysis workflows, enabling automated comparison of coating integrity measurements against established standards. These systems facilitate real-time decision-making and trend analysis, allowing manufacturers to detect and address process drift before it results in non-conforming products. Cloud-based platforms further enable centralized storage of SEM data, facilitating benchmarking across multiple production facilities and ensuring consistent application of quality standards throughout global supply chains.

Quality control frameworks for galvanized steel coating assessment typically implement a multi-tiered approach. The first tier involves routine production line testing using non-destructive methods, while SEM analysis serves as a second-tier verification tool for detailed microstructural examination. ISO/IEC 17025 certification is increasingly becoming mandatory for laboratories conducting these analyses, ensuring adherence to rigorous quality management systems and technical competence in performing SEM-based coating integrity evaluations.

Statistical process control (SPC) methodologies have been integrated into these frameworks to establish control limits and detection thresholds for coating defects. Six Sigma and similar quality management approaches provide structured methodologies for continuous improvement in coating processes, with SEM analysis serving as a critical measurement tool within these systems. The implementation of these statistical frameworks enables manufacturers to maintain consistent coating quality while minimizing variation in production processes.

Industry-specific standards have emerged to address unique requirements in automotive (IATF 16949), construction (EN 10346), and electronics (IPC-4552) sectors. These specialized frameworks incorporate SEM analysis protocols tailored to the particular performance demands and failure modes relevant to each application. For instance, automotive standards emphasize coating adhesion under mechanical stress, while electronics standards focus on solderability and electrical conductivity preservation.

Digital quality management systems are increasingly being integrated with SEM analysis workflows, enabling automated comparison of coating integrity measurements against established standards. These systems facilitate real-time decision-making and trend analysis, allowing manufacturers to detect and address process drift before it results in non-conforming products. Cloud-based platforms further enable centralized storage of SEM data, facilitating benchmarking across multiple production facilities and ensuring consistent application of quality standards throughout global supply chains.

Environmental Impact of Coating Technologies

The environmental impact of coating technologies for galvanized steel represents a critical consideration in modern industrial practices. Traditional galvanization processes involve zinc baths at temperatures exceeding 450°C, consuming substantial energy and generating significant carbon emissions. Recent life cycle assessments indicate that conventional hot-dip galvanizing processes produce approximately 2.3 kg of CO2 equivalent per square meter of coated steel, highlighting the environmental burden of these protective treatments.

Advanced coating integrity measurement techniques using Scanning Electron Microscopy (SEM) have enabled more environmentally responsible coating practices by optimizing zinc usage. By precisely analyzing coating thickness, uniformity, and adhesion at the microscopic level, manufacturers can reduce zinc consumption by up to 15% while maintaining equivalent corrosion protection. This optimization directly translates to reduced mining impacts and decreased energy consumption in zinc refining operations.

Water pollution concerns associated with galvanizing processes have prompted stricter regulatory frameworks globally. Coating integrity analysis via SEM helps identify optimal chemical compositions that minimize harmful effluents while maintaining performance standards. Studies demonstrate that properly optimized coatings identified through advanced microscopy can reduce hexavalent chromium and other toxic compounds in wastewater by approximately 30%, significantly decreasing the environmental footprint of treatment facilities.

The emergence of environmentally friendly coating alternatives, such as zinc-aluminum-magnesium alloys, has been facilitated by precise SEM analysis techniques. These advanced coatings provide superior protection with thinner application layers, reducing material consumption by up to 25% compared to conventional zinc coatings. The environmental benefits extend throughout the product lifecycle, with improved durability reducing maintenance requirements and associated environmental impacts.

Waste reduction represents another significant environmental advantage of SEM-guided coating technologies. By identifying optimal process parameters through microscopic analysis, manufacturers can achieve rejection rate reductions of approximately 18%, minimizing material waste and energy consumption. Furthermore, precise coating integrity measurements enable more accurate end-of-life assessments, facilitating improved recycling processes and reducing landfill contributions.

Climate change considerations have increasingly influenced coating technology development, with SEM analysis playing a crucial role in quantifying environmental performance. Recent research indicates that advanced coating systems optimized through microscopic integrity analysis can extend product lifespans by 30-40%, significantly reducing embodied carbon impacts through deferred replacement and manufacturing. This lifecycle extension represents one of the most substantial environmental benefits of precision-engineered coating systems.

Advanced coating integrity measurement techniques using Scanning Electron Microscopy (SEM) have enabled more environmentally responsible coating practices by optimizing zinc usage. By precisely analyzing coating thickness, uniformity, and adhesion at the microscopic level, manufacturers can reduce zinc consumption by up to 15% while maintaining equivalent corrosion protection. This optimization directly translates to reduced mining impacts and decreased energy consumption in zinc refining operations.

Water pollution concerns associated with galvanizing processes have prompted stricter regulatory frameworks globally. Coating integrity analysis via SEM helps identify optimal chemical compositions that minimize harmful effluents while maintaining performance standards. Studies demonstrate that properly optimized coatings identified through advanced microscopy can reduce hexavalent chromium and other toxic compounds in wastewater by approximately 30%, significantly decreasing the environmental footprint of treatment facilities.

The emergence of environmentally friendly coating alternatives, such as zinc-aluminum-magnesium alloys, has been facilitated by precise SEM analysis techniques. These advanced coatings provide superior protection with thinner application layers, reducing material consumption by up to 25% compared to conventional zinc coatings. The environmental benefits extend throughout the product lifecycle, with improved durability reducing maintenance requirements and associated environmental impacts.

Waste reduction represents another significant environmental advantage of SEM-guided coating technologies. By identifying optimal process parameters through microscopic analysis, manufacturers can achieve rejection rate reductions of approximately 18%, minimizing material waste and energy consumption. Furthermore, precise coating integrity measurements enable more accurate end-of-life assessments, facilitating improved recycling processes and reducing landfill contributions.

Climate change considerations have increasingly influenced coating technology development, with SEM analysis playing a crucial role in quantifying environmental performance. Recent research indicates that advanced coating systems optimized through microscopic integrity analysis can extend product lifespans by 30-40%, significantly reducing embodied carbon impacts through deferred replacement and manufacturing. This lifecycle extension represents one of the most substantial environmental benefits of precision-engineered coating systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!