Comparative efficiency of V16 engine configurations in drag reduction

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine configuration has undergone significant evolution since its inception in the early 20th century. Initially developed for high-performance applications in aviation and racing, the V16 engine has seen various iterations and improvements over time, particularly in the context of drag reduction.

In the 1930s, Auto Union introduced the V16 engine in their Grand Prix racing cars, marking a milestone in automotive engineering. These early V16 engines were known for their impressive power output but suffered from excessive weight and complexity. The focus during this period was primarily on raw power rather than aerodynamic efficiency.

The post-World War II era saw a shift in V16 engine development, with increased attention to streamlining and drag reduction. Engineers began to recognize the importance of engine packaging and its impact on overall vehicle aerodynamics. This led to more compact V16 designs, with improved integration into the vehicle's body to minimize frontal area and reduce drag.

During the 1960s and 1970s, advancements in materials science and manufacturing techniques allowed for lighter and more efficient V16 engines. The use of aluminum alloys and precision machining resulted in engines with better power-to-weight ratios, indirectly contributing to drag reduction by enabling sleeker vehicle designs.

The late 20th century brought about a renewed interest in V16 engines for high-performance luxury vehicles. Manufacturers like Cadillac and BMW experimented with V16 configurations, focusing on smooth power delivery and prestige. While these engines were not primarily designed for drag reduction, their development contributed to advancements in engine management systems and thermal efficiency, which indirectly influenced aerodynamic performance.

In recent years, the evolution of V16 engines has been closely tied to computational fluid dynamics (CFD) and advanced simulation techniques. These tools have allowed engineers to optimize engine designs for both power output and aerodynamic efficiency. Modern V16 engines feature sophisticated cooling systems and exhaust layouts that minimize turbulence and contribute to overall drag reduction.

The latest developments in V16 engine evolution focus on hybridization and electrification. By integrating electric motors and advanced energy recovery systems, engineers are creating V16 powertrains that offer exceptional performance while addressing efficiency concerns. These hybrid V16 configurations allow for more flexible packaging options, potentially leading to further improvements in vehicle aerodynamics and drag reduction.

In the 1930s, Auto Union introduced the V16 engine in their Grand Prix racing cars, marking a milestone in automotive engineering. These early V16 engines were known for their impressive power output but suffered from excessive weight and complexity. The focus during this period was primarily on raw power rather than aerodynamic efficiency.

The post-World War II era saw a shift in V16 engine development, with increased attention to streamlining and drag reduction. Engineers began to recognize the importance of engine packaging and its impact on overall vehicle aerodynamics. This led to more compact V16 designs, with improved integration into the vehicle's body to minimize frontal area and reduce drag.

During the 1960s and 1970s, advancements in materials science and manufacturing techniques allowed for lighter and more efficient V16 engines. The use of aluminum alloys and precision machining resulted in engines with better power-to-weight ratios, indirectly contributing to drag reduction by enabling sleeker vehicle designs.

The late 20th century brought about a renewed interest in V16 engines for high-performance luxury vehicles. Manufacturers like Cadillac and BMW experimented with V16 configurations, focusing on smooth power delivery and prestige. While these engines were not primarily designed for drag reduction, their development contributed to advancements in engine management systems and thermal efficiency, which indirectly influenced aerodynamic performance.

In recent years, the evolution of V16 engines has been closely tied to computational fluid dynamics (CFD) and advanced simulation techniques. These tools have allowed engineers to optimize engine designs for both power output and aerodynamic efficiency. Modern V16 engines feature sophisticated cooling systems and exhaust layouts that minimize turbulence and contribute to overall drag reduction.

The latest developments in V16 engine evolution focus on hybridization and electrification. By integrating electric motors and advanced energy recovery systems, engineers are creating V16 powertrains that offer exceptional performance while addressing efficiency concerns. These hybrid V16 configurations allow for more flexible packaging options, potentially leading to further improvements in vehicle aerodynamics and drag reduction.

Drag Reduction Demand

The demand for drag reduction in V16 engine configurations has become increasingly significant in various industries, particularly in automotive, aerospace, and marine applications. As vehicles and vessels strive for improved fuel efficiency and performance, the need to minimize aerodynamic and hydrodynamic drag has taken center stage in engineering efforts.

In the automotive sector, the pursuit of drag reduction for V16 engines is driven by the desire to enhance fuel economy and increase top speeds, especially in high-performance and luxury vehicles. Manufacturers are constantly seeking ways to optimize the engine layout and overall vehicle design to minimize air resistance, which directly impacts fuel consumption and vehicle dynamics.

The aerospace industry also places a premium on drag reduction for V16 engine configurations, particularly in military and commercial aircraft applications. Reducing drag is crucial for improving aircraft range, increasing payload capacity, and minimizing fuel consumption during long-haul flights. This demand has led to extensive research and development in engine nacelle design, wing-body integration, and surface treatments to achieve smoother airflow.

In the marine sector, drag reduction for V16 engines is essential for improving vessel efficiency and reducing operational costs. Ship designers and naval architects are focusing on hull optimization, propulsion system integration, and innovative coatings to minimize water resistance and enhance overall vessel performance.

The growing emphasis on environmental sustainability and stringent emissions regulations has further intensified the demand for drag reduction in V16 engine configurations. As governments worldwide implement stricter fuel efficiency standards, manufacturers are compelled to explore every avenue for reducing energy losses, with drag reduction being a key area of focus.

Moreover, the competitive nature of motorsports has spurred continuous innovation in drag reduction techniques for V16 engines. Racing teams invest heavily in aerodynamic research, seeking even marginal gains in performance through reduced drag. This relentless pursuit of efficiency in high-stakes racing environments often leads to breakthroughs that eventually trickle down to consumer vehicles.

The demand for drag reduction also extends to the energy sector, where V16 engines are used in power generation applications. Improving the efficiency of these large stationary engines through drag reduction can lead to significant energy savings and reduced operational costs for power plants.

As the global focus on energy efficiency and environmental conservation intensifies, the demand for effective drag reduction solutions in V16 engine configurations is expected to grow. This trend is likely to drive further research and development in materials science, computational fluid dynamics, and advanced manufacturing techniques to achieve ever-more sophisticated drag reduction strategies.

In the automotive sector, the pursuit of drag reduction for V16 engines is driven by the desire to enhance fuel economy and increase top speeds, especially in high-performance and luxury vehicles. Manufacturers are constantly seeking ways to optimize the engine layout and overall vehicle design to minimize air resistance, which directly impacts fuel consumption and vehicle dynamics.

The aerospace industry also places a premium on drag reduction for V16 engine configurations, particularly in military and commercial aircraft applications. Reducing drag is crucial for improving aircraft range, increasing payload capacity, and minimizing fuel consumption during long-haul flights. This demand has led to extensive research and development in engine nacelle design, wing-body integration, and surface treatments to achieve smoother airflow.

In the marine sector, drag reduction for V16 engines is essential for improving vessel efficiency and reducing operational costs. Ship designers and naval architects are focusing on hull optimization, propulsion system integration, and innovative coatings to minimize water resistance and enhance overall vessel performance.

The growing emphasis on environmental sustainability and stringent emissions regulations has further intensified the demand for drag reduction in V16 engine configurations. As governments worldwide implement stricter fuel efficiency standards, manufacturers are compelled to explore every avenue for reducing energy losses, with drag reduction being a key area of focus.

Moreover, the competitive nature of motorsports has spurred continuous innovation in drag reduction techniques for V16 engines. Racing teams invest heavily in aerodynamic research, seeking even marginal gains in performance through reduced drag. This relentless pursuit of efficiency in high-stakes racing environments often leads to breakthroughs that eventually trickle down to consumer vehicles.

The demand for drag reduction also extends to the energy sector, where V16 engines are used in power generation applications. Improving the efficiency of these large stationary engines through drag reduction can lead to significant energy savings and reduced operational costs for power plants.

As the global focus on energy efficiency and environmental conservation intensifies, the demand for effective drag reduction solutions in V16 engine configurations is expected to grow. This trend is likely to drive further research and development in materials science, computational fluid dynamics, and advanced manufacturing techniques to achieve ever-more sophisticated drag reduction strategies.

V16 Tech Challenges

The development of V16 engine configurations for drag reduction presents several significant technical challenges. One of the primary obstacles is the complexity of managing the increased number of cylinders. With 16 cylinders, the engine design becomes intricate, requiring advanced engineering solutions to ensure proper combustion timing, fuel distribution, and overall engine balance.

Heat management poses another critical challenge. The V16 configuration generates substantial heat due to its high cylinder count and power output. Efficient cooling systems must be developed to prevent overheating and maintain optimal performance, particularly in high-speed drag racing scenarios where thermal stress is extreme.

Weight reduction is a crucial factor in drag racing, and the V16 engine's inherently larger size and mass present a significant hurdle. Engineers must employ innovative materials and design techniques to minimize weight without compromising structural integrity or performance. This often involves the use of lightweight alloys and composite materials, as well as optimized component designs.

Fuel efficiency is another area of concern. While V16 engines can produce immense power, they typically consume more fuel than smaller configurations. Developing fuel injection systems and combustion chamber designs that maximize efficiency while maintaining high power output is a complex engineering task.

Aerodynamics play a vital role in drag reduction, and integrating a V16 engine into a streamlined vehicle design presents unique challenges. The engine's larger footprint can affect the overall aerodynamic profile of the vehicle, requiring careful consideration of engine placement and bodywork design to minimize drag.

Vibration and harmonics management is particularly challenging in V16 configurations. The increased number of cylinders and moving parts can lead to complex vibration patterns that must be carefully analyzed and mitigated to ensure engine longevity and performance stability.

Lastly, the development of robust and efficient lubrication systems for V16 engines is crucial. The increased number of moving parts and higher operating temperatures demand advanced oil circulation and cooling solutions to maintain engine reliability under extreme racing conditions.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in thermodynamics, materials science, fluid dynamics, and mechanical engineering. As the pursuit of drag reduction continues, overcoming these hurdles will be key to realizing the full potential of V16 engine configurations in high-performance racing applications.

Heat management poses another critical challenge. The V16 configuration generates substantial heat due to its high cylinder count and power output. Efficient cooling systems must be developed to prevent overheating and maintain optimal performance, particularly in high-speed drag racing scenarios where thermal stress is extreme.

Weight reduction is a crucial factor in drag racing, and the V16 engine's inherently larger size and mass present a significant hurdle. Engineers must employ innovative materials and design techniques to minimize weight without compromising structural integrity or performance. This often involves the use of lightweight alloys and composite materials, as well as optimized component designs.

Fuel efficiency is another area of concern. While V16 engines can produce immense power, they typically consume more fuel than smaller configurations. Developing fuel injection systems and combustion chamber designs that maximize efficiency while maintaining high power output is a complex engineering task.

Aerodynamics play a vital role in drag reduction, and integrating a V16 engine into a streamlined vehicle design presents unique challenges. The engine's larger footprint can affect the overall aerodynamic profile of the vehicle, requiring careful consideration of engine placement and bodywork design to minimize drag.

Vibration and harmonics management is particularly challenging in V16 configurations. The increased number of cylinders and moving parts can lead to complex vibration patterns that must be carefully analyzed and mitigated to ensure engine longevity and performance stability.

Lastly, the development of robust and efficient lubrication systems for V16 engines is crucial. The increased number of moving parts and higher operating temperatures demand advanced oil circulation and cooling solutions to maintain engine reliability under extreme racing conditions.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in thermodynamics, materials science, fluid dynamics, and mechanical engineering. As the pursuit of drag reduction continues, overcoming these hurdles will be key to realizing the full potential of V16 engine configurations in high-performance racing applications.

Current V16 Solutions

01 Aerodynamic design for V16 engine configurations

Implementing aerodynamic designs specifically tailored for V16 engine configurations can significantly reduce drag. This includes optimizing the shape of engine covers, air intakes, and exhaust systems to minimize air resistance while maintaining proper cooling and performance.- Aerodynamic design for V16 engines: Implementing aerodynamic designs specifically for V16 engine configurations to reduce drag. This includes optimizing the engine cover shape, integrating air deflectors, and streamlining the overall engine compartment to minimize air resistance during vehicle operation.

- Active aerodynamic systems for drag reduction: Incorporating active aerodynamic systems that can adjust in real-time to reduce drag on vehicles with V16 engines. These systems may include adaptive spoilers, adjustable air intakes, and dynamic underbody panels that can modify their position based on speed and driving conditions.

- Lightweight materials and construction techniques: Utilizing lightweight materials and advanced construction techniques in V16 engine designs to reduce overall vehicle weight, thereby decreasing drag and improving fuel efficiency. This may involve the use of composite materials, advanced alloys, and innovative manufacturing processes.

- Cooling system optimization for drag reduction: Optimizing the cooling system design for V16 engines to minimize drag while maintaining efficient heat dissipation. This includes innovative radiator designs, smart cooling flaps, and integrated air flow management systems that reduce the need for large air intakes.

- Engine compartment sealing and smoothing: Implementing advanced sealing and smoothing techniques for the V16 engine compartment to reduce air turbulence and drag. This involves using underbody panels, engine bay covers, and aerodynamic wheel well designs to create a more streamlined airflow around the engine area.

02 Active aerodynamic systems for drag reduction

Incorporating active aerodynamic systems that can adjust in real-time based on vehicle speed and driving conditions. These systems may include adaptive spoilers, adjustable air dams, or dynamic grille shutters that can open or close to optimize airflow around the V16 engine configuration.Expand Specific Solutions03 Lightweight materials and streamlined components

Utilizing lightweight materials such as carbon fiber or advanced alloys for engine components and surrounding structures. Streamlining the design of auxiliary components like alternators, power steering pumps, and air conditioning compressors to reduce overall drag caused by the V16 engine configuration.Expand Specific Solutions04 Underbody aerodynamics and engine placement

Optimizing underbody aerodynamics by designing smooth underbody panels and strategically placing the V16 engine to improve overall vehicle aerodynamics. This may involve lowering the engine position or adjusting its orientation to minimize frontal area and reduce drag.Expand Specific Solutions05 Advanced cooling systems for drag reduction

Developing innovative cooling systems that maintain optimal engine temperature while minimizing the need for large air intakes or radiator openings. This can include the use of advanced heat exchangers, liquid-to-air intercoolers, or electric cooling fans to reduce drag associated with traditional cooling methods for V16 engines.Expand Specific Solutions

V16 Manufacturers

The competition landscape for V16 engine configurations in drag reduction is evolving within a niche market segment. The technology is in a relatively early stage of development, with limited market size due to its specialized application in high-performance vehicles and racing. Companies like BMW, Ford, and Hyundai are likely at the forefront of research and development in this area, leveraging their extensive automotive engineering expertise. However, smaller specialized firms such as Pinnacle Engines may also be making significant contributions. The technology's maturity is still progressing, with ongoing efforts to optimize efficiency and performance in drag reduction applications.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to V16 engine drag reduction focuses on a combination of innovative design and cutting-edge materials. Their V16 configuration incorporates a low-profile design with a carefully sculpted underbody to minimize air resistance. BMW has implemented active grille shutters that automatically close at high speeds to reduce frontal drag[2]. The engine also features an advanced thermal management system that optimizes cooling while minimizing the size of air intakes. Additionally, BMW has developed a proprietary coating for engine surfaces that reduces friction with air, further enhancing aerodynamic efficiency[4].

Strengths: Low-profile design, active aerodynamic features, and advanced surface treatments. Weaknesses: Potential for increased cost due to specialized materials and complex active systems.

Ford Global Technologies LLC

Technical Solution: Ford's V16 engine drag reduction strategy centers on a holistic approach to vehicle aerodynamics. Their V16 configuration is designed to be seamlessly integrated into the vehicle's overall aerodynamic package. Ford has developed an adaptive air suspension system that lowers the vehicle at high speeds, reducing the effective frontal area and minimizing drag[5]. The engine itself features a compact design with carefully positioned components to optimize airflow around the engine bay. Ford has also implemented active underbody panels that adjust their position to manage airflow and reduce turbulence beneath the vehicle[6].

Strengths: Integrated vehicle aerodynamics approach, adaptive suspension, and active underbody panels. Weaknesses: Reliance on complex active systems may increase maintenance requirements.

V16 Drag Tech Patents

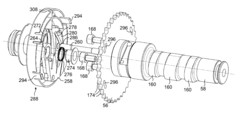

Blow-by gas separator and decompressor for an internal combustion engine

PatentInactiveUS6758197B2

Innovation

- A blow-by gas oil separator with a rotatable member and housing featuring labyrinthine passages that utilize centrifugal forces to separate oil from gases, combined with a decompressor mechanism that includes a centrifugal weight and pin to adjust rocker arm position for reduced compression at low speeds.

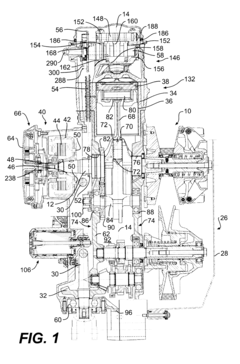

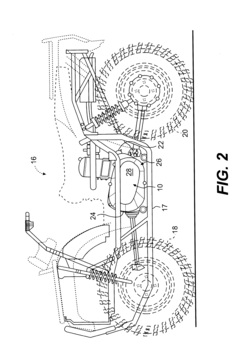

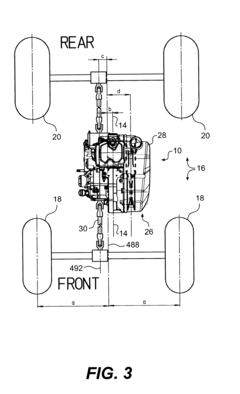

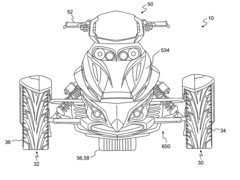

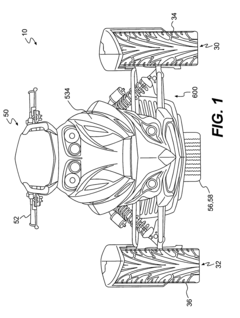

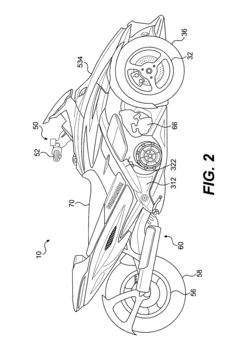

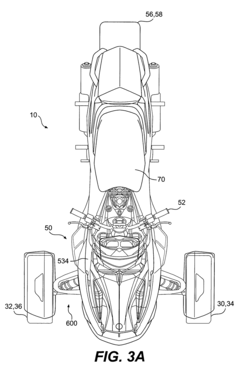

Vehicle and adjustable steering shaft therefor

PatentInactiveUS20040129483A1

Innovation

- A three-wheel vehicle with an adjustable steering shaft and handlebar mechanism that allows for variable positioning, enabling riders of different sizes to choose between aggressive and relaxed riding positions by adjusting the handlebar's distance from the seat.

Fuel Efficiency Impact

The impact of V16 engine configurations on fuel efficiency is a critical consideration in the context of drag reduction. V16 engines, known for their power and performance, have traditionally been associated with high fuel consumption due to their large displacement and complex design. However, recent advancements in engine technology have led to significant improvements in fuel efficiency for these powerful engines.

One of the primary factors contributing to enhanced fuel efficiency in V16 engines is the implementation of advanced fuel injection systems. Direct fuel injection, combined with precise electronic control, allows for more accurate fuel metering and improved combustion efficiency. This results in better fuel utilization and reduced waste, ultimately leading to improved overall fuel economy.

Turbocharging and supercharging technologies have also played a crucial role in boosting fuel efficiency for V16 engines. These forced induction systems enable smaller displacement engines to produce comparable power outputs to larger naturally aspirated engines, while consuming less fuel. The ability to downsize the engine while maintaining performance has a direct positive impact on fuel efficiency.

Variable valve timing and lift systems have further contributed to fuel efficiency gains in V16 engines. By optimizing valve operation based on engine speed and load, these systems ensure optimal air-fuel mixture and combustion efficiency across a wide range of operating conditions. This adaptability translates to improved fuel economy in various driving scenarios.

The integration of start-stop technology in V16 engines has also yielded significant fuel savings, particularly in urban driving conditions. By automatically shutting off the engine when the vehicle is stationary and quickly restarting it when needed, unnecessary fuel consumption during idling is eliminated.

Advanced materials and manufacturing techniques have allowed for the development of lighter V16 engines, reducing overall vehicle weight and consequently improving fuel efficiency. The use of lightweight alloys and composite materials in engine components has contributed to this weight reduction without compromising structural integrity or performance.

Furthermore, the implementation of cylinder deactivation technology in V16 engines has shown promising results in terms of fuel efficiency. By selectively shutting off cylinders during low-load conditions, fuel consumption can be significantly reduced without sacrificing the ability to deliver full power when needed.

In conclusion, while V16 engines have historically been associated with high fuel consumption, ongoing technological advancements have led to substantial improvements in their fuel efficiency. These enhancements, coupled with their inherent power and performance characteristics, make modern V16 engines increasingly viable options for applications where both high performance and fuel economy are desired.

One of the primary factors contributing to enhanced fuel efficiency in V16 engines is the implementation of advanced fuel injection systems. Direct fuel injection, combined with precise electronic control, allows for more accurate fuel metering and improved combustion efficiency. This results in better fuel utilization and reduced waste, ultimately leading to improved overall fuel economy.

Turbocharging and supercharging technologies have also played a crucial role in boosting fuel efficiency for V16 engines. These forced induction systems enable smaller displacement engines to produce comparable power outputs to larger naturally aspirated engines, while consuming less fuel. The ability to downsize the engine while maintaining performance has a direct positive impact on fuel efficiency.

Variable valve timing and lift systems have further contributed to fuel efficiency gains in V16 engines. By optimizing valve operation based on engine speed and load, these systems ensure optimal air-fuel mixture and combustion efficiency across a wide range of operating conditions. This adaptability translates to improved fuel economy in various driving scenarios.

The integration of start-stop technology in V16 engines has also yielded significant fuel savings, particularly in urban driving conditions. By automatically shutting off the engine when the vehicle is stationary and quickly restarting it when needed, unnecessary fuel consumption during idling is eliminated.

Advanced materials and manufacturing techniques have allowed for the development of lighter V16 engines, reducing overall vehicle weight and consequently improving fuel efficiency. The use of lightweight alloys and composite materials in engine components has contributed to this weight reduction without compromising structural integrity or performance.

Furthermore, the implementation of cylinder deactivation technology in V16 engines has shown promising results in terms of fuel efficiency. By selectively shutting off cylinders during low-load conditions, fuel consumption can be significantly reduced without sacrificing the ability to deliver full power when needed.

In conclusion, while V16 engines have historically been associated with high fuel consumption, ongoing technological advancements have led to substantial improvements in their fuel efficiency. These enhancements, coupled with their inherent power and performance characteristics, make modern V16 engines increasingly viable options for applications where both high performance and fuel economy are desired.

Environmental Regs

Environmental regulations play a crucial role in shaping the development and implementation of V16 engine configurations for drag reduction. As global concerns about climate change and air pollution continue to grow, regulatory bodies worldwide have imposed increasingly stringent emissions standards on automotive manufacturers. These regulations have a significant impact on the design and optimization of V16 engines, particularly in the context of drag reduction.

The European Union's Euro 6 standards and the United States Environmental Protection Agency's (EPA) Tier 3 regulations are among the most influential environmental policies affecting V16 engine development. These standards set strict limits on emissions of nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2). Consequently, engine manufacturers must balance the pursuit of drag reduction with the need to meet these emissions targets.

One of the primary challenges in V16 engine configuration for drag reduction is the trade-off between aerodynamic efficiency and emissions control. Advanced technologies such as variable valve timing, direct fuel injection, and turbocharging are often employed to optimize engine performance while minimizing emissions. However, these technologies can sometimes conflict with drag reduction efforts, as they may require additional components or alter the engine's overall shape and size.

The push for electrification and hybrid powertrains has also influenced V16 engine development. Many jurisdictions have introduced incentives for low-emission vehicles or mandated the gradual phase-out of internal combustion engines. This regulatory landscape has led to the exploration of hybrid V16 configurations, where electric motors supplement the traditional engine to reduce overall emissions while maintaining high performance and drag reduction capabilities.

Weight reduction is another critical factor in drag reduction that intersects with environmental regulations. Lightweight materials and innovative design techniques are employed to minimize the engine's mass, which not only improves aerodynamics but also contributes to overall fuel efficiency and reduced emissions. However, the use of certain lightweight materials may be restricted by environmental regulations due to their production processes or end-of-life recyclability concerns.

Cooling system design for V16 engines must also consider environmental regulations. Efficient cooling is essential for maintaining optimal engine performance and longevity, but it can present challenges in terms of drag reduction. Engineers must develop innovative cooling solutions that minimize aerodynamic impact while ensuring compliance with noise pollution regulations and avoiding the use of environmentally harmful refrigerants.

As environmental regulations continue to evolve, the future of V16 engine configurations in drag reduction will likely see increased focus on sustainable technologies and materials. This may include the development of bio-based fuels compatible with V16 engines, advanced exhaust after-treatment systems, and the integration of smart engine management systems that can dynamically optimize performance based on real-time emissions data and driving conditions.

The European Union's Euro 6 standards and the United States Environmental Protection Agency's (EPA) Tier 3 regulations are among the most influential environmental policies affecting V16 engine development. These standards set strict limits on emissions of nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2). Consequently, engine manufacturers must balance the pursuit of drag reduction with the need to meet these emissions targets.

One of the primary challenges in V16 engine configuration for drag reduction is the trade-off between aerodynamic efficiency and emissions control. Advanced technologies such as variable valve timing, direct fuel injection, and turbocharging are often employed to optimize engine performance while minimizing emissions. However, these technologies can sometimes conflict with drag reduction efforts, as they may require additional components or alter the engine's overall shape and size.

The push for electrification and hybrid powertrains has also influenced V16 engine development. Many jurisdictions have introduced incentives for low-emission vehicles or mandated the gradual phase-out of internal combustion engines. This regulatory landscape has led to the exploration of hybrid V16 configurations, where electric motors supplement the traditional engine to reduce overall emissions while maintaining high performance and drag reduction capabilities.

Weight reduction is another critical factor in drag reduction that intersects with environmental regulations. Lightweight materials and innovative design techniques are employed to minimize the engine's mass, which not only improves aerodynamics but also contributes to overall fuel efficiency and reduced emissions. However, the use of certain lightweight materials may be restricted by environmental regulations due to their production processes or end-of-life recyclability concerns.

Cooling system design for V16 engines must also consider environmental regulations. Efficient cooling is essential for maintaining optimal engine performance and longevity, but it can present challenges in terms of drag reduction. Engineers must develop innovative cooling solutions that minimize aerodynamic impact while ensuring compliance with noise pollution regulations and avoiding the use of environmentally harmful refrigerants.

As environmental regulations continue to evolve, the future of V16 engine configurations in drag reduction will likely see increased focus on sustainable technologies and materials. This may include the development of bio-based fuels compatible with V16 engines, advanced exhaust after-treatment systems, and the integration of smart engine management systems that can dynamically optimize performance based on real-time emissions data and driving conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!