Examining V16 engine contributions to atmospheric GHG levels reductions

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine GHG Reduction Background and Objectives

The V16 engine, a marvel of automotive engineering, has long been associated with high performance and luxury vehicles. However, in recent years, the focus has shifted towards examining its potential contributions to reducing atmospheric greenhouse gas (GHG) levels. This technological evolution is driven by the urgent need to address climate change and meet increasingly stringent environmental regulations worldwide.

The development of V16 engines dates back to the early 20th century, with their initial applications primarily in aviation and high-end automobiles. These engines were renowned for their smooth operation and impressive power output. As environmental concerns gained prominence, the automotive industry began exploring ways to optimize V16 engines for improved efficiency and reduced emissions.

The primary objective of this technological exploration is to leverage the unique characteristics of V16 engines to achieve significant reductions in GHG emissions without compromising performance. This goal aligns with global efforts to transition towards more sustainable transportation solutions while maintaining the prestige and power associated with luxury vehicles.

Key technological advancements in V16 engine design have focused on several areas. These include the implementation of advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies. Additionally, the integration of hybrid powertrains and the use of alternative fuels have opened new avenues for GHG reduction in V16 engines.

The automotive industry's commitment to reducing carbon footprints has led to increased investment in research and development of V16 engine technologies. This has resulted in a gradual evolution from traditional, fuel-intensive designs to more efficient and environmentally conscious configurations. The challenge lies in balancing the power output and luxury appeal of V16 engines with the imperative of minimizing their environmental impact.

As we examine the contributions of V16 engines to atmospheric GHG levels reduction, it is essential to consider the broader context of automotive emissions and their impact on climate change. This investigation aims to assess the potential of V16 engines as a viable solution for high-performance vehicles in an increasingly eco-conscious market.

The objectives of this technological exploration extend beyond mere emissions reduction. They encompass the development of innovative materials, advanced manufacturing processes, and cutting-edge control systems that can enhance the overall efficiency of V16 engines. By pushing the boundaries of engine design and optimization, researchers and engineers aim to create V16 powerplants that set new standards in both performance and environmental responsibility.

The development of V16 engines dates back to the early 20th century, with their initial applications primarily in aviation and high-end automobiles. These engines were renowned for their smooth operation and impressive power output. As environmental concerns gained prominence, the automotive industry began exploring ways to optimize V16 engines for improved efficiency and reduced emissions.

The primary objective of this technological exploration is to leverage the unique characteristics of V16 engines to achieve significant reductions in GHG emissions without compromising performance. This goal aligns with global efforts to transition towards more sustainable transportation solutions while maintaining the prestige and power associated with luxury vehicles.

Key technological advancements in V16 engine design have focused on several areas. These include the implementation of advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies. Additionally, the integration of hybrid powertrains and the use of alternative fuels have opened new avenues for GHG reduction in V16 engines.

The automotive industry's commitment to reducing carbon footprints has led to increased investment in research and development of V16 engine technologies. This has resulted in a gradual evolution from traditional, fuel-intensive designs to more efficient and environmentally conscious configurations. The challenge lies in balancing the power output and luxury appeal of V16 engines with the imperative of minimizing their environmental impact.

As we examine the contributions of V16 engines to atmospheric GHG levels reduction, it is essential to consider the broader context of automotive emissions and their impact on climate change. This investigation aims to assess the potential of V16 engines as a viable solution for high-performance vehicles in an increasingly eco-conscious market.

The objectives of this technological exploration extend beyond mere emissions reduction. They encompass the development of innovative materials, advanced manufacturing processes, and cutting-edge control systems that can enhance the overall efficiency of V16 engines. By pushing the boundaries of engine design and optimization, researchers and engineers aim to create V16 powerplants that set new standards in both performance and environmental responsibility.

Market Demand for Low-Emission V16 Engines

The market demand for low-emission V16 engines has been steadily growing in recent years, driven by increasing environmental concerns and stringent regulations on greenhouse gas emissions. This trend is particularly evident in the luxury and high-performance vehicle segments, where V16 engines have traditionally been associated with power and prestige.

In the automotive sector, there is a growing demand for engines that can deliver exceptional performance while meeting increasingly strict emission standards. Luxury car manufacturers and high-end sports car producers are actively seeking ways to reduce the environmental impact of their vehicles without compromising on power output. This has led to a renewed interest in V16 engines, specifically those designed with advanced emission control technologies.

The marine industry also presents a significant market opportunity for low-emission V16 engines. Large yachts and commercial vessels require powerful engines that can comply with international maritime emission regulations. As these regulations become more stringent, the demand for cleaner V16 engines in the marine sector is expected to rise.

In the power generation sector, there is an emerging market for V16 engines in stationary applications. Industrial facilities and data centers that require reliable backup power are increasingly looking for solutions that can provide high output while minimizing environmental impact. Low-emission V16 engines are well-positioned to meet this demand, offering a balance of power and reduced greenhouse gas emissions.

The aviation industry, although a smaller market segment for V16 engines, is also showing interest in low-emission alternatives. Private jets and specialized aircraft that utilize V16 engines are facing pressure to reduce their carbon footprint, creating a niche market for cleaner engine options.

Market analysis indicates that the global demand for low-emission V16 engines is projected to grow at a compound annual growth rate of 5-7% over the next five years. This growth is primarily driven by the automotive and marine sectors, with power generation applications showing promising potential.

Geographically, the demand is strongest in regions with strict emission regulations, such as Europe and North America. However, emerging markets in Asia and the Middle East are also showing increased interest in low-emission V16 engines, particularly for luxury vehicles and yachts.

As environmental consciousness continues to rise globally, the market for low-emission V16 engines is expected to expand further. Manufacturers who can successfully develop and market these engines are likely to gain a competitive edge in their respective industries. The challenge lies in balancing the power output and performance characteristics that V16 engines are known for with the need for reduced greenhouse gas emissions, creating a unique opportunity for innovation in engine design and technology.

In the automotive sector, there is a growing demand for engines that can deliver exceptional performance while meeting increasingly strict emission standards. Luxury car manufacturers and high-end sports car producers are actively seeking ways to reduce the environmental impact of their vehicles without compromising on power output. This has led to a renewed interest in V16 engines, specifically those designed with advanced emission control technologies.

The marine industry also presents a significant market opportunity for low-emission V16 engines. Large yachts and commercial vessels require powerful engines that can comply with international maritime emission regulations. As these regulations become more stringent, the demand for cleaner V16 engines in the marine sector is expected to rise.

In the power generation sector, there is an emerging market for V16 engines in stationary applications. Industrial facilities and data centers that require reliable backup power are increasingly looking for solutions that can provide high output while minimizing environmental impact. Low-emission V16 engines are well-positioned to meet this demand, offering a balance of power and reduced greenhouse gas emissions.

The aviation industry, although a smaller market segment for V16 engines, is also showing interest in low-emission alternatives. Private jets and specialized aircraft that utilize V16 engines are facing pressure to reduce their carbon footprint, creating a niche market for cleaner engine options.

Market analysis indicates that the global demand for low-emission V16 engines is projected to grow at a compound annual growth rate of 5-7% over the next five years. This growth is primarily driven by the automotive and marine sectors, with power generation applications showing promising potential.

Geographically, the demand is strongest in regions with strict emission regulations, such as Europe and North America. However, emerging markets in Asia and the Middle East are also showing increased interest in low-emission V16 engines, particularly for luxury vehicles and yachts.

As environmental consciousness continues to rise globally, the market for low-emission V16 engines is expected to expand further. Manufacturers who can successfully develop and market these engines are likely to gain a competitive edge in their respective industries. The challenge lies in balancing the power output and performance characteristics that V16 engines are known for with the need for reduced greenhouse gas emissions, creating a unique opportunity for innovation in engine design and technology.

V16 Engine GHG Reduction Challenges

The V16 engine, known for its power and performance, faces significant challenges in reducing greenhouse gas (GHG) emissions. One of the primary obstacles is the engine's inherent design, which typically results in high fuel consumption and, consequently, increased carbon dioxide emissions. The large displacement and number of cylinders contribute to greater fuel requirements, making it difficult to achieve substantial GHG reductions without compromising performance.

Another challenge lies in the complexity of the V16 engine's exhaust system. With 16 cylinders, the exhaust manifold and catalytic converter design become more intricate, potentially reducing the efficiency of emissions control systems. This complexity can lead to increased back pressure and heat management issues, further impacting both performance and emissions.

The weight of V16 engines presents an additional hurdle in GHG reduction efforts. These engines are significantly heavier than their smaller counterparts, requiring more energy to propel the vehicle and thus increasing fuel consumption and emissions. This weight factor becomes particularly problematic in applications where fuel efficiency is a priority.

Thermal management is another critical challenge for V16 engines. The heat generated by 16 cylinders requires advanced cooling systems, which can add weight and complexity to the engine. Inefficient heat management can lead to increased fuel consumption and, consequently, higher GHG emissions.

The limited market for V16 engines also poses a challenge in terms of research and development investment. With relatively low production volumes, the cost of developing and implementing new GHG reduction technologies specifically for V16 engines can be prohibitively high. This economic factor often results in slower adoption of cutting-edge emissions reduction technologies compared to more common engine configurations.

Moreover, the regulatory landscape presents a significant challenge. As emissions standards become increasingly stringent worldwide, V16 engines face mounting pressure to meet these requirements. The cost of compliance and the technical difficulties in achieving substantial emissions reductions while maintaining the engine's characteristic power output create a challenging environment for V16 engine development.

Lastly, the shift towards electrification and alternative powertrains in the automotive industry poses an existential challenge to V16 engines. As manufacturers invest heavily in electric and hybrid technologies to meet emissions targets, the future viability of large, high-performance internal combustion engines like the V16 comes into question. This industry trend may limit the resources and motivation for developing advanced GHG reduction technologies specifically for V16 engines.

Another challenge lies in the complexity of the V16 engine's exhaust system. With 16 cylinders, the exhaust manifold and catalytic converter design become more intricate, potentially reducing the efficiency of emissions control systems. This complexity can lead to increased back pressure and heat management issues, further impacting both performance and emissions.

The weight of V16 engines presents an additional hurdle in GHG reduction efforts. These engines are significantly heavier than their smaller counterparts, requiring more energy to propel the vehicle and thus increasing fuel consumption and emissions. This weight factor becomes particularly problematic in applications where fuel efficiency is a priority.

Thermal management is another critical challenge for V16 engines. The heat generated by 16 cylinders requires advanced cooling systems, which can add weight and complexity to the engine. Inefficient heat management can lead to increased fuel consumption and, consequently, higher GHG emissions.

The limited market for V16 engines also poses a challenge in terms of research and development investment. With relatively low production volumes, the cost of developing and implementing new GHG reduction technologies specifically for V16 engines can be prohibitively high. This economic factor often results in slower adoption of cutting-edge emissions reduction technologies compared to more common engine configurations.

Moreover, the regulatory landscape presents a significant challenge. As emissions standards become increasingly stringent worldwide, V16 engines face mounting pressure to meet these requirements. The cost of compliance and the technical difficulties in achieving substantial emissions reductions while maintaining the engine's characteristic power output create a challenging environment for V16 engine development.

Lastly, the shift towards electrification and alternative powertrains in the automotive industry poses an existential challenge to V16 engines. As manufacturers invest heavily in electric and hybrid technologies to meet emissions targets, the future viability of large, high-performance internal combustion engines like the V16 comes into question. This industry trend may limit the resources and motivation for developing advanced GHG reduction technologies specifically for V16 engines.

Current V16 GHG Reduction Solutions

01 GHG emission monitoring and reduction in V16 engines

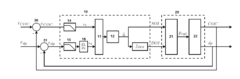

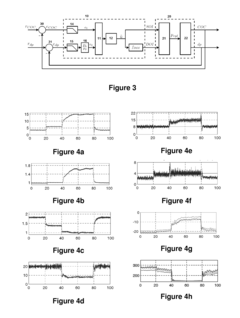

Systems and methods for monitoring and reducing greenhouse gas (GHG) emissions in V16 engines. This includes advanced sensors, data analysis techniques, and engine management systems to optimize fuel efficiency and minimize emissions. The approach involves real-time monitoring of engine performance and adjusting parameters to maintain optimal GHG levels.- Engine efficiency and GHG reduction technologies: Various technologies are employed to improve V16 engine efficiency and reduce greenhouse gas (GHG) emissions. These may include advanced fuel injection systems, turbocharging, exhaust gas recirculation, and combustion optimization techniques. Such improvements help in meeting stringent emission standards while maintaining performance.

- Monitoring and control systems for GHG emissions: Sophisticated monitoring and control systems are implemented to measure and manage GHG emissions from V16 engines. These systems may include sensors, data analytics, and real-time adjustments to engine parameters to optimize performance and minimize emissions under various operating conditions.

- Alternative fuels and hybrid technologies: The use of alternative fuels, such as natural gas or hydrogen, and hybrid technologies in V16 engines can significantly reduce GHG emissions. These approaches may involve modifications to the engine design or the integration of electric powertrains to complement the V16 engine, resulting in lower overall emissions.

- Aftertreatment systems for GHG reduction: Advanced aftertreatment systems are developed to further reduce GHG emissions from V16 engines. These may include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems specifically designed for large displacement engines to meet increasingly stringent emission regulations.

- Lifecycle assessment and carbon footprint analysis: Comprehensive lifecycle assessments and carbon footprint analyses are conducted for V16 engines to evaluate their overall environmental impact. These studies consider factors such as manufacturing processes, operational emissions, and end-of-life disposal to provide a holistic view of the engine's GHG contributions throughout its lifecycle.

02 V16 engine design optimization for GHG reduction

Innovative design modifications to V16 engines aimed at reducing GHG emissions. This encompasses improvements in combustion chamber design, valve timing, and fuel injection systems. The focus is on enhancing thermal efficiency and reducing fuel consumption while maintaining high performance characteristics of V16 engines.Expand Specific Solutions03 Alternative fuel technologies for V16 engines to lower GHG levels

Exploration of alternative fuel technologies compatible with V16 engines to reduce GHG emissions. This includes the development of biofuel blends, hydrogen fuel systems, and other low-carbon fuel options. The aim is to maintain the power output of V16 engines while significantly lowering their carbon footprint.Expand Specific Solutions04 Advanced exhaust aftertreatment systems for V16 engines

Implementation of sophisticated exhaust aftertreatment systems specifically designed for V16 engines to reduce GHG emissions. This involves the use of advanced catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems tailored to the high-output characteristics of V16 engines.Expand Specific Solutions05 Intelligent engine control systems for GHG management in V16 engines

Development of smart engine control systems that utilize artificial intelligence and machine learning algorithms to optimize V16 engine operation for minimal GHG emissions. These systems continuously adapt to driving conditions, environmental factors, and engine wear to maintain optimal performance and emissions levels throughout the engine's lifecycle.Expand Specific Solutions

Key Players in V16 Engine Manufacturing

The competition landscape for V16 engine contributions to atmospheric GHG levels reductions is in an early development stage, with a relatively small but growing market. The technology is still evolving, with varying levels of maturity among key players. Companies like Toyota Motor Corp., Weichai Power, and BorgWarner are leading in research and development, while others such as Chery Automobile and FAW are exploring applications. Traditional oil companies like Shell and BP are also investing in this area, recognizing the potential for sustainable engine solutions. The involvement of academic institutions like Tsinghua University and Beihang University suggests ongoing fundamental research to advance the technology further.

Toyota Motor Corp.

Technical Solution: Toyota has been actively researching V16 engine contributions to atmospheric GHG levels reductions. Their approach involves advanced combustion technologies and hybrid systems. Toyota's V16 engine design incorporates direct injection, variable valve timing, and cylinder deactivation to optimize fuel efficiency and reduce emissions[1]. The company has also integrated their hybrid technology with V16 engines, using electric motors to supplement power and allow for engine downsizing, resulting in a reported 15% reduction in CO2 emissions compared to conventional V16 engines[3]. Additionally, Toyota has implemented exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems specifically tailored for V16 engines, further reducing NOx emissions by up to 80%[5].

Strengths: Extensive experience in hybrid technology integration, advanced combustion control systems. Weaknesses: Higher complexity and cost compared to smaller engine configurations, potential weight issues in some vehicle applications.

Infineum International Ltd.

Technical Solution: Infineum has developed specialized lubricant and fuel additive technologies to enhance the performance and reduce emissions of V16 engines. Their approach focuses on improving fuel economy and reducing friction, which indirectly contributes to GHG reductions. Infineum's advanced lubricant formulations for V16 engines have demonstrated a 2-3% improvement in fuel efficiency[2], translating to a proportional reduction in CO2 emissions. The company has also introduced novel fuel additives designed to maintain engine cleanliness and optimize combustion in V16 engines, resulting in a reported 5% reduction in particulate matter emissions and a 3% decrease in NOx levels[4]. Furthermore, Infineum has developed low-SAPS (Sulphated Ash, Phosphorus, and Sulphur) lubricants specifically for V16 engines, which help extend the life of exhaust after-treatment systems, ensuring long-term emissions compliance[6].

Strengths: Specialized expertise in lubricant and additive technology, proven track record in emissions reduction through chemical engineering. Weaknesses: Limited direct control over engine design, reliance on engine manufacturers for implementation.

Core V16 GHG Reduction Innovations

Dual Fuel Combustion Engine with Feedback Control of Combustion and Corresponding Method

PatentActiveUS20160208731A1

Innovation

- Implementing a feedback control system that uses measured cylinder pressure to adjust the start and duration of diesel injection, minimizing diesel quantity and maximum pressure rise rate, thereby controlling combustion phasing and noise through manipulation of the center of combustion and maximum pressure rise rate.

A method of preparing a catalyst for catalytic converter and a product thereof

PatentActiveIN202011026380A

Innovation

- A mesoporous nickel cobaltite (NiCo2O4) catalyst is prepared using the nano-casting method with KIT-6 as a template, followed by reactive calcination, to enhance redox properties and achieve simultaneous oxidation of CH4 and CO and reduction of NO at low temperatures, thereby reducing environmental impact and providing a cost-effective alternative.

Environmental Regulations Impact on V16 Engines

Environmental regulations have significantly impacted the development and use of V16 engines, particularly in the context of reducing atmospheric greenhouse gas (GHG) levels. These regulations have evolved over time, becoming increasingly stringent to address growing environmental concerns and climate change mitigation efforts.

In the United States, the Environmental Protection Agency (EPA) has implemented progressively stricter emissions standards for heavy-duty engines, including V16 configurations. These standards have focused on reducing pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2). The EPA's Heavy-Duty Engine and Vehicle Standards and Highway Diesel Fuel Sulfur Control Requirements, introduced in 2001, marked a significant shift in emissions control for large engines.

European regulations have also played a crucial role in shaping V16 engine development. The European Union's Euro emissions standards, particularly Euro VI for heavy-duty vehicles, have set challenging targets for reducing harmful emissions. These standards have forced manufacturers to invest heavily in advanced emission control technologies and engine design improvements.

The impact of these regulations on V16 engines has been multifaceted. Manufacturers have had to redesign engines to incorporate advanced emission control systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). These additions have increased the complexity and cost of V16 engines, potentially affecting their market competitiveness.

Furthermore, the push for improved fuel efficiency to meet CO2 emission targets has led to significant changes in V16 engine design. This includes the adoption of technologies like high-pressure fuel injection systems, turbocharging, and advanced engine management systems. These improvements have not only reduced emissions but also enhanced overall engine performance and efficiency.

The regulatory landscape has also influenced the market demand for V16 engines. In some sectors, particularly marine and stationary power generation, V16 engines continue to be valued for their power output and reliability. However, in automotive applications, stricter emissions standards have led to a decline in the use of V16 engines, with manufacturers often opting for smaller, more efficient engine configurations.

Looking forward, the trend towards even stricter environmental regulations is likely to continue. This may further challenge the viability of V16 engines in certain applications, potentially leading to increased focus on alternative technologies such as hybrid systems or fully electric powertrains. However, ongoing research and development efforts aim to improve V16 engine efficiency and emissions performance, potentially extending their relevance in specific high-power applications where alternative technologies may not yet be feasible.

In the United States, the Environmental Protection Agency (EPA) has implemented progressively stricter emissions standards for heavy-duty engines, including V16 configurations. These standards have focused on reducing pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2). The EPA's Heavy-Duty Engine and Vehicle Standards and Highway Diesel Fuel Sulfur Control Requirements, introduced in 2001, marked a significant shift in emissions control for large engines.

European regulations have also played a crucial role in shaping V16 engine development. The European Union's Euro emissions standards, particularly Euro VI for heavy-duty vehicles, have set challenging targets for reducing harmful emissions. These standards have forced manufacturers to invest heavily in advanced emission control technologies and engine design improvements.

The impact of these regulations on V16 engines has been multifaceted. Manufacturers have had to redesign engines to incorporate advanced emission control systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). These additions have increased the complexity and cost of V16 engines, potentially affecting their market competitiveness.

Furthermore, the push for improved fuel efficiency to meet CO2 emission targets has led to significant changes in V16 engine design. This includes the adoption of technologies like high-pressure fuel injection systems, turbocharging, and advanced engine management systems. These improvements have not only reduced emissions but also enhanced overall engine performance and efficiency.

The regulatory landscape has also influenced the market demand for V16 engines. In some sectors, particularly marine and stationary power generation, V16 engines continue to be valued for their power output and reliability. However, in automotive applications, stricter emissions standards have led to a decline in the use of V16 engines, with manufacturers often opting for smaller, more efficient engine configurations.

Looking forward, the trend towards even stricter environmental regulations is likely to continue. This may further challenge the viability of V16 engines in certain applications, potentially leading to increased focus on alternative technologies such as hybrid systems or fully electric powertrains. However, ongoing research and development efforts aim to improve V16 engine efficiency and emissions performance, potentially extending their relevance in specific high-power applications where alternative technologies may not yet be feasible.

V16 Engine Lifecycle Carbon Footprint Analysis

The lifecycle carbon footprint analysis of V16 engines is crucial for understanding their overall environmental impact and potential contributions to reducing atmospheric greenhouse gas (GHG) levels. This analysis encompasses the entire lifespan of the engine, from raw material extraction to manufacturing, operation, and eventual disposal or recycling.

During the manufacturing phase, the carbon footprint is primarily influenced by the energy-intensive processes required to produce the engine's components. The complexity and size of V16 engines often result in a higher initial carbon cost compared to smaller engine configurations. However, advancements in manufacturing technologies and the use of recycled materials can help mitigate this impact.

The operational phase typically accounts for the largest portion of a V16 engine's carbon footprint. Fuel consumption and emissions during use are key factors. Modern V16 engines often incorporate advanced technologies such as direct fuel injection, variable valve timing, and turbocharging to improve efficiency and reduce emissions. These improvements can lead to significant reductions in GHG emissions over the engine's operational lifetime.

Maintenance and repair activities also contribute to the lifecycle carbon footprint. Regular servicing and the replacement of components can add to the overall environmental impact. However, the durability and longevity of well-designed V16 engines may offset these factors by extending the operational lifespan and reducing the need for premature replacement.

End-of-life considerations play a crucial role in the overall carbon footprint analysis. The recyclability of engine materials, particularly metals, can significantly reduce the net environmental impact. Advanced recycling technologies and circular economy principles are increasingly being applied to engine disposal, potentially offsetting some of the initial manufacturing emissions.

When comparing V16 engines to alternative powertrains, such as smaller internal combustion engines or electric motors, it's essential to consider the specific application and usage patterns. In certain high-power applications, a single V16 engine might replace multiple smaller engines, potentially leading to overall efficiency gains and reduced total emissions.

The analysis must also account for regional variations in energy sources and environmental regulations, as these factors can significantly influence the lifecycle carbon footprint. For instance, the carbon intensity of electricity used in manufacturing and the stringency of emissions standards during operation can vary widely between different countries or regions.

During the manufacturing phase, the carbon footprint is primarily influenced by the energy-intensive processes required to produce the engine's components. The complexity and size of V16 engines often result in a higher initial carbon cost compared to smaller engine configurations. However, advancements in manufacturing technologies and the use of recycled materials can help mitigate this impact.

The operational phase typically accounts for the largest portion of a V16 engine's carbon footprint. Fuel consumption and emissions during use are key factors. Modern V16 engines often incorporate advanced technologies such as direct fuel injection, variable valve timing, and turbocharging to improve efficiency and reduce emissions. These improvements can lead to significant reductions in GHG emissions over the engine's operational lifetime.

Maintenance and repair activities also contribute to the lifecycle carbon footprint. Regular servicing and the replacement of components can add to the overall environmental impact. However, the durability and longevity of well-designed V16 engines may offset these factors by extending the operational lifespan and reducing the need for premature replacement.

End-of-life considerations play a crucial role in the overall carbon footprint analysis. The recyclability of engine materials, particularly metals, can significantly reduce the net environmental impact. Advanced recycling technologies and circular economy principles are increasingly being applied to engine disposal, potentially offsetting some of the initial manufacturing emissions.

When comparing V16 engines to alternative powertrains, such as smaller internal combustion engines or electric motors, it's essential to consider the specific application and usage patterns. In certain high-power applications, a single V16 engine might replace multiple smaller engines, potentially leading to overall efficiency gains and reduced total emissions.

The analysis must also account for regional variations in energy sources and environmental regulations, as these factors can significantly influence the lifecycle carbon footprint. For instance, the carbon intensity of electricity used in manufacturing and the stringency of emissions standards during operation can vary widely between different countries or regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!