Integrating AI technologies into V16 engine design and operations

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI in V16 Engine Design: Background and Objectives

The integration of Artificial Intelligence (AI) technologies into V16 engine design and operations represents a significant leap forward in automotive engineering. This technological fusion aims to enhance the performance, efficiency, and reliability of V16 engines, which are known for their power and prestige in high-end vehicles and marine applications.

The V16 engine, with its 16 cylinders arranged in a V configuration, has a rich history dating back to the early 20th century. Initially developed for luxury automobiles and racing cars, V16 engines have since found applications in marine vessels and specialized vehicles. However, their complexity and high fuel consumption have limited widespread adoption.

The evolution of AI technologies, particularly in machine learning and data analytics, has opened new possibilities for optimizing engine design and operation. By leveraging AI, engineers can now analyze vast amounts of data to identify patterns and insights that were previously unattainable through traditional methods.

The primary objective of integrating AI into V16 engine design is to address the inherent challenges associated with these powerful yet complex engines. These challenges include fuel efficiency, emissions reduction, performance optimization, and maintenance predictability. AI-driven solutions aim to strike a balance between the raw power that V16 engines are known for and the increasing demand for environmental sustainability in the automotive industry.

One key area of focus is the use of AI in computational fluid dynamics (CFD) simulations. These simulations can model the intricate airflow and combustion processes within the engine, allowing for rapid iteration and optimization of cylinder design, valve timing, and fuel injection systems. This approach significantly reduces the time and cost associated with physical prototyping and testing.

Another critical objective is the development of AI-powered engine control units (ECUs) that can adapt in real-time to varying driving conditions and user preferences. These intelligent systems can optimize fuel injection, ignition timing, and valve operation on-the-fly, potentially leading to substantial improvements in both performance and efficiency.

Furthermore, the integration of AI technologies aims to enhance the reliability and longevity of V16 engines through predictive maintenance. By continuously monitoring engine parameters and analyzing historical data, AI algorithms can predict potential failures before they occur, allowing for proactive maintenance and reducing downtime.

As we look to the future, the goal is to create V16 engines that not only deliver exceptional power but also meet increasingly stringent environmental regulations. This involves exploring AI-driven solutions for emissions control, alternative fuel compatibility, and even hybrid powertrain integration, pushing the boundaries of what is possible with these iconic engines.

The V16 engine, with its 16 cylinders arranged in a V configuration, has a rich history dating back to the early 20th century. Initially developed for luxury automobiles and racing cars, V16 engines have since found applications in marine vessels and specialized vehicles. However, their complexity and high fuel consumption have limited widespread adoption.

The evolution of AI technologies, particularly in machine learning and data analytics, has opened new possibilities for optimizing engine design and operation. By leveraging AI, engineers can now analyze vast amounts of data to identify patterns and insights that were previously unattainable through traditional methods.

The primary objective of integrating AI into V16 engine design is to address the inherent challenges associated with these powerful yet complex engines. These challenges include fuel efficiency, emissions reduction, performance optimization, and maintenance predictability. AI-driven solutions aim to strike a balance between the raw power that V16 engines are known for and the increasing demand for environmental sustainability in the automotive industry.

One key area of focus is the use of AI in computational fluid dynamics (CFD) simulations. These simulations can model the intricate airflow and combustion processes within the engine, allowing for rapid iteration and optimization of cylinder design, valve timing, and fuel injection systems. This approach significantly reduces the time and cost associated with physical prototyping and testing.

Another critical objective is the development of AI-powered engine control units (ECUs) that can adapt in real-time to varying driving conditions and user preferences. These intelligent systems can optimize fuel injection, ignition timing, and valve operation on-the-fly, potentially leading to substantial improvements in both performance and efficiency.

Furthermore, the integration of AI technologies aims to enhance the reliability and longevity of V16 engines through predictive maintenance. By continuously monitoring engine parameters and analyzing historical data, AI algorithms can predict potential failures before they occur, allowing for proactive maintenance and reducing downtime.

As we look to the future, the goal is to create V16 engines that not only deliver exceptional power but also meet increasingly stringent environmental regulations. This involves exploring AI-driven solutions for emissions control, alternative fuel compatibility, and even hybrid powertrain integration, pushing the boundaries of what is possible with these iconic engines.

Market Analysis for AI-Enhanced V16 Engines

The market for AI-enhanced V16 engines represents a significant opportunity in the automotive and industrial sectors. As traditional V16 engines are known for their power and prestige, integrating AI technologies into their design and operation opens up new avenues for performance optimization, efficiency gains, and advanced functionalities.

The demand for AI-enhanced V16 engines is primarily driven by the luxury automotive market, where high-performance vehicles and supercars continue to push the boundaries of engineering. These engines are also finding applications in specialized industrial equipment, marine propulsion systems, and high-end power generation units. The market size for AI-enhanced V16 engines is expected to grow steadily over the next decade, as manufacturers seek to differentiate their products and meet increasingly stringent environmental regulations.

One of the key market trends is the focus on improving fuel efficiency and reducing emissions without compromising on power output. AI technologies enable real-time engine management, predictive maintenance, and adaptive performance tuning, which are highly valued by both manufacturers and end-users. Additionally, there is a growing demand for engines that can seamlessly integrate with hybrid and electric powertrains, further expanding the potential market for AI-enhanced V16 engines.

The automotive sector remains the largest market segment for these engines, with luxury car manufacturers leading the adoption of AI technologies. However, there is increasing interest from other sectors, including aerospace, marine, and stationary power generation. These industries are attracted by the potential for AI to optimize engine performance under varying operational conditions and to extend engine lifespan through predictive maintenance.

Geographically, North America and Europe are the primary markets for AI-enhanced V16 engines, driven by the presence of major luxury car manufacturers and a strong base of high-net-worth individuals. However, emerging markets in Asia, particularly China and India, are showing rapid growth potential as their luxury automotive sectors expand and industrial applications increase.

The market is characterized by high barriers to entry due to the significant research and development costs associated with integrating AI technologies into complex engine designs. This has led to a concentration of market share among established engine manufacturers and technology companies with strong AI capabilities. Collaborations between traditional engine manufacturers and AI specialists are becoming more common, as companies seek to leverage complementary expertise.

Looking ahead, the market for AI-enhanced V16 engines is expected to evolve with advancements in AI technologies, materials science, and changing regulatory landscapes. The integration of machine learning algorithms for continuous performance optimization and the development of more sophisticated sensor networks are likely to drive future innovations in this space.

The demand for AI-enhanced V16 engines is primarily driven by the luxury automotive market, where high-performance vehicles and supercars continue to push the boundaries of engineering. These engines are also finding applications in specialized industrial equipment, marine propulsion systems, and high-end power generation units. The market size for AI-enhanced V16 engines is expected to grow steadily over the next decade, as manufacturers seek to differentiate their products and meet increasingly stringent environmental regulations.

One of the key market trends is the focus on improving fuel efficiency and reducing emissions without compromising on power output. AI technologies enable real-time engine management, predictive maintenance, and adaptive performance tuning, which are highly valued by both manufacturers and end-users. Additionally, there is a growing demand for engines that can seamlessly integrate with hybrid and electric powertrains, further expanding the potential market for AI-enhanced V16 engines.

The automotive sector remains the largest market segment for these engines, with luxury car manufacturers leading the adoption of AI technologies. However, there is increasing interest from other sectors, including aerospace, marine, and stationary power generation. These industries are attracted by the potential for AI to optimize engine performance under varying operational conditions and to extend engine lifespan through predictive maintenance.

Geographically, North America and Europe are the primary markets for AI-enhanced V16 engines, driven by the presence of major luxury car manufacturers and a strong base of high-net-worth individuals. However, emerging markets in Asia, particularly China and India, are showing rapid growth potential as their luxury automotive sectors expand and industrial applications increase.

The market is characterized by high barriers to entry due to the significant research and development costs associated with integrating AI technologies into complex engine designs. This has led to a concentration of market share among established engine manufacturers and technology companies with strong AI capabilities. Collaborations between traditional engine manufacturers and AI specialists are becoming more common, as companies seek to leverage complementary expertise.

Looking ahead, the market for AI-enhanced V16 engines is expected to evolve with advancements in AI technologies, materials science, and changing regulatory landscapes. The integration of machine learning algorithms for continuous performance optimization and the development of more sophisticated sensor networks are likely to drive future innovations in this space.

Current AI Integration Challenges in V16 Engines

The integration of AI technologies into V16 engine design and operations faces several significant challenges. One of the primary obstacles is the complexity of V16 engines, which require intricate modeling and simulation to accurately represent their performance characteristics. AI algorithms must be capable of processing and analyzing vast amounts of data from multiple sensors and systems within the engine, making real-time decision-making a formidable task.

Data quality and availability pose another major challenge. V16 engines generate enormous volumes of data, but ensuring its consistency, accuracy, and relevance for AI training and implementation is difficult. Legacy systems and outdated data collection methods may not provide the level of detail or frequency required for advanced AI applications, necessitating substantial upgrades to existing infrastructure.

The integration of AI systems with existing engine control units (ECUs) and other electronic systems presents significant technical hurdles. Compatibility issues between AI software and traditional engine management systems can lead to conflicts in control logic and potential safety risks. Developing robust interfaces and protocols for seamless communication between AI and conventional systems is crucial but technically demanding.

Regulatory compliance and safety considerations also present challenges in AI integration. V16 engines are often used in critical applications where reliability and safety are paramount. Ensuring that AI-driven decisions meet stringent regulatory requirements and do not compromise engine safety is a complex undertaking that requires extensive testing and validation.

The lack of standardization in AI technologies for engine applications is another obstacle. Different AI approaches and frameworks may be used by various stakeholders in the engine development process, leading to integration difficulties and potential incompatibilities. Establishing industry-wide standards for AI implementation in engine design and operation is necessary but challenging due to the rapidly evolving nature of AI technologies.

Lastly, the shortage of skilled professionals who possess both deep knowledge of V16 engine dynamics and expertise in AI technologies presents a significant human resource challenge. Training and retaining personnel capable of bridging the gap between traditional engine engineering and cutting-edge AI applications is essential for successful integration but remains a considerable hurdle for many organizations in the industry.

Data quality and availability pose another major challenge. V16 engines generate enormous volumes of data, but ensuring its consistency, accuracy, and relevance for AI training and implementation is difficult. Legacy systems and outdated data collection methods may not provide the level of detail or frequency required for advanced AI applications, necessitating substantial upgrades to existing infrastructure.

The integration of AI systems with existing engine control units (ECUs) and other electronic systems presents significant technical hurdles. Compatibility issues between AI software and traditional engine management systems can lead to conflicts in control logic and potential safety risks. Developing robust interfaces and protocols for seamless communication between AI and conventional systems is crucial but technically demanding.

Regulatory compliance and safety considerations also present challenges in AI integration. V16 engines are often used in critical applications where reliability and safety are paramount. Ensuring that AI-driven decisions meet stringent regulatory requirements and do not compromise engine safety is a complex undertaking that requires extensive testing and validation.

The lack of standardization in AI technologies for engine applications is another obstacle. Different AI approaches and frameworks may be used by various stakeholders in the engine development process, leading to integration difficulties and potential incompatibilities. Establishing industry-wide standards for AI implementation in engine design and operation is necessary but challenging due to the rapidly evolving nature of AI technologies.

Lastly, the shortage of skilled professionals who possess both deep knowledge of V16 engine dynamics and expertise in AI technologies presents a significant human resource challenge. Training and retaining personnel capable of bridging the gap between traditional engine engineering and cutting-edge AI applications is essential for successful integration but remains a considerable hurdle for many organizations in the industry.

Existing AI Solutions for V16 Engine Optimization

01 Design and structure of V16 engines

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V configuration. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-shape design allows for a more compact engine layout compared to inline configurations, while still providing significant power output.- Design and structure of V16 engines: V16 engines are characterized by their unique configuration of 16 cylinders arranged in a V-shape. This design allows for high power output while maintaining a relatively compact size. The engine's structure typically includes advanced cooling systems, specialized crankshafts, and optimized fuel delivery systems to manage the high performance demands.

- Applications of V16 engines: V16 engines find applications in various high-performance vehicles and industrial equipment. They are commonly used in luxury automobiles, marine vessels, locomotives, and stationary power generation units. The high power output and torque make them suitable for demanding applications requiring significant horsepower.

- Control systems for V16 engines: Advanced control systems are crucial for managing the complex operations of V16 engines. These systems often incorporate electronic fuel injection, variable valve timing, and sophisticated engine management units. They optimize performance, fuel efficiency, and emissions control across various operating conditions.

- Cooling and lubrication systems for V16 engines: Efficient cooling and lubrication systems are essential for V16 engines due to their high power output and heat generation. These systems often include advanced oil circulation methods, specialized coolant passages, and high-capacity radiators to maintain optimal operating temperatures and ensure longevity of engine components.

- Sound and vibration management in V16 engines: Managing sound and vibration is crucial in V16 engines to enhance performance and user experience. This involves the use of specialized mufflers, sound-dampening materials, and advanced engine mounts. Additionally, precise balancing of rotating components and optimized firing orders contribute to smoother operation and reduced vibration.

02 Applications of V16 engines

V16 engines find applications in various fields due to their high power output and efficiency. They are commonly used in luxury automobiles, racing cars, large marine vessels, and stationary power generation systems. The versatility of V16 engines makes them suitable for both mobile and stationary applications requiring substantial power.Expand Specific Solutions03 Cooling systems for V16 engines

Efficient cooling systems are crucial for V16 engines due to their high power output and heat generation. These engines often employ advanced cooling technologies, including liquid cooling systems, oil coolers, and specialized radiators. Proper cooling ensures optimal performance and longevity of the engine components.Expand Specific Solutions04 Electronic control systems for V16 engines

Modern V16 engines incorporate sophisticated electronic control systems to optimize performance, fuel efficiency, and emissions. These systems may include advanced engine management units, fuel injection control, ignition timing adjustment, and various sensors to monitor engine parameters in real-time.Expand Specific Solutions05 Aesthetic design of V16 engine components

The visual appearance of V16 engines and their components is often given significant consideration, especially in luxury and high-performance applications. Designers focus on creating aesthetically pleasing engine covers, intake manifolds, and other visible parts to enhance the overall appeal of the vehicle or machinery housing the V16 engine.Expand Specific Solutions

Key Players in AI-Powered Engine Design

The integration of AI technologies into V16 engine design and operations represents a competitive landscape in its early growth stage. The market is expanding rapidly as automotive manufacturers and technology companies recognize the potential for AI to enhance engine performance, efficiency, and reliability. While the technology is still evolving, major players like GM, Volkswagen, and Delphi are investing heavily in research and development. Universities such as Tsinghua and Beihang are contributing to advancements through academic research. The involvement of diverse stakeholders, from traditional automakers to tech giants and startups, indicates a dynamic and increasingly mature ecosystem, with significant potential for innovation and market growth in the coming years.

GM Global Technology Operations LLC

Technical Solution: GM has developed an AI-driven V16 engine design and optimization system. This system utilizes machine learning algorithms to analyze vast amounts of performance data, enabling real-time adjustments to engine parameters. The AI system can predict wear and tear, optimize fuel efficiency, and enhance overall engine performance. GM's approach integrates sensor data from various engine components, using neural networks to process this information and make intelligent decisions about engine operation[1][3]. The system also incorporates predictive maintenance capabilities, reducing downtime and extending engine life[5].

Strengths: Comprehensive data integration, real-time optimization, and predictive maintenance capabilities. Weaknesses: High initial implementation costs and potential over-reliance on AI for critical engine functions.

Volkswagen AG

Technical Solution: Volkswagen has implemented an AI-powered V16 engine management system that focuses on emissions reduction and performance optimization. Their approach uses reinforcement learning algorithms to continuously adapt engine parameters based on driving conditions and environmental factors. The system incorporates a digital twin of the V16 engine, allowing for virtual testing and optimization before real-world implementation[2]. Volkswagen's AI also integrates with the vehicle's navigation system to anticipate road conditions and adjust engine performance accordingly, improving fuel efficiency and reducing emissions[4].

Strengths: Advanced emissions control, adaptive performance optimization, and integration with vehicle systems. Weaknesses: Complexity in implementation across diverse vehicle models and potential regulatory challenges.

Core AI Innovations for V16 Engine Performance

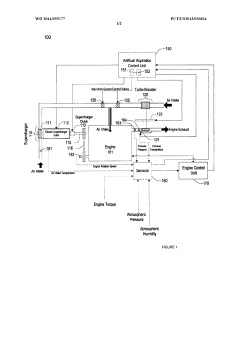

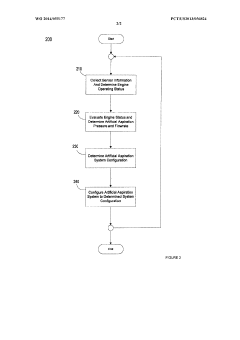

Artificial aspiration methods and systems for increasing engine efficiency

PatentWO2014055177A1

Innovation

- An artificial aspiration system that determines engine operating status and configures itself to optimize engine efficiency by using a hybrid supercharger and turbo booster with control valves, minimizing fuel usage or maximizing power based on real-time conditions.

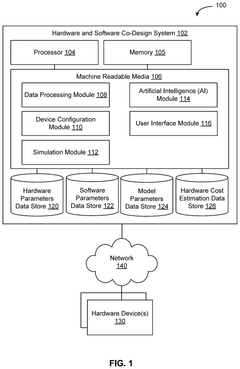

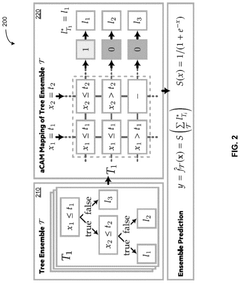

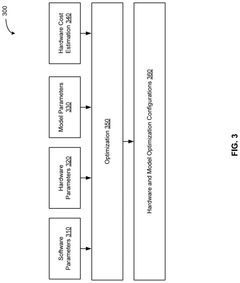

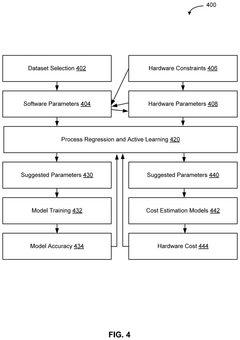

Artificial intelligence (AI) for hardware/software co-design of accelerators and machine learning models

PatentPendingUS20250173604A1

Innovation

- The system employs a hardware and software co-design approach that iteratively determines optimized configurations by co-designing hardware and software elements, using machine learning regression processes with active learning to simulate and evaluate various device configurations, thereby maximizing model accuracy and minimizing hardware costs.

Environmental Impact of AI-Optimized V16 Engines

The integration of AI technologies into V16 engine design and operations has significant implications for environmental impact. AI-optimized V16 engines have the potential to substantially reduce fuel consumption and emissions through more efficient combustion processes and adaptive control systems. Machine learning algorithms can analyze vast amounts of operational data to fine-tune engine parameters in real-time, maximizing performance while minimizing environmental footprint.

One of the key environmental benefits of AI-optimized V16 engines is the reduction in greenhouse gas emissions. By continuously adjusting fuel injection timing, air-fuel ratios, and valve timing based on driving conditions and engine load, AI systems can ensure optimal combustion efficiency. This results in lower CO2 emissions per unit of power output, contributing to overall climate change mitigation efforts.

AI technologies also enable more precise control of exhaust aftertreatment systems, such as selective catalytic reduction (SCR) for NOx reduction and diesel particulate filters (DPF) for particulate matter control. By predicting and adapting to changing operating conditions, AI can optimize the performance of these systems, further reducing harmful emissions and improving air quality.

Furthermore, AI-driven predictive maintenance strategies can extend the lifespan of V16 engines and their components. By detecting potential issues before they escalate, AI systems can prevent catastrophic failures that could lead to environmental contamination from oil leaks or other hazardous materials. This proactive approach not only reduces the environmental impact of engine failures but also minimizes the need for replacement parts, conserving resources and reducing waste.

The application of AI in V16 engine design processes can lead to more environmentally friendly materials and manufacturing techniques. AI algorithms can optimize component designs for lighter weight and improved durability, reducing the overall environmental footprint of engine production. Additionally, AI-powered simulations can accelerate the development of alternative fuel compatibility, potentially facilitating the transition to cleaner energy sources for V16 engines.

However, it is important to consider the potential negative environmental impacts associated with the increased use of AI in engine systems. The energy consumption of AI algorithms and the hardware required to run them must be factored into the overall environmental assessment. Efforts should be made to develop energy-efficient AI solutions and to power the associated computing infrastructure with renewable energy sources to mitigate this concern.

One of the key environmental benefits of AI-optimized V16 engines is the reduction in greenhouse gas emissions. By continuously adjusting fuel injection timing, air-fuel ratios, and valve timing based on driving conditions and engine load, AI systems can ensure optimal combustion efficiency. This results in lower CO2 emissions per unit of power output, contributing to overall climate change mitigation efforts.

AI technologies also enable more precise control of exhaust aftertreatment systems, such as selective catalytic reduction (SCR) for NOx reduction and diesel particulate filters (DPF) for particulate matter control. By predicting and adapting to changing operating conditions, AI can optimize the performance of these systems, further reducing harmful emissions and improving air quality.

Furthermore, AI-driven predictive maintenance strategies can extend the lifespan of V16 engines and their components. By detecting potential issues before they escalate, AI systems can prevent catastrophic failures that could lead to environmental contamination from oil leaks or other hazardous materials. This proactive approach not only reduces the environmental impact of engine failures but also minimizes the need for replacement parts, conserving resources and reducing waste.

The application of AI in V16 engine design processes can lead to more environmentally friendly materials and manufacturing techniques. AI algorithms can optimize component designs for lighter weight and improved durability, reducing the overall environmental footprint of engine production. Additionally, AI-powered simulations can accelerate the development of alternative fuel compatibility, potentially facilitating the transition to cleaner energy sources for V16 engines.

However, it is important to consider the potential negative environmental impacts associated with the increased use of AI in engine systems. The energy consumption of AI algorithms and the hardware required to run them must be factored into the overall environmental assessment. Efforts should be made to develop energy-efficient AI solutions and to power the associated computing infrastructure with renewable energy sources to mitigate this concern.

Cybersecurity in AI-Integrated V16 Engine Systems

The integration of AI technologies into V16 engine design and operations introduces new cybersecurity challenges that must be addressed to ensure the safety and reliability of these advanced systems. As AI becomes more deeply embedded in engine control and optimization processes, the potential attack surface expands, necessitating a comprehensive approach to cybersecurity.

One of the primary concerns is the protection of sensitive data used in AI algorithms. This includes proprietary engine design parameters, operational data, and machine learning models. Unauthorized access to this information could lead to intellectual property theft or enable malicious actors to exploit vulnerabilities in the engine's AI systems. Implementing robust encryption protocols and secure data storage solutions is crucial to mitigate these risks.

Another critical aspect is securing the communication channels between AI components and the engine's various subsystems. As AI-integrated V16 engines rely on real-time data exchange for optimal performance, ensuring the integrity and confidentiality of these communications is paramount. Implementing secure protocols, such as TLS/SSL, and utilizing virtual private networks (VPNs) can help protect against man-in-the-middle attacks and data interception.

The potential for adversarial attacks on AI models used in engine control systems presents a unique challenge. Malicious actors could attempt to manipulate input data or exploit vulnerabilities in machine learning algorithms to cause the engine to behave erratically or inefficiently. Developing robust AI models that are resilient to such attacks and implementing anomaly detection systems to identify unusual patterns in engine behavior are essential countermeasures.

Ensuring the integrity of software updates and patches for AI-integrated engine systems is another crucial consideration. Cybercriminals may attempt to introduce malware or backdoors through compromised update channels. Implementing secure update mechanisms, including digital signatures and verification processes, can help maintain the trustworthiness of the engine's software ecosystem.

As AI systems in V16 engines become more autonomous in decision-making, the need for human oversight and intervention capabilities becomes increasingly important from a cybersecurity perspective. Implementing secure remote access protocols and multi-factor authentication for critical control functions can help prevent unauthorized tampering while maintaining the ability to manually override AI-driven decisions in emergency situations.

Lastly, the interconnected nature of modern vehicles and engine systems introduces risks associated with external connectivity. AI-integrated V16 engines may communicate with cloud-based services or other vehicles, potentially exposing them to network-based attacks. Implementing robust firewalls, intrusion detection systems, and segmentation of critical engine control networks from less secure systems is essential to maintain the overall cybersecurity posture of AI-integrated V16 engine systems.

One of the primary concerns is the protection of sensitive data used in AI algorithms. This includes proprietary engine design parameters, operational data, and machine learning models. Unauthorized access to this information could lead to intellectual property theft or enable malicious actors to exploit vulnerabilities in the engine's AI systems. Implementing robust encryption protocols and secure data storage solutions is crucial to mitigate these risks.

Another critical aspect is securing the communication channels between AI components and the engine's various subsystems. As AI-integrated V16 engines rely on real-time data exchange for optimal performance, ensuring the integrity and confidentiality of these communications is paramount. Implementing secure protocols, such as TLS/SSL, and utilizing virtual private networks (VPNs) can help protect against man-in-the-middle attacks and data interception.

The potential for adversarial attacks on AI models used in engine control systems presents a unique challenge. Malicious actors could attempt to manipulate input data or exploit vulnerabilities in machine learning algorithms to cause the engine to behave erratically or inefficiently. Developing robust AI models that are resilient to such attacks and implementing anomaly detection systems to identify unusual patterns in engine behavior are essential countermeasures.

Ensuring the integrity of software updates and patches for AI-integrated engine systems is another crucial consideration. Cybercriminals may attempt to introduce malware or backdoors through compromised update channels. Implementing secure update mechanisms, including digital signatures and verification processes, can help maintain the trustworthiness of the engine's software ecosystem.

As AI systems in V16 engines become more autonomous in decision-making, the need for human oversight and intervention capabilities becomes increasingly important from a cybersecurity perspective. Implementing secure remote access protocols and multi-factor authentication for critical control functions can help prevent unauthorized tampering while maintaining the ability to manually override AI-driven decisions in emergency situations.

Lastly, the interconnected nature of modern vehicles and engine systems introduces risks associated with external connectivity. AI-integrated V16 engines may communicate with cloud-based services or other vehicles, potentially exposing them to network-based attacks. Implementing robust firewalls, intrusion detection systems, and segmentation of critical engine control networks from less secure systems is essential to maintain the overall cybersecurity posture of AI-integrated V16 engine systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!