Materials science advancements enhancing V16 engine longevity and performance

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance aircraft, the V16 configuration has been a symbol of engineering prowess and automotive excellence. The evolution of this engine type has been closely tied to advancements in materials science, which have played a crucial role in enhancing its longevity and performance.

In the early stages of V16 engine development, cast iron was the primary material used for engine blocks and cylinder heads. While durable, these early engines were heavy and limited in their power output due to material constraints. The introduction of aluminum alloys in the mid-20th century marked a significant milestone in V16 engine evolution. Aluminum's lighter weight and superior heat dissipation properties allowed for higher compression ratios and increased power output while reducing overall engine weight.

The 1960s and 1970s saw further advancements in metallurgy, leading to the development of more robust alloys capable of withstanding higher temperatures and pressures. This enabled V16 engines to achieve greater efficiency and power density. The introduction of nickel-based superalloys, originally developed for aerospace applications, found their way into high-performance V16 engines, particularly in racing applications.

As environmental concerns grew in the late 20th century, the focus shifted towards improving fuel efficiency and reducing emissions. This led to the integration of lightweight composite materials in non-load-bearing components of V16 engines. Carbon fiber reinforced polymers (CFRP) and other advanced composites allowed for further weight reduction without compromising structural integrity.

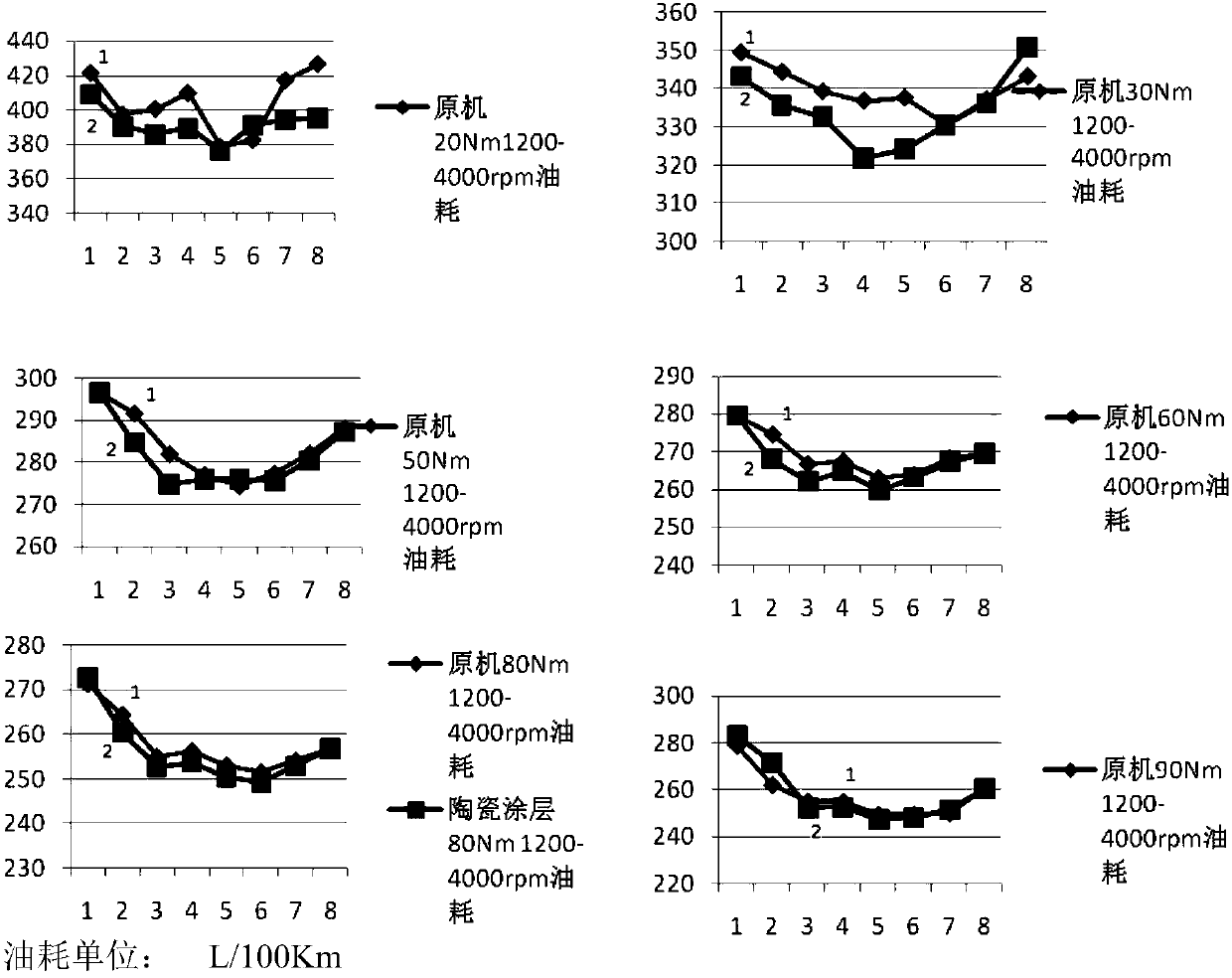

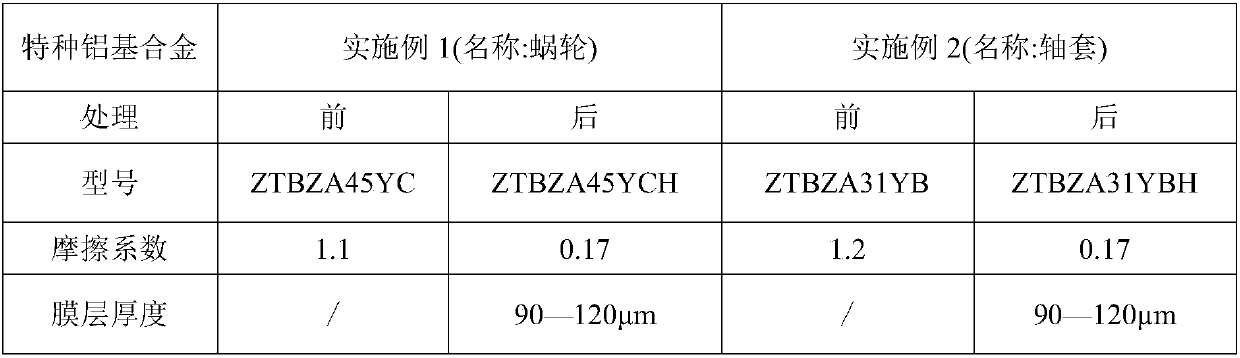

The turn of the 21st century brought about a revolution in surface engineering techniques. Advanced coatings, such as diamond-like carbon (DLC) and ceramic thermal barrier coatings, were applied to critical engine components. These coatings significantly reduced friction, improved wear resistance, and enhanced thermal management, all contributing to increased engine longevity and performance.

Recent years have seen the emergence of additive manufacturing technologies, which have opened new possibilities in V16 engine design and production. 3D printing of complex metal parts has allowed for the creation of optimized internal structures that were previously impossible to manufacture. This has led to improvements in cooling efficiency, weight reduction, and overall engine performance.

The latest frontier in V16 engine evolution involves the integration of smart materials and nanotechnology. Self-healing materials and nanocomposites are being researched for their potential to extend engine life and improve reliability. Additionally, the development of high-temperature superconductors holds promise for future V16 engines, potentially revolutionizing electrical systems and power management within these complex powerplants.

In the early stages of V16 engine development, cast iron was the primary material used for engine blocks and cylinder heads. While durable, these early engines were heavy and limited in their power output due to material constraints. The introduction of aluminum alloys in the mid-20th century marked a significant milestone in V16 engine evolution. Aluminum's lighter weight and superior heat dissipation properties allowed for higher compression ratios and increased power output while reducing overall engine weight.

The 1960s and 1970s saw further advancements in metallurgy, leading to the development of more robust alloys capable of withstanding higher temperatures and pressures. This enabled V16 engines to achieve greater efficiency and power density. The introduction of nickel-based superalloys, originally developed for aerospace applications, found their way into high-performance V16 engines, particularly in racing applications.

As environmental concerns grew in the late 20th century, the focus shifted towards improving fuel efficiency and reducing emissions. This led to the integration of lightweight composite materials in non-load-bearing components of V16 engines. Carbon fiber reinforced polymers (CFRP) and other advanced composites allowed for further weight reduction without compromising structural integrity.

The turn of the 21st century brought about a revolution in surface engineering techniques. Advanced coatings, such as diamond-like carbon (DLC) and ceramic thermal barrier coatings, were applied to critical engine components. These coatings significantly reduced friction, improved wear resistance, and enhanced thermal management, all contributing to increased engine longevity and performance.

Recent years have seen the emergence of additive manufacturing technologies, which have opened new possibilities in V16 engine design and production. 3D printing of complex metal parts has allowed for the creation of optimized internal structures that were previously impossible to manufacture. This has led to improvements in cooling efficiency, weight reduction, and overall engine performance.

The latest frontier in V16 engine evolution involves the integration of smart materials and nanotechnology. Self-healing materials and nanocomposites are being researched for their potential to extend engine life and improve reliability. Additionally, the development of high-temperature superconductors holds promise for future V16 engines, potentially revolutionizing electrical systems and power management within these complex powerplants.

Market Demand Analysis

The market demand for materials science advancements enhancing V16 engine longevity and performance has been steadily growing in recent years. This trend is primarily driven by the luxury automotive and high-performance marine sectors, where V16 engines are predominantly used due to their power output and prestige.

In the automotive industry, ultra-luxury brands such as Bugatti, Cadillac, and Rolls-Royce have shown renewed interest in V16 engines for their flagship models. These manufacturers are constantly seeking ways to improve engine durability and performance to meet the expectations of their discerning clientele. The demand for enhanced V16 engines in this segment is fueled by the desire for exclusivity, superior power-to-weight ratios, and smoother operation.

The marine industry, particularly in the superyacht and high-speed boat markets, represents another significant area of demand for advanced V16 engines. These vessels require powerful, reliable engines that can withstand harsh marine environments while delivering consistent performance over long periods. The ability to extend engine life and improve fuel efficiency through materials science innovations is highly valued in this sector.

Racing and motorsport applications also contribute to the market demand for V16 engine advancements. While not as common as in the past, V16 engines still hold a niche in certain racing categories where maximum power output is crucial. Teams and manufacturers in these fields are constantly seeking materials that can withstand extreme temperatures and pressures while reducing overall engine weight.

The industrial and power generation sectors present an emerging market for enhanced V16 engines. Large-scale generators and heavy machinery often employ V16 configurations, and improvements in longevity and performance can lead to significant cost savings and increased reliability in critical infrastructure applications.

Environmental regulations and the push for sustainability are also shaping the market demand. There is a growing need for materials that can improve fuel efficiency, reduce emissions, and allow for the use of alternative fuels without compromising engine performance or lifespan. This trend is particularly relevant in regions with strict environmental policies.

The global market for high-performance engines, including V16 configurations, is expected to grow as emerging economies develop their luxury goods and industrial sectors. Countries with rapidly expanding wealthy populations, such as China and India, are likely to drive demand for premium vehicles and yachts equipped with advanced V16 engines.

In conclusion, the market demand for materials science advancements in V16 engines is multifaceted, spanning various industries and driven by the need for improved performance, longevity, and efficiency. As technology progresses and new materials are developed, this demand is likely to intensify, creating opportunities for innovation and market growth in the coming years.

In the automotive industry, ultra-luxury brands such as Bugatti, Cadillac, and Rolls-Royce have shown renewed interest in V16 engines for their flagship models. These manufacturers are constantly seeking ways to improve engine durability and performance to meet the expectations of their discerning clientele. The demand for enhanced V16 engines in this segment is fueled by the desire for exclusivity, superior power-to-weight ratios, and smoother operation.

The marine industry, particularly in the superyacht and high-speed boat markets, represents another significant area of demand for advanced V16 engines. These vessels require powerful, reliable engines that can withstand harsh marine environments while delivering consistent performance over long periods. The ability to extend engine life and improve fuel efficiency through materials science innovations is highly valued in this sector.

Racing and motorsport applications also contribute to the market demand for V16 engine advancements. While not as common as in the past, V16 engines still hold a niche in certain racing categories where maximum power output is crucial. Teams and manufacturers in these fields are constantly seeking materials that can withstand extreme temperatures and pressures while reducing overall engine weight.

The industrial and power generation sectors present an emerging market for enhanced V16 engines. Large-scale generators and heavy machinery often employ V16 configurations, and improvements in longevity and performance can lead to significant cost savings and increased reliability in critical infrastructure applications.

Environmental regulations and the push for sustainability are also shaping the market demand. There is a growing need for materials that can improve fuel efficiency, reduce emissions, and allow for the use of alternative fuels without compromising engine performance or lifespan. This trend is particularly relevant in regions with strict environmental policies.

The global market for high-performance engines, including V16 configurations, is expected to grow as emerging economies develop their luxury goods and industrial sectors. Countries with rapidly expanding wealthy populations, such as China and India, are likely to drive demand for premium vehicles and yachts equipped with advanced V16 engines.

In conclusion, the market demand for materials science advancements in V16 engines is multifaceted, spanning various industries and driven by the need for improved performance, longevity, and efficiency. As technology progresses and new materials are developed, this demand is likely to intensify, creating opportunities for innovation and market growth in the coming years.

Current Challenges

The development of V16 engines for enhanced longevity and performance faces several significant challenges in the current landscape of materials science and engineering. One of the primary obstacles is the extreme thermal stress experienced by engine components during operation. The high temperatures generated in V16 engines, particularly in high-performance applications, push traditional materials to their limits, leading to accelerated wear, thermal fatigue, and potential failure.

Another critical challenge lies in the weight reduction of engine components without compromising strength and durability. As the automotive industry strives for improved fuel efficiency and reduced emissions, there is a pressing need to develop lighter yet equally robust materials for V16 engines. This balance between weight reduction and structural integrity poses a significant engineering challenge, especially for large, high-output engines like the V16.

Friction and wear remain persistent issues in V16 engine design. The multiple moving parts in these complex engines experience substantial friction, leading to energy losses and accelerated component degradation. Current lubricant technologies and surface treatments struggle to provide adequate protection under the extreme conditions present in high-performance V16 engines, necessitating frequent maintenance and reducing overall engine longevity.

The environmental impact of V16 engines also presents a considerable challenge. Stricter emissions regulations worldwide demand cleaner-burning engines, which in turn requires advanced materials capable of withstanding higher combustion temperatures and pressures. Developing materials that can maintain their properties under these increasingly demanding conditions while also being environmentally friendly in their production and disposal is a significant hurdle.

Manufacturability and cost-effectiveness of advanced materials for V16 engines pose additional challenges. Many cutting-edge materials with superior properties are often difficult to process or prohibitively expensive for mass production. Bridging the gap between laboratory-developed materials and their practical, cost-effective implementation in engine manufacturing remains a significant obstacle.

Lastly, the integration of new materials into existing engine designs presents compatibility issues. Novel materials may interact differently with traditional components, potentially leading to unforeseen problems in areas such as thermal expansion, chemical reactivity, or electrical conductivity. Ensuring seamless integration of advanced materials into complex V16 engine systems without compromising overall performance or reliability is a multifaceted challenge that requires extensive research and testing.

Another critical challenge lies in the weight reduction of engine components without compromising strength and durability. As the automotive industry strives for improved fuel efficiency and reduced emissions, there is a pressing need to develop lighter yet equally robust materials for V16 engines. This balance between weight reduction and structural integrity poses a significant engineering challenge, especially for large, high-output engines like the V16.

Friction and wear remain persistent issues in V16 engine design. The multiple moving parts in these complex engines experience substantial friction, leading to energy losses and accelerated component degradation. Current lubricant technologies and surface treatments struggle to provide adequate protection under the extreme conditions present in high-performance V16 engines, necessitating frequent maintenance and reducing overall engine longevity.

The environmental impact of V16 engines also presents a considerable challenge. Stricter emissions regulations worldwide demand cleaner-burning engines, which in turn requires advanced materials capable of withstanding higher combustion temperatures and pressures. Developing materials that can maintain their properties under these increasingly demanding conditions while also being environmentally friendly in their production and disposal is a significant hurdle.

Manufacturability and cost-effectiveness of advanced materials for V16 engines pose additional challenges. Many cutting-edge materials with superior properties are often difficult to process or prohibitively expensive for mass production. Bridging the gap between laboratory-developed materials and their practical, cost-effective implementation in engine manufacturing remains a significant obstacle.

Lastly, the integration of new materials into existing engine designs presents compatibility issues. Novel materials may interact differently with traditional components, potentially leading to unforeseen problems in areas such as thermal expansion, chemical reactivity, or electrical conductivity. Ensuring seamless integration of advanced materials into complex V16 engine systems without compromising overall performance or reliability is a multifaceted challenge that requires extensive research and testing.

Existing Solutions

01 Engine performance monitoring and optimization

Advanced monitoring systems can be implemented to track V16 engine performance in real-time. These systems analyze various parameters such as fuel consumption, temperature, and pressure to optimize engine efficiency and longevity. By continuously adjusting operating conditions based on collected data, the engine's performance can be maintained at peak levels while extending its lifespan.- Engine performance optimization: V16 engines can be optimized for improved performance through advanced control systems and algorithms. These systems can monitor and adjust various engine parameters in real-time, such as fuel injection, ignition timing, and valve timing, to maximize power output and efficiency while maintaining longevity.

- Predictive maintenance for engine longevity: Implementing predictive maintenance strategies can significantly enhance the longevity of V16 engines. By utilizing sensors, data analytics, and machine learning algorithms, potential issues can be identified and addressed before they lead to major failures, thus extending the engine's lifespan and maintaining optimal performance.

- Advanced materials and coatings: The use of advanced materials and coatings in V16 engine components can improve both performance and longevity. These materials can include high-strength alloys, ceramic coatings, and nanocomposites that offer better wear resistance, reduced friction, and improved heat management, leading to enhanced engine efficiency and durability.

- Thermal management systems: Effective thermal management is crucial for V16 engine longevity and performance. Advanced cooling systems, heat exchangers, and thermal barrier coatings can help maintain optimal operating temperatures, reduce thermal stress on components, and improve overall engine efficiency and lifespan.

- Lubrication system enhancements: Improving the lubrication system of V16 engines can significantly impact their longevity and performance. Advanced oil formulations, smart oil pumps, and optimized oil circulation pathways can reduce friction, minimize wear, and enhance heat dissipation, contributing to increased engine life and sustained high performance.

02 Predictive maintenance for V16 engines

Implementing predictive maintenance strategies can significantly improve the longevity of V16 engines. By utilizing machine learning algorithms and historical data, potential issues can be identified before they lead to major failures. This proactive approach allows for timely interventions, reducing downtime and extending the engine's operational life.Expand Specific Solutions03 Advanced materials and coatings for engine components

Incorporating advanced materials and coatings in V16 engine components can enhance durability and performance. These innovations can include ceramic coatings for pistons, high-strength alloys for crankshafts, and nano-engineered surfaces for reducing friction. Such materials can withstand higher temperatures and pressures, leading to improved engine efficiency and longevity.Expand Specific Solutions04 Intelligent fuel management systems

Developing intelligent fuel management systems can optimize the performance and efficiency of V16 engines. These systems can dynamically adjust fuel injection parameters based on driving conditions, load, and environmental factors. By ensuring optimal fuel-air mixture and combustion, engine performance is enhanced while reducing wear and extending lifespan.Expand Specific Solutions05 Thermal management and cooling innovations

Implementing advanced thermal management and cooling systems can significantly impact V16 engine longevity and performance. These innovations may include precision-controlled coolant flow, heat recovery systems, and advanced radiator designs. Effective thermal management ensures optimal operating temperatures, reducing thermal stress on engine components and improving overall efficiency and lifespan.Expand Specific Solutions

Key Industry Players

The materials science advancements enhancing V16 engine longevity and performance are in a mature stage of development, with a significant market size driven by the automotive and heavy machinery industries. The technology's maturity is evident from the involvement of established players like Toyota Motor Corp., Honda Motor Co., Ltd., and General Electric Company. These companies, along with specialized firms such as Guangxi Yuchai Machinery Co., Ltd. and MAHLE International GmbH, are actively contributing to innovations in engine materials, focusing on improving durability, efficiency, and performance of high-capacity engines like the V16.

General Electric Company

Technical Solution: General Electric has developed advanced ceramic matrix composites (CMCs) for V16 engine components, particularly in high-temperature applications. These materials offer superior heat resistance and reduced weight compared to traditional metal alloys[1]. GE's CMCs can withstand temperatures up to 2400°F (1316°C), significantly higher than nickel-based superalloys[2]. The company has also implemented additive manufacturing techniques to produce complex geometries in engine parts, enhancing cooling efficiency and reducing overall weight[3]. GE's materials science advancements include the development of novel coatings that provide improved thermal barrier properties and corrosion resistance, extending the lifespan of critical engine components[4].

Strengths: Exceptional high-temperature performance, significant weight reduction, and improved fuel efficiency. Weaknesses: Higher production costs and limited long-term durability data compared to traditional materials.

Toyota Motor Corp.

Technical Solution: Toyota has focused on developing advanced alloys and coatings for V16 engine components to enhance durability and performance. Their research includes the use of plasma-sprayed thermal barrier coatings (TBCs) on piston crowns and cylinder heads, which can reduce heat transfer by up to 50% compared to uncoated parts[5]. Toyota has also pioneered the use of aluminum-silicon alloys with nano-scale dispersoids for pistons, improving wear resistance and thermal stability[6]. Additionally, they have developed a new generation of low-friction coatings for engine bearings, reducing friction losses by up to 30% compared to conventional materials[7].

Strengths: Improved thermal management, enhanced wear resistance, and reduced friction losses. Weaknesses: Potential increase in manufacturing complexity and cost.

Innovative Materials

Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

PatentInactiveCN105951151A

Innovation

- Using nano-graphene ceramic composite coating, through multi-component composite oxidation technology under the action of high voltage, strong current and multi-component composite nano-oxidation liquid, a nano-ceramic coating with physical metallurgical combination is formed to improve surface hardness, wear resistance and reflective heat insulation. Thermal performance, blind holes closed, low friction, high durability.

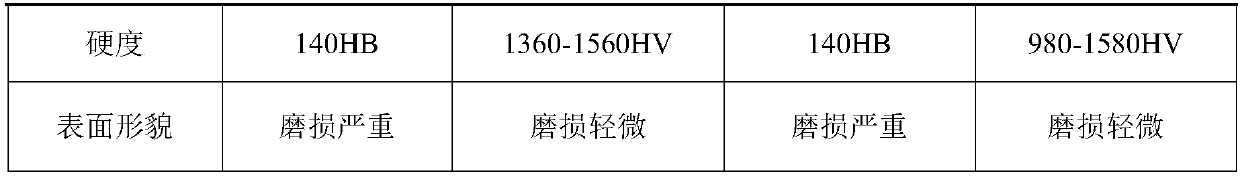

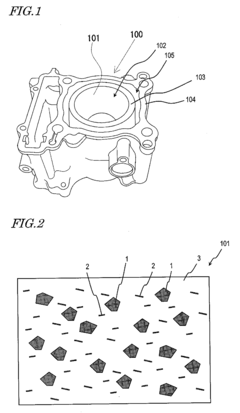

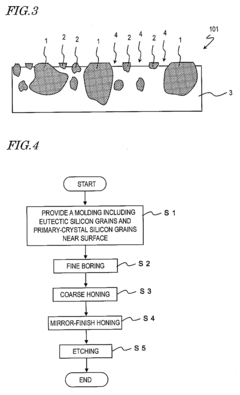

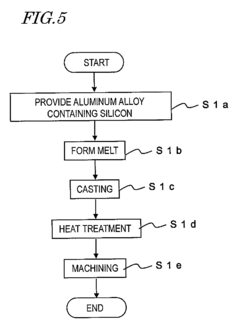

Internal combustion engine component and method for producing the same

PatentActiveUS20090151689A1

Innovation

- An internal combustion engine component with a slide surface featuring a ten point-average roughness RzJIS of 0.54 μm or more and a load length ratio Rmr(30) of 20% or more, utilizing a combination of primary-crystal and eutectic silicon grains with specific size distributions and an aluminum alloy composition, is produced through a polishing and etching process to enhance lubricant retention and abrasion resistance.

Environmental Impact

The advancements in materials science for enhancing V16 engine longevity and performance have significant environmental implications. These improvements contribute to reduced emissions and increased fuel efficiency, aligning with global efforts to mitigate climate change and improve air quality.

One of the primary environmental benefits is the reduction in greenhouse gas emissions. Enhanced engine longevity means fewer replacements over time, reducing the carbon footprint associated with manufacturing new engines. Additionally, improved performance often translates to better fuel economy, resulting in lower CO2 emissions per mile traveled.

The use of advanced materials in V16 engines also contributes to weight reduction. Lighter engines require less energy to operate, further improving fuel efficiency and reducing overall vehicle emissions. This weight reduction can have cascading effects on vehicle design, potentially leading to lighter vehicles that consume less fuel and produce fewer emissions throughout their lifecycle.

Durability improvements in V16 engines extend their operational lifespan, reducing the frequency of engine replacements and repairs. This longevity decreases the demand for raw materials and energy required for manufacturing replacement parts, thereby lowering the environmental impact associated with production and disposal processes.

Advanced materials often enable more efficient combustion processes, resulting in more complete fuel burning and reduced harmful emissions such as nitrogen oxides (NOx) and particulate matter. This improvement in air quality can have significant positive impacts on public health, particularly in urban areas with high traffic density.

The development of heat-resistant materials for V16 engines allows for higher operating temperatures, which can improve thermal efficiency. This increased efficiency translates to better fuel utilization, reducing overall fuel consumption and the associated environmental impacts of fuel extraction, refining, and transportation.

Moreover, the advancements in materials science often lead to the use of more environmentally friendly manufacturing processes and materials. For instance, the adoption of recyclable or biodegradable components can reduce the environmental impact at the end of the engine's life cycle.

However, it is important to consider potential trade-offs. The production of advanced materials may require energy-intensive processes or rare earth elements, which could have their own environmental implications. A comprehensive life cycle assessment is necessary to fully understand the net environmental impact of these material advancements in V16 engines.

One of the primary environmental benefits is the reduction in greenhouse gas emissions. Enhanced engine longevity means fewer replacements over time, reducing the carbon footprint associated with manufacturing new engines. Additionally, improved performance often translates to better fuel economy, resulting in lower CO2 emissions per mile traveled.

The use of advanced materials in V16 engines also contributes to weight reduction. Lighter engines require less energy to operate, further improving fuel efficiency and reducing overall vehicle emissions. This weight reduction can have cascading effects on vehicle design, potentially leading to lighter vehicles that consume less fuel and produce fewer emissions throughout their lifecycle.

Durability improvements in V16 engines extend their operational lifespan, reducing the frequency of engine replacements and repairs. This longevity decreases the demand for raw materials and energy required for manufacturing replacement parts, thereby lowering the environmental impact associated with production and disposal processes.

Advanced materials often enable more efficient combustion processes, resulting in more complete fuel burning and reduced harmful emissions such as nitrogen oxides (NOx) and particulate matter. This improvement in air quality can have significant positive impacts on public health, particularly in urban areas with high traffic density.

The development of heat-resistant materials for V16 engines allows for higher operating temperatures, which can improve thermal efficiency. This increased efficiency translates to better fuel utilization, reducing overall fuel consumption and the associated environmental impacts of fuel extraction, refining, and transportation.

Moreover, the advancements in materials science often lead to the use of more environmentally friendly manufacturing processes and materials. For instance, the adoption of recyclable or biodegradable components can reduce the environmental impact at the end of the engine's life cycle.

However, it is important to consider potential trade-offs. The production of advanced materials may require energy-intensive processes or rare earth elements, which could have their own environmental implications. A comprehensive life cycle assessment is necessary to fully understand the net environmental impact of these material advancements in V16 engines.

Cost-Benefit Analysis

The cost-benefit analysis of materials science advancements for enhancing V16 engine longevity and performance reveals a complex interplay of factors. Initial research and development costs for advanced materials can be substantial, often requiring significant investments in specialized equipment, testing facilities, and highly skilled personnel.

However, these upfront expenses are typically offset by the long-term benefits of improved engine performance and durability. Enhanced materials can lead to reduced fuel consumption, lower maintenance costs, and extended engine life, resulting in substantial savings over the operational lifespan of the engine.

The use of advanced materials, such as ceramic matrix composites or high-temperature alloys, can significantly increase the thermal efficiency of V16 engines. This improvement translates to better fuel economy, potentially saving millions of dollars in fuel costs for large-scale operations like shipping or power generation.

Maintenance costs are another area where the benefits of materials science advancements become apparent. More durable components reduce the frequency of repairs and replacements, leading to decreased downtime and lower overall maintenance expenses. This is particularly crucial for industries where engine reliability is paramount, such as aerospace or marine applications.

The environmental impact of these advancements should also be considered in the cost-benefit analysis. Improved engine efficiency and longevity contribute to reduced emissions and less frequent engine replacements, aligning with increasingly stringent environmental regulations and potentially avoiding costly penalties.

From a competitive standpoint, the adoption of cutting-edge materials can provide a significant market advantage. Engines with superior performance and reliability can command premium prices and capture larger market shares, potentially offsetting the initial development costs through increased sales and brand value.

However, it's important to note that the full benefits of these advancements may take time to materialize. The automotive and engine manufacturing industries often have long development cycles, and the integration of new materials into production can be a gradual process. This time lag should be factored into any cost-benefit calculations.

In conclusion, while the initial costs of materials science advancements for V16 engines can be high, the long-term benefits in terms of performance, efficiency, durability, and environmental impact generally outweigh these expenses. The key to maximizing the return on investment lies in careful planning, strategic implementation, and a long-term perspective on the value these advancements bring to both manufacturers and end-users.

However, these upfront expenses are typically offset by the long-term benefits of improved engine performance and durability. Enhanced materials can lead to reduced fuel consumption, lower maintenance costs, and extended engine life, resulting in substantial savings over the operational lifespan of the engine.

The use of advanced materials, such as ceramic matrix composites or high-temperature alloys, can significantly increase the thermal efficiency of V16 engines. This improvement translates to better fuel economy, potentially saving millions of dollars in fuel costs for large-scale operations like shipping or power generation.

Maintenance costs are another area where the benefits of materials science advancements become apparent. More durable components reduce the frequency of repairs and replacements, leading to decreased downtime and lower overall maintenance expenses. This is particularly crucial for industries where engine reliability is paramount, such as aerospace or marine applications.

The environmental impact of these advancements should also be considered in the cost-benefit analysis. Improved engine efficiency and longevity contribute to reduced emissions and less frequent engine replacements, aligning with increasingly stringent environmental regulations and potentially avoiding costly penalties.

From a competitive standpoint, the adoption of cutting-edge materials can provide a significant market advantage. Engines with superior performance and reliability can command premium prices and capture larger market shares, potentially offsetting the initial development costs through increased sales and brand value.

However, it's important to note that the full benefits of these advancements may take time to materialize. The automotive and engine manufacturing industries often have long development cycles, and the integration of new materials into production can be a gradual process. This time lag should be factored into any cost-benefit calculations.

In conclusion, while the initial costs of materials science advancements for V16 engines can be high, the long-term benefits in terms of performance, efficiency, durability, and environmental impact generally outweigh these expenses. The key to maximizing the return on investment lies in careful planning, strategic implementation, and a long-term perspective on the value these advancements bring to both manufacturers and end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!