The future of V16 engines in an era of electrification and sustainable mobility

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury and high-performance vehicles, V16 engines represented the pinnacle of power and prestige in the automotive world. The first notable V16 engine appeared in the Cadillac V-16 in 1930, setting a new standard for smooth operation and power delivery.

Throughout the mid-20th century, V16 engines found their place in various applications, from luxury automobiles to marine and aviation sectors. The design's ability to produce high power output while maintaining smooth operation made it particularly attractive for these specialized uses. However, the complexity and cost of manufacturing V16 engines limited their widespread adoption in mainstream vehicles.

The 1980s and 1990s saw a resurgence of interest in V16 engines, particularly in the realm of Formula One racing. Teams experimented with V16 configurations to maximize power output within regulatory constraints. This period of innovation led to advancements in engine design, materials, and manufacturing techniques, pushing the boundaries of what was possible with internal combustion engines.

In the luxury automotive sector, the early 2000s witnessed a brief revival of V16 engines. Notable examples include the Cadillac Sixteen concept car in 2003 and the Bugatti Veyron's quad-turbocharged W16 engine, which, while not a true V16, shared many characteristics with the configuration. These modern interpretations of the V16 showcased the engine's potential for extreme performance and exclusivity in the 21st century.

As the automotive industry entered an era of increased focus on fuel efficiency and emissions reduction, the role of V16 engines began to shift. While still revered for their power and smoothness, these engines faced challenges in meeting increasingly stringent environmental regulations. This led to a decline in their development and use in production vehicles, with manufacturers focusing on smaller, more efficient engine configurations.

The advent of hybrid and electric powertrains has further transformed the landscape for high-performance engines. While this shift has reduced the practical applications for V16 engines in road-going vehicles, it has also opened up new possibilities for integrating V16 technology with electrification. Some luxury and hypercar manufacturers have explored the concept of hybrid V16 powertrains, combining the heritage and performance of the V16 with the efficiency and instant torque of electric motors.

Looking towards the future, the evolution of V16 engines is likely to be characterized by niche applications and technological hybridization. While pure internal combustion V16 engines may become increasingly rare, the configuration's legacy of power, smoothness, and prestige continues to inspire engineers and designers in the pursuit of ultimate performance and luxury in the automotive world.

Throughout the mid-20th century, V16 engines found their place in various applications, from luxury automobiles to marine and aviation sectors. The design's ability to produce high power output while maintaining smooth operation made it particularly attractive for these specialized uses. However, the complexity and cost of manufacturing V16 engines limited their widespread adoption in mainstream vehicles.

The 1980s and 1990s saw a resurgence of interest in V16 engines, particularly in the realm of Formula One racing. Teams experimented with V16 configurations to maximize power output within regulatory constraints. This period of innovation led to advancements in engine design, materials, and manufacturing techniques, pushing the boundaries of what was possible with internal combustion engines.

In the luxury automotive sector, the early 2000s witnessed a brief revival of V16 engines. Notable examples include the Cadillac Sixteen concept car in 2003 and the Bugatti Veyron's quad-turbocharged W16 engine, which, while not a true V16, shared many characteristics with the configuration. These modern interpretations of the V16 showcased the engine's potential for extreme performance and exclusivity in the 21st century.

As the automotive industry entered an era of increased focus on fuel efficiency and emissions reduction, the role of V16 engines began to shift. While still revered for their power and smoothness, these engines faced challenges in meeting increasingly stringent environmental regulations. This led to a decline in their development and use in production vehicles, with manufacturers focusing on smaller, more efficient engine configurations.

The advent of hybrid and electric powertrains has further transformed the landscape for high-performance engines. While this shift has reduced the practical applications for V16 engines in road-going vehicles, it has also opened up new possibilities for integrating V16 technology with electrification. Some luxury and hypercar manufacturers have explored the concept of hybrid V16 powertrains, combining the heritage and performance of the V16 with the efficiency and instant torque of electric motors.

Looking towards the future, the evolution of V16 engines is likely to be characterized by niche applications and technological hybridization. While pure internal combustion V16 engines may become increasingly rare, the configuration's legacy of power, smoothness, and prestige continues to inspire engineers and designers in the pursuit of ultimate performance and luxury in the automotive world.

Market Demand Analysis

The market demand for V16 engines has been steadily declining in recent years, primarily due to the global shift towards electrification and sustainable mobility solutions. This trend is driven by increasingly stringent emissions regulations, growing environmental concerns, and the automotive industry's commitment to reducing carbon footprints.

In the luxury and high-performance vehicle segments, where V16 engines have traditionally found their niche, there is a noticeable shift in consumer preferences. Buyers are increasingly prioritizing fuel efficiency, lower emissions, and advanced technology features over raw power and the prestige associated with large displacement engines. This change in consumer behavior has led to a significant reduction in the market size for V16-powered vehicles.

The commercial vehicle sector, another potential market for V16 engines, is also experiencing a transformation. Fleet operators and logistics companies are under pressure to adopt more sustainable transportation solutions, leading to a growing interest in electric and hydrogen-powered trucks and buses. This shift further diminishes the potential market for V16 engines in heavy-duty applications.

Despite the overall decline, there remains a small but dedicated market for V16 engines among collectors, enthusiasts, and ultra-luxury vehicle manufacturers. These niche segments continue to value the unique characteristics of V16 engines, such as their smooth power delivery and distinctive sound. However, this market is not substantial enough to sustain large-scale production or significant research and development investments.

The automotive industry's focus on electrification has led to rapid advancements in electric powertrain technology. Electric vehicles are now capable of delivering performance levels that match or exceed those of traditional high-displacement engines, including V16s. This technological progress has further eroded the market appeal of V16 engines, even among performance enthusiasts.

Looking ahead, the market demand for V16 engines is expected to continue its downward trajectory. The global push for carbon neutrality and the increasing adoption of zero-emission vehicle mandates in key markets will likely accelerate this trend. Automotive manufacturers are reallocating resources from internal combustion engine development to electric and hybrid powertrain technologies, signaling a long-term shift away from large displacement engines like the V16.

In conclusion, while there may still be limited applications and a small collector's market for V16 engines, the overall market demand is shrinking rapidly. The future of automotive propulsion clearly lies in electrification and other sustainable technologies, leaving little room for the continued development and production of V16 engines on a significant scale.

In the luxury and high-performance vehicle segments, where V16 engines have traditionally found their niche, there is a noticeable shift in consumer preferences. Buyers are increasingly prioritizing fuel efficiency, lower emissions, and advanced technology features over raw power and the prestige associated with large displacement engines. This change in consumer behavior has led to a significant reduction in the market size for V16-powered vehicles.

The commercial vehicle sector, another potential market for V16 engines, is also experiencing a transformation. Fleet operators and logistics companies are under pressure to adopt more sustainable transportation solutions, leading to a growing interest in electric and hydrogen-powered trucks and buses. This shift further diminishes the potential market for V16 engines in heavy-duty applications.

Despite the overall decline, there remains a small but dedicated market for V16 engines among collectors, enthusiasts, and ultra-luxury vehicle manufacturers. These niche segments continue to value the unique characteristics of V16 engines, such as their smooth power delivery and distinctive sound. However, this market is not substantial enough to sustain large-scale production or significant research and development investments.

The automotive industry's focus on electrification has led to rapid advancements in electric powertrain technology. Electric vehicles are now capable of delivering performance levels that match or exceed those of traditional high-displacement engines, including V16s. This technological progress has further eroded the market appeal of V16 engines, even among performance enthusiasts.

Looking ahead, the market demand for V16 engines is expected to continue its downward trajectory. The global push for carbon neutrality and the increasing adoption of zero-emission vehicle mandates in key markets will likely accelerate this trend. Automotive manufacturers are reallocating resources from internal combustion engine development to electric and hybrid powertrain technologies, signaling a long-term shift away from large displacement engines like the V16.

In conclusion, while there may still be limited applications and a small collector's market for V16 engines, the overall market demand is shrinking rapidly. The future of automotive propulsion clearly lies in electrification and other sustainable technologies, leaving little room for the continued development and production of V16 engines on a significant scale.

Technical Challenges

The transition towards electrification and sustainable mobility presents significant technical challenges for V16 engines. These large, powerful engines, known for their impressive performance and distinctive sound, face an uncertain future in an increasingly environmentally conscious automotive landscape.

One of the primary challenges is meeting stringent emissions regulations. V16 engines, due to their size and fuel consumption, produce substantial amounts of CO2 and other pollutants. Developing advanced exhaust after-treatment systems and improving combustion efficiency to meet ever-tightening emissions standards is becoming increasingly difficult and costly.

Fuel efficiency is another major hurdle. V16 engines are inherently less fuel-efficient than smaller engines, which conflicts with the global push for reduced fuel consumption and improved miles per gallon ratings. Implementing technologies like cylinder deactivation, variable valve timing, and advanced fuel injection systems can help, but may not be sufficient to meet future efficiency requirements.

The integration of hybrid technology with V16 engines presents both opportunities and challenges. While hybridization can potentially improve fuel efficiency and reduce emissions, it also adds complexity, weight, and cost to an already complex and expensive powertrain. Balancing performance expectations with the added components of a hybrid system requires significant engineering efforts.

Weight reduction is crucial for improving efficiency and performance, but V16 engines are inherently heavy. Developing lightweight materials and redesigning engine components to reduce mass while maintaining strength and durability is a significant technical challenge.

The cost of manufacturing and maintaining V16 engines is another obstacle. As production volumes decrease due to shifting market demands, the per-unit cost increases, making it difficult to justify their continued development and production.

Adapting V16 engines to alternative fuels, such as hydrogen or synthetic fuels, could potentially extend their lifespan. However, this requires substantial research and development to ensure compatibility, performance, and reliability with new fuel types.

The noise, vibration, and harshness (NVH) characteristics of V16 engines, while part of their appeal to enthusiasts, may need to be refined to meet modern comfort standards and noise regulations. Developing advanced sound dampening and engine mount technologies without compromising the engine's character is a delicate balance.

Lastly, the challenge of relevance in an increasingly electrified market cannot be overlooked. As electric powertrains continue to improve in performance and range, justifying the continued development of large combustion engines becomes more difficult from both a market and engineering perspective.

One of the primary challenges is meeting stringent emissions regulations. V16 engines, due to their size and fuel consumption, produce substantial amounts of CO2 and other pollutants. Developing advanced exhaust after-treatment systems and improving combustion efficiency to meet ever-tightening emissions standards is becoming increasingly difficult and costly.

Fuel efficiency is another major hurdle. V16 engines are inherently less fuel-efficient than smaller engines, which conflicts with the global push for reduced fuel consumption and improved miles per gallon ratings. Implementing technologies like cylinder deactivation, variable valve timing, and advanced fuel injection systems can help, but may not be sufficient to meet future efficiency requirements.

The integration of hybrid technology with V16 engines presents both opportunities and challenges. While hybridization can potentially improve fuel efficiency and reduce emissions, it also adds complexity, weight, and cost to an already complex and expensive powertrain. Balancing performance expectations with the added components of a hybrid system requires significant engineering efforts.

Weight reduction is crucial for improving efficiency and performance, but V16 engines are inherently heavy. Developing lightweight materials and redesigning engine components to reduce mass while maintaining strength and durability is a significant technical challenge.

The cost of manufacturing and maintaining V16 engines is another obstacle. As production volumes decrease due to shifting market demands, the per-unit cost increases, making it difficult to justify their continued development and production.

Adapting V16 engines to alternative fuels, such as hydrogen or synthetic fuels, could potentially extend their lifespan. However, this requires substantial research and development to ensure compatibility, performance, and reliability with new fuel types.

The noise, vibration, and harshness (NVH) characteristics of V16 engines, while part of their appeal to enthusiasts, may need to be refined to meet modern comfort standards and noise regulations. Developing advanced sound dampening and engine mount technologies without compromising the engine's character is a delicate balance.

Lastly, the challenge of relevance in an increasingly electrified market cannot be overlooked. As electric powertrains continue to improve in performance and range, justifying the continued development of large combustion engines becomes more difficult from both a market and engineering perspective.

Current V16 Solutions

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V configuration. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-shape design allows for a more compact engine layout compared to inline configurations, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.

- V16 engine applications in vehicles: V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as military tanks and large trucks. These engines provide exceptional power and torque, making them suitable for heavy-duty applications and high-speed performance vehicles.

- V16 engine control systems: Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.

- Historical development of V16 engines: V16 engines have a rich history dating back to the early 20th century. They were initially developed for use in luxury automobiles and racing cars, with various manufacturers experimenting with different designs and configurations. Over time, V16 engines have evolved to incorporate new technologies and materials, improving their performance and reliability.

- V16 engine cooling and lubrication systems: Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems to maintain optimal operating temperatures and prevent wear. These systems may include advanced oil pumps, multiple radiators, and carefully designed coolant passages to ensure efficient heat dissipation and proper lubrication of all moving parts.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as military tanks and large trucks. These engines provide exceptional power and torque, making them suitable for vehicles that require high output and performance capabilities.Expand Specific Solutions03 Historical development of V16 engines

The development of V16 engines dates back to the early 20th century, with various designs and improvements made over time. Early applications included aircraft engines and luxury automobiles. The evolution of V16 engines has led to increased efficiency, power output, and reliability in modern designs.Expand Specific Solutions04 V16 engine performance optimization

Optimizing V16 engine performance involves various techniques such as improving fuel injection systems, enhancing combustion efficiency, and implementing advanced engine management systems. These optimizations aim to increase power output, reduce fuel consumption, and minimize emissions while maintaining reliability.Expand Specific Solutions05 V16 engine manufacturing and assembly

The manufacturing and assembly of V16 engines require specialized processes and equipment due to their complexity and size. This includes precision machining of engine components, advanced assembly techniques, and rigorous quality control measures to ensure optimal performance and reliability of the finished engine.Expand Specific Solutions

Key Industry Players

The future of V16 engines faces significant challenges in the era of electrification and sustainable mobility. The market for these high-performance engines is shrinking as automakers shift towards more fuel-efficient and environmentally friendly powertrains. Major players like GM, Toyota, BMW, and Hyundai are investing heavily in electric and hybrid technologies, signaling a transition away from large displacement engines. However, niche markets may persist for luxury and high-performance vehicles. Companies such as Ballard Power Systems and BRUSA Elektronik are developing fuel cell and electric powertrain technologies, which are likely to play a more prominent role in the future automotive landscape. The overall trend indicates a decline in V16 engine development and production as the industry moves towards electrification and sustainable mobility solutions.

GM Global Technology Operations LLC

Technical Solution: GM is addressing the future of V16 engines through a multi-faceted approach to electrification and sustainability. The company is developing a scalable hybrid powertrain platform that can incorporate V16 engines for specialized high-performance and heavy-duty applications[10]. This system utilizes advanced power electronics and battery technology to supplement the V16 engine's output and improve overall efficiency. GM is also investing in variable compression ratio technology for V16 engines, allowing for optimal performance across a wide range of operating conditions[11]. Furthermore, the company is exploring the use of hydrogen fuel cell technology in conjunction with V16 engines for long-haul trucking and marine applications[12].

Strengths: Versatile powertrain platform, potential for use in multiple vehicle segments, explores alternative fuel technologies. Weaknesses: High development and production costs, limited consumer demand for V16 engines, potential conflicts with stricter emission standards.

Toyota Motor Corp.

Technical Solution: Toyota is adapting its V16 engine technology for the era of electrification and sustainable mobility. The company is developing a hybrid V16 powertrain that combines a downsized V16 engine with electric motors[1]. This system utilizes advanced fuel injection and combustion technologies to improve efficiency while maintaining high performance. Toyota is also exploring the use of sustainable fuels, such as hydrogen and synthetic fuels, in V16 engines to reduce carbon emissions[2]. Additionally, the company is investing in lightweight materials and aerodynamic designs to enhance the overall efficiency of vehicles equipped with V16 engines[3].

Strengths: Combines high performance with improved efficiency, leverages existing V16 expertise, potential for use with sustainable fuels. Weaknesses: Still relies on fossil fuels, may face regulatory challenges in some markets, higher complexity compared to fully electric powertrains.

V16 Innovations

An inductive coupling based electric vehicle charging system

PatentPendingIN202211035067A

Innovation

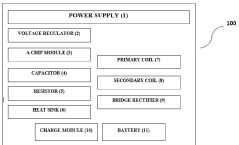

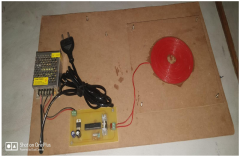

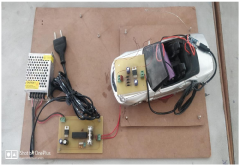

- An inductive coupling based electric vehicle charging system that uses a switching power supply, voltage regulator, chip module, capacitors, resistors, heat sink, primary and secondary coils, bridge rectifier, and battery to transfer power wirelessly through magnetic fields, eliminating the need for physical contact and wires.

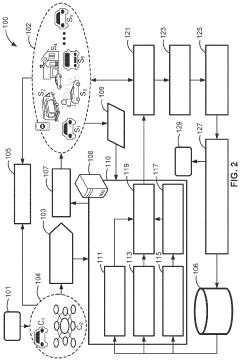

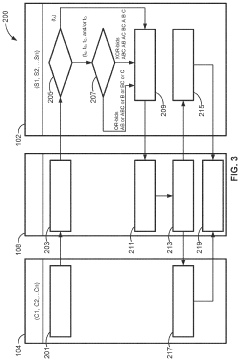

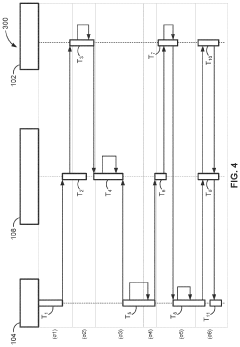

Intelligent charging systems and control logic for crowdsourced vehicle energy transfer

PatentActiveUS11827117B2

Innovation

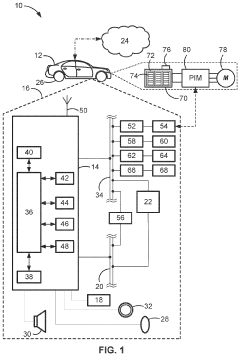

- The implementation of intelligent charging systems with agent-mediated, market-based approaches for vehicle-to-vehicle (V2V) and vehicle-to-grid (V2G) energy transfer, utilizing a middleware node to facilitate energy requests, bid selection, and task allocation among registered service providers, enabling optimized energy distribution and storage within a geo-fenced region.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, posing significant challenges for high-performance engines like the V16. These regulations aim to reduce greenhouse gas emissions and improve air quality, particularly in urban areas. The European Union, for instance, has set ambitious targets to reduce CO2 emissions from new cars by 37.5% by 2030 compared to 2021 levels.

In the United States, the Corporate Average Fuel Economy (CAFE) standards require automakers to achieve an average fuel economy of 54.5 miles per gallon for their fleet by 2025. These regulations have forced manufacturers to prioritize fuel efficiency and emissions reduction in their engine designs, putting pressure on large displacement engines such as the V16.

China, the world's largest automotive market, has also implemented strict emissions standards. The China 6 standard, introduced in 2019, is comparable to Euro 6 regulations and imposes tight limits on pollutants such as nitrogen oxides and particulate matter. This has led to a shift towards smaller, more efficient engines and alternative powertrains in the Chinese market.

The impact of these regulations on V16 engines has been substantial. Manufacturers have been forced to implement advanced technologies to meet emissions targets, including direct injection, variable valve timing, and turbocharging. However, these measures often come at the cost of increased complexity and reduced performance characteristics that are traditionally associated with V16 engines.

Furthermore, many countries have announced plans to phase out internal combustion engines entirely in the coming decades. The United Kingdom, for example, has set a target to ban the sale of new petrol and diesel cars by 2030. Similar initiatives are being considered or implemented in other European countries, as well as in parts of the United States and Asia.

These regulatory pressures have led to a significant decline in the development and production of V16 engines. Luxury and high-performance car manufacturers, who were once the primary users of V16 engines, are now focusing on smaller displacement engines, hybrid powertrains, and fully electric vehicles to comply with emissions regulations while still delivering high performance.

The future of V16 engines in this regulatory environment appears challenging. While there may still be niche applications for these engines in limited production runs or specialized vehicles, their widespread use in production cars is likely to diminish further as emissions regulations continue to tighten globally.

In the United States, the Corporate Average Fuel Economy (CAFE) standards require automakers to achieve an average fuel economy of 54.5 miles per gallon for their fleet by 2025. These regulations have forced manufacturers to prioritize fuel efficiency and emissions reduction in their engine designs, putting pressure on large displacement engines such as the V16.

China, the world's largest automotive market, has also implemented strict emissions standards. The China 6 standard, introduced in 2019, is comparable to Euro 6 regulations and imposes tight limits on pollutants such as nitrogen oxides and particulate matter. This has led to a shift towards smaller, more efficient engines and alternative powertrains in the Chinese market.

The impact of these regulations on V16 engines has been substantial. Manufacturers have been forced to implement advanced technologies to meet emissions targets, including direct injection, variable valve timing, and turbocharging. However, these measures often come at the cost of increased complexity and reduced performance characteristics that are traditionally associated with V16 engines.

Furthermore, many countries have announced plans to phase out internal combustion engines entirely in the coming decades. The United Kingdom, for example, has set a target to ban the sale of new petrol and diesel cars by 2030. Similar initiatives are being considered or implemented in other European countries, as well as in parts of the United States and Asia.

These regulatory pressures have led to a significant decline in the development and production of V16 engines. Luxury and high-performance car manufacturers, who were once the primary users of V16 engines, are now focusing on smaller displacement engines, hybrid powertrains, and fully electric vehicles to comply with emissions regulations while still delivering high performance.

The future of V16 engines in this regulatory environment appears challenging. While there may still be niche applications for these engines in limited production runs or specialized vehicles, their widespread use in production cars is likely to diminish further as emissions regulations continue to tighten globally.

Hybrid V16 Potential

The potential for hybrid V16 engines represents a fascinating intersection of traditional high-performance engineering and modern sustainable mobility solutions. As the automotive industry shifts towards electrification, the integration of electric powertrains with V16 engines could offer a unique compromise between power and efficiency.

Hybrid V16 systems could potentially leverage the best of both worlds: the raw power and prestige of a V16 engine combined with the efficiency and instant torque of electric motors. This configuration could allow for improved fuel economy during city driving, where electric power could be primarily used, while still providing the exhilarating performance of a V16 engine for high-speed or performance-oriented driving scenarios.

One potential application for hybrid V16 engines could be in the ultra-luxury and high-performance vehicle segments. These markets often prioritize exclusivity and performance over pure efficiency, making them ideal candidates for such a complex and powerful drivetrain. The hybrid V16 could offer unparalleled smoothness and power delivery, with electric assist filling in any gaps in the power band and providing instant acceleration at low speeds.

From a technical standpoint, integrating electric motors with a V16 engine presents several challenges. The complexity of packaging such a large engine alongside batteries and electric motors would require innovative design solutions. Additionally, managing the heat generated by both the combustion engine and electric components would necessitate advanced cooling systems.

However, the potential benefits are significant. The electric motors could be used to eliminate turbo lag, providing instant boost and improving overall engine response. Furthermore, regenerative braking could be employed to recover energy typically lost during deceleration, improving overall efficiency.

Another interesting possibility is the use of the electric motors to smooth out the power delivery of the V16 engine. By carefully controlling the electric assist, engineers could potentially create an even more refined driving experience, eliminating any roughness or vibration typically associated with large displacement engines.

While the environmental impact of a hybrid V16 would still be considerable compared to fully electric vehicles, it could represent a significant improvement over traditional V16 engines. This could allow manufacturers to continue offering these prestigious powerplants in markets with increasingly stringent emissions regulations, albeit in limited numbers and for specialized applications.

Hybrid V16 systems could potentially leverage the best of both worlds: the raw power and prestige of a V16 engine combined with the efficiency and instant torque of electric motors. This configuration could allow for improved fuel economy during city driving, where electric power could be primarily used, while still providing the exhilarating performance of a V16 engine for high-speed or performance-oriented driving scenarios.

One potential application for hybrid V16 engines could be in the ultra-luxury and high-performance vehicle segments. These markets often prioritize exclusivity and performance over pure efficiency, making them ideal candidates for such a complex and powerful drivetrain. The hybrid V16 could offer unparalleled smoothness and power delivery, with electric assist filling in any gaps in the power band and providing instant acceleration at low speeds.

From a technical standpoint, integrating electric motors with a V16 engine presents several challenges. The complexity of packaging such a large engine alongside batteries and electric motors would require innovative design solutions. Additionally, managing the heat generated by both the combustion engine and electric components would necessitate advanced cooling systems.

However, the potential benefits are significant. The electric motors could be used to eliminate turbo lag, providing instant boost and improving overall engine response. Furthermore, regenerative braking could be employed to recover energy typically lost during deceleration, improving overall efficiency.

Another interesting possibility is the use of the electric motors to smooth out the power delivery of the V16 engine. By carefully controlling the electric assist, engineers could potentially create an even more refined driving experience, eliminating any roughness or vibration typically associated with large displacement engines.

While the environmental impact of a hybrid V16 would still be considerable compared to fully electric vehicles, it could represent a significant improvement over traditional V16 engines. This could allow manufacturers to continue offering these prestigious powerplants in markets with increasingly stringent emissions regulations, albeit in limited numbers and for specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!