The evolution of V16 engines from early prototypes to modern engineering marvels

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine History and Development Goals

The V16 engine, a marvel of automotive engineering, has a rich history dating back to the early 20th century. Its development was driven by the pursuit of power, prestige, and technological advancement in the automotive industry. The journey of V16 engines began in the 1910s when manufacturers sought to create engines with unprecedented power and smoothness.

The initial prototypes of V16 engines emerged in the 1920s, with Cadillac introducing the first production V16 engine in 1930. This groundbreaking engine set new standards for luxury and performance, boasting 452 cubic inches of displacement and producing 165 horsepower. The Cadillac V16 became a symbol of automotive excellence and engineering prowess during the Golden Age of American automobiles.

Throughout the 1930s, other manufacturers followed suit, with Marmon and Peerless introducing their own V16 engines. These early V16s were primarily designed for high-end luxury vehicles, emphasizing smooth operation and impressive power delivery. The goal was to create an engine that could provide effortless acceleration and whisper-quiet operation, catering to the demands of wealthy clientele.

As technology progressed, the focus of V16 engine development shifted towards performance and racing applications. In the 1930s and 1940s, Auto Union (now Audi) developed V16 engines for their Grand Prix racing cars, pushing the boundaries of power and speed. These racing engines demonstrated the potential of the V16 configuration in high-performance scenarios.

The post-World War II era saw a decline in V16 engine production for passenger vehicles, as more efficient and cost-effective V8 and V12 engines gained popularity. However, the concept of V16 engines continued to evolve in specialized applications, such as marine engines and industrial power plants.

In recent decades, there has been a resurgence of interest in V16 engines, particularly in the realm of hypercars and concept vehicles. Modern engineering techniques and materials have allowed for the creation of V16 engines that are more compact, efficient, and powerful than their predecessors. The development goals for these contemporary V16 engines focus on achieving extraordinary power outputs while meeting stringent emissions regulations and fuel efficiency standards.

The evolution of V16 engines from early prototypes to modern engineering marvels reflects the continuous pursuit of automotive excellence. Today's V16 engines represent the pinnacle of internal combustion engine technology, combining cutting-edge materials, advanced manufacturing techniques, and sophisticated electronic control systems to deliver unparalleled performance and refinement.

The initial prototypes of V16 engines emerged in the 1920s, with Cadillac introducing the first production V16 engine in 1930. This groundbreaking engine set new standards for luxury and performance, boasting 452 cubic inches of displacement and producing 165 horsepower. The Cadillac V16 became a symbol of automotive excellence and engineering prowess during the Golden Age of American automobiles.

Throughout the 1930s, other manufacturers followed suit, with Marmon and Peerless introducing their own V16 engines. These early V16s were primarily designed for high-end luxury vehicles, emphasizing smooth operation and impressive power delivery. The goal was to create an engine that could provide effortless acceleration and whisper-quiet operation, catering to the demands of wealthy clientele.

As technology progressed, the focus of V16 engine development shifted towards performance and racing applications. In the 1930s and 1940s, Auto Union (now Audi) developed V16 engines for their Grand Prix racing cars, pushing the boundaries of power and speed. These racing engines demonstrated the potential of the V16 configuration in high-performance scenarios.

The post-World War II era saw a decline in V16 engine production for passenger vehicles, as more efficient and cost-effective V8 and V12 engines gained popularity. However, the concept of V16 engines continued to evolve in specialized applications, such as marine engines and industrial power plants.

In recent decades, there has been a resurgence of interest in V16 engines, particularly in the realm of hypercars and concept vehicles. Modern engineering techniques and materials have allowed for the creation of V16 engines that are more compact, efficient, and powerful than their predecessors. The development goals for these contemporary V16 engines focus on achieving extraordinary power outputs while meeting stringent emissions regulations and fuel efficiency standards.

The evolution of V16 engines from early prototypes to modern engineering marvels reflects the continuous pursuit of automotive excellence. Today's V16 engines represent the pinnacle of internal combustion engine technology, combining cutting-edge materials, advanced manufacturing techniques, and sophisticated electronic control systems to deliver unparalleled performance and refinement.

Market Analysis for V16 Engines

The market for V16 engines has undergone significant changes since their inception in the early 20th century. Initially developed for luxury automobiles and high-performance aircraft, V16 engines represented the pinnacle of engineering prowess and exclusivity. However, their market presence has dramatically shifted over time due to various factors including technological advancements, economic considerations, and changing consumer preferences.

In the automotive sector, V16 engines once adorned the most prestigious vehicles, symbolizing ultimate luxury and power. Marques such as Cadillac, Marmon, and Peerless utilized these engines to differentiate their top-tier offerings. The market for such vehicles was inherently limited, catering to affluent enthusiasts and heads of state. This exclusivity contributed to their allure but also restricted widespread adoption.

The aviation industry saw a brief but intense period of V16 engine usage, particularly during the interwar years and World War II. These engines powered some of the most formidable aircraft of their time, offering unparalleled performance for military applications. However, the advent of jet propulsion technology rapidly diminished the market for piston engines in aviation, including V16 configurations.

Post-war economic realities and the push for greater fuel efficiency led to a decline in V16 engine production for consumer vehicles. The market shifted towards more practical and economical engine configurations, with V8 and V12 engines often filling the high-performance niche previously occupied by V16s.

In recent decades, the market for V16 engines has become highly specialized. They are now primarily found in ultra-luxury vehicles, concept cars, and bespoke creations. Manufacturers like Bugatti have revived the V16 configuration for their hypercars, targeting a niche market of ultra-high-net-worth individuals seeking the ultimate in automotive engineering and exclusivity.

The marine sector represents another small but significant market for modern V16 engines. These powerplants are utilized in large yachts and commercial vessels where high power output and reliability are paramount. Companies specializing in marine propulsion systems continue to develop and refine V16 engines for these applications.

Looking forward, the market for V16 engines faces challenges from increasingly stringent emissions regulations and the global shift towards electrification. However, there remains a small but passionate market segment that values the historical significance, engineering complexity, and sheer audacity of V16 engines. This niche is likely to sustain limited production and development of V16 engines in the foreseeable future, primarily in the realms of collector vehicles, motorsports, and specialized industrial applications.

In the automotive sector, V16 engines once adorned the most prestigious vehicles, symbolizing ultimate luxury and power. Marques such as Cadillac, Marmon, and Peerless utilized these engines to differentiate their top-tier offerings. The market for such vehicles was inherently limited, catering to affluent enthusiasts and heads of state. This exclusivity contributed to their allure but also restricted widespread adoption.

The aviation industry saw a brief but intense period of V16 engine usage, particularly during the interwar years and World War II. These engines powered some of the most formidable aircraft of their time, offering unparalleled performance for military applications. However, the advent of jet propulsion technology rapidly diminished the market for piston engines in aviation, including V16 configurations.

Post-war economic realities and the push for greater fuel efficiency led to a decline in V16 engine production for consumer vehicles. The market shifted towards more practical and economical engine configurations, with V8 and V12 engines often filling the high-performance niche previously occupied by V16s.

In recent decades, the market for V16 engines has become highly specialized. They are now primarily found in ultra-luxury vehicles, concept cars, and bespoke creations. Manufacturers like Bugatti have revived the V16 configuration for their hypercars, targeting a niche market of ultra-high-net-worth individuals seeking the ultimate in automotive engineering and exclusivity.

The marine sector represents another small but significant market for modern V16 engines. These powerplants are utilized in large yachts and commercial vessels where high power output and reliability are paramount. Companies specializing in marine propulsion systems continue to develop and refine V16 engines for these applications.

Looking forward, the market for V16 engines faces challenges from increasingly stringent emissions regulations and the global shift towards electrification. However, there remains a small but passionate market segment that values the historical significance, engineering complexity, and sheer audacity of V16 engines. This niche is likely to sustain limited production and development of V16 engines in the foreseeable future, primarily in the realms of collector vehicles, motorsports, and specialized industrial applications.

Current V16 Technology and Engineering Challenges

The current state of V16 engine technology represents a pinnacle of engineering achievement, blending raw power with sophisticated design. Modern V16 engines, while rare, continue to push the boundaries of performance and efficiency. These engines typically displace between 8 and 14 liters, producing power outputs that can exceed 1,000 horsepower in some applications.

One of the primary challenges in V16 engine development is thermal management. The sheer size and power output of these engines generate significant heat, requiring advanced cooling systems to maintain optimal operating temperatures. Engineers employ cutting-edge materials and design techniques to enhance heat dissipation and improve overall efficiency.

Weight reduction remains a critical focus in V16 engine engineering. Despite their massive size, modern V16 engines utilize lightweight alloys and innovative manufacturing processes to minimize overall mass. This approach helps to improve power-to-weight ratios and vehicle dynamics, particularly in high-performance applications.

Fuel efficiency and emissions control present ongoing challenges for V16 engine designers. With increasing global emphasis on environmental sustainability, engineers must balance the demand for power with the need for cleaner operation. Advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies are being implemented to improve fuel economy and reduce emissions without compromising performance.

Vibration and balance issues inherent to large, multi-cylinder engines require sophisticated solutions. Modern V16 engines incorporate advanced balancing shafts and computer-controlled engine mounts to minimize vibrations and ensure smooth operation across the entire RPM range.

The complexity of V16 engines poses significant manufacturing challenges. Precision engineering is crucial, with tight tolerances required for components such as crankshafts, camshafts, and cylinder heads. Advanced manufacturing techniques, including 3D printing and CNC machining, are employed to produce these intricate parts with the necessary accuracy.

Durability and reliability remain key concerns in V16 engine development. The extreme forces and temperatures experienced by these engines demand robust design and high-quality materials. Extensive testing and simulation are essential to ensure longevity and consistent performance under various operating conditions.

Looking ahead, the future of V16 engine technology faces challenges from emerging propulsion systems, particularly electric and hybrid powertrains. Engineers are exploring ways to integrate V16 engines into hybrid systems, potentially extending their relevance in an increasingly electrified automotive landscape. This integration presents new engineering hurdles, including the seamless coordination between combustion and electric power sources.

One of the primary challenges in V16 engine development is thermal management. The sheer size and power output of these engines generate significant heat, requiring advanced cooling systems to maintain optimal operating temperatures. Engineers employ cutting-edge materials and design techniques to enhance heat dissipation and improve overall efficiency.

Weight reduction remains a critical focus in V16 engine engineering. Despite their massive size, modern V16 engines utilize lightweight alloys and innovative manufacturing processes to minimize overall mass. This approach helps to improve power-to-weight ratios and vehicle dynamics, particularly in high-performance applications.

Fuel efficiency and emissions control present ongoing challenges for V16 engine designers. With increasing global emphasis on environmental sustainability, engineers must balance the demand for power with the need for cleaner operation. Advanced fuel injection systems, variable valve timing, and cylinder deactivation technologies are being implemented to improve fuel economy and reduce emissions without compromising performance.

Vibration and balance issues inherent to large, multi-cylinder engines require sophisticated solutions. Modern V16 engines incorporate advanced balancing shafts and computer-controlled engine mounts to minimize vibrations and ensure smooth operation across the entire RPM range.

The complexity of V16 engines poses significant manufacturing challenges. Precision engineering is crucial, with tight tolerances required for components such as crankshafts, camshafts, and cylinder heads. Advanced manufacturing techniques, including 3D printing and CNC machining, are employed to produce these intricate parts with the necessary accuracy.

Durability and reliability remain key concerns in V16 engine development. The extreme forces and temperatures experienced by these engines demand robust design and high-quality materials. Extensive testing and simulation are essential to ensure longevity and consistent performance under various operating conditions.

Looking ahead, the future of V16 engine technology faces challenges from emerging propulsion systems, particularly electric and hybrid powertrains. Engineers are exploring ways to integrate V16 engines into hybrid systems, potentially extending their relevance in an increasingly electrified automotive landscape. This integration presents new engineering hurdles, including the seamless coordination between combustion and electric power sources.

Modern V16 Engine Design Solutions

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.

- V16 engine applications in vehicles: V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as racing cars and concept vehicles. These engines provide exceptional power and torque, making them suitable for vehicles that require outstanding performance characteristics.

- V16 engine control systems: Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.

- Historical development of V16 engines: The development of V16 engines dates back to the early 20th century, with various designs and configurations being explored over the years. These engines have been used in a range of applications, from aircraft to automobiles, and have played a significant role in the evolution of high-performance internal combustion engines.

- V16 engine cooling and lubrication systems: Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems to maintain optimal operating temperatures and ensure longevity. These systems may include advanced oil circulation methods, multiple radiators, and specialized coolant formulations to manage the heat generated by the engine effectively.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as military tanks and large trucks. These engines provide exceptional power and torque, making them suitable for heavy-duty applications and high-speed performance vehicles.Expand Specific Solutions03 V16 engine control systems

Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.Expand Specific Solutions04 Historical development of V16 engines

V16 engines have a rich history dating back to the early 20th century. They were initially developed for use in luxury automobiles and racing cars, with various manufacturers experimenting with different designs and configurations. Over time, V16 engines have evolved to incorporate new technologies and materials, improving their performance and reliability.Expand Specific Solutions05 V16 engine cooling and lubrication systems

Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems to maintain optimal operating temperatures and reduce wear. These systems may include advanced oil pumps, multiple radiators, and precision-engineered coolant passages to ensure efficient heat dissipation and proper lubrication of all moving parts.Expand Specific Solutions

Major V16 Engine Manufacturers and Competitors

The evolution of V16 engines represents a niche but significant area of automotive engineering, currently in a mature phase with limited market size. The technology has progressed from early prototypes to highly specialized applications, primarily in luxury and high-performance vehicles. Companies like Honda Motor Co., Ltd., Yamaha Motor Co., Ltd., and Toyota Motor Corp. have contributed to advancements in engine technology, though not specifically in V16 configurations. The market for V16 engines remains small, with limited production runs and specialized use cases. Technical maturity is high, with modern V16 engines showcasing advanced engineering and materials, but widespread adoption is constrained by practical and economic factors in mainstream automotive applications.

Cummins, Inc.

Technical Solution: Cummins has made significant strides in V16 engine development, particularly for heavy-duty applications such as mining, marine, and power generation. Their evolution of V16 engines has focused on increasing power output, improving fuel efficiency, and meeting stringent emissions regulations. Cummins has implemented advanced technologies such as high-pressure fuel injection systems, turbocharging with intercooling, and sophisticated electronic control units to optimize engine performance[7]. The company has also invested in materials science, using stronger and lighter alloys to improve durability and reduce weight. Cummins' modern V16 engines feature modular designs that allow for easier maintenance and customization to specific application requirements[8]. They have also integrated exhaust aftertreatment systems to meet global emissions standards while maintaining high performance levels[9].

Strengths: Extensive experience in heavy-duty applications, strong global presence, and advanced emissions control technologies. Weaknesses: Limited presence in passenger vehicle markets and potential challenges in transitioning to alternative fuel sources.

Liebherr-Components Colmar SAS

Technical Solution: Liebherr has contributed to the evolution of V16 engines, particularly in the construction and mining equipment sectors. Their approach has focused on developing robust, high-torque engines capable of operating in extreme conditions. Liebherr's V16 engines have evolved to incorporate advanced electronic control systems, optimized combustion chambers, and high-pressure common rail injection systems[10]. The company has also implemented innovative cooling solutions to manage the high heat output of their powerful V16 engines. Liebherr's modern V16 engines feature modular designs that allow for easy maintenance and component replacement, reducing downtime in industrial applications[11]. They have also focused on improving fuel efficiency and reducing emissions through the use of advanced exhaust gas recirculation systems and selective catalytic reduction technology[12].

Strengths: Specialized expertise in heavy-duty industrial applications, robust engine designs, and integrated systems approach. Weaknesses: Limited presence in automotive and marine markets, and potential challenges in adapting to rapidly changing emissions regulations.

Key Innovations in V16 Engine Technology

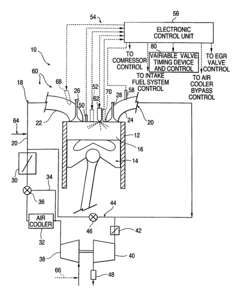

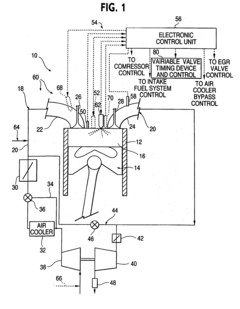

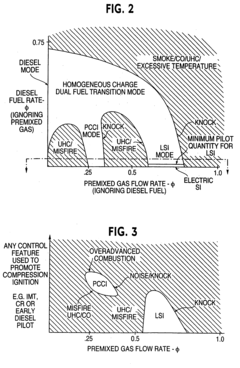

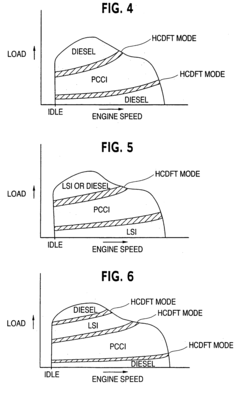

Multiple operating mode engine and method of operation

PatentInactiveUS20040149255A1

Innovation

- A multi-mode internal combustion engine with a control system that allows seamless transitions between diesel, premixed charge compression ignition (PCCI), and spark ignition modes by adjusting fuel delivery and equivalence ratios, using a homogeneous charge dual fuel transition mode to maintain constant torque and reduce emissions.

Internal cooling method for engines and engine in which it is applied

PatentPendingUS20240318607A1

Innovation

- An internal cooling method for internal combustion engines that incorporates a 'ventilation cycle' alongside the standard thermodynamic cycle, utilizing modified intake and exhaust valve operations to create a scavenging effect without compression or expansion, and the introduction of a cooling fluid to absorb heat, allowing for alternative engine functioning modes to manage temperature and emissions.

Environmental Impact and Regulations for V16 Engines

The environmental impact of V16 engines has been a significant concern throughout their evolution, leading to increasingly stringent regulations. These massive powerplants, known for their impressive performance, have historically been associated with high fuel consumption and substantial emissions. As environmental awareness grew, regulatory bodies worldwide began implementing stricter standards to mitigate the ecological footprint of these engines.

In the early stages of V16 development, environmental considerations were minimal. However, as the negative effects of vehicle emissions became apparent, governments started introducing basic emission controls. The Clean Air Act of 1970 in the United States marked a turning point, setting the stage for more comprehensive regulations on engine emissions.

As V16 engines continued to evolve, manufacturers faced mounting pressure to improve fuel efficiency and reduce emissions. This led to the development of advanced technologies such as direct fuel injection, variable valve timing, and improved combustion chamber designs. Despite these advancements, V16 engines still struggled to meet increasingly stringent environmental standards.

The introduction of Euro emissions standards in the European Union and similar regulations in other regions further challenged the viability of V16 engines in production vehicles. These standards set specific limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. Compliance with these regulations often required extensive redesigns and the integration of complex aftertreatment systems.

In response to tightening regulations, some manufacturers explored alternative fuel options for V16 engines, including biofuels and hydrogen. However, these efforts were largely experimental and did not lead to widespread adoption. The inherent inefficiency of such large displacement engines made it challenging to meet both performance expectations and environmental requirements.

As global focus shifted towards reducing carbon emissions and combating climate change, many jurisdictions introduced carbon dioxide emission targets for vehicle fleets. These regulations posed a significant challenge for V16 engines, which typically produce high levels of CO2 due to their size and power output. Consequently, the use of V16 engines in production vehicles became increasingly rare, with manufacturers opting for smaller, more efficient powerplants.

In recent years, the push towards electrification has further marginalized V16 engines. Many countries have announced plans to phase out internal combustion engines entirely, setting deadlines for the transition to zero-emission vehicles. This regulatory landscape has effectively ended the development of new V16 engines for road-going vehicles, relegating them to specialized applications such as marine propulsion or stationary power generation where different regulatory frameworks apply.

In the early stages of V16 development, environmental considerations were minimal. However, as the negative effects of vehicle emissions became apparent, governments started introducing basic emission controls. The Clean Air Act of 1970 in the United States marked a turning point, setting the stage for more comprehensive regulations on engine emissions.

As V16 engines continued to evolve, manufacturers faced mounting pressure to improve fuel efficiency and reduce emissions. This led to the development of advanced technologies such as direct fuel injection, variable valve timing, and improved combustion chamber designs. Despite these advancements, V16 engines still struggled to meet increasingly stringent environmental standards.

The introduction of Euro emissions standards in the European Union and similar regulations in other regions further challenged the viability of V16 engines in production vehicles. These standards set specific limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. Compliance with these regulations often required extensive redesigns and the integration of complex aftertreatment systems.

In response to tightening regulations, some manufacturers explored alternative fuel options for V16 engines, including biofuels and hydrogen. However, these efforts were largely experimental and did not lead to widespread adoption. The inherent inefficiency of such large displacement engines made it challenging to meet both performance expectations and environmental requirements.

As global focus shifted towards reducing carbon emissions and combating climate change, many jurisdictions introduced carbon dioxide emission targets for vehicle fleets. These regulations posed a significant challenge for V16 engines, which typically produce high levels of CO2 due to their size and power output. Consequently, the use of V16 engines in production vehicles became increasingly rare, with manufacturers opting for smaller, more efficient powerplants.

In recent years, the push towards electrification has further marginalized V16 engines. Many countries have announced plans to phase out internal combustion engines entirely, setting deadlines for the transition to zero-emission vehicles. This regulatory landscape has effectively ended the development of new V16 engines for road-going vehicles, relegating them to specialized applications such as marine propulsion or stationary power generation where different regulatory frameworks apply.

V16 Engine Applications in Various Industries

V16 engines have found applications across various industries, showcasing their versatility and power. In the automotive sector, V16 engines have been utilized in luxury and high-performance vehicles, offering unparalleled smoothness and prestige. Notable examples include the Cadillac V16, which dominated the luxury car market in the 1930s, and more recently, the Bugatti Veyron's quad-turbocharged W16 engine, a close relative of the V16 configuration.

In the marine industry, V16 engines have been employed in large vessels and yachts, providing the necessary power and reliability for extended voyages. These engines are particularly favored in high-speed boats and luxury yachts, where their compact design and impressive power-to-weight ratio offer significant advantages.

The aviation sector has also benefited from V16 engines, particularly in the early days of flight. During World War II, V16 engines were used in some military aircraft, offering a balance between power output and engine size. Although less common in modern aviation, their legacy continues to influence engine design principles.

In the realm of power generation, V16 engines have found a niche in stationary applications. Large-scale power plants and backup generators often utilize V16 configurations, capitalizing on their ability to produce substantial power output while maintaining relatively compact dimensions. These engines are particularly valuable in remote locations or for critical infrastructure that requires reliable, high-capacity power generation.

The railroad industry has also embraced V16 engines, incorporating them into locomotive designs. These engines provide the necessary power and torque to haul heavy freight trains across long distances, offering improved fuel efficiency and reduced maintenance requirements compared to earlier steam-powered locomotives.

In industrial applications, V16 engines have been adapted for use in heavy machinery and mining equipment. Their robust design and high power output make them suitable for demanding environments where reliability and performance are crucial. Additionally, some specialized agricultural equipment, such as large harvesters and tractors, have utilized V16 engines to meet the power demands of modern farming practices.

The diverse applications of V16 engines across these industries demonstrate their adaptability and enduring relevance in various technological contexts. From luxury automobiles to critical infrastructure, the V16 configuration continues to play a significant role in powering some of the world's most demanding machines and vehicles.

In the marine industry, V16 engines have been employed in large vessels and yachts, providing the necessary power and reliability for extended voyages. These engines are particularly favored in high-speed boats and luxury yachts, where their compact design and impressive power-to-weight ratio offer significant advantages.

The aviation sector has also benefited from V16 engines, particularly in the early days of flight. During World War II, V16 engines were used in some military aircraft, offering a balance between power output and engine size. Although less common in modern aviation, their legacy continues to influence engine design principles.

In the realm of power generation, V16 engines have found a niche in stationary applications. Large-scale power plants and backup generators often utilize V16 configurations, capitalizing on their ability to produce substantial power output while maintaining relatively compact dimensions. These engines are particularly valuable in remote locations or for critical infrastructure that requires reliable, high-capacity power generation.

The railroad industry has also embraced V16 engines, incorporating them into locomotive designs. These engines provide the necessary power and torque to haul heavy freight trains across long distances, offering improved fuel efficiency and reduced maintenance requirements compared to earlier steam-powered locomotives.

In industrial applications, V16 engines have been adapted for use in heavy machinery and mining equipment. Their robust design and high power output make them suitable for demanding environments where reliability and performance are crucial. Additionally, some specialized agricultural equipment, such as large harvesters and tractors, have utilized V16 engines to meet the power demands of modern farming practices.

The diverse applications of V16 engines across these industries demonstrate their adaptability and enduring relevance in various technological contexts. From luxury automobiles to critical infrastructure, the V16 configuration continues to play a significant role in powering some of the world's most demanding machines and vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!