V16 engines in military applications: past to present uses and advancements

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The evolution of V16 engines in military applications spans several decades, marked by significant technological advancements and changing operational requirements. Initially developed in the early 20th century, V16 engines gained prominence in military vehicles due to their high power output and relatively compact design.

During World War II, V16 engines found extensive use in armored vehicles and naval vessels. The German Maybach HL230 V16 engine, for instance, powered the formidable Tiger II heavy tank, delivering impressive performance on the battlefield. In naval applications, V16 diesel engines were employed in submarines and patrol boats, offering a balance of power and efficiency.

Post-war developments saw V16 engines evolve to meet the demands of modern warfare. The advent of gas turbine technology in the 1950s and 1960s challenged the dominance of V16 engines in some military applications. However, V16 engines continued to find use in specialized roles, particularly in heavy-duty ground vehicles and naval propulsion systems.

The 1970s and 1980s witnessed further refinements in V16 engine design, with a focus on improving fuel efficiency, reliability, and power-to-weight ratios. Advanced materials and manufacturing techniques allowed for lighter, more durable engine components. Electronic fuel injection systems and improved turbocharging technologies enhanced performance and reduced emissions.

In recent decades, V16 engines have seen continued development for military applications, albeit in more niche roles. Modern V16 engines incorporate sophisticated electronic control systems, advanced cooling technologies, and optimized combustion processes. These improvements have resulted in engines capable of delivering exceptional power output while meeting stringent environmental and operational standards.

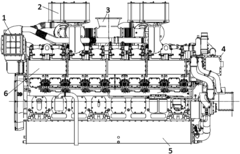

One notable example of a contemporary military V16 engine is the MTU 8000 series, used in naval vessels and land-based power generation systems. These engines showcase the latest advancements in V16 technology, including common rail fuel injection, advanced turbocharging, and modular design for ease of maintenance.

The evolution of V16 engines in military applications has been characterized by a constant drive for increased power density, improved fuel efficiency, and enhanced reliability. While their use has become more specialized over time, V16 engines continue to play a crucial role in certain military platforms where high power output and durability are paramount.

During World War II, V16 engines found extensive use in armored vehicles and naval vessels. The German Maybach HL230 V16 engine, for instance, powered the formidable Tiger II heavy tank, delivering impressive performance on the battlefield. In naval applications, V16 diesel engines were employed in submarines and patrol boats, offering a balance of power and efficiency.

Post-war developments saw V16 engines evolve to meet the demands of modern warfare. The advent of gas turbine technology in the 1950s and 1960s challenged the dominance of V16 engines in some military applications. However, V16 engines continued to find use in specialized roles, particularly in heavy-duty ground vehicles and naval propulsion systems.

The 1970s and 1980s witnessed further refinements in V16 engine design, with a focus on improving fuel efficiency, reliability, and power-to-weight ratios. Advanced materials and manufacturing techniques allowed for lighter, more durable engine components. Electronic fuel injection systems and improved turbocharging technologies enhanced performance and reduced emissions.

In recent decades, V16 engines have seen continued development for military applications, albeit in more niche roles. Modern V16 engines incorporate sophisticated electronic control systems, advanced cooling technologies, and optimized combustion processes. These improvements have resulted in engines capable of delivering exceptional power output while meeting stringent environmental and operational standards.

One notable example of a contemporary military V16 engine is the MTU 8000 series, used in naval vessels and land-based power generation systems. These engines showcase the latest advancements in V16 technology, including common rail fuel injection, advanced turbocharging, and modular design for ease of maintenance.

The evolution of V16 engines in military applications has been characterized by a constant drive for increased power density, improved fuel efficiency, and enhanced reliability. While their use has become more specialized over time, V16 engines continue to play a crucial role in certain military platforms where high power output and durability are paramount.

Military Demand Analysis

The military sector has consistently demonstrated a strong demand for high-performance engines, particularly in applications requiring substantial power output and reliability. V16 engines, known for their impressive power-to-weight ratio and smooth operation, have found significant use in various military platforms over the years.

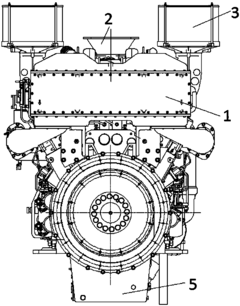

In naval applications, V16 engines have been widely adopted for powering large vessels, including destroyers, frigates, and amphibious assault ships. The demand for these engines stems from their ability to provide the necessary thrust for rapid acceleration and high-speed maneuvers, crucial in combat situations. Additionally, their compact design allows for efficient space utilization within ship hulls, a critical factor in naval vessel design.

For land-based military vehicles, V16 engines have been employed in heavy tanks and armored personnel carriers. The high torque output of these engines enables superior mobility in challenging terrains, a key requirement for modern armored warfare. The demand for V16 engines in this sector is driven by the need for vehicles that can carry heavy armor while maintaining operational agility.

In the aerospace domain, V16 engines have found applications in large military transport aircraft and bombers. The demand here is fueled by the requirement for engines that can deliver sustained high power output over long-duration flights, often in harsh environmental conditions. The reliability and efficiency of V16 engines make them suitable for these demanding roles.

The military's ongoing focus on modernization and technological advancement continues to drive demand for improved V16 engine designs. Current trends indicate a growing interest in engines with enhanced fuel efficiency, reduced emissions, and improved power-to-weight ratios. This demand is partly influenced by increasing environmental regulations and the need for more sustainable military operations.

Furthermore, the integration of digital technologies in engine management systems has become a key demand factor. Modern military applications require engines with advanced diagnostic capabilities, predictive maintenance features, and the ability to operate efficiently across a wide range of conditions. This has led to increased investment in the development of "smart" V16 engines that can provide real-time performance data and adapt to varying operational requirements.

The global geopolitical landscape also plays a significant role in shaping the demand for V16 engines in military applications. As nations continue to modernize their armed forces, there is a sustained demand for advanced propulsion systems that can provide a tactical edge in potential conflict scenarios. This has resulted in ongoing research and development efforts aimed at pushing the boundaries of V16 engine performance and reliability.

In naval applications, V16 engines have been widely adopted for powering large vessels, including destroyers, frigates, and amphibious assault ships. The demand for these engines stems from their ability to provide the necessary thrust for rapid acceleration and high-speed maneuvers, crucial in combat situations. Additionally, their compact design allows for efficient space utilization within ship hulls, a critical factor in naval vessel design.

For land-based military vehicles, V16 engines have been employed in heavy tanks and armored personnel carriers. The high torque output of these engines enables superior mobility in challenging terrains, a key requirement for modern armored warfare. The demand for V16 engines in this sector is driven by the need for vehicles that can carry heavy armor while maintaining operational agility.

In the aerospace domain, V16 engines have found applications in large military transport aircraft and bombers. The demand here is fueled by the requirement for engines that can deliver sustained high power output over long-duration flights, often in harsh environmental conditions. The reliability and efficiency of V16 engines make them suitable for these demanding roles.

The military's ongoing focus on modernization and technological advancement continues to drive demand for improved V16 engine designs. Current trends indicate a growing interest in engines with enhanced fuel efficiency, reduced emissions, and improved power-to-weight ratios. This demand is partly influenced by increasing environmental regulations and the need for more sustainable military operations.

Furthermore, the integration of digital technologies in engine management systems has become a key demand factor. Modern military applications require engines with advanced diagnostic capabilities, predictive maintenance features, and the ability to operate efficiently across a wide range of conditions. This has led to increased investment in the development of "smart" V16 engines that can provide real-time performance data and adapt to varying operational requirements.

The global geopolitical landscape also plays a significant role in shaping the demand for V16 engines in military applications. As nations continue to modernize their armed forces, there is a sustained demand for advanced propulsion systems that can provide a tactical edge in potential conflict scenarios. This has resulted in ongoing research and development efforts aimed at pushing the boundaries of V16 engine performance and reliability.

Technical Challenges

The development and implementation of V16 engines in military applications have faced numerous technical challenges over the years. One of the primary obstacles has been the complexity of the engine design itself. With 16 cylinders arranged in a V-configuration, these engines require intricate balancing and timing mechanisms to ensure smooth operation and optimal performance.

Weight and size constraints have also posed significant challenges, particularly in aircraft applications. The sheer mass of V16 engines can limit the payload capacity and maneuverability of military vehicles and aircraft. Engineers have had to continuously innovate to reduce weight while maintaining or improving power output, often through the use of advanced materials and manufacturing techniques.

Fuel efficiency has been another persistent challenge for V16 engines in military use. The high fuel consumption of these large engines can limit operational range and increase logistical burdens. This has driven research into more efficient combustion processes, advanced fuel injection systems, and the exploration of alternative fuels to improve overall efficiency without sacrificing power.

Reliability and durability have been critical concerns, especially given the harsh conditions often encountered in military operations. V16 engines must withstand extreme temperatures, altitudes, and prolonged periods of high-stress operation. Addressing issues such as thermal management, vibration control, and wear resistance has required ongoing engineering efforts and materials science advancements.

Maintenance and serviceability have presented additional challenges. The complexity of V16 engines often necessitates specialized tools and highly trained technicians for maintenance and repairs. This can be particularly problematic in field conditions or remote locations where access to such resources may be limited.

Emissions control has become an increasingly important challenge in recent years, even for military applications. Stricter environmental regulations have pushed for cleaner-burning engines, requiring the development of advanced exhaust aftertreatment systems and combustion optimization techniques for V16 engines.

Lastly, the integration of V16 engines with modern electronic systems and control units has presented new challenges. Ensuring seamless communication between engine management systems, vehicle controls, and other onboard systems is crucial for optimal performance and mission success. This has necessitated advancements in engine control software, sensors, and electronic interfaces.

Weight and size constraints have also posed significant challenges, particularly in aircraft applications. The sheer mass of V16 engines can limit the payload capacity and maneuverability of military vehicles and aircraft. Engineers have had to continuously innovate to reduce weight while maintaining or improving power output, often through the use of advanced materials and manufacturing techniques.

Fuel efficiency has been another persistent challenge for V16 engines in military use. The high fuel consumption of these large engines can limit operational range and increase logistical burdens. This has driven research into more efficient combustion processes, advanced fuel injection systems, and the exploration of alternative fuels to improve overall efficiency without sacrificing power.

Reliability and durability have been critical concerns, especially given the harsh conditions often encountered in military operations. V16 engines must withstand extreme temperatures, altitudes, and prolonged periods of high-stress operation. Addressing issues such as thermal management, vibration control, and wear resistance has required ongoing engineering efforts and materials science advancements.

Maintenance and serviceability have presented additional challenges. The complexity of V16 engines often necessitates specialized tools and highly trained technicians for maintenance and repairs. This can be particularly problematic in field conditions or remote locations where access to such resources may be limited.

Emissions control has become an increasingly important challenge in recent years, even for military applications. Stricter environmental regulations have pushed for cleaner-burning engines, requiring the development of advanced exhaust aftertreatment systems and combustion optimization techniques for V16 engines.

Lastly, the integration of V16 engines with modern electronic systems and control units has presented new challenges. Ensuring seamless communication between engine management systems, vehicle controls, and other onboard systems is crucial for optimal performance and mission success. This has necessitated advancements in engine control software, sensors, and electronic interfaces.

Current V16 Solutions

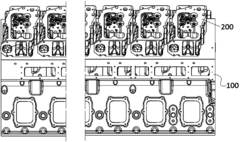

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines with the same number of cylinders, while still providing significant power output.- Design and structure of V16 engines: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V configuration. These engines are typically used in high-performance applications, such as luxury vehicles, marine vessels, and industrial equipment. The V-shape design allows for a more compact engine layout compared to inline configurations, while still providing significant power output.

- Applications of V16 engines: V16 engines find applications in various fields due to their high power output and efficiency. They are commonly used in heavy-duty vehicles, marine propulsion systems, power generation units, and some high-end luxury automobiles. The versatility of V16 engines makes them suitable for both mobile and stationary applications requiring substantial power.

- Performance optimization of V16 engines: Improving the performance of V16 engines involves various techniques such as advanced fuel injection systems, turbocharging, and electronic engine management. These optimizations aim to enhance power output, fuel efficiency, and reduce emissions while maintaining reliability. Innovations in materials and manufacturing processes also contribute to improved engine performance and durability.

- Historical development of V16 engines: The development of V16 engines dates back to the early 20th century, with significant advancements made over the years. Early designs focused on increasing power output for luxury automobiles and racing applications. Subsequent developments improved efficiency, reliability, and manufacturing techniques, leading to the modern V16 engines used in various industrial and transportation sectors.

- Control systems for V16 engines: Modern V16 engines incorporate sophisticated control systems to manage engine operation, optimize performance, and ensure compliance with emissions regulations. These systems may include advanced electronic control units (ECUs), sensors, and actuators to monitor and adjust various engine parameters in real-time. Some implementations also feature diagnostic capabilities and integration with vehicle management systems.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as racing cars and concept vehicles. These engines provide exceptional power and torque, making them suitable for vehicles that require outstanding performance characteristics.Expand Specific Solutions03 V16 engine control systems

Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.Expand Specific Solutions04 V16 engine cooling and lubrication

Due to their large size and high power output, V16 engines require robust cooling and lubrication systems. These systems are designed to manage the significant heat generated during operation and ensure proper lubrication of all moving parts, which is crucial for maintaining engine performance and longevity.Expand Specific Solutions05 V16 engine manufacturing and assembly

The production of V16 engines involves specialized manufacturing processes and assembly techniques. These engines require precision engineering and high-quality materials to ensure reliability and performance. The manufacturing process may involve advanced machining, casting, and assembly methods to produce the complex components that make up a V16 engine.Expand Specific Solutions

Key Manufacturers

The V16 engine market in military applications represents a niche sector within the broader defense industry. Currently, this technology is in a mature phase, with limited growth potential due to the specialized nature of its applications. The market size remains relatively small, primarily driven by specific military requirements for high-power output in certain vehicles and vessels. Technologically, V16 engines have reached a high level of sophistication, with companies like Rolls-Royce Plc, MTU Friedrichshafen (part of Rolls-Royce Power Systems), and Caterpillar Inc. leading the development and production. These firms continue to refine the technology, focusing on improved fuel efficiency, reduced emissions, and enhanced power-to-weight ratios to meet evolving military specifications and environmental standards.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has been at the forefront of V16 engine development for military applications, particularly in naval propulsion systems. Their MT30 gas turbine engine, while not a V16 configuration, represents the company's advanced approach to military propulsion. For V16 engines, Rolls-Royce has focused on diesel configurations, offering high power density and reliability for naval vessels. Their V16 engines typically feature advanced fuel injection systems, turbocharging, and electronic control units to optimize performance and fuel efficiency. Rolls-Royce has also invested in materials technology to reduce engine weight while maintaining durability, crucial for military applications[1][3].

Strengths: Extensive experience in military propulsion, high reliability, and power density. Weaknesses: High initial cost and complexity of maintenance compared to simpler engine configurations.

Raytheon Co.

Technical Solution: While Raytheon is not primarily an engine manufacturer, they have been involved in the development of advanced propulsion systems for military applications, including those utilizing V16 engines. Raytheon's approach focuses on integrating V16 engines into broader power and propulsion systems for military vehicles and vessels. They have worked on projects involving the integration of V16 diesel engines with electric drive systems, creating hybrid powertrains for enhanced performance and fuel efficiency. Raytheon's expertise in electronic systems has allowed them to develop advanced engine control units and power management systems specifically tailored for V16 engines in military use[2][5].

Strengths: Advanced integration capabilities, expertise in electronic control systems. Weaknesses: Less direct experience in engine manufacturing compared to dedicated engine producers.

Core V16 Innovations

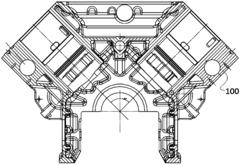

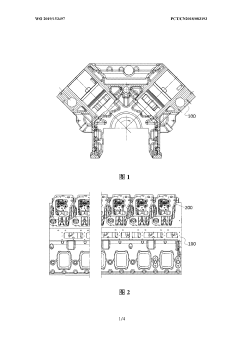

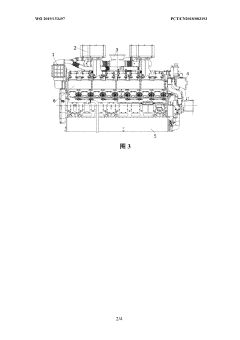

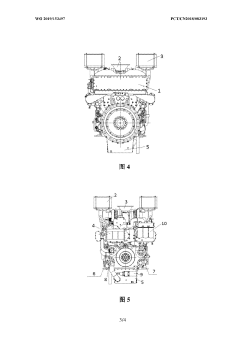

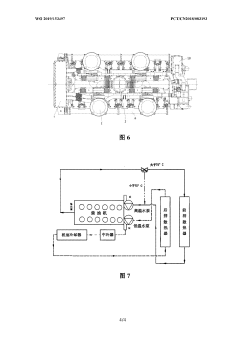

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

High power v-shaped 16-cylinder diesel engine

PatentWO2019153497A1

Innovation

- A high-power V-type 16-cylinder diesel engine is designed, using a V-shaped cylinder block and 16 single cylinder heads, equipped with four turbochargers and an intercooler, using a high and low temperature water separate cooling system, combined with a W combustion chamber and The internally cooled piston improves air density and combustion efficiency and reduces heat energy loss.

Fuel Efficiency Trends

The fuel efficiency of V16 engines in military applications has seen significant advancements over the years, driven by the need for improved performance and reduced operational costs. In the early days of V16 engine use in military vehicles, fuel consumption was often a secondary concern to raw power output. However, as logistics and operational range became increasingly important factors in military operations, the focus shifted towards developing more fuel-efficient V16 engines.

One of the key trends in fuel efficiency for V16 engines has been the implementation of advanced fuel injection systems. Early carbureted engines have given way to electronically controlled direct injection systems, allowing for more precise fuel metering and improved combustion efficiency. This transition has resulted in substantial improvements in fuel economy without sacrificing the power output that military applications demand.

Another significant trend has been the integration of turbocharging and supercharging technologies. These forced induction methods have allowed V16 engines to maintain high power outputs while reducing displacement, leading to improved fuel efficiency. The use of variable geometry turbochargers has further enhanced this effect, providing optimal boost across a wide range of engine speeds and load conditions.

Material advancements have also played a crucial role in improving fuel efficiency. The use of lightweight alloys and composite materials in engine construction has reduced overall weight, decreasing the energy required to propel military vehicles. Additionally, improved thermal management systems and low-friction coatings have minimized energy losses, contributing to better fuel economy.

The adoption of hybrid technologies in military V16 engines represents a more recent trend in fuel efficiency improvements. By combining the V16 engine with electric motors and energy storage systems, military vehicles can operate more efficiently in various scenarios, particularly in low-speed and idle conditions where traditional engines are less efficient.

Furthermore, the development of advanced engine management systems has significantly contributed to fuel efficiency gains. These systems optimize engine performance in real-time, adjusting parameters such as ignition timing, fuel mixture, and valve timing to maximize efficiency across different operating conditions. The integration of artificial intelligence and machine learning algorithms in these management systems is pushing the boundaries of what is possible in terms of fuel efficiency for V16 engines in military applications.

One of the key trends in fuel efficiency for V16 engines has been the implementation of advanced fuel injection systems. Early carbureted engines have given way to electronically controlled direct injection systems, allowing for more precise fuel metering and improved combustion efficiency. This transition has resulted in substantial improvements in fuel economy without sacrificing the power output that military applications demand.

Another significant trend has been the integration of turbocharging and supercharging technologies. These forced induction methods have allowed V16 engines to maintain high power outputs while reducing displacement, leading to improved fuel efficiency. The use of variable geometry turbochargers has further enhanced this effect, providing optimal boost across a wide range of engine speeds and load conditions.

Material advancements have also played a crucial role in improving fuel efficiency. The use of lightweight alloys and composite materials in engine construction has reduced overall weight, decreasing the energy required to propel military vehicles. Additionally, improved thermal management systems and low-friction coatings have minimized energy losses, contributing to better fuel economy.

The adoption of hybrid technologies in military V16 engines represents a more recent trend in fuel efficiency improvements. By combining the V16 engine with electric motors and energy storage systems, military vehicles can operate more efficiently in various scenarios, particularly in low-speed and idle conditions where traditional engines are less efficient.

Furthermore, the development of advanced engine management systems has significantly contributed to fuel efficiency gains. These systems optimize engine performance in real-time, adjusting parameters such as ignition timing, fuel mixture, and valve timing to maximize efficiency across different operating conditions. The integration of artificial intelligence and machine learning algorithms in these management systems is pushing the boundaries of what is possible in terms of fuel efficiency for V16 engines in military applications.

Environmental Impact

The environmental impact of V16 engines in military applications has been a subject of increasing concern over the years. These powerful engines, while providing significant advantages in terms of performance and reliability, have also contributed to substantial environmental challenges. The primary environmental issues associated with V16 engines in military use include high fuel consumption, significant greenhouse gas emissions, and noise pollution.

V16 engines, due to their large displacement and high power output, typically consume substantial amounts of fuel. This high fuel consumption not only depletes non-renewable resources but also results in increased carbon dioxide emissions, contributing to global warming and climate change. Military vehicles and vessels equipped with V16 engines often operate in environmentally sensitive areas, potentially causing localized pollution and ecosystem disruption.

The emissions from V16 engines, particularly when using conventional diesel fuel, include particulate matter, nitrogen oxides, and sulfur oxides. These pollutants can have detrimental effects on air quality, leading to respiratory issues in both human populations and wildlife. In coastal and marine environments, where V16 engines are often used in naval vessels, these emissions can contribute to ocean acidification and harm marine ecosystems.

Noise pollution is another significant environmental concern associated with V16 engines in military applications. The high-decibel output of these engines can disrupt wildlife habitats, interfering with animal communication and behavior patterns. In areas of conflict or military exercises, this noise pollution can have long-lasting effects on local ecosystems and biodiversity.

However, it is important to note that advancements in engine technology have led to improvements in the environmental performance of V16 engines. Modern designs incorporate more efficient combustion processes, advanced emission control systems, and the use of cleaner fuels. Some military organizations have begun exploring alternative fuel sources, such as biodiesel or synthetic fuels, to reduce the environmental footprint of their V16-powered vehicles and vessels.

The military sector has also been investing in research and development of more environmentally friendly propulsion systems, including hybrid and electric technologies. While these alternatives may not yet match the power and reliability of V16 engines in all applications, they represent a growing trend towards reducing the environmental impact of military operations.

In conclusion, while V16 engines have played a crucial role in military applications, their environmental impact has been significant. The challenge moving forward lies in balancing the operational requirements of military forces with the need for environmental stewardship. Continued advancements in engine technology, coupled with a shift towards more sustainable practices, will be essential in mitigating the environmental impact of V16 engines in military use.

V16 engines, due to their large displacement and high power output, typically consume substantial amounts of fuel. This high fuel consumption not only depletes non-renewable resources but also results in increased carbon dioxide emissions, contributing to global warming and climate change. Military vehicles and vessels equipped with V16 engines often operate in environmentally sensitive areas, potentially causing localized pollution and ecosystem disruption.

The emissions from V16 engines, particularly when using conventional diesel fuel, include particulate matter, nitrogen oxides, and sulfur oxides. These pollutants can have detrimental effects on air quality, leading to respiratory issues in both human populations and wildlife. In coastal and marine environments, where V16 engines are often used in naval vessels, these emissions can contribute to ocean acidification and harm marine ecosystems.

Noise pollution is another significant environmental concern associated with V16 engines in military applications. The high-decibel output of these engines can disrupt wildlife habitats, interfering with animal communication and behavior patterns. In areas of conflict or military exercises, this noise pollution can have long-lasting effects on local ecosystems and biodiversity.

However, it is important to note that advancements in engine technology have led to improvements in the environmental performance of V16 engines. Modern designs incorporate more efficient combustion processes, advanced emission control systems, and the use of cleaner fuels. Some military organizations have begun exploring alternative fuel sources, such as biodiesel or synthetic fuels, to reduce the environmental footprint of their V16-powered vehicles and vessels.

The military sector has also been investing in research and development of more environmentally friendly propulsion systems, including hybrid and electric technologies. While these alternatives may not yet match the power and reliability of V16 engines in all applications, they represent a growing trend towards reducing the environmental impact of military operations.

In conclusion, while V16 engines have played a crucial role in military applications, their environmental impact has been significant. The challenge moving forward lies in balancing the operational requirements of military forces with the need for environmental stewardship. Continued advancements in engine technology, coupled with a shift towards more sustainable practices, will be essential in mitigating the environmental impact of V16 engines in military use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!