Understanding Digital Twin applications for V16 engine performance tweaking

AUG 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin for V16 Engines: Background and Objectives

Digital Twin technology has emerged as a revolutionary approach in the field of engine performance optimization, particularly for complex systems like V16 engines. This advanced simulation technique creates a virtual replica of physical assets, processes, and systems, enabling real-time monitoring, analysis, and optimization. The concept of Digital Twins originated in the early 2000s, primarily in the aerospace industry, but has since expanded to various sectors, including automotive and heavy machinery.

The evolution of Digital Twin technology for V16 engines is closely tied to advancements in sensor technology, data analytics, and computational power. As these technologies have progressed, the ability to create accurate, real-time digital representations of V16 engines has significantly improved. This progression has allowed for more precise performance tweaking and predictive maintenance, addressing the complex challenges associated with these high-performance engines.

The primary objective of implementing Digital Twin technology for V16 engine performance tweaking is to enhance overall engine efficiency, reliability, and longevity. By creating a virtual model that accurately reflects the physical engine's behavior, engineers can simulate various operating conditions, identify potential issues before they occur, and optimize performance parameters without the need for extensive physical testing.

Another key goal is to reduce development time and costs associated with V16 engine design and optimization. Digital Twins allow for rapid prototyping and testing of new configurations, significantly shortening the development cycle. This capability is particularly valuable for V16 engines, which are often used in specialized applications where customization and fine-tuning are critical.

Furthermore, Digital Twin technology aims to improve maintenance strategies for V16 engines. By continuously monitoring engine performance and comparing it to the digital model, potential failures can be predicted and addressed proactively. This predictive maintenance approach can significantly reduce downtime and extend the operational life of these complex engines.

The implementation of Digital Twin technology for V16 engines also aligns with broader industry trends towards digitalization and Industry 4.0. As such, it represents a crucial step in the modernization of engine manufacturing and maintenance processes, paving the way for more intelligent, data-driven decision-making in engine performance management.

Looking ahead, the continued development of Digital Twin applications for V16 engines is expected to focus on enhancing the accuracy and real-time capabilities of these virtual models. This will likely involve advancements in machine learning algorithms, improved sensor technologies, and more sophisticated data integration techniques. The ultimate goal is to create a seamless interface between the physical and digital realms, enabling unprecedented levels of control and optimization in V16 engine performance.

The evolution of Digital Twin technology for V16 engines is closely tied to advancements in sensor technology, data analytics, and computational power. As these technologies have progressed, the ability to create accurate, real-time digital representations of V16 engines has significantly improved. This progression has allowed for more precise performance tweaking and predictive maintenance, addressing the complex challenges associated with these high-performance engines.

The primary objective of implementing Digital Twin technology for V16 engine performance tweaking is to enhance overall engine efficiency, reliability, and longevity. By creating a virtual model that accurately reflects the physical engine's behavior, engineers can simulate various operating conditions, identify potential issues before they occur, and optimize performance parameters without the need for extensive physical testing.

Another key goal is to reduce development time and costs associated with V16 engine design and optimization. Digital Twins allow for rapid prototyping and testing of new configurations, significantly shortening the development cycle. This capability is particularly valuable for V16 engines, which are often used in specialized applications where customization and fine-tuning are critical.

Furthermore, Digital Twin technology aims to improve maintenance strategies for V16 engines. By continuously monitoring engine performance and comparing it to the digital model, potential failures can be predicted and addressed proactively. This predictive maintenance approach can significantly reduce downtime and extend the operational life of these complex engines.

The implementation of Digital Twin technology for V16 engines also aligns with broader industry trends towards digitalization and Industry 4.0. As such, it represents a crucial step in the modernization of engine manufacturing and maintenance processes, paving the way for more intelligent, data-driven decision-making in engine performance management.

Looking ahead, the continued development of Digital Twin applications for V16 engines is expected to focus on enhancing the accuracy and real-time capabilities of these virtual models. This will likely involve advancements in machine learning algorithms, improved sensor technologies, and more sophisticated data integration techniques. The ultimate goal is to create a seamless interface between the physical and digital realms, enabling unprecedented levels of control and optimization in V16 engine performance.

Market Demand Analysis for Engine Performance Optimization

The market demand for engine performance optimization, particularly in the context of V16 engines and digital twin applications, has been steadily growing in recent years. This demand is driven by several factors, including the need for improved fuel efficiency, reduced emissions, and enhanced overall performance in various industries such as marine, power generation, and heavy machinery.

In the marine sector, large vessels equipped with V16 engines are facing increasing pressure to comply with stringent environmental regulations while maintaining optimal performance. This has led to a surge in demand for advanced optimization techniques, with digital twin technology emerging as a promising solution. The global marine engine market, which includes V16 engines, is projected to reach $13.5 billion by 2026, growing at a CAGR of 3.1% from 2021 to 2026.

The power generation industry is another significant driver of demand for V16 engine performance optimization. As the world transitions towards cleaner energy sources, there is a growing need for more efficient and flexible power generation systems. Digital twin applications in this sector are enabling operators to optimize engine performance, predict maintenance needs, and reduce downtime. The global power generation market is expected to reach $1.7 trillion by 2027, with a substantial portion of this growth attributed to advancements in engine technology and optimization techniques.

In the heavy machinery sector, which includes construction and mining equipment, the demand for V16 engine performance optimization is driven by the need for increased productivity and reduced operational costs. Digital twin applications are being increasingly adopted to simulate and optimize engine performance under various operating conditions. The global construction equipment market, a significant user of V16 engines, is forecasted to reach $205 billion by 2025, growing at a CAGR of 4.3% from 2020 to 2025.

The adoption of digital twin technology for engine performance optimization is also being fueled by the broader trend of Industry 4.0 and the Industrial Internet of Things (IIoT). As more companies embrace digital transformation, the demand for advanced simulation and optimization tools is expected to rise. The global digital twin market is projected to grow from $3.1 billion in 2020 to $48.2 billion by 2026, at a CAGR of 58%.

Furthermore, the increasing focus on predictive maintenance and condition-based monitoring is driving the demand for digital twin applications in engine performance optimization. By leveraging real-time data and advanced analytics, companies can reduce maintenance costs, minimize unplanned downtime, and extend the lifespan of their V16 engines. This trend is particularly evident in industries with high-value assets, such as aerospace and defense, where engine reliability is critical.

In conclusion, the market demand for V16 engine performance optimization using digital twin applications is robust and growing across multiple industries. As companies continue to prioritize efficiency, sustainability, and cost-effectiveness, the adoption of advanced optimization techniques is expected to accelerate, creating significant opportunities for technology providers and engine manufacturers alike.

In the marine sector, large vessels equipped with V16 engines are facing increasing pressure to comply with stringent environmental regulations while maintaining optimal performance. This has led to a surge in demand for advanced optimization techniques, with digital twin technology emerging as a promising solution. The global marine engine market, which includes V16 engines, is projected to reach $13.5 billion by 2026, growing at a CAGR of 3.1% from 2021 to 2026.

The power generation industry is another significant driver of demand for V16 engine performance optimization. As the world transitions towards cleaner energy sources, there is a growing need for more efficient and flexible power generation systems. Digital twin applications in this sector are enabling operators to optimize engine performance, predict maintenance needs, and reduce downtime. The global power generation market is expected to reach $1.7 trillion by 2027, with a substantial portion of this growth attributed to advancements in engine technology and optimization techniques.

In the heavy machinery sector, which includes construction and mining equipment, the demand for V16 engine performance optimization is driven by the need for increased productivity and reduced operational costs. Digital twin applications are being increasingly adopted to simulate and optimize engine performance under various operating conditions. The global construction equipment market, a significant user of V16 engines, is forecasted to reach $205 billion by 2025, growing at a CAGR of 4.3% from 2020 to 2025.

The adoption of digital twin technology for engine performance optimization is also being fueled by the broader trend of Industry 4.0 and the Industrial Internet of Things (IIoT). As more companies embrace digital transformation, the demand for advanced simulation and optimization tools is expected to rise. The global digital twin market is projected to grow from $3.1 billion in 2020 to $48.2 billion by 2026, at a CAGR of 58%.

Furthermore, the increasing focus on predictive maintenance and condition-based monitoring is driving the demand for digital twin applications in engine performance optimization. By leveraging real-time data and advanced analytics, companies can reduce maintenance costs, minimize unplanned downtime, and extend the lifespan of their V16 engines. This trend is particularly evident in industries with high-value assets, such as aerospace and defense, where engine reliability is critical.

In conclusion, the market demand for V16 engine performance optimization using digital twin applications is robust and growing across multiple industries. As companies continue to prioritize efficiency, sustainability, and cost-effectiveness, the adoption of advanced optimization techniques is expected to accelerate, creating significant opportunities for technology providers and engine manufacturers alike.

Current State and Challenges in V16 Engine Digital Twinning

Digital Twin technology for V16 engine performance optimization is currently at a pivotal stage of development, with significant advancements and challenges shaping its trajectory. The current state of this technology reflects a growing integration of sophisticated sensors, real-time data analytics, and advanced simulation models to create highly accurate virtual representations of V16 engines.

One of the primary achievements in this field is the development of high-fidelity sensor networks capable of capturing a wide array of engine parameters in real-time. These sensors monitor everything from temperature and pressure to vibration and fuel consumption, providing a comprehensive data stream for the digital twin. However, the challenge lies in effectively managing and processing this vast amount of data without introducing latency or compromising accuracy.

Machine learning algorithms and artificial intelligence have become integral components in interpreting the sensor data and predicting engine behavior. These technologies enable digital twins to not only mirror current engine states but also forecast potential issues and optimize performance proactively. The integration of AI, however, presents challenges in terms of model training, data quality assurance, and the need for continuous refinement to maintain predictive accuracy.

Another significant advancement is the improvement in simulation capabilities, allowing for more precise modeling of complex engine dynamics. This includes better representation of thermodynamic processes, combustion dynamics, and mechanical interactions within the V16 engine. The challenge here is balancing simulation fidelity with computational efficiency, especially when real-time performance is crucial.

Interoperability and standardization remain ongoing challenges in the field. As different manufacturers and research institutions develop their own digital twin solutions, ensuring seamless integration and data exchange between various systems and platforms becomes increasingly complex. This lack of standardization can hinder widespread adoption and collaboration within the industry.

Cybersecurity is another critical concern in the current state of V16 engine digital twinning. As these systems become more connected and reliant on data exchange, protecting sensitive engine data and preventing unauthorized access to control systems becomes paramount. Developing robust security protocols without compromising system performance is a delicate balance that researchers and engineers continue to navigate.

The geographical distribution of digital twin technology for V16 engines shows concentrations in traditional automotive and engineering hubs, with notable developments in countries like Germany, the United States, and Japan. However, emerging markets, particularly in China and India, are rapidly advancing their capabilities in this domain, potentially shifting the global landscape of expertise and innovation.

In conclusion, while digital twin technology for V16 engine performance tweaking has made significant strides, it faces multifaceted challenges that require ongoing research and development. Addressing these challenges will be crucial for realizing the full potential of digital twins in revolutionizing engine design, maintenance, and optimization processes.

One of the primary achievements in this field is the development of high-fidelity sensor networks capable of capturing a wide array of engine parameters in real-time. These sensors monitor everything from temperature and pressure to vibration and fuel consumption, providing a comprehensive data stream for the digital twin. However, the challenge lies in effectively managing and processing this vast amount of data without introducing latency or compromising accuracy.

Machine learning algorithms and artificial intelligence have become integral components in interpreting the sensor data and predicting engine behavior. These technologies enable digital twins to not only mirror current engine states but also forecast potential issues and optimize performance proactively. The integration of AI, however, presents challenges in terms of model training, data quality assurance, and the need for continuous refinement to maintain predictive accuracy.

Another significant advancement is the improvement in simulation capabilities, allowing for more precise modeling of complex engine dynamics. This includes better representation of thermodynamic processes, combustion dynamics, and mechanical interactions within the V16 engine. The challenge here is balancing simulation fidelity with computational efficiency, especially when real-time performance is crucial.

Interoperability and standardization remain ongoing challenges in the field. As different manufacturers and research institutions develop their own digital twin solutions, ensuring seamless integration and data exchange between various systems and platforms becomes increasingly complex. This lack of standardization can hinder widespread adoption and collaboration within the industry.

Cybersecurity is another critical concern in the current state of V16 engine digital twinning. As these systems become more connected and reliant on data exchange, protecting sensitive engine data and preventing unauthorized access to control systems becomes paramount. Developing robust security protocols without compromising system performance is a delicate balance that researchers and engineers continue to navigate.

The geographical distribution of digital twin technology for V16 engines shows concentrations in traditional automotive and engineering hubs, with notable developments in countries like Germany, the United States, and Japan. However, emerging markets, particularly in China and India, are rapidly advancing their capabilities in this domain, potentially shifting the global landscape of expertise and innovation.

In conclusion, while digital twin technology for V16 engine performance tweaking has made significant strides, it faces multifaceted challenges that require ongoing research and development. Addressing these challenges will be crucial for realizing the full potential of digital twins in revolutionizing engine design, maintenance, and optimization processes.

Existing Digital Twin Solutions for Engine Performance Tuning

01 Digital Twin Performance Optimization

Techniques for optimizing the performance of digital twins, including improving simulation accuracy, reducing computational overhead, and enhancing real-time data processing capabilities. These methods aim to create more efficient and responsive digital representations of physical assets or systems.- Digital Twin Performance Optimization: Techniques for optimizing the performance of digital twins, including improving simulation accuracy, reducing computational overhead, and enhancing real-time data processing capabilities. These methods focus on streamlining the digital twin's ability to mirror physical assets efficiently and effectively.

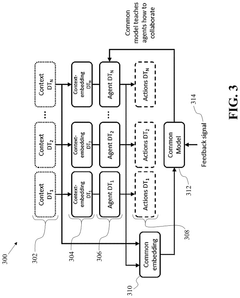

- Integration of AI and Machine Learning in Digital Twins: Incorporation of artificial intelligence and machine learning algorithms to enhance the predictive capabilities and adaptive nature of digital twins. This integration allows for more accurate forecasting, anomaly detection, and autonomous decision-making within the digital twin environment.

- Real-time Data Synchronization and Analysis: Methods for ensuring seamless and real-time synchronization between physical assets and their digital counterparts. This includes advanced data collection, processing, and analysis techniques to maintain an up-to-date and accurate representation of the physical system's state.

- Scalability and Interoperability of Digital Twins: Approaches to enhance the scalability of digital twin systems across multiple assets or entire ecosystems. This also includes improving interoperability between different digital twin platforms and ensuring seamless integration with existing industrial systems and IoT infrastructures.

- Security and Privacy in Digital Twin Environments: Strategies for ensuring data security and privacy in digital twin implementations. This involves developing robust encryption methods, access control mechanisms, and compliance frameworks to protect sensitive information within the digital twin ecosystem.

02 Integration of AI and Machine Learning in Digital Twins

Incorporation of artificial intelligence and machine learning algorithms into digital twin systems to enhance predictive capabilities, automate decision-making processes, and improve overall system performance. This integration allows for more accurate forecasting and adaptive responses to changing conditions.Expand Specific Solutions03 Real-time Data Synchronization and Analysis

Methods for ensuring seamless and efficient synchronization between physical assets and their digital counterparts, as well as techniques for real-time data analysis. These approaches focus on minimizing latency and maximizing the accuracy of the digital representation.Expand Specific Solutions04 Scalability and Interoperability of Digital Twin Systems

Strategies for designing and implementing scalable digital twin architectures that can accommodate growing complexity and data volumes. This includes developing standardized interfaces and protocols to ensure interoperability between different digital twin systems and platforms.Expand Specific Solutions05 Security and Privacy in Digital Twin Environments

Techniques for ensuring the security and privacy of data within digital twin systems, including encryption methods, access control mechanisms, and secure data transmission protocols. These measures aim to protect sensitive information and maintain the integrity of digital twin operations.Expand Specific Solutions

Key Players in Digital Twin and V16 Engine Industries

The digital twin technology for V16 engine performance optimization is in a nascent stage of development, with significant growth potential. The market size is expanding rapidly as industries recognize the value of digital twins in enhancing engine efficiency and reducing operational costs. While the technology is still evolving, several key players are driving innovation. Companies like Siemens AG, Robert Bosch GmbH, and IBM are leveraging their expertise in industrial automation and data analytics to develop sophisticated digital twin solutions. Universities such as Beihang University and Northwestern Polytechnical University are contributing to research and development, bridging the gap between academia and industry. As the technology matures, we can expect increased competition and collaboration among these players, leading to more advanced and integrated digital twin applications for V16 engine optimization.

Cummins Power Generation Ltd.

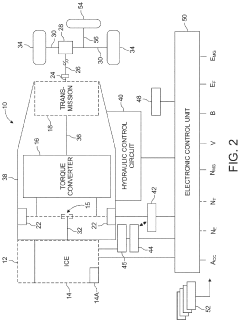

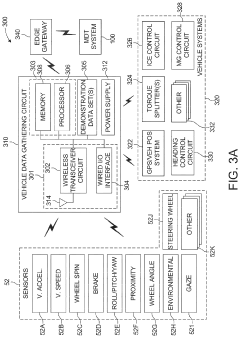

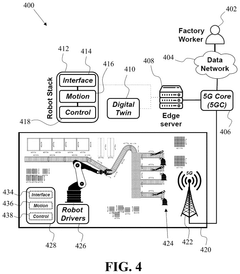

Technical Solution: Cummins has developed a comprehensive Digital Twin application for V16 engine performance optimization. Their approach integrates real-time sensor data, advanced simulation models, and machine learning algorithms to create a highly accurate virtual representation of the V16 engine[1]. This digital twin continuously monitors and analyzes engine performance, predicting potential issues and suggesting optimal operating parameters. The system utilizes a combination of physics-based models and data-driven analytics to simulate various operating conditions, allowing engineers to fine-tune engine parameters without physical testing[3]. Cummins' digital twin also incorporates predictive maintenance capabilities, using historical data and real-time monitoring to forecast component wear and schedule maintenance proactively[5].

Strengths: Extensive experience with large engines, robust data analytics capabilities, and integration with existing engine management systems. Weaknesses: May require significant computational resources for real-time simulation of complex V16 engines.

Robert Bosch GmbH

Technical Solution: Bosch has implemented a sophisticated Digital Twin solution for V16 engine performance optimization. Their approach combines high-fidelity 3D modeling with real-time data acquisition and advanced control algorithms[2]. The digital twin creates a virtual replica of the V16 engine, incorporating detailed component geometries and material properties. Bosch's system utilizes a network of smart sensors to collect real-time data on various engine parameters, including temperature, pressure, and vibration[4]. This data is then fed into the digital twin, which uses machine learning algorithms to analyze performance trends and identify optimization opportunities. The system also employs predictive modeling to simulate the effects of different tuning parameters on engine performance, emissions, and fuel efficiency[6].

Strengths: Extensive sensor technology expertise, strong integration with automotive systems, and advanced machine learning capabilities. Weaknesses: May face challenges in scaling the solution for very large or specialized V16 engines.

Core Innovations in V16 Engine Digital Twin Technology

Systems and methods for active road surface maintenance with cloud-based mobility digital twin

PatentPendingUS20240166230A1

Innovation

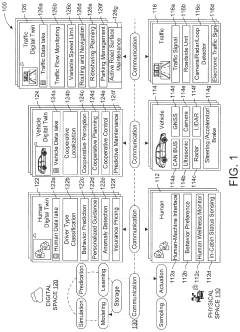

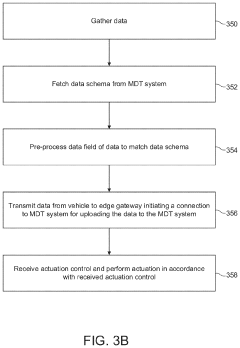

- The implementation of a Mobility Digital Twin (MDT) framework that uses advanced sensing technology to collect data from humans, vehicles, and infrastructure, applying machine learning to assess and predict road conditions, and providing guidance to connected vehicles to avoid excessive loads on deteriorating road surfaces, thereby enabling proactive maintenance.

Energy consumption optimization in digital twin applications

PatentPendingUS20240319774A1

Innovation

- A computer-implemented method that receives input metrics from digital twins, determines updated configurations including radio, computing, and digital twin configurations to reduce power consumption, and provides these configurations through APIs, leveraging delay budgets to optimize energy use and resource allocation.

Environmental Impact of Digital Twin-Optimized V16 Engines

The implementation of Digital Twin technology for optimizing V16 engine performance has significant environmental implications. By creating a virtual replica of the physical engine, engineers can simulate and analyze various operational scenarios, leading to more efficient and environmentally friendly engine designs. This approach allows for the fine-tuning of engine parameters without the need for extensive physical testing, reducing material waste and energy consumption associated with traditional development processes.

Digital Twin-optimized V16 engines can potentially achieve substantial reductions in fuel consumption and emissions. Through continuous monitoring and real-time data analysis, the Digital Twin can identify areas for improvement in engine efficiency, such as optimizing combustion timing, fuel injection patterns, and exhaust gas recirculation. These optimizations can lead to lower carbon dioxide emissions and reduced particulate matter, contributing to improved air quality and decreased environmental impact.

Furthermore, the use of Digital Twin technology enables predictive maintenance strategies, which can extend the lifespan of V16 engines and reduce the need for premature replacements. By accurately predicting component wear and potential failures, maintenance can be scheduled proactively, minimizing downtime and reducing the environmental footprint associated with manufacturing replacement parts and disposing of worn components.

The environmental benefits of Digital Twin-optimized V16 engines extend beyond direct emissions reductions. By improving overall engine efficiency, these optimizations can lead to decreased fuel consumption, which in turn reduces the environmental impact of fuel production and transportation. Additionally, the ability to simulate various fuel types and blends virtually allows for the exploration of alternative and renewable fuel sources without the need for extensive physical testing, potentially accelerating the transition to more sustainable energy solutions.

However, it is important to consider the environmental impact of the digital infrastructure required to support Digital Twin technology. The increased demand for data centers and computing power to process and analyze the vast amounts of data generated by Digital Twins may lead to higher energy consumption and associated carbon emissions. Balancing these factors against the environmental benefits achieved through engine optimization is crucial for a comprehensive assessment of the technology's overall environmental impact.

Digital Twin-optimized V16 engines can potentially achieve substantial reductions in fuel consumption and emissions. Through continuous monitoring and real-time data analysis, the Digital Twin can identify areas for improvement in engine efficiency, such as optimizing combustion timing, fuel injection patterns, and exhaust gas recirculation. These optimizations can lead to lower carbon dioxide emissions and reduced particulate matter, contributing to improved air quality and decreased environmental impact.

Furthermore, the use of Digital Twin technology enables predictive maintenance strategies, which can extend the lifespan of V16 engines and reduce the need for premature replacements. By accurately predicting component wear and potential failures, maintenance can be scheduled proactively, minimizing downtime and reducing the environmental footprint associated with manufacturing replacement parts and disposing of worn components.

The environmental benefits of Digital Twin-optimized V16 engines extend beyond direct emissions reductions. By improving overall engine efficiency, these optimizations can lead to decreased fuel consumption, which in turn reduces the environmental impact of fuel production and transportation. Additionally, the ability to simulate various fuel types and blends virtually allows for the exploration of alternative and renewable fuel sources without the need for extensive physical testing, potentially accelerating the transition to more sustainable energy solutions.

However, it is important to consider the environmental impact of the digital infrastructure required to support Digital Twin technology. The increased demand for data centers and computing power to process and analyze the vast amounts of data generated by Digital Twins may lead to higher energy consumption and associated carbon emissions. Balancing these factors against the environmental benefits achieved through engine optimization is crucial for a comprehensive assessment of the technology's overall environmental impact.

Data Security in Engine Performance Digital Twins

Data security is a critical concern in the implementation of digital twins for V16 engine performance optimization. As these virtual replicas collect, process, and analyze vast amounts of sensitive engine data, protecting this information from unauthorized access, manipulation, or theft becomes paramount. Engine manufacturers and operators must implement robust security measures to safeguard proprietary performance data, operational parameters, and intellectual property associated with their V16 engines.

One of the primary security challenges in engine performance digital twins is ensuring data integrity throughout the entire lifecycle of the digital twin. This includes securing data during collection from physical sensors, transmission to the digital twin platform, processing within the virtual environment, and storage in databases. Encryption techniques, such as end-to-end encryption and secure socket layer (SSL) protocols, are essential for protecting data in transit and at rest.

Access control mechanisms play a crucial role in maintaining the confidentiality of engine performance data. Implementing multi-factor authentication, role-based access control (RBAC), and least privilege principles helps ensure that only authorized personnel can view, modify, or analyze sensitive engine data within the digital twin environment. Regular audits and access logs should be maintained to track user activities and detect any suspicious behavior.

Another significant aspect of data security in engine performance digital twins is the protection against cyber threats and attacks. As these systems are often connected to broader industrial networks or the internet for remote monitoring and analysis, they become potential targets for malicious actors. Implementing robust firewalls, intrusion detection systems, and regular security patches is essential to mitigate the risk of cyber attacks that could compromise engine data or disrupt operations.

Data privacy regulations, such as the General Data Protection Regulation (GDPR) and industry-specific standards, must also be considered when implementing digital twins for V16 engine performance optimization. Ensuring compliance with these regulations requires careful management of personal data, consent mechanisms, and data retention policies. Anonymization and pseudonymization techniques may be employed to protect individual privacy while still allowing for meaningful analysis of engine performance data.

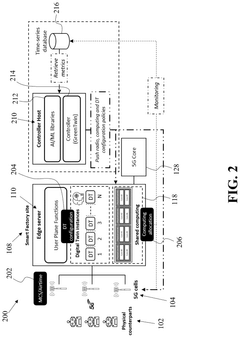

As digital twins increasingly leverage cloud computing and edge computing technologies for enhanced processing capabilities, additional security considerations arise. Secure cloud configurations, data residency requirements, and proper isolation of virtual environments become critical factors in maintaining the overall security posture of the digital twin ecosystem. Regular security assessments and penetration testing should be conducted to identify and address potential vulnerabilities in the system architecture.

One of the primary security challenges in engine performance digital twins is ensuring data integrity throughout the entire lifecycle of the digital twin. This includes securing data during collection from physical sensors, transmission to the digital twin platform, processing within the virtual environment, and storage in databases. Encryption techniques, such as end-to-end encryption and secure socket layer (SSL) protocols, are essential for protecting data in transit and at rest.

Access control mechanisms play a crucial role in maintaining the confidentiality of engine performance data. Implementing multi-factor authentication, role-based access control (RBAC), and least privilege principles helps ensure that only authorized personnel can view, modify, or analyze sensitive engine data within the digital twin environment. Regular audits and access logs should be maintained to track user activities and detect any suspicious behavior.

Another significant aspect of data security in engine performance digital twins is the protection against cyber threats and attacks. As these systems are often connected to broader industrial networks or the internet for remote monitoring and analysis, they become potential targets for malicious actors. Implementing robust firewalls, intrusion detection systems, and regular security patches is essential to mitigate the risk of cyber attacks that could compromise engine data or disrupt operations.

Data privacy regulations, such as the General Data Protection Regulation (GDPR) and industry-specific standards, must also be considered when implementing digital twins for V16 engine performance optimization. Ensuring compliance with these regulations requires careful management of personal data, consent mechanisms, and data retention policies. Anonymization and pseudonymization techniques may be employed to protect individual privacy while still allowing for meaningful analysis of engine performance data.

As digital twins increasingly leverage cloud computing and edge computing technologies for enhanced processing capabilities, additional security considerations arise. Secure cloud configurations, data residency requirements, and proper isolation of virtual environments become critical factors in maintaining the overall security posture of the digital twin ecosystem. Regular security assessments and penetration testing should be conducted to identify and address potential vulnerabilities in the system architecture.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!