Fuel efficiency and emissions: the environmental impact of V16 engine technology

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance aircraft, the V16 configuration represented the pinnacle of engineering prowess and prestige. The first notable V16 engine was introduced by Cadillac in 1930, setting a new standard for power and smoothness in automotive applications.

Throughout the 1930s and 1940s, V16 engines found their way into various high-end vehicles, including those produced by Marmon, Peerless, and Cadillac. These engines were characterized by their impressive displacement, often exceeding 7 liters, and their ability to produce substantial power while maintaining smooth operation. The unique configuration of 16 cylinders arranged in a V-shape allowed for excellent balance and reduced vibration, qualities highly prized in luxury automobiles of the era.

The post-World War II period saw a decline in V16 engine production for passenger vehicles, as more efficient and compact engine designs gained popularity. However, the concept found new life in marine and industrial applications, where the demand for high power output and reliability remained strong. In these sectors, V16 engines continued to evolve, incorporating advancements in materials science and combustion technology.

The late 20th century witnessed a resurgence of interest in V16 engines for automotive use, particularly in concept cars and limited-production supercars. Manufacturers such as BMW and Cadillac explored the potential of modern V16 designs, leveraging advanced electronic engine management systems and lightweight materials to address historical challenges of fuel efficiency and emissions.

In recent years, the focus on environmental impact has significantly influenced V16 engine development. Engineers have been tasked with balancing the inherent power and prestige of the V16 configuration with increasingly stringent emissions regulations and fuel efficiency requirements. This has led to innovations in areas such as direct fuel injection, variable valve timing, and cylinder deactivation technologies, all aimed at improving the environmental performance of these large-displacement engines.

The evolution of V16 engine technology has also seen advancements in thermal management and lubrication systems, crucial for maintaining efficiency and longevity in high-output applications. Additionally, the integration of hybrid and electric assist technologies has emerged as a potential pathway for preserving the V16 configuration while meeting modern environmental standards.

As we move further into the 21st century, the future of V16 engines remains uncertain. While their historical significance and engineering appeal are undeniable, the automotive industry's shift towards electrification and sustainable propulsion systems poses significant challenges to the continued development and application of V16 technology in mainstream vehicles.

Throughout the 1930s and 1940s, V16 engines found their way into various high-end vehicles, including those produced by Marmon, Peerless, and Cadillac. These engines were characterized by their impressive displacement, often exceeding 7 liters, and their ability to produce substantial power while maintaining smooth operation. The unique configuration of 16 cylinders arranged in a V-shape allowed for excellent balance and reduced vibration, qualities highly prized in luxury automobiles of the era.

The post-World War II period saw a decline in V16 engine production for passenger vehicles, as more efficient and compact engine designs gained popularity. However, the concept found new life in marine and industrial applications, where the demand for high power output and reliability remained strong. In these sectors, V16 engines continued to evolve, incorporating advancements in materials science and combustion technology.

The late 20th century witnessed a resurgence of interest in V16 engines for automotive use, particularly in concept cars and limited-production supercars. Manufacturers such as BMW and Cadillac explored the potential of modern V16 designs, leveraging advanced electronic engine management systems and lightweight materials to address historical challenges of fuel efficiency and emissions.

In recent years, the focus on environmental impact has significantly influenced V16 engine development. Engineers have been tasked with balancing the inherent power and prestige of the V16 configuration with increasingly stringent emissions regulations and fuel efficiency requirements. This has led to innovations in areas such as direct fuel injection, variable valve timing, and cylinder deactivation technologies, all aimed at improving the environmental performance of these large-displacement engines.

The evolution of V16 engine technology has also seen advancements in thermal management and lubrication systems, crucial for maintaining efficiency and longevity in high-output applications. Additionally, the integration of hybrid and electric assist technologies has emerged as a potential pathway for preserving the V16 configuration while meeting modern environmental standards.

As we move further into the 21st century, the future of V16 engines remains uncertain. While their historical significance and engineering appeal are undeniable, the automotive industry's shift towards electrification and sustainable propulsion systems poses significant challenges to the continued development and application of V16 technology in mainstream vehicles.

Market Demand Analysis

The market demand for V16 engine technology has been steadily declining in recent years, primarily due to increasing environmental concerns and stricter emissions regulations worldwide. This shift in market dynamics is driven by a growing awareness of climate change and the need for more sustainable transportation solutions.

In the automotive sector, there is a clear trend towards downsizing engines and improving fuel efficiency. Consumers are increasingly prioritizing vehicles with lower fuel consumption and reduced carbon footprints. This has led to a significant decrease in demand for large displacement engines, including V16 configurations, which are known for their high fuel consumption and emissions.

The luxury and high-performance vehicle segments, traditionally the primary markets for V16 engines, are also experiencing a transformation. Many luxury automakers are transitioning towards hybrid and electric powertrains to meet both customer expectations and regulatory requirements. This shift has further reduced the market potential for V16 engines.

Commercial applications of V16 engines, such as in marine vessels and industrial equipment, are also facing challenges. The maritime industry, in particular, is under pressure to reduce emissions, leading to a preference for more efficient propulsion systems. This trend is likely to continue as international maritime regulations become more stringent.

Despite the overall decline, there remains a niche market for V16 engines in ultra-luxury and collector vehicles. However, this segment is extremely limited and does not represent a significant market opportunity for large-scale production.

The aerospace industry, another potential market for high-power engines, is similarly moving towards more fuel-efficient and environmentally friendly solutions. This further narrows the potential applications for V16 engine technology.

Looking at market projections, the global demand for large displacement engines is expected to continue its downward trajectory. This decline is particularly pronounced in developed markets with strict emissions standards, such as Europe and North America. Emerging markets, which previously showed potential for growth in high-performance engines, are now leapfrogging to more advanced, cleaner technologies.

The shift in market demand is also reflected in research and development investments. Major engine manufacturers are allocating more resources to alternative propulsion technologies, such as electric motors, fuel cells, and advanced hybrid systems, rather than further developing large combustion engines like the V16.

In conclusion, the market demand analysis for V16 engine technology reveals a challenging landscape. The combination of environmental concerns, regulatory pressures, and changing consumer preferences has significantly reduced the market potential for these engines. While a small niche market may persist, the overall trend suggests a continued decline in demand for V16 engines across most sectors.

In the automotive sector, there is a clear trend towards downsizing engines and improving fuel efficiency. Consumers are increasingly prioritizing vehicles with lower fuel consumption and reduced carbon footprints. This has led to a significant decrease in demand for large displacement engines, including V16 configurations, which are known for their high fuel consumption and emissions.

The luxury and high-performance vehicle segments, traditionally the primary markets for V16 engines, are also experiencing a transformation. Many luxury automakers are transitioning towards hybrid and electric powertrains to meet both customer expectations and regulatory requirements. This shift has further reduced the market potential for V16 engines.

Commercial applications of V16 engines, such as in marine vessels and industrial equipment, are also facing challenges. The maritime industry, in particular, is under pressure to reduce emissions, leading to a preference for more efficient propulsion systems. This trend is likely to continue as international maritime regulations become more stringent.

Despite the overall decline, there remains a niche market for V16 engines in ultra-luxury and collector vehicles. However, this segment is extremely limited and does not represent a significant market opportunity for large-scale production.

The aerospace industry, another potential market for high-power engines, is similarly moving towards more fuel-efficient and environmentally friendly solutions. This further narrows the potential applications for V16 engine technology.

Looking at market projections, the global demand for large displacement engines is expected to continue its downward trajectory. This decline is particularly pronounced in developed markets with strict emissions standards, such as Europe and North America. Emerging markets, which previously showed potential for growth in high-performance engines, are now leapfrogging to more advanced, cleaner technologies.

The shift in market demand is also reflected in research and development investments. Major engine manufacturers are allocating more resources to alternative propulsion technologies, such as electric motors, fuel cells, and advanced hybrid systems, rather than further developing large combustion engines like the V16.

In conclusion, the market demand analysis for V16 engine technology reveals a challenging landscape. The combination of environmental concerns, regulatory pressures, and changing consumer preferences has significantly reduced the market potential for these engines. While a small niche market may persist, the overall trend suggests a continued decline in demand for V16 engines across most sectors.

Technical Challenges

The development of V16 engine technology faces significant technical challenges, particularly in the areas of fuel efficiency and emissions reduction. One of the primary obstacles is the inherent inefficiency of large displacement engines. V16 engines, with their massive size and high cylinder count, consume substantial amounts of fuel, making it difficult to meet increasingly stringent fuel economy standards imposed by regulatory bodies worldwide.

Emissions control presents another major hurdle for V16 engines. The sheer volume of exhaust gases produced by these powerplants requires advanced aftertreatment systems to meet current and future emissions regulations. Developing catalytic converters and particulate filters capable of effectively treating the exhaust from 16 cylinders without creating excessive back pressure is a complex engineering task.

Thermal management is a critical challenge in V16 engine design. The large number of cylinders generates significant heat, which must be efficiently dissipated to maintain optimal performance and prevent component degradation. Designing cooling systems that can adequately manage heat across such a large engine block while minimizing parasitic losses is a formidable task for engineers.

Weight reduction is another key technical challenge. V16 engines are inherently heavy due to their size and complexity, which negatively impacts overall vehicle efficiency. Manufacturers must explore advanced materials and innovative design techniques to reduce engine weight without compromising structural integrity or performance.

The complexity of V16 engines also poses challenges in terms of manufacturing and maintenance. The high part count and intricate assembly processes increase production costs and potential points of failure. Developing streamlined manufacturing techniques and ensuring long-term reliability are crucial for the viability of V16 technology in modern vehicles.

Balancing performance with environmental concerns is perhaps the most significant challenge facing V16 engine technology. While these engines are capable of producing immense power and torque, reconciling this performance with the need for improved fuel efficiency and reduced emissions requires cutting-edge engineering solutions. Technologies such as variable valve timing, direct injection, and cylinder deactivation must be optimized for the unique characteristics of V16 configurations.

Lastly, the integration of electrification presents both opportunities and challenges for V16 engine technology. Hybrid systems could potentially offset some of the efficiency losses inherent to large displacement engines, but integrating electric motors and battery systems with such massive powerplants introduces new complexities in packaging, weight distribution, and power management.

Emissions control presents another major hurdle for V16 engines. The sheer volume of exhaust gases produced by these powerplants requires advanced aftertreatment systems to meet current and future emissions regulations. Developing catalytic converters and particulate filters capable of effectively treating the exhaust from 16 cylinders without creating excessive back pressure is a complex engineering task.

Thermal management is a critical challenge in V16 engine design. The large number of cylinders generates significant heat, which must be efficiently dissipated to maintain optimal performance and prevent component degradation. Designing cooling systems that can adequately manage heat across such a large engine block while minimizing parasitic losses is a formidable task for engineers.

Weight reduction is another key technical challenge. V16 engines are inherently heavy due to their size and complexity, which negatively impacts overall vehicle efficiency. Manufacturers must explore advanced materials and innovative design techniques to reduce engine weight without compromising structural integrity or performance.

The complexity of V16 engines also poses challenges in terms of manufacturing and maintenance. The high part count and intricate assembly processes increase production costs and potential points of failure. Developing streamlined manufacturing techniques and ensuring long-term reliability are crucial for the viability of V16 technology in modern vehicles.

Balancing performance with environmental concerns is perhaps the most significant challenge facing V16 engine technology. While these engines are capable of producing immense power and torque, reconciling this performance with the need for improved fuel efficiency and reduced emissions requires cutting-edge engineering solutions. Technologies such as variable valve timing, direct injection, and cylinder deactivation must be optimized for the unique characteristics of V16 configurations.

Lastly, the integration of electrification presents both opportunities and challenges for V16 engine technology. Hybrid systems could potentially offset some of the efficiency losses inherent to large displacement engines, but integrating electric motors and battery systems with such massive powerplants introduces new complexities in packaging, weight distribution, and power management.

Current Efficiency Solutions

01 Fuel injection and combustion optimization

Advanced fuel injection systems and combustion optimization techniques are employed in V16 engines to improve fuel efficiency and reduce emissions. These include precise fuel metering, multiple injection events per cycle, and optimized combustion chamber designs to ensure more complete fuel burning.- Fuel injection and combustion optimization: Advanced fuel injection systems and combustion optimization techniques are employed in V16 engines to improve fuel efficiency and reduce emissions. These technologies include direct injection, variable valve timing, and precise fuel metering to ensure optimal air-fuel mixture and combustion process.

- Exhaust gas recirculation and aftertreatment: V16 engines utilize exhaust gas recirculation (EGR) systems and advanced aftertreatment technologies to reduce emissions. These may include selective catalytic reduction (SCR), diesel particulate filters (DPF), and oxidation catalysts to minimize harmful pollutants in the exhaust.

- Turbocharging and supercharging: Forced induction systems such as turbochargers and superchargers are implemented in V16 engines to increase power output while maintaining or improving fuel efficiency. These systems help to optimize air intake and combustion, resulting in better overall engine performance.

- Engine management and control systems: Advanced electronic control units (ECUs) and engine management systems are used to optimize V16 engine performance, fuel efficiency, and emissions. These systems continuously monitor and adjust various engine parameters in real-time to ensure optimal operation under different conditions.

- Lightweight materials and design optimization: The use of lightweight materials and optimized engine designs helps to reduce the overall weight of V16 engines, improving fuel efficiency and performance. Advanced manufacturing techniques and computer-aided design are employed to create more efficient engine components and structures.

02 Exhaust gas recirculation (EGR) systems

EGR systems are implemented in V16 engines to reduce NOx emissions by recirculating a portion of the exhaust gas back into the combustion chamber. This lowers combustion temperatures and helps meet stringent emission standards while maintaining engine performance.Expand Specific Solutions03 Variable valve timing and lift

V16 engines incorporate variable valve timing and lift mechanisms to optimize engine breathing across different operating conditions. This technology allows for improved fuel efficiency and reduced emissions by adjusting valve operation based on engine speed and load.Expand Specific Solutions04 Turbocharging and supercharging

Forced induction systems such as turbochargers and superchargers are used in V16 engines to increase power output while improving fuel efficiency. These systems allow for engine downsizing and optimize air-fuel mixture, resulting in better combustion and reduced emissions.Expand Specific Solutions05 Engine management and control systems

Advanced engine management systems and electronic control units (ECUs) are employed in V16 engines to continuously monitor and adjust engine parameters. These systems optimize fuel injection, ignition timing, and other variables in real-time to maximize efficiency and minimize emissions across various operating conditions.Expand Specific Solutions

Key Industry Players

The V16 engine technology market is in a mature stage, with a relatively small but stable market size due to its niche applications in luxury and high-performance vehicles. The technology's maturity is evident from the involvement of established automotive giants like Toyota, General Electric, and Rolls-Royce Solutions GmbH, who have extensive experience in engine development. However, environmental concerns are driving innovation in fuel efficiency and emissions reduction. Research institutions such as the University of Iowa Research Foundation and Tianjin University are likely contributing to advancements in this area. The competitive landscape is characterized by a mix of traditional automakers, specialized engine manufacturers, and research institutions working on improving V16 technology while addressing environmental challenges.

Rolls-Royce Solutions GmbH

Technical Solution: Rolls-Royce Solutions GmbH has developed advanced V16 engine technology focusing on fuel efficiency and emissions reduction. Their approach includes implementing a high-pressure common rail fuel injection system, which allows for precise control of fuel delivery and combustion timing[1]. This system, combined with advanced turbocharging and intercooling, optimizes air-fuel mixture for more complete combustion. They have also integrated exhaust gas recirculation (EGR) technology to reduce NOx emissions by lowering combustion temperatures[2]. Additionally, Rolls-Royce has implemented a sophisticated engine management system that continuously adjusts operating parameters based on load and environmental conditions, further enhancing efficiency and reducing emissions[3].

Strengths: High power output with improved fuel efficiency, significant reduction in emissions, adaptability to various operating conditions. Weaknesses: Complex system requiring specialized maintenance, potentially higher initial cost compared to simpler engine designs.

Weichai Power

Technical Solution: Weichai Power has made significant strides in V16 engine technology, focusing on both fuel efficiency and emissions reduction. They have developed a high-pressure common rail fuel injection system capable of injection pressures up to 2,500 bar, enabling finer fuel atomization and more complete combustion[10]. Weichai's V16 engines feature a two-stage turbocharging system with intercooling, optimizing air intake across a wide range of operating conditions. To address emissions, they have implemented a Diesel Oxidation Catalyst (DOC) combined with Selective Catalytic Reduction (SCR) and a Diesel Particulate Filter (DPF), significantly reducing both NOx and particulate matter emissions[11]. Weichai has also integrated an advanced engine control unit (ECU) that uses real-time data to optimize engine performance and emissions control.

Strengths: High-efficiency combustion system, comprehensive emissions control technology, adaptability to various fuel types including natural gas. Weaknesses: Potential for increased complexity in maintenance and repair, higher initial cost compared to simpler engine designs.

Emissions Reduction Tech

Engine efficiency enhancement and pollution reduction system

PatentInactiveIN201811020390A

Innovation

- A compact ion generator system powered by variable DC voltage, using an array of metallic plates and a magnet module to dissociate water into hydrogen and oxygen ions, which are then fed into the engine's air intake manifold, promoting efficient combustion and reducing emissions.

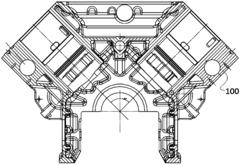

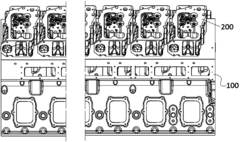

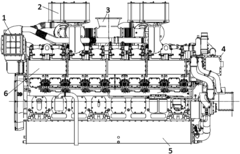

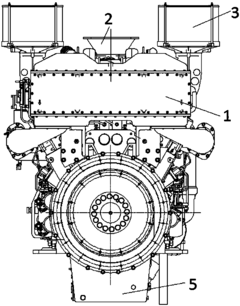

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of V16 engine technology, particularly concerning fuel efficiency and emissions. These regulations have become increasingly stringent over the years, reflecting growing global concerns about climate change and air quality.

In the United States, the Environmental Protection Agency (EPA) sets standards for vehicle emissions and fuel economy. The Corporate Average Fuel Economy (CAFE) standards, first enacted in 1975, have been progressively tightened to push manufacturers towards more fuel-efficient vehicles. For V16 engines, which are typically found in high-performance luxury vehicles, meeting these standards presents a significant challenge due to their inherently high fuel consumption.

The European Union has implemented similar regulations through its Euro emissions standards. These standards, currently at Euro 6 for passenger cars, set limits on various pollutants including carbon monoxide, nitrogen oxides, and particulate matter. The EU has also set targets for fleet-wide average CO2 emissions, which directly impact the viability of V16 engines in the European market.

China, now the world's largest automotive market, has also introduced strict emissions standards modeled after European regulations. The China 6 standard, implemented in 2020, is one of the most stringent in the world, putting pressure on manufacturers to improve the environmental performance of all engine types, including V16s.

Many countries have announced plans to phase out internal combustion engines entirely in favor of electric vehicles. For instance, the UK plans to ban the sale of new petrol and diesel cars by 2030, with hybrid vehicles following in 2035. Such policies create an uncertain future for V16 engines and other high-performance internal combustion technologies.

To comply with these regulations, manufacturers employing V16 engines have had to invest heavily in technologies such as direct injection, variable valve timing, and cylinder deactivation. Some have also explored hybridization as a means to improve overall vehicle efficiency while retaining the power and prestige associated with V16 engines.

The impact of these regulations on V16 engine technology is twofold. On one hand, they have spurred innovation in engine design and efficiency improvements. On the other, they have significantly increased the cost and complexity of developing and producing V16 engines, potentially limiting their market viability in the long term.

In the United States, the Environmental Protection Agency (EPA) sets standards for vehicle emissions and fuel economy. The Corporate Average Fuel Economy (CAFE) standards, first enacted in 1975, have been progressively tightened to push manufacturers towards more fuel-efficient vehicles. For V16 engines, which are typically found in high-performance luxury vehicles, meeting these standards presents a significant challenge due to their inherently high fuel consumption.

The European Union has implemented similar regulations through its Euro emissions standards. These standards, currently at Euro 6 for passenger cars, set limits on various pollutants including carbon monoxide, nitrogen oxides, and particulate matter. The EU has also set targets for fleet-wide average CO2 emissions, which directly impact the viability of V16 engines in the European market.

China, now the world's largest automotive market, has also introduced strict emissions standards modeled after European regulations. The China 6 standard, implemented in 2020, is one of the most stringent in the world, putting pressure on manufacturers to improve the environmental performance of all engine types, including V16s.

Many countries have announced plans to phase out internal combustion engines entirely in favor of electric vehicles. For instance, the UK plans to ban the sale of new petrol and diesel cars by 2030, with hybrid vehicles following in 2035. Such policies create an uncertain future for V16 engines and other high-performance internal combustion technologies.

To comply with these regulations, manufacturers employing V16 engines have had to invest heavily in technologies such as direct injection, variable valve timing, and cylinder deactivation. Some have also explored hybridization as a means to improve overall vehicle efficiency while retaining the power and prestige associated with V16 engines.

The impact of these regulations on V16 engine technology is twofold. On one hand, they have spurred innovation in engine design and efficiency improvements. On the other, they have significantly increased the cost and complexity of developing and producing V16 engines, potentially limiting their market viability in the long term.

Sustainable Alternatives

As the environmental impact of traditional combustion engines becomes increasingly concerning, the automotive industry is exploring sustainable alternatives to V16 engine technology. These alternatives aim to address the fuel efficiency and emissions challenges associated with high-performance engines while maintaining or improving vehicle performance.

Electric powertrains have emerged as a leading sustainable alternative to V16 engines. Battery electric vehicles (BEVs) offer zero tailpipe emissions and significantly higher energy efficiency compared to internal combustion engines. Advanced electric motor technologies, coupled with high-capacity lithium-ion batteries, can deliver comparable or superior performance to V16 engines while drastically reducing environmental impact.

Hydrogen fuel cell technology presents another promising avenue for sustainable high-performance vehicles. Fuel cell electric vehicles (FCEVs) combine the zero-emission benefits of electric vehicles with the quick refueling capabilities of conventional engines. This technology could potentially offer the power output required for luxury and high-performance applications traditionally served by V16 engines.

Hybrid powertrains represent a transitional solution, combining internal combustion engines with electric motors. Plug-in hybrid electric vehicles (PHEVs) with smaller, more efficient combustion engines paired with electric motors can provide substantial improvements in fuel efficiency and emissions reduction while maintaining high performance levels.

Advanced biofuels and synthetic fuels are being developed as drop-in replacements for conventional fossil fuels. These sustainable fuel alternatives can potentially power modified V16 engines or other high-performance internal combustion engines with significantly lower carbon footprints.

Lightweight materials and advanced aerodynamics are complementary technologies that can enhance the efficiency of alternative powertrains. The use of carbon fiber composites, advanced alloys, and optimized vehicle designs can reduce overall vehicle weight and improve energy efficiency, regardless of the propulsion system employed.

As the automotive industry continues to innovate, the integration of artificial intelligence and advanced control systems in these sustainable alternatives is expected to further optimize energy management and performance. This holistic approach to vehicle design and propulsion technology aims to create high-performance vehicles that meet stringent environmental standards without compromising on the power and prestige associated with V16 engines.

Electric powertrains have emerged as a leading sustainable alternative to V16 engines. Battery electric vehicles (BEVs) offer zero tailpipe emissions and significantly higher energy efficiency compared to internal combustion engines. Advanced electric motor technologies, coupled with high-capacity lithium-ion batteries, can deliver comparable or superior performance to V16 engines while drastically reducing environmental impact.

Hydrogen fuel cell technology presents another promising avenue for sustainable high-performance vehicles. Fuel cell electric vehicles (FCEVs) combine the zero-emission benefits of electric vehicles with the quick refueling capabilities of conventional engines. This technology could potentially offer the power output required for luxury and high-performance applications traditionally served by V16 engines.

Hybrid powertrains represent a transitional solution, combining internal combustion engines with electric motors. Plug-in hybrid electric vehicles (PHEVs) with smaller, more efficient combustion engines paired with electric motors can provide substantial improvements in fuel efficiency and emissions reduction while maintaining high performance levels.

Advanced biofuels and synthetic fuels are being developed as drop-in replacements for conventional fossil fuels. These sustainable fuel alternatives can potentially power modified V16 engines or other high-performance internal combustion engines with significantly lower carbon footprints.

Lightweight materials and advanced aerodynamics are complementary technologies that can enhance the efficiency of alternative powertrains. The use of carbon fiber composites, advanced alloys, and optimized vehicle designs can reduce overall vehicle weight and improve energy efficiency, regardless of the propulsion system employed.

As the automotive industry continues to innovate, the integration of artificial intelligence and advanced control systems in these sustainable alternatives is expected to further optimize energy management and performance. This holistic approach to vehicle design and propulsion technology aims to create high-performance vehicles that meet stringent environmental standards without compromising on the power and prestige associated with V16 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!