Mechanistic insights into V16 engine belt-driven systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Belt Systems: Background and Objectives

The V16 engine, a marvel of automotive engineering, has a rich history dating back to the early 20th century. This powerful and complex engine configuration has been utilized in various high-performance vehicles, luxury automobiles, and even aircraft. The belt-driven systems in V16 engines play a crucial role in their operation, ensuring the synchronization of multiple components and the efficient transfer of power.

The development of V16 engine belt systems has been driven by the need for increased power output, improved fuel efficiency, and enhanced reliability. Over the years, engineers have continuously refined these systems to meet the evolving demands of the automotive industry. The primary objective of studying V16 engine belt-driven systems is to gain a comprehensive understanding of their mechanical principles, performance characteristics, and potential areas for improvement.

One of the key aspects of V16 engine belt systems is their complexity. With 16 cylinders arranged in a V-configuration, these engines require intricate belt-driven mechanisms to coordinate the movement of various components, including camshafts, water pumps, alternators, and other auxiliary systems. The design and optimization of these belt systems present unique challenges that demand innovative solutions.

The evolution of materials science has played a significant role in advancing V16 engine belt technology. Modern belt materials, such as high-strength polymers and reinforced composites, have greatly enhanced the durability and performance of these systems. These advancements have allowed for increased power transmission capabilities while reducing overall weight and improving fuel efficiency.

Another critical factor in the development of V16 engine belt systems is the integration of advanced control mechanisms. Electronic control units (ECUs) and sensors have been incorporated to monitor belt tension, temperature, and wear, enabling real-time adjustments and predictive maintenance. This integration of smart technologies has significantly improved the reliability and longevity of V16 engine belt systems.

The study of V16 engine belt-driven systems also aims to address specific technical challenges, such as minimizing vibration, reducing noise, and optimizing power distribution across the engine's components. Engineers focus on developing innovative belt tensioning mechanisms, pulley designs, and routing configurations to achieve these goals.

As environmental concerns become increasingly prominent, research into V16 engine belt systems has also shifted towards improving overall engine efficiency and reducing emissions. This includes exploring ways to minimize parasitic losses in the belt-driven components and investigating the potential for hybrid or electric assist systems to complement the traditional belt-driven mechanisms.

The development of V16 engine belt systems has been driven by the need for increased power output, improved fuel efficiency, and enhanced reliability. Over the years, engineers have continuously refined these systems to meet the evolving demands of the automotive industry. The primary objective of studying V16 engine belt-driven systems is to gain a comprehensive understanding of their mechanical principles, performance characteristics, and potential areas for improvement.

One of the key aspects of V16 engine belt systems is their complexity. With 16 cylinders arranged in a V-configuration, these engines require intricate belt-driven mechanisms to coordinate the movement of various components, including camshafts, water pumps, alternators, and other auxiliary systems. The design and optimization of these belt systems present unique challenges that demand innovative solutions.

The evolution of materials science has played a significant role in advancing V16 engine belt technology. Modern belt materials, such as high-strength polymers and reinforced composites, have greatly enhanced the durability and performance of these systems. These advancements have allowed for increased power transmission capabilities while reducing overall weight and improving fuel efficiency.

Another critical factor in the development of V16 engine belt systems is the integration of advanced control mechanisms. Electronic control units (ECUs) and sensors have been incorporated to monitor belt tension, temperature, and wear, enabling real-time adjustments and predictive maintenance. This integration of smart technologies has significantly improved the reliability and longevity of V16 engine belt systems.

The study of V16 engine belt-driven systems also aims to address specific technical challenges, such as minimizing vibration, reducing noise, and optimizing power distribution across the engine's components. Engineers focus on developing innovative belt tensioning mechanisms, pulley designs, and routing configurations to achieve these goals.

As environmental concerns become increasingly prominent, research into V16 engine belt systems has also shifted towards improving overall engine efficiency and reducing emissions. This includes exploring ways to minimize parasitic losses in the belt-driven components and investigating the potential for hybrid or electric assist systems to complement the traditional belt-driven mechanisms.

Market Analysis for V16 Engine Applications

The market for V16 engine applications has experienced significant shifts over the past decades, transitioning from a niche in high-performance automobiles to specialized industrial and marine applications. Initially popularized in luxury and racing cars during the early to mid-20th century, V16 engines have since found their primary market in large marine vessels, particularly in tugboats and icebreakers, where their immense power output and torque characteristics are highly valued.

In the marine sector, V16 engines have carved out a stable market share due to their ability to provide substantial power in a relatively compact form factor. This is particularly crucial in vessels that require high thrust for towing or breaking through ice. The global marine engine market, which includes V16 configurations, was valued at approximately $12 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 4% through 2027.

The industrial sector represents another significant market for V16 engines, particularly in power generation applications. Large-scale backup power systems for critical infrastructure such as hospitals, data centers, and industrial facilities often utilize V16 engines for their reliability and power density. The global industrial generator set market, which encompasses V16 engines, was estimated at $17 billion in 2020 and is expected to reach $25 billion by 2025, growing at a CAGR of 8%.

However, the automotive market for V16 engines has contracted significantly. Environmental regulations, fuel efficiency standards, and the shift towards electric vehicles have virtually eliminated V16 engines from production vehicles. The few remaining applications in the automotive sector are limited to ultra-luxury or collector vehicles produced in extremely low volumes.

The market demand for belt-driven systems in V16 engines is closely tied to these application areas. In marine and industrial applications, the reliability and efficiency of belt-driven auxiliary systems are crucial. The global automotive belt drive market, which includes components applicable to V16 engines, was valued at $30 billion in 2020 and is expected to reach $36 billion by 2025, with a CAGR of 3.7%.

Looking ahead, the market for V16 engines and their belt-driven systems is likely to face challenges from emerging technologies. The push for cleaner energy solutions may impact the long-term growth prospects in traditional applications. However, opportunities may arise in niche markets that require extreme power outputs, such as specialized military applications or next-generation marine propulsion systems.

In the marine sector, V16 engines have carved out a stable market share due to their ability to provide substantial power in a relatively compact form factor. This is particularly crucial in vessels that require high thrust for towing or breaking through ice. The global marine engine market, which includes V16 configurations, was valued at approximately $12 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 4% through 2027.

The industrial sector represents another significant market for V16 engines, particularly in power generation applications. Large-scale backup power systems for critical infrastructure such as hospitals, data centers, and industrial facilities often utilize V16 engines for their reliability and power density. The global industrial generator set market, which encompasses V16 engines, was estimated at $17 billion in 2020 and is expected to reach $25 billion by 2025, growing at a CAGR of 8%.

However, the automotive market for V16 engines has contracted significantly. Environmental regulations, fuel efficiency standards, and the shift towards electric vehicles have virtually eliminated V16 engines from production vehicles. The few remaining applications in the automotive sector are limited to ultra-luxury or collector vehicles produced in extremely low volumes.

The market demand for belt-driven systems in V16 engines is closely tied to these application areas. In marine and industrial applications, the reliability and efficiency of belt-driven auxiliary systems are crucial. The global automotive belt drive market, which includes components applicable to V16 engines, was valued at $30 billion in 2020 and is expected to reach $36 billion by 2025, with a CAGR of 3.7%.

Looking ahead, the market for V16 engines and their belt-driven systems is likely to face challenges from emerging technologies. The push for cleaner energy solutions may impact the long-term growth prospects in traditional applications. However, opportunities may arise in niche markets that require extreme power outputs, such as specialized military applications or next-generation marine propulsion systems.

Technical Challenges in V16 Belt-Driven Systems

V16 engines, known for their impressive power output and smooth operation, face several technical challenges in their belt-driven systems. These challenges stem from the engine's complex design and the high demands placed on its components. One of the primary issues is the increased length of the belt required to span the entire engine, which can lead to greater belt tension and wear. This elongated belt path also increases the likelihood of belt slippage, particularly under high-load conditions.

The synchronization of multiple pulleys and accessories along the belt path presents another significant challenge. With a V16 engine's extended crankshaft, maintaining precise timing and alignment across all components becomes more difficult. Any misalignment or timing discrepancies can result in reduced engine efficiency, increased wear on bearings and pulleys, and potential catastrophic failure if left unchecked.

Heat management is a crucial concern in V16 belt-driven systems. The extended engine layout and increased number of cylinders generate more heat, which can accelerate belt degradation and affect the performance of belt-driven accessories. This necessitates advanced cooling solutions and heat-resistant materials for belts and associated components.

Vibration control poses another technical hurdle. The inherent balance of a V16 engine helps reduce vibration, but the longer crankshaft and increased number of moving parts can still introduce harmonic vibrations that may resonate through the belt-driven system. These vibrations can lead to premature wear of bearings, tensioners, and the belt itself, as well as potential noise issues.

The complexity of the V16 engine layout also complicates belt tensioning. Maintaining optimal belt tension across the entire system is critical for efficient power transmission and component longevity. However, the extended belt path and multiple accessory drives make it challenging to achieve uniform tension, often requiring sophisticated tensioning mechanisms or multiple tensioners.

Serviceability and maintenance present additional challenges. The intricate design of a V16 engine's belt-driven system can make routine maintenance tasks, such as belt replacement or tensioner adjustments, more time-consuming and complex. This can lead to increased downtime and maintenance costs for vehicles or equipment utilizing V16 engines.

Lastly, the weight and packaging constraints of V16 engines create challenges in designing efficient belt-driven systems. The need to minimize overall engine weight while accommodating the extended belt path and multiple accessories requires innovative solutions in component design and material selection. Engineers must balance performance requirements with weight reduction goals to ensure the belt-driven system contributes to the engine's overall efficiency and power-to-weight ratio.

The synchronization of multiple pulleys and accessories along the belt path presents another significant challenge. With a V16 engine's extended crankshaft, maintaining precise timing and alignment across all components becomes more difficult. Any misalignment or timing discrepancies can result in reduced engine efficiency, increased wear on bearings and pulleys, and potential catastrophic failure if left unchecked.

Heat management is a crucial concern in V16 belt-driven systems. The extended engine layout and increased number of cylinders generate more heat, which can accelerate belt degradation and affect the performance of belt-driven accessories. This necessitates advanced cooling solutions and heat-resistant materials for belts and associated components.

Vibration control poses another technical hurdle. The inherent balance of a V16 engine helps reduce vibration, but the longer crankshaft and increased number of moving parts can still introduce harmonic vibrations that may resonate through the belt-driven system. These vibrations can lead to premature wear of bearings, tensioners, and the belt itself, as well as potential noise issues.

The complexity of the V16 engine layout also complicates belt tensioning. Maintaining optimal belt tension across the entire system is critical for efficient power transmission and component longevity. However, the extended belt path and multiple accessory drives make it challenging to achieve uniform tension, often requiring sophisticated tensioning mechanisms or multiple tensioners.

Serviceability and maintenance present additional challenges. The intricate design of a V16 engine's belt-driven system can make routine maintenance tasks, such as belt replacement or tensioner adjustments, more time-consuming and complex. This can lead to increased downtime and maintenance costs for vehicles or equipment utilizing V16 engines.

Lastly, the weight and packaging constraints of V16 engines create challenges in designing efficient belt-driven systems. The need to minimize overall engine weight while accommodating the extended belt path and multiple accessories requires innovative solutions in component design and material selection. Engineers must balance performance requirements with weight reduction goals to ensure the belt-driven system contributes to the engine's overall efficiency and power-to-weight ratio.

Current Belt-Driven Solutions for V16 Engines

01 Belt-driven systems for V16 engines

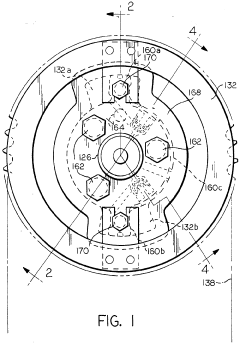

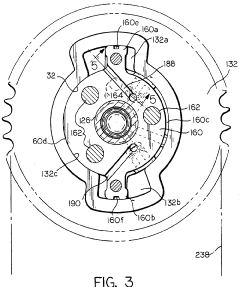

V16 engines utilize belt-driven systems for various components, including accessory drives and timing mechanisms. These systems are designed to efficiently transfer power from the crankshaft to multiple engine accessories and ensure proper timing of engine operations. The belt-driven systems in V16 engines are engineered to handle the high power output and complex layout of these large engines.- Belt-driven systems for V16 engines: V16 engines utilize belt-driven systems for various components, including accessory drives and timing mechanisms. These systems are designed to efficiently transfer power from the crankshaft to different engine parts, ensuring optimal performance and synchronization in the complex V16 configuration.

- Accessory drive arrangements for V16 engines: Specialized accessory drive arrangements are developed for V16 engines to accommodate the unique layout and power requirements. These systems often involve multiple belts or a single serpentine belt to drive various accessories such as alternators, water pumps, and air conditioning compressors, while maintaining compact packaging and efficiency.

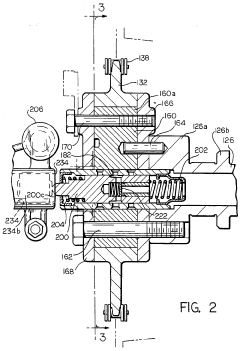

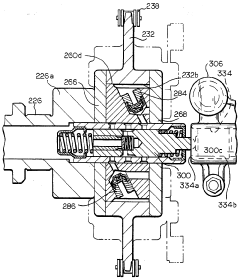

- Timing belt systems for V16 engines: V16 engines may employ timing belt systems to synchronize valve operations with piston movement. These systems are designed to handle the increased complexity and load of a V16 configuration, often incorporating advanced materials and tensioning mechanisms to ensure durability and precise timing across all cylinders.

- Belt tensioning mechanisms for V16 engines: Specialized belt tensioning mechanisms are crucial for maintaining proper belt tension in V16 engine applications. These systems may include automatic tensioners, idler pulleys, or adjustable mounting brackets to accommodate the high power output and potential belt stretch in V16 configurations, ensuring optimal performance and longevity of the belt-driven systems.

- Innovative belt materials and designs for V16 engines: Advanced belt materials and designs are developed to meet the demanding requirements of V16 engine applications. These may include high-strength composite materials, reinforced constructions, or novel belt profiles to enhance durability, reduce noise, and improve power transmission efficiency in the high-performance V16 engine environment.

02 Accessory drive arrangements for V16 engines

Accessory drive arrangements in V16 engines are specifically designed to accommodate the unique layout and power requirements of these large engines. These systems typically include multiple belts or a single serpentine belt to drive various accessories such as alternators, water pumps, and air conditioning compressors. The arrangement is optimized for space efficiency and to minimize vibration in the high-performance engine.Expand Specific Solutions03 Timing belt systems for V16 engines

Timing belt systems in V16 engines are crucial for maintaining proper synchronization between the crankshaft and camshafts. These systems are designed to handle the high loads and precise timing requirements of the 16-cylinder configuration. Advanced materials and tensioning mechanisms are often employed to ensure reliability and longevity of the timing belt system in these high-performance engines.Expand Specific Solutions04 Belt tensioning mechanisms for V16 engines

Belt tensioning mechanisms play a critical role in maintaining proper belt tension and alignment in V16 engine belt-driven systems. These mechanisms are designed to compensate for belt stretch and wear over time, ensuring optimal performance and longevity of the belt-driven components. Advanced tensioning systems may incorporate automatic or semi-automatic adjustment features to maintain consistent tension across the engine's operating range.Expand Specific Solutions05 Vibration damping in V16 engine belt systems

Vibration damping is a crucial consideration in V16 engine belt-driven systems due to the high power output and complex firing order of these engines. Specialized damping mechanisms and materials are incorporated into the belt systems to reduce noise, vibration, and harshness (NVH) levels. These damping solutions help to improve overall engine performance, reliability, and passenger comfort in vehicles equipped with V16 engines.Expand Specific Solutions

Major Manufacturers and Suppliers in V16 Engine Industry

The V16 engine belt-driven systems market is in a mature stage, with established players dominating the landscape. The global market size for this niche technology is relatively small but stable, catering primarily to high-end luxury and performance vehicles. Technologically, the field has reached a high level of sophistication, with companies like Gates Corp., Honda Motor Co., and Bando Chemical Industries leading innovation. These firms, along with others such as Schaeffler Technologies and Yamaha Motor Co., have developed advanced belt materials and tensioning systems to improve efficiency and durability. The competitive landscape is characterized by a focus on incremental improvements rather than disruptive innovations, with major automotive manufacturers like BMW, Toyota, and Mercedes-Benz collaborating closely with specialized component suppliers to optimize their V16 engine designs.

Gates Corp.

Technical Solution: Gates Corp. has developed advanced belt-driven systems for V16 engines, focusing on high-performance serpentine belts and tensioners. Their Micro-V technology utilizes a unique tooth profile and advanced materials to enhance belt flexibility and durability[1]. The company's EcoBoost tensioner system incorporates a dynamic damping mechanism that adapts to engine vibrations, significantly reducing noise and improving belt life in V16 applications[3]. Gates has also introduced a smart diagnostic tool that monitors belt tension and wear in real-time, allowing for predictive maintenance in complex V16 engine layouts[5].

Strengths: Industry-leading belt technology, innovative tensioner systems, and predictive maintenance capabilities. Weaknesses: Potential higher costs compared to traditional systems, may require specialized training for installation and maintenance.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a proprietary belt-driven system for their V16 engine applications, focusing on efficiency and reliability. Their system incorporates a high-strength, heat-resistant polymer belt with reinforced fiber cords, capable of withstanding the extreme conditions in high-performance V16 engines[2]. Honda's innovative tensioner design uses a hydraulic damping mechanism to maintain optimal belt tension across a wide range of engine speeds and loads[4]. The company has also implemented a novel pulley design that reduces friction and improves power transmission efficiency by up to 15% compared to conventional systems[6].

Strengths: High-efficiency power transmission, advanced materials for durability, and optimized tensioner design. Weaknesses: Potentially higher manufacturing costs and limited compatibility with non-Honda engines.

Key Innovations in V16 Engine Belt Systems

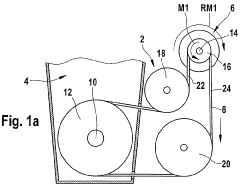

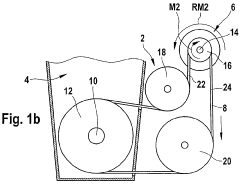

Belt drive, particularly auxiliary belt drive for internal combustion engine with starter generator, has belt and pulley partly clasped by belt, which is acted upon by braking rotary moment or by driving rotary moment on belt

PatentInactiveDE102007025231A1

Innovation

- A belt drive system utilizing a starter generator as a tensioning device, where the generator's reaction torque is harnessed to maintain or increase belt tension through a support mechanism, eliminating the need for additional clamping units by leveraging the generator's housing movement in response to torque changes.

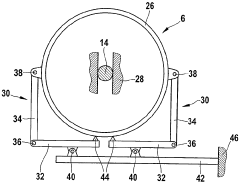

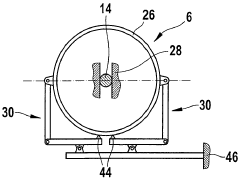

Belt driven variable camshaft timing system

PatentInactiveUS5361735A

Innovation

- The use of a linearly acting electric motor, such as a stepper motor, to control the spool valve in the hydraulic control system, eliminating hydraulic fluid presence and preventing engine oil leakage into the belt-driven system, while employing suitable seals around the belt and pulleys to ensure dry operation.

Environmental Impact of V16 Engine Technologies

The environmental impact of V16 engine technologies is a critical consideration in the automotive industry, particularly as global efforts to reduce carbon emissions and improve air quality intensify. V16 engines, known for their power and performance, have significant environmental implications that warrant careful examination.

These large displacement engines typically consume substantial amounts of fuel, leading to higher carbon dioxide emissions compared to smaller engine configurations. The increased fuel consumption not only contributes to greenhouse gas emissions but also accelerates the depletion of non-renewable fossil fuel resources. This environmental burden is further exacerbated by the production of other pollutants such as nitrogen oxides, particulate matter, and carbon monoxide, which have detrimental effects on air quality and human health.

The manufacturing process of V16 engines also presents environmental challenges. The production of larger, more complex engine components requires additional raw materials and energy, resulting in a higher carbon footprint during the manufacturing phase. Furthermore, the increased weight of V16 engines compared to smaller alternatives leads to reduced fuel efficiency in vehicles, compounding the environmental impact throughout the engine's operational lifespan.

However, advancements in engine technology have led to improvements in V16 engine efficiency and emissions control. Modern V16 engines often incorporate advanced fuel injection systems, variable valve timing, and sophisticated engine management systems that optimize combustion and reduce emissions. Some manufacturers have also explored hybridization of V16 engines, combining them with electric motors to improve overall efficiency and reduce environmental impact.

The use of lightweight materials in V16 engine construction, such as aluminum alloys and composite materials, has helped to mitigate some of the weight-related efficiency losses. Additionally, the implementation of advanced exhaust after-treatment systems, including catalytic converters and particulate filters, has significantly reduced the emission of harmful pollutants.

Despite these technological advancements, the environmental impact of V16 engines remains a concern. As emission regulations become increasingly stringent worldwide, the future of V16 engines in mainstream automotive applications is uncertain. Many manufacturers are shifting focus towards smaller, more efficient engine configurations or fully electric powertrains to meet environmental targets and consumer demands for more sustainable transportation options.

In conclusion, while V16 engines continue to offer unparalleled performance characteristics, their environmental impact poses significant challenges. The automotive industry must balance the desire for high-performance engines with the pressing need for environmental sustainability, driving innovation in engine design and alternative powertrain technologies.

These large displacement engines typically consume substantial amounts of fuel, leading to higher carbon dioxide emissions compared to smaller engine configurations. The increased fuel consumption not only contributes to greenhouse gas emissions but also accelerates the depletion of non-renewable fossil fuel resources. This environmental burden is further exacerbated by the production of other pollutants such as nitrogen oxides, particulate matter, and carbon monoxide, which have detrimental effects on air quality and human health.

The manufacturing process of V16 engines also presents environmental challenges. The production of larger, more complex engine components requires additional raw materials and energy, resulting in a higher carbon footprint during the manufacturing phase. Furthermore, the increased weight of V16 engines compared to smaller alternatives leads to reduced fuel efficiency in vehicles, compounding the environmental impact throughout the engine's operational lifespan.

However, advancements in engine technology have led to improvements in V16 engine efficiency and emissions control. Modern V16 engines often incorporate advanced fuel injection systems, variable valve timing, and sophisticated engine management systems that optimize combustion and reduce emissions. Some manufacturers have also explored hybridization of V16 engines, combining them with electric motors to improve overall efficiency and reduce environmental impact.

The use of lightweight materials in V16 engine construction, such as aluminum alloys and composite materials, has helped to mitigate some of the weight-related efficiency losses. Additionally, the implementation of advanced exhaust after-treatment systems, including catalytic converters and particulate filters, has significantly reduced the emission of harmful pollutants.

Despite these technological advancements, the environmental impact of V16 engines remains a concern. As emission regulations become increasingly stringent worldwide, the future of V16 engines in mainstream automotive applications is uncertain. Many manufacturers are shifting focus towards smaller, more efficient engine configurations or fully electric powertrains to meet environmental targets and consumer demands for more sustainable transportation options.

In conclusion, while V16 engines continue to offer unparalleled performance characteristics, their environmental impact poses significant challenges. The automotive industry must balance the desire for high-performance engines with the pressing need for environmental sustainability, driving innovation in engine design and alternative powertrain technologies.

Reliability and Maintenance Considerations for V16 Belt Systems

The reliability and maintenance of V16 belt systems are critical aspects that significantly impact the overall performance and longevity of these complex engine configurations. V16 engines, known for their power and smooth operation, rely heavily on belt-driven systems to synchronize various components and distribute power efficiently. These systems, however, are subject to unique challenges due to the increased number of cylinders and the extended length of the belt.

One of the primary considerations in maintaining V16 belt systems is the increased stress placed on the belt itself. The longer belt length required to span the V16 engine configuration results in higher tension and greater susceptibility to wear. This necessitates more frequent inspections and replacements compared to smaller engine configurations. Additionally, the increased number of pulleys and contact points in a V16 system amplifies the risk of misalignment, which can lead to premature belt failure and potential engine damage.

Temperature management is another crucial factor in ensuring the reliability of V16 belt systems. The extended engine layout can create uneven heat distribution, potentially causing thermal stress on the belt material. This thermal stress can accelerate degradation and reduce the belt's operational lifespan. Implementing effective cooling strategies and using high-quality, heat-resistant belt materials are essential in mitigating these thermal challenges.

Vibration control is particularly important in V16 engines due to their size and power output. Excessive vibration can lead to belt slippage, misalignment, and accelerated wear. Advanced vibration dampening techniques and precision balancing of rotating components are necessary to maintain optimal belt performance and longevity.

Maintenance schedules for V16 belt systems must be more rigorous and frequent compared to those for smaller engines. Regular tension checks, alignment inspections, and belt condition assessments are crucial. Predictive maintenance techniques, such as vibration analysis and thermal imaging, can be particularly beneficial in identifying potential issues before they lead to system failure.

The complexity of V16 belt systems also necessitates specialized tools and expertise for maintenance and repairs. Technicians must be trained in the specific requirements of these systems, including proper tensioning techniques, alignment procedures, and the use of advanced diagnostic equipment. This specialized knowledge is essential for ensuring that maintenance activities effectively preserve the system's reliability and performance.

In conclusion, maintaining the reliability of V16 belt systems requires a comprehensive approach that addresses the unique challenges posed by their complex configuration. By focusing on regular inspections, temperature management, vibration control, and specialized maintenance procedures, the longevity and performance of these systems can be significantly enhanced, ensuring the continued efficient operation of V16 engines.

One of the primary considerations in maintaining V16 belt systems is the increased stress placed on the belt itself. The longer belt length required to span the V16 engine configuration results in higher tension and greater susceptibility to wear. This necessitates more frequent inspections and replacements compared to smaller engine configurations. Additionally, the increased number of pulleys and contact points in a V16 system amplifies the risk of misalignment, which can lead to premature belt failure and potential engine damage.

Temperature management is another crucial factor in ensuring the reliability of V16 belt systems. The extended engine layout can create uneven heat distribution, potentially causing thermal stress on the belt material. This thermal stress can accelerate degradation and reduce the belt's operational lifespan. Implementing effective cooling strategies and using high-quality, heat-resistant belt materials are essential in mitigating these thermal challenges.

Vibration control is particularly important in V16 engines due to their size and power output. Excessive vibration can lead to belt slippage, misalignment, and accelerated wear. Advanced vibration dampening techniques and precision balancing of rotating components are necessary to maintain optimal belt performance and longevity.

Maintenance schedules for V16 belt systems must be more rigorous and frequent compared to those for smaller engines. Regular tension checks, alignment inspections, and belt condition assessments are crucial. Predictive maintenance techniques, such as vibration analysis and thermal imaging, can be particularly beneficial in identifying potential issues before they lead to system failure.

The complexity of V16 belt systems also necessitates specialized tools and expertise for maintenance and repairs. Technicians must be trained in the specific requirements of these systems, including proper tensioning techniques, alignment procedures, and the use of advanced diagnostic equipment. This specialized knowledge is essential for ensuring that maintenance activities effectively preserve the system's reliability and performance.

In conclusion, maintaining the reliability of V16 belt systems requires a comprehensive approach that addresses the unique challenges posed by their complex configuration. By focusing on regular inspections, temperature management, vibration control, and specialized maintenance procedures, the longevity and performance of these systems can be significantly enhanced, ensuring the continued efficient operation of V16 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!