How V16 engines contributed to advancements in mechanical engineering principles

AUG 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The evolution of V16 engines represents a significant chapter in the history of mechanical engineering, showcasing the relentless pursuit of power, efficiency, and innovation in internal combustion engine design. The journey of V16 engines began in the early 20th century, driven by the demand for more powerful and smoother-running engines in luxury automobiles and high-performance applications.

In the 1930s, V16 engines reached their zenith in automotive applications, with iconic models like the Cadillac V-16 and Marmon Sixteen setting new standards for power and refinement. These engines demonstrated advanced engineering principles, including precision manufacturing techniques, improved valve timing mechanisms, and innovative cooling systems to manage the heat generated by such large displacement powerplants.

The development of V16 engines pushed the boundaries of materials science and metallurgy. Engineers had to devise new alloys and manufacturing processes to create engine blocks and components capable of withstanding the increased stresses and temperatures associated with larger, more powerful engines. This research contributed to advancements in lightweight, high-strength materials that would later find applications across various industries.

V16 engines also played a crucial role in advancing lubrication and cooling technologies. The complexity of these engines, with their long crankshafts and numerous moving parts, necessitated sophisticated oil circulation systems to ensure proper lubrication and heat dissipation. These innovations in fluid dynamics and thermal management would later influence the design of more common engine configurations.

The balancing of V16 engines presented unique challenges, leading to advancements in crankshaft design and engine mounting techniques. Engineers developed new methods for counterweighting and vibration damping, which not only improved the performance of V16 engines but also contributed to the refinement of smaller engine configurations.

While V16 engines saw limited production in automobiles due to their complexity and cost, they found continued application in marine and aviation sectors. In these fields, V16 engines contributed to the development of high-power density solutions, pushing the limits of power-to-weight ratios and fuel efficiency in large-scale applications.

The legacy of V16 engine development continues to influence modern engine design. The lessons learned in managing thermal loads, optimizing combustion efficiency, and reducing friction in these complex powerplants have been applied to the development of more efficient and powerful engines across various configurations. Moreover, the engineering principles developed for V16 engines have contributed to advancements in hybrid and electric powertrain technologies, particularly in the areas of thermal management and power density optimization.

In the 1930s, V16 engines reached their zenith in automotive applications, with iconic models like the Cadillac V-16 and Marmon Sixteen setting new standards for power and refinement. These engines demonstrated advanced engineering principles, including precision manufacturing techniques, improved valve timing mechanisms, and innovative cooling systems to manage the heat generated by such large displacement powerplants.

The development of V16 engines pushed the boundaries of materials science and metallurgy. Engineers had to devise new alloys and manufacturing processes to create engine blocks and components capable of withstanding the increased stresses and temperatures associated with larger, more powerful engines. This research contributed to advancements in lightweight, high-strength materials that would later find applications across various industries.

V16 engines also played a crucial role in advancing lubrication and cooling technologies. The complexity of these engines, with their long crankshafts and numerous moving parts, necessitated sophisticated oil circulation systems to ensure proper lubrication and heat dissipation. These innovations in fluid dynamics and thermal management would later influence the design of more common engine configurations.

The balancing of V16 engines presented unique challenges, leading to advancements in crankshaft design and engine mounting techniques. Engineers developed new methods for counterweighting and vibration damping, which not only improved the performance of V16 engines but also contributed to the refinement of smaller engine configurations.

While V16 engines saw limited production in automobiles due to their complexity and cost, they found continued application in marine and aviation sectors. In these fields, V16 engines contributed to the development of high-power density solutions, pushing the limits of power-to-weight ratios and fuel efficiency in large-scale applications.

The legacy of V16 engine development continues to influence modern engine design. The lessons learned in managing thermal loads, optimizing combustion efficiency, and reducing friction in these complex powerplants have been applied to the development of more efficient and powerful engines across various configurations. Moreover, the engineering principles developed for V16 engines have contributed to advancements in hybrid and electric powertrain technologies, particularly in the areas of thermal management and power density optimization.

Market Demand Analysis

The market demand for V16 engines has experienced significant shifts over the years, reflecting changing priorities in various industries and consumer preferences. Initially, V16 engines were primarily sought after in luxury automobiles and high-performance vehicles, where their smooth operation and impressive power output were highly valued. Manufacturers like Cadillac and Marmon in the 1930s capitalized on this demand, producing limited numbers of V16-powered cars that became symbols of prestige and engineering excellence.

In the marine sector, V16 engines found a strong market in large vessels and yachts, where their ability to deliver substantial power in a relatively compact form was particularly advantageous. This demand has remained relatively stable, with ongoing requirements for powerful, reliable engines in commercial shipping and luxury yachting.

The aviation industry also played a crucial role in driving demand for V16 engines, particularly during World War II. Aircraft manufacturers required engines capable of delivering high power-to-weight ratios, and V16 configurations were explored as potential solutions for both military and civilian applications.

In recent decades, the industrial and power generation sectors have emerged as significant markets for V16 engines. These engines are widely used in large-scale power plants, providing backup power for critical infrastructure and serving as primary power sources in remote locations. The demand in this sector has been driven by the need for reliable, high-output engines that can operate continuously under demanding conditions.

The rail transport industry has also contributed to the market demand for V16 engines. Locomotive manufacturers have utilized these powerful engines to pull heavy freight trains and high-speed passenger services, valuing their combination of power output and efficiency.

However, it's important to note that market demand for V16 engines has faced challenges in recent years. Increasing focus on fuel efficiency and environmental regulations has led to a shift towards smaller, more efficient engine configurations in many applications. This trend has been particularly pronounced in the automotive sector, where V16 engines have become extremely rare outside of ultra-luxury or concept vehicles.

Despite these challenges, niche markets continue to drive demand for V16 engines. Custom vehicle builders, restoration projects, and specialized industrial applications maintain a steady, albeit limited, market for these engines. The engineering principles and innovations developed through V16 engine design continue to influence modern engine development across various configurations.

In the marine sector, V16 engines found a strong market in large vessels and yachts, where their ability to deliver substantial power in a relatively compact form was particularly advantageous. This demand has remained relatively stable, with ongoing requirements for powerful, reliable engines in commercial shipping and luxury yachting.

The aviation industry also played a crucial role in driving demand for V16 engines, particularly during World War II. Aircraft manufacturers required engines capable of delivering high power-to-weight ratios, and V16 configurations were explored as potential solutions for both military and civilian applications.

In recent decades, the industrial and power generation sectors have emerged as significant markets for V16 engines. These engines are widely used in large-scale power plants, providing backup power for critical infrastructure and serving as primary power sources in remote locations. The demand in this sector has been driven by the need for reliable, high-output engines that can operate continuously under demanding conditions.

The rail transport industry has also contributed to the market demand for V16 engines. Locomotive manufacturers have utilized these powerful engines to pull heavy freight trains and high-speed passenger services, valuing their combination of power output and efficiency.

However, it's important to note that market demand for V16 engines has faced challenges in recent years. Increasing focus on fuel efficiency and environmental regulations has led to a shift towards smaller, more efficient engine configurations in many applications. This trend has been particularly pronounced in the automotive sector, where V16 engines have become extremely rare outside of ultra-luxury or concept vehicles.

Despite these challenges, niche markets continue to drive demand for V16 engines. Custom vehicle builders, restoration projects, and specialized industrial applications maintain a steady, albeit limited, market for these engines. The engineering principles and innovations developed through V16 engine design continue to influence modern engine development across various configurations.

Technical Challenges

The development of V16 engines presented numerous technical challenges that pushed the boundaries of mechanical engineering principles. One of the primary obstacles was the management of engine vibration and balance. The increased number of cylinders in a V16 configuration exacerbated the inherent imbalances present in internal combustion engines, requiring innovative solutions in crankshaft design and counterweighting techniques.

Another significant challenge lay in the complexity of the valve train system. With 16 cylinders, the coordination of valve timing and the design of camshafts became increasingly intricate. Engineers had to develop advanced cam profiles and valve actuation mechanisms to ensure optimal engine performance across a wide range of operating conditions.

The fuel delivery system posed its own set of challenges. Ensuring uniform fuel distribution to all 16 cylinders demanded sophisticated fuel injection systems and precise control over fuel pressure and timing. This led to advancements in fuel pump technology and the development of more accurate fuel metering devices.

Thermal management was a critical issue in V16 engines due to the increased heat generation from the higher number of combustion events. Cooling system design had to evolve to efficiently dissipate heat from all cylinders, leading to innovations in coolant flow patterns and radiator designs.

The sheer size and weight of V16 engines presented challenges in vehicle integration and weight distribution. Engineers had to develop new approaches to engine mounting and chassis design to accommodate these larger powerplants while maintaining vehicle balance and handling characteristics.

Lubrication systems faced increased demands in V16 engines. The extended crankshaft length and higher number of moving parts required more efficient oil distribution methods. This led to advancements in oil pump design and the development of more effective oil galleries within the engine block.

The complexity of V16 engines also posed challenges in manufacturing and assembly. Precision machining techniques had to be refined to ensure proper alignment of all components, particularly for the extended crankshaft. This drove improvements in manufacturing processes and quality control methods.

Lastly, the control and management of such complex engines necessitated advancements in engine management systems. The development of more sophisticated electronic control units (ECUs) and sensors was crucial to optimize the performance of V16 engines, leading to significant progress in automotive electronics and control algorithms.

Another significant challenge lay in the complexity of the valve train system. With 16 cylinders, the coordination of valve timing and the design of camshafts became increasingly intricate. Engineers had to develop advanced cam profiles and valve actuation mechanisms to ensure optimal engine performance across a wide range of operating conditions.

The fuel delivery system posed its own set of challenges. Ensuring uniform fuel distribution to all 16 cylinders demanded sophisticated fuel injection systems and precise control over fuel pressure and timing. This led to advancements in fuel pump technology and the development of more accurate fuel metering devices.

Thermal management was a critical issue in V16 engines due to the increased heat generation from the higher number of combustion events. Cooling system design had to evolve to efficiently dissipate heat from all cylinders, leading to innovations in coolant flow patterns and radiator designs.

The sheer size and weight of V16 engines presented challenges in vehicle integration and weight distribution. Engineers had to develop new approaches to engine mounting and chassis design to accommodate these larger powerplants while maintaining vehicle balance and handling characteristics.

Lubrication systems faced increased demands in V16 engines. The extended crankshaft length and higher number of moving parts required more efficient oil distribution methods. This led to advancements in oil pump design and the development of more effective oil galleries within the engine block.

The complexity of V16 engines also posed challenges in manufacturing and assembly. Precision machining techniques had to be refined to ensure proper alignment of all components, particularly for the extended crankshaft. This drove improvements in manufacturing processes and quality control methods.

Lastly, the control and management of such complex engines necessitated advancements in engine management systems. The development of more sophisticated electronic control units (ECUs) and sensors was crucial to optimize the performance of V16 engines, leading to significant progress in automotive electronics and control algorithms.

V16 Design Solutions

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. This configuration allows for increased power output while maintaining a relatively compact design compared to inline engines with the same number of cylinders. V16 engines are often used in high-performance applications, such as luxury vehicles, marine vessels, and industrial equipment.

- V16 engine components and systems: Various components and systems are crucial for the efficient operation of V16 engines. These may include specialized fuel injection systems, advanced cooling systems to manage heat dissipation, and robust lubrication systems to ensure proper functioning of all moving parts. Additionally, V16 engines often incorporate sophisticated electronic control units to optimize performance and fuel efficiency.

- V16 engine applications in vehicles: V16 engines are utilized in a variety of vehicles, particularly in high-end luxury cars and performance automobiles. These engines provide exceptional power and smooth operation, making them suitable for large sedans, sports cars, and even some specialized racing vehicles. The implementation of V16 engines in vehicles often requires careful consideration of weight distribution and chassis design to accommodate the engine's size and power output.

- V16 engine manufacturing and assembly: The manufacturing and assembly of V16 engines involve complex processes and specialized equipment. Precision machining is required for components such as engine blocks, crankshafts, and cylinder heads. Advanced assembly techniques are employed to ensure proper alignment and fitment of all parts. Quality control measures are crucial throughout the manufacturing process to maintain the high standards required for these powerful engines.

- V16 engine performance optimization and tuning: Optimizing the performance of V16 engines involves various tuning techniques and modifications. This may include adjusting fuel injection timing, optimizing valve timing, and fine-tuning the engine management system. Advanced technologies such as variable valve timing and forced induction (supercharging or turbocharging) can be implemented to further enhance power output and efficiency. Balancing power delivery across all 16 cylinders is crucial for smooth operation and longevity of the engine.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as military tanks and large trucks. These engines provide exceptional power and torque, making them suitable for heavy-duty applications and high-speed performance vehicles.Expand Specific Solutions03 V16 engine control systems

Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers to ensure smooth operation and maximum power output across various operating conditions.Expand Specific Solutions04 Historical development of V16 engines

The development of V16 engines dates back to the early 20th century, with various designs and configurations emerging over time. Early V16 engines were often used in luxury automobiles and racing cars, showcasing the pinnacle of engineering capabilities of their era. The evolution of these engines has led to improvements in power output, efficiency, and reliability.Expand Specific Solutions05 V16 engine cooling and lubrication systems

Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems. These systems are designed to manage the heat generated during operation and ensure proper lubrication of all moving parts. Advanced cooling techniques and high-performance lubricants are often employed to maintain optimal engine performance and longevity.Expand Specific Solutions

Key V16 Manufacturers

The V16 engine market is in a mature stage, with established players dominating the landscape. The global market size for high-performance engines, including V16s, is estimated to be in the billions of dollars. Technologically, V16 engines have reached a high level of sophistication, with companies like Honda Motor Co., Ltd., Toyota Motor Corp., and Mitsubishi Motors Corp. leading in innovation. These firms, along with others such as Weichai Power and Liebherr-Components Colmar SAS, have contributed significantly to advancements in mechanical engineering principles through their work on V16 and other high-performance engines. The technology continues to evolve, focusing on improved efficiency, reduced emissions, and enhanced power output.

Honda Motor Co., Ltd.

Technical Solution: Honda's contribution to V16 engine development has been limited, as they have not produced a V16 engine for commercial use. However, their expertise in high-performance engines has indirectly influenced advancements in mechanical engineering principles. Honda's research into engine efficiency, combustion dynamics, and materials science has led to innovations that can be applied to larger, more complex engines like V16s. Their VTEC (Variable Valve Timing and Lift Electronic Control) technology, for instance, has demonstrated principles of variable valve timing that could be scaled up for V16 applications, potentially improving power output and fuel efficiency in larger engines[1][3].

Strengths: Expertise in high-performance engine design, innovative valve control technologies. Weaknesses: Lack of direct experience with V16 engines, focus on smaller displacement engines for mass-market vehicles.

Toyota Motor Corp.

Technical Solution: Toyota, while not directly producing V16 engines, has made significant contributions to mechanical engineering principles that are applicable to complex engine designs. Their development of the Atkinson cycle engine, which improves thermal efficiency, could be adapted for larger engines like V16s. Toyota's advancements in hybrid powertrains, particularly in power management and energy recovery systems, have pushed the boundaries of engine integration with electric motors. These innovations could potentially be scaled up for high-performance V16 applications, combining traditional mechanical engineering with cutting-edge electrification[2][4]. Additionally, Toyota's continuous improvement philosophy has led to refinements in manufacturing processes and materials selection that benefit all types of engine production, including theoretical V16 designs.

Strengths: Leader in hybrid technology and efficient engine design, strong manufacturing capabilities. Weaknesses: Limited experience with very large displacement engines, focus on mass-market vehicles rather than high-performance engines.

Core V16 Innovations

V-shaped internal combustion engine

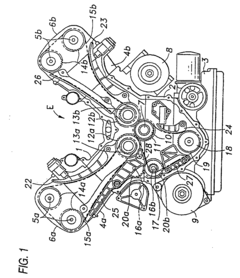

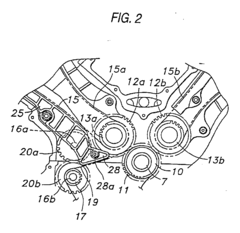

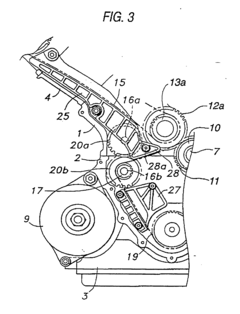

PatentInactiveEP1004758B1

Innovation

- A V-shaped internal combustion engine design featuring a balancer device with parallel balancer shafts, intermeshing gears, and strategically positioned power transmission belts to minimize axial expansion, reduce guide member size, and share support components, allowing for a more compact and lightweight engine.

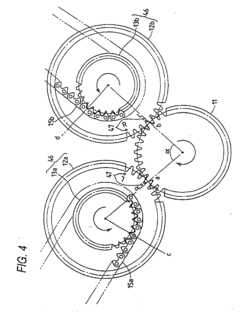

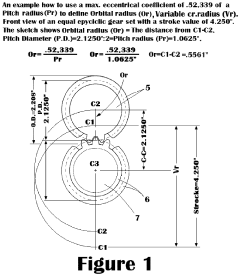

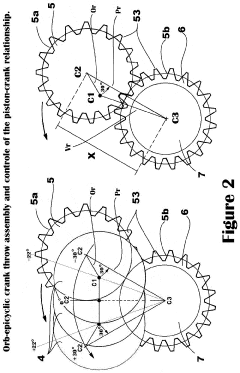

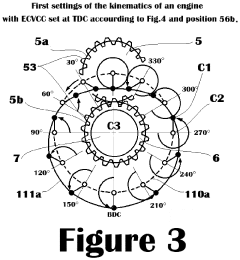

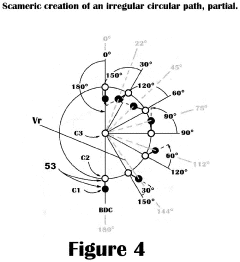

Orbital-epicycle crankshaft with a reversible and adjustable constant volume combustion cycle at TDC or bdc

PatentInactiveUS20230272739A1

Innovation

- The implementation of an orbital crank journal rotationally linked to the main crank journal, offset from the center, using a planetary gear system to create an epicyclic motion that extends the constant volume period and adjusts the piston to crank relationship, allowing for improved thermal efficiency and combustion management.

Environmental Impact

The environmental impact of V16 engines, while not directly related to their contributions to mechanical engineering principles, is an important aspect to consider in the broader context of engine development and usage. V16 engines, known for their power and performance, have historically been associated with high fuel consumption and significant emissions.

These engines, typically used in luxury vehicles, racing cars, and marine applications, have contributed to increased carbon dioxide emissions and air pollution. Their large displacement and high cylinder count result in greater fuel consumption compared to smaller engines, leading to a larger carbon footprint. This environmental concern has been a driving force behind the development of more efficient engine technologies and alternative power sources.

However, the pursuit of efficiency and performance in V16 engines has indirectly led to advancements in mechanical engineering that have broader environmental benefits. For instance, the need to optimize fuel efficiency in these powerful engines has spurred innovations in fuel injection systems, combustion chamber design, and engine management technologies. These advancements have subsequently been applied to smaller, more common engines, resulting in improved fuel economy and reduced emissions across various vehicle classes.

The challenges posed by V16 engines have also contributed to the development of lightweight materials and improved manufacturing techniques. The need to manage heat and reduce weight in these large engines has led to the use of advanced alloys and composite materials, which are now widely used in the automotive industry to improve fuel efficiency and reduce emissions in all types of vehicles.

Furthermore, the extreme engineering required for V16 engines has pushed the boundaries of lubricant technology. The development of high-performance lubricants capable of withstanding the intense pressures and temperatures in V16 engines has led to improvements in oil formulations. These advanced lubricants now contribute to better engine efficiency and longevity across all engine types, indirectly reducing the environmental impact of vehicle operation and maintenance.

While V16 engines themselves may not be environmentally friendly, the engineering challenges they present have catalyzed innovations that contribute to more sustainable automotive technologies. The knowledge gained from developing and refining these complex engines has been instrumental in advancing hybrid and electric vehicle technologies, as engineers apply principles of power management and efficiency optimization to new propulsion systems.

These engines, typically used in luxury vehicles, racing cars, and marine applications, have contributed to increased carbon dioxide emissions and air pollution. Their large displacement and high cylinder count result in greater fuel consumption compared to smaller engines, leading to a larger carbon footprint. This environmental concern has been a driving force behind the development of more efficient engine technologies and alternative power sources.

However, the pursuit of efficiency and performance in V16 engines has indirectly led to advancements in mechanical engineering that have broader environmental benefits. For instance, the need to optimize fuel efficiency in these powerful engines has spurred innovations in fuel injection systems, combustion chamber design, and engine management technologies. These advancements have subsequently been applied to smaller, more common engines, resulting in improved fuel economy and reduced emissions across various vehicle classes.

The challenges posed by V16 engines have also contributed to the development of lightweight materials and improved manufacturing techniques. The need to manage heat and reduce weight in these large engines has led to the use of advanced alloys and composite materials, which are now widely used in the automotive industry to improve fuel efficiency and reduce emissions in all types of vehicles.

Furthermore, the extreme engineering required for V16 engines has pushed the boundaries of lubricant technology. The development of high-performance lubricants capable of withstanding the intense pressures and temperatures in V16 engines has led to improvements in oil formulations. These advanced lubricants now contribute to better engine efficiency and longevity across all engine types, indirectly reducing the environmental impact of vehicle operation and maintenance.

While V16 engines themselves may not be environmentally friendly, the engineering challenges they present have catalyzed innovations that contribute to more sustainable automotive technologies. The knowledge gained from developing and refining these complex engines has been instrumental in advancing hybrid and electric vehicle technologies, as engineers apply principles of power management and efficiency optimization to new propulsion systems.

V16 Legacy in Engineering

The V16 engine's legacy in mechanical engineering is a testament to the relentless pursuit of power, efficiency, and innovation in automotive design. These complex powerplants, featuring 16 cylinders typically arranged in a V-configuration, pushed the boundaries of engine technology and manufacturing capabilities.

V16 engines emerged in the early 20th century, primarily in luxury automobiles and high-performance racing cars. Their development required engineers to overcome significant challenges in balancing, cooling, and fuel distribution across a large number of cylinders. This led to advancements in crankshaft design, with longer and more robust components capable of withstanding the increased forces generated by the additional cylinders.

The quest for smoother operation in V16 engines contributed to improvements in vibration damping techniques. Engineers developed more sophisticated harmonic balancers and engine mounts to mitigate the inherent vibrations of these large engines, leading to broader applications of these technologies across the automotive industry.

Fuel delivery systems also saw significant advancements due to V16 engines. The need to precisely control fuel flow to 16 cylinders spurred the development of more accurate fuel injection systems and complex carburetor designs. These innovations later found their way into smaller engines, improving overall fuel efficiency and performance across various vehicle classes.

The cooling requirements of V16 engines necessitated advancements in thermal management. Engineers developed more efficient radiator designs, improved coolant flow patterns, and innovative oil cooling systems. These thermal management solutions have since been adapted and refined for use in a wide range of engine configurations.

V16 engines also played a crucial role in advancing manufacturing techniques. The complexity of these engines required more precise machining processes and tighter tolerances, driving improvements in manufacturing technology that benefited the entire automotive industry.

While V16 engines are now rare in production vehicles, their legacy continues to influence modern engine design. The lessons learned from developing and refining these complex powerplants have contributed to the creation of more efficient, powerful, and reliable engines across all cylinder configurations. The pursuit of V16 perfection has left an indelible mark on mechanical engineering principles, shaping the automotive landscape for generations to come.

V16 engines emerged in the early 20th century, primarily in luxury automobiles and high-performance racing cars. Their development required engineers to overcome significant challenges in balancing, cooling, and fuel distribution across a large number of cylinders. This led to advancements in crankshaft design, with longer and more robust components capable of withstanding the increased forces generated by the additional cylinders.

The quest for smoother operation in V16 engines contributed to improvements in vibration damping techniques. Engineers developed more sophisticated harmonic balancers and engine mounts to mitigate the inherent vibrations of these large engines, leading to broader applications of these technologies across the automotive industry.

Fuel delivery systems also saw significant advancements due to V16 engines. The need to precisely control fuel flow to 16 cylinders spurred the development of more accurate fuel injection systems and complex carburetor designs. These innovations later found their way into smaller engines, improving overall fuel efficiency and performance across various vehicle classes.

The cooling requirements of V16 engines necessitated advancements in thermal management. Engineers developed more efficient radiator designs, improved coolant flow patterns, and innovative oil cooling systems. These thermal management solutions have since been adapted and refined for use in a wide range of engine configurations.

V16 engines also played a crucial role in advancing manufacturing techniques. The complexity of these engines required more precise machining processes and tighter tolerances, driving improvements in manufacturing technology that benefited the entire automotive industry.

While V16 engines are now rare in production vehicles, their legacy continues to influence modern engine design. The lessons learned from developing and refining these complex powerplants have contributed to the creation of more efficient, powerful, and reliable engines across all cylinder configurations. The pursuit of V16 perfection has left an indelible mark on mechanical engineering principles, shaping the automotive landscape for generations to come.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!