Modern innovations: reviving V16 engine concepts for hybrid or electric-assisted systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury and high-performance applications, the V16 configuration offered unparalleled smoothness and power output. The first notable V16 engine appeared in the Cadillac V-16 in 1930, setting a new standard for automotive excellence and prestige.

Throughout the 1930s and 1940s, V16 engines found their way into various luxury automobiles and racing cars. Manufacturers like Marmon, Peerless, and Auto Union experimented with this configuration, pushing the boundaries of engine design and performance. However, the complexity and cost of V16 engines limited their widespread adoption, confining them to niche applications.

The post-World War II era saw a decline in V16 engine development as more practical and efficient alternatives gained prominence. V8 and V12 engines became the preferred choices for high-performance applications, offering a balance between power and complexity. Despite this shift, the allure of the V16 never completely faded, with occasional concept cars and limited production models featuring this iconic engine layout.

In recent years, there has been a resurgence of interest in V16 engines, driven by advancements in materials science, manufacturing techniques, and powertrain technologies. Modern V16 concepts are being explored not just for their historical significance but for their potential in hybrid and electric-assisted systems. The inherent balance and smooth power delivery of V16 engines make them ideal candidates for integration with electric motors, offering a unique blend of traditional engineering and cutting-edge technology.

The evolution of V16 engines in the context of hybrid and electric systems presents exciting possibilities. By combining the torque characteristics of electric motors with the power and prestige of a V16 engine, manufacturers can create powertrains that offer unparalleled performance and efficiency. This fusion of technologies allows for innovative power management strategies, such as using electric assistance at low speeds and engaging the V16 for high-performance driving scenarios.

Furthermore, the revival of V16 concepts in modern automotive design serves as a bridge between heritage and innovation. It allows manufacturers to showcase their engineering prowess while addressing contemporary demands for reduced emissions and improved fuel efficiency. The integration of advanced materials, such as carbon fiber and lightweight alloys, enables the creation of V16 engines that are lighter and more compact than their historical counterparts, mitigating some of the traditional drawbacks associated with this configuration.

Throughout the 1930s and 1940s, V16 engines found their way into various luxury automobiles and racing cars. Manufacturers like Marmon, Peerless, and Auto Union experimented with this configuration, pushing the boundaries of engine design and performance. However, the complexity and cost of V16 engines limited their widespread adoption, confining them to niche applications.

The post-World War II era saw a decline in V16 engine development as more practical and efficient alternatives gained prominence. V8 and V12 engines became the preferred choices for high-performance applications, offering a balance between power and complexity. Despite this shift, the allure of the V16 never completely faded, with occasional concept cars and limited production models featuring this iconic engine layout.

In recent years, there has been a resurgence of interest in V16 engines, driven by advancements in materials science, manufacturing techniques, and powertrain technologies. Modern V16 concepts are being explored not just for their historical significance but for their potential in hybrid and electric-assisted systems. The inherent balance and smooth power delivery of V16 engines make them ideal candidates for integration with electric motors, offering a unique blend of traditional engineering and cutting-edge technology.

The evolution of V16 engines in the context of hybrid and electric systems presents exciting possibilities. By combining the torque characteristics of electric motors with the power and prestige of a V16 engine, manufacturers can create powertrains that offer unparalleled performance and efficiency. This fusion of technologies allows for innovative power management strategies, such as using electric assistance at low speeds and engaging the V16 for high-performance driving scenarios.

Furthermore, the revival of V16 concepts in modern automotive design serves as a bridge between heritage and innovation. It allows manufacturers to showcase their engineering prowess while addressing contemporary demands for reduced emissions and improved fuel efficiency. The integration of advanced materials, such as carbon fiber and lightweight alloys, enables the creation of V16 engines that are lighter and more compact than their historical counterparts, mitigating some of the traditional drawbacks associated with this configuration.

Market for High-End Powertrains

The market for high-end powertrains has been experiencing significant shifts in recent years, driven by a combination of technological advancements, changing consumer preferences, and stringent environmental regulations. The revival of V16 engine concepts for hybrid or electric-assisted systems represents a fascinating intersection of traditional automotive engineering and cutting-edge electrification technologies.

Luxury and ultra-luxury vehicle segments have shown a growing demand for powertrains that offer both exceptional performance and improved efficiency. This trend has led to increased interest in hybrid and electric-assisted systems, even in the most exclusive automotive categories. The integration of V16 engines with electrification technologies caters to a niche but influential market segment that values both heritage and innovation.

The potential market for these advanced powertrains extends beyond traditional luxury car manufacturers. Hypercar producers, limited-edition vehicle creators, and even some high-end yacht builders have expressed interest in incorporating such sophisticated power units. This diversification of potential applications broadens the market scope and increases the economic viability of developing these complex systems.

Consumer behavior in the high-end automotive sector indicates a willingness to pay premium prices for vehicles that offer unique technological features and unparalleled performance. The exclusivity and engineering prowess associated with a modernized V16 hybrid powertrain align well with the expectations of this discerning customer base. Additionally, the improved fuel efficiency and reduced emissions of these systems help address growing environmental concerns without compromising on the power and prestige desired by luxury vehicle owners.

Market analysis suggests that while the volume for such specialized powertrains may be relatively low, the profit margins can be substantial. The high development costs associated with these advanced systems can be offset by the premium pricing strategies typically employed in the ultra-luxury segment. Furthermore, the technological advancements and innovations developed for these powertrains often have trickle-down effects, benefiting broader product lines and potentially opening up new market segments.

The global nature of the luxury automotive market also plays a crucial role in the potential success of these advanced powertrains. Emerging markets, particularly in Asia and the Middle East, have shown strong appetites for high-end vehicles with cutting-edge technologies. This global demand helps to justify the significant investments required for the development and production of these sophisticated powertrain systems.

Luxury and ultra-luxury vehicle segments have shown a growing demand for powertrains that offer both exceptional performance and improved efficiency. This trend has led to increased interest in hybrid and electric-assisted systems, even in the most exclusive automotive categories. The integration of V16 engines with electrification technologies caters to a niche but influential market segment that values both heritage and innovation.

The potential market for these advanced powertrains extends beyond traditional luxury car manufacturers. Hypercar producers, limited-edition vehicle creators, and even some high-end yacht builders have expressed interest in incorporating such sophisticated power units. This diversification of potential applications broadens the market scope and increases the economic viability of developing these complex systems.

Consumer behavior in the high-end automotive sector indicates a willingness to pay premium prices for vehicles that offer unique technological features and unparalleled performance. The exclusivity and engineering prowess associated with a modernized V16 hybrid powertrain align well with the expectations of this discerning customer base. Additionally, the improved fuel efficiency and reduced emissions of these systems help address growing environmental concerns without compromising on the power and prestige desired by luxury vehicle owners.

Market analysis suggests that while the volume for such specialized powertrains may be relatively low, the profit margins can be substantial. The high development costs associated with these advanced systems can be offset by the premium pricing strategies typically employed in the ultra-luxury segment. Furthermore, the technological advancements and innovations developed for these powertrains often have trickle-down effects, benefiting broader product lines and potentially opening up new market segments.

The global nature of the luxury automotive market also plays a crucial role in the potential success of these advanced powertrains. Emerging markets, particularly in Asia and the Middle East, have shown strong appetites for high-end vehicles with cutting-edge technologies. This global demand helps to justify the significant investments required for the development and production of these sophisticated powertrain systems.

V16 Hybrid Challenges

The revival of V16 engine concepts for hybrid or electric-assisted systems presents several significant challenges. One of the primary obstacles is the integration of modern hybrid technology with the complex and large-scale V16 engine architecture. The sheer size and weight of a V16 engine pose difficulties in achieving optimal weight distribution and packaging within contemporary vehicle designs, which prioritize efficiency and space utilization.

Another major challenge lies in meeting stringent emissions regulations while maintaining the performance characteristics that make V16 engines desirable. Hybrid systems must be carefully engineered to complement the V16's power output while simultaneously reducing its environmental impact. This requires sophisticated control systems to manage the interplay between the combustion engine and electric components.

The cost factor presents a substantial hurdle in the development and production of V16 hybrid systems. The complexity of combining two advanced technologies – the V16 engine and hybrid electric systems – results in high research, development, and manufacturing expenses. This challenge is compounded by the limited market for such high-end, specialized powertrains, making it difficult to achieve economies of scale.

Thermal management is another critical issue. V16 engines generate significant heat, and when combined with the additional thermal output from electric motors and battery systems, cooling becomes a complex engineering problem. Innovative solutions are required to efficiently dissipate heat without compromising performance or reliability.

Balancing performance with fuel efficiency remains a persistent challenge. While hybrid systems can improve overall efficiency, the inherent fuel consumption of a large V16 engine must be addressed to meet modern expectations for reduced carbon footprints. Engineers must find ways to leverage electric assistance to enhance both power delivery and fuel economy without sacrificing the unique character of the V16 configuration.

The complexity of the powertrain control unit (PCU) increases exponentially with a V16 hybrid system. Coordinating the operation of 16 cylinders alongside electric motors, batteries, and regenerative braking systems requires highly sophisticated software and hardware solutions. This complexity not only affects development time and costs but also impacts long-term reliability and maintenance considerations.

Lastly, the challenge of market positioning and consumer acceptance cannot be overlooked. Convincing buyers to invest in a V16 hybrid system, which may be perceived as anachronistic in an era increasingly focused on downsizing and electrification, requires careful marketing strategies and a clear value proposition that justifies the technology's existence in modern vehicles.

Another major challenge lies in meeting stringent emissions regulations while maintaining the performance characteristics that make V16 engines desirable. Hybrid systems must be carefully engineered to complement the V16's power output while simultaneously reducing its environmental impact. This requires sophisticated control systems to manage the interplay between the combustion engine and electric components.

The cost factor presents a substantial hurdle in the development and production of V16 hybrid systems. The complexity of combining two advanced technologies – the V16 engine and hybrid electric systems – results in high research, development, and manufacturing expenses. This challenge is compounded by the limited market for such high-end, specialized powertrains, making it difficult to achieve economies of scale.

Thermal management is another critical issue. V16 engines generate significant heat, and when combined with the additional thermal output from electric motors and battery systems, cooling becomes a complex engineering problem. Innovative solutions are required to efficiently dissipate heat without compromising performance or reliability.

Balancing performance with fuel efficiency remains a persistent challenge. While hybrid systems can improve overall efficiency, the inherent fuel consumption of a large V16 engine must be addressed to meet modern expectations for reduced carbon footprints. Engineers must find ways to leverage electric assistance to enhance both power delivery and fuel economy without sacrificing the unique character of the V16 configuration.

The complexity of the powertrain control unit (PCU) increases exponentially with a V16 hybrid system. Coordinating the operation of 16 cylinders alongside electric motors, batteries, and regenerative braking systems requires highly sophisticated software and hardware solutions. This complexity not only affects development time and costs but also impacts long-term reliability and maintenance considerations.

Lastly, the challenge of market positioning and consumer acceptance cannot be overlooked. Convincing buyers to invest in a V16 hybrid system, which may be perceived as anachronistic in an era increasingly focused on downsizing and electrification, requires careful marketing strategies and a clear value proposition that justifies the technology's existence in modern vehicles.

Current V16 Hybrid Solutions

01 V16 engine design and configuration

V16 engines are characterized by their unique configuration of 16 cylinders arranged in a V-shape. This design allows for high power output while maintaining a relatively compact size. The V16 layout is often used in high-performance and luxury vehicles, as well as in some marine and industrial applications.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. This configuration allows for increased power output and smooth operation, making them suitable for high-performance vehicles and heavy-duty applications. The design typically involves two banks of eight cylinders, providing a balance between power and compactness.

- V16 engine applications in vehicles: V16 engines are used in various types of vehicles, including luxury cars, high-performance sports cars, and heavy-duty trucks. These engines provide exceptional power and torque, making them ideal for applications that require significant output. The implementation of V16 engines in vehicles often involves specialized design considerations to accommodate their size and power characteristics.

- V16 engine control systems: Advanced control systems are crucial for managing the complex operation of V16 engines. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers. Such control systems optimize performance, fuel efficiency, and emissions while ensuring smooth operation across various operating conditions.

- V16 engine cooling and lubrication: Effective cooling and lubrication systems are essential for V16 engines due to their high power output and thermal load. These systems may incorporate advanced cooling techniques, high-capacity oil pumps, and specialized lubricants to maintain optimal operating temperatures and reduce wear on engine components.

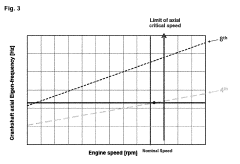

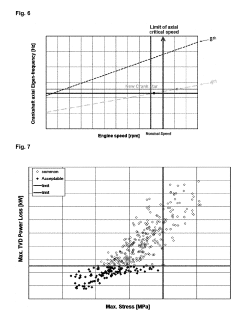

- V16 engine sound and vibration management: Managing sound and vibration is crucial in V16 engines to ensure smooth operation and passenger comfort. This may involve the use of specialized mounts, balancing shafts, and acoustic treatments. Additionally, some designs may incorporate active noise cancellation systems or tuned exhaust systems to enhance the engine's sound characteristics.

02 V16 engine components and accessories

Various components and accessories are specifically designed for V16 engines, including engine blocks, crankshafts, pistons, and cooling systems. These specialized parts are engineered to withstand the high power output and unique requirements of V16 engines, ensuring optimal performance and reliability.Expand Specific Solutions03 V16 engine control systems

Advanced control systems are employed in V16 engines to manage fuel injection, ignition timing, and other critical parameters. These systems often incorporate sophisticated electronic controls and sensors to optimize engine performance, fuel efficiency, and emissions across various operating conditions.Expand Specific Solutions04 V16 engine applications in vehicles

V16 engines are utilized in various vehicle applications, particularly in high-end luxury cars, sports cars, and specialized racing vehicles. The implementation of V16 engines in these vehicles requires careful integration with the vehicle's chassis, transmission, and other systems to harness the engine's power effectively.Expand Specific Solutions05 V16 engine sound and acoustics

The unique sound produced by V16 engines is a distinctive characteristic that contributes to their appeal. Acoustic engineering and exhaust system design play crucial roles in optimizing the engine's sound profile, balancing performance requirements with noise regulations and consumer preferences.Expand Specific Solutions

Key Automotive Innovators

The revival of V16 engine concepts for hybrid or electric-assisted systems represents an emerging trend in the automotive industry, currently in its early development stage. The market size for this technology is relatively small but growing, driven by luxury and high-performance vehicle segments. Technologically, it's still in the experimental phase, with companies like Ford Global Technologies, GM Global Technology Operations, and BYD Co., Ltd. leading research efforts. These firms are exploring ways to combine the power and prestige of V16 engines with modern hybrid or electric technologies to meet evolving emissions standards and performance demands. The integration of advanced materials and electrification techniques is crucial for overcoming traditional V16 limitations, such as weight and fuel efficiency.

Ford Global Technologies LLC

Technical Solution: Ford has been exploring innovative ways to revive the V16 engine concept for hybrid systems. Their approach involves integrating a compact V16 engine with electric motors to create a high-performance hybrid powertrain. The V16 engine is designed with advanced materials and manufacturing techniques to reduce weight and improve efficiency. Ford's system utilizes cylinder deactivation technology, allowing the engine to operate on fewer cylinders when full power is not needed, thus improving fuel economy[1]. The hybrid system incorporates a sophisticated power management system that optimizes the use of the V16 engine and electric motors based on driving conditions and power demands[3].

Strengths: High power output, improved fuel efficiency in hybrid configuration, and potential for use in luxury and performance vehicles. Weaknesses: Complexity of the system, potentially high production costs, and challenges in meeting stringent emissions regulations.

GM Global Technology Operations LLC

Technical Solution: GM's approach to reviving the V16 engine concept focuses on creating a modular hybrid powertrain system. Their design incorporates a compact V16 engine with advanced combustion technology and integrated electric motors. The system utilizes a split-power transmission that allows for seamless transitions between electric, hybrid, and full engine power modes[2]. GM's V16 hybrid concept also features advanced thermal management systems to optimize engine efficiency and reduce emissions. The company has developed a sophisticated electronic control unit that manages power distribution between the V16 engine and electric motors, adapting to various driving conditions and power requirements[4].

Strengths: Versatile powertrain suitable for various vehicle types, potential for high performance and efficiency. Weaknesses: High development costs, complexity in manufacturing and maintenance, potential weight issues.

V16 Electrification Patents

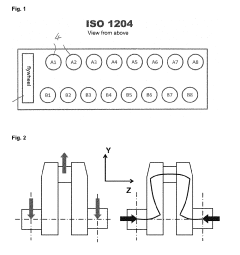

V16 crankstar and firing sequences

PatentActiveUS20190249598A1

Innovation

- The implementation of specific firing sequences and crankshaft designs with lengthwise symmetric or quasi-symmetric crank stars, combined with a torsional vibration damper, to optimize the angular sequence of crank throws and firing intervals, reducing axial and torsional vibrations and enhancing dynamic behavior.

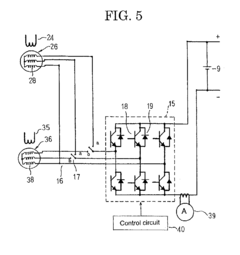

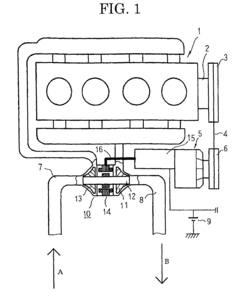

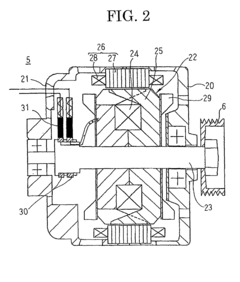

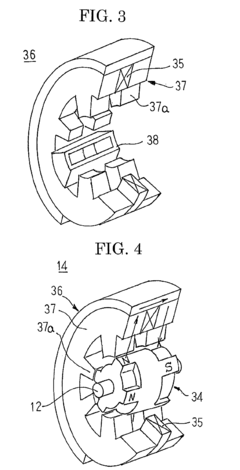

Hybrid engine assist system for vehicle

PatentInactiveEP2088300A1

Innovation

- An automotive hybrid engine assist system that shares a single inverter between a generator-motor and a turbocharger using an electric power direction change-over switch, reducing the number of inverters and simplifying wiring, allowing for a more compact and lightweight design.

Emissions Regulations Impact

The impact of emissions regulations on the revival of V16 engine concepts for hybrid or electric-assisted systems is significant and multifaceted. These regulations have become increasingly stringent over the years, pushing automotive manufacturers to explore innovative solutions that balance performance with environmental responsibility.

Historically, V16 engines were known for their power and smoothness but fell out of favor due to their high fuel consumption and emissions. However, the integration of hybrid or electric-assisted systems presents an opportunity to revive these engines while meeting modern emissions standards.

Emissions regulations, such as the European Union's Euro 6d and the United States' Tier 3 standards, have set strict limits on pollutants like carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. These regulations have forced manufacturers to reconsider traditional engine designs and explore alternative powertrains.

The combination of a V16 engine with hybrid or electric assistance can potentially address these regulatory challenges. By utilizing electric motors to supplement the V16 engine's power, manufacturers can reduce the overall fuel consumption and emissions while maintaining the desirable characteristics of a large-displacement engine.

Electric assistance can provide instant torque at low speeds, allowing the V16 engine to operate more efficiently in its optimal power band. This hybrid approach can also enable start-stop technology and regenerative braking, further improving fuel economy and reducing emissions in urban driving scenarios.

Moreover, the integration of advanced emission control technologies, such as selective catalytic reduction (SCR) and gasoline particulate filters (GPF), can help V16 hybrid systems meet stringent emissions standards. These technologies can effectively reduce NOx and particulate matter emissions, addressing key regulatory concerns.

The development of more efficient battery technologies and power electronics also plays a crucial role in making V16 hybrid systems viable under current emissions regulations. High-capacity batteries and advanced energy management systems can extend the electric-only range and optimize the overall powertrain efficiency.

However, challenges remain in balancing the weight and complexity of a V16 hybrid system with emissions targets. Manufacturers must carefully consider the trade-offs between performance, efficiency, and regulatory compliance when designing these advanced powertrains.

As emissions regulations continue to evolve, the future of V16 hybrid systems will depend on their ability to meet increasingly strict standards while delivering the performance and prestige associated with large-displacement engines. Ongoing research and development in areas such as lightweight materials, advanced combustion techniques, and electrification technologies will be crucial in ensuring the viability of these innovative powertrains in the face of tightening emissions regulations.

Historically, V16 engines were known for their power and smoothness but fell out of favor due to their high fuel consumption and emissions. However, the integration of hybrid or electric-assisted systems presents an opportunity to revive these engines while meeting modern emissions standards.

Emissions regulations, such as the European Union's Euro 6d and the United States' Tier 3 standards, have set strict limits on pollutants like carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. These regulations have forced manufacturers to reconsider traditional engine designs and explore alternative powertrains.

The combination of a V16 engine with hybrid or electric assistance can potentially address these regulatory challenges. By utilizing electric motors to supplement the V16 engine's power, manufacturers can reduce the overall fuel consumption and emissions while maintaining the desirable characteristics of a large-displacement engine.

Electric assistance can provide instant torque at low speeds, allowing the V16 engine to operate more efficiently in its optimal power band. This hybrid approach can also enable start-stop technology and regenerative braking, further improving fuel economy and reducing emissions in urban driving scenarios.

Moreover, the integration of advanced emission control technologies, such as selective catalytic reduction (SCR) and gasoline particulate filters (GPF), can help V16 hybrid systems meet stringent emissions standards. These technologies can effectively reduce NOx and particulate matter emissions, addressing key regulatory concerns.

The development of more efficient battery technologies and power electronics also plays a crucial role in making V16 hybrid systems viable under current emissions regulations. High-capacity batteries and advanced energy management systems can extend the electric-only range and optimize the overall powertrain efficiency.

However, challenges remain in balancing the weight and complexity of a V16 hybrid system with emissions targets. Manufacturers must carefully consider the trade-offs between performance, efficiency, and regulatory compliance when designing these advanced powertrains.

As emissions regulations continue to evolve, the future of V16 hybrid systems will depend on their ability to meet increasingly strict standards while delivering the performance and prestige associated with large-displacement engines. Ongoing research and development in areas such as lightweight materials, advanced combustion techniques, and electrification technologies will be crucial in ensuring the viability of these innovative powertrains in the face of tightening emissions regulations.

V16 E-System Integration

The integration of V16 engine concepts with hybrid or electric-assisted systems represents a significant technological challenge and opportunity in the automotive industry. This fusion aims to combine the power and prestige of traditional V16 engines with the efficiency and environmental benefits of modern electric propulsion systems.

The primary focus of V16 E-System Integration lies in developing a harmonious blend of mechanical and electrical components. Engineers must address the complex task of incorporating electric motors, battery packs, and power management systems into the existing V16 engine architecture. This integration requires careful consideration of weight distribution, thermal management, and overall vehicle dynamics.

One of the key challenges in this integration process is optimizing the power delivery between the V16 engine and the electric system. Sophisticated control algorithms are necessary to seamlessly transition between combustion and electric power, ensuring smooth acceleration and efficient energy utilization. These algorithms must account for various driving conditions, power demands, and battery state of charge.

The packaging of electric components within the limited space of a V16-powered vehicle presents another significant hurdle. Designers must find innovative ways to accommodate battery packs, inverters, and cooling systems without compromising the vehicle's performance or aesthetics. This may involve redesigning certain aspects of the vehicle's structure or utilizing advanced materials to reduce weight and create additional space.

Thermal management is a critical aspect of V16 E-System Integration. The combination of a high-performance combustion engine with electric components generates substantial heat, necessitating advanced cooling solutions. Engineers are exploring integrated cooling circuits that can efficiently manage heat from both the V16 engine and the electric system, ensuring optimal performance and longevity of all components.

The electrical architecture of the hybrid V16 system requires careful consideration. High-voltage systems must be safely integrated with the vehicle's existing 12V electrical system, ensuring proper isolation and protection. This integration also involves developing robust communication protocols between the engine control unit (ECU) and the hybrid system controller to optimize overall powertrain performance.

As emissions regulations become increasingly stringent, the V16 E-System Integration must also focus on reducing the environmental impact of these powerful engines. The electric assist can be leveraged to improve fuel efficiency and reduce emissions during low-load conditions, while the V16 engine provides the desired performance characteristics during high-demand situations.

The primary focus of V16 E-System Integration lies in developing a harmonious blend of mechanical and electrical components. Engineers must address the complex task of incorporating electric motors, battery packs, and power management systems into the existing V16 engine architecture. This integration requires careful consideration of weight distribution, thermal management, and overall vehicle dynamics.

One of the key challenges in this integration process is optimizing the power delivery between the V16 engine and the electric system. Sophisticated control algorithms are necessary to seamlessly transition between combustion and electric power, ensuring smooth acceleration and efficient energy utilization. These algorithms must account for various driving conditions, power demands, and battery state of charge.

The packaging of electric components within the limited space of a V16-powered vehicle presents another significant hurdle. Designers must find innovative ways to accommodate battery packs, inverters, and cooling systems without compromising the vehicle's performance or aesthetics. This may involve redesigning certain aspects of the vehicle's structure or utilizing advanced materials to reduce weight and create additional space.

Thermal management is a critical aspect of V16 E-System Integration. The combination of a high-performance combustion engine with electric components generates substantial heat, necessitating advanced cooling solutions. Engineers are exploring integrated cooling circuits that can efficiently manage heat from both the V16 engine and the electric system, ensuring optimal performance and longevity of all components.

The electrical architecture of the hybrid V16 system requires careful consideration. High-voltage systems must be safely integrated with the vehicle's existing 12V electrical system, ensuring proper isolation and protection. This integration also involves developing robust communication protocols between the engine control unit (ECU) and the hybrid system controller to optimize overall powertrain performance.

As emissions regulations become increasingly stringent, the V16 E-System Integration must also focus on reducing the environmental impact of these powerful engines. The electric assist can be leveraged to improve fuel efficiency and reduce emissions during low-load conditions, while the V16 engine provides the desired performance characteristics during high-demand situations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!