The acoustic signature distinctive to V16 engines and its importance in design

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Sound Evolution

The acoustic signature of V16 engines has undergone a significant evolution since their inception in the early 20th century. Initially developed for luxury automobiles and high-performance racing cars, V16 engines have always been synonymous with power, prestige, and a distinctive sound profile. The early V16 engines, such as those found in the Cadillac V-16 of the 1930s, produced a smooth, refined sound that set them apart from their smaller counterparts.

As engine technology advanced, so did the acoustic characteristics of V16 engines. The mid-20th century saw a shift towards higher-revving V16 engines in motorsports, particularly in Formula One. These engines produced a more aggressive, high-pitched sound that became iconic in racing circles. The sound was characterized by a complex harmonic structure, with a fundamental frequency determined by the engine's firing order and a rich tapestry of overtones.

The late 20th and early 21st centuries brought about significant changes in engine design, driven by environmental concerns and efficiency requirements. This led to the development of more compact and efficient V16 engines, often incorporating turbocharging or supercharging. These advancements altered the acoustic signature, introducing new elements such as the distinctive whistle of turbochargers and the whine of superchargers, layered over the traditional V16 sound.

Modern V16 engines, while rare, continue to evolve in their acoustic properties. Advanced materials and precision engineering have allowed for tighter tolerances and reduced mechanical noise, resulting in a purer expression of the engine's fundamental tones. Simultaneously, the integration of active sound design technologies has enabled manufacturers to fine-tune the acoustic output, enhancing desirable frequencies while suppressing others.

The importance of the V16 engine's acoustic signature in design cannot be overstated. It serves as a crucial brand identifier, particularly for luxury and high-performance vehicles. The unique sound profile contributes significantly to the emotional connection between the driver and the vehicle, enhancing the overall driving experience. Moreover, the acoustic characteristics play a vital role in marketing and brand perception, often becoming a key selling point for discerning customers who appreciate the auditory aspects of automotive engineering.

In recent years, the challenge of maintaining the distinctive V16 sound while meeting increasingly stringent noise regulations has led to innovative solutions. These include the use of electronically controlled exhaust systems, which can modulate the engine's sound based on driving conditions and user preferences. Additionally, some manufacturers have explored the use of artificial sound enhancement to preserve the essence of the V16 acoustic signature in an era of quieter, more efficient engines.

As engine technology advanced, so did the acoustic characteristics of V16 engines. The mid-20th century saw a shift towards higher-revving V16 engines in motorsports, particularly in Formula One. These engines produced a more aggressive, high-pitched sound that became iconic in racing circles. The sound was characterized by a complex harmonic structure, with a fundamental frequency determined by the engine's firing order and a rich tapestry of overtones.

The late 20th and early 21st centuries brought about significant changes in engine design, driven by environmental concerns and efficiency requirements. This led to the development of more compact and efficient V16 engines, often incorporating turbocharging or supercharging. These advancements altered the acoustic signature, introducing new elements such as the distinctive whistle of turbochargers and the whine of superchargers, layered over the traditional V16 sound.

Modern V16 engines, while rare, continue to evolve in their acoustic properties. Advanced materials and precision engineering have allowed for tighter tolerances and reduced mechanical noise, resulting in a purer expression of the engine's fundamental tones. Simultaneously, the integration of active sound design technologies has enabled manufacturers to fine-tune the acoustic output, enhancing desirable frequencies while suppressing others.

The importance of the V16 engine's acoustic signature in design cannot be overstated. It serves as a crucial brand identifier, particularly for luxury and high-performance vehicles. The unique sound profile contributes significantly to the emotional connection between the driver and the vehicle, enhancing the overall driving experience. Moreover, the acoustic characteristics play a vital role in marketing and brand perception, often becoming a key selling point for discerning customers who appreciate the auditory aspects of automotive engineering.

In recent years, the challenge of maintaining the distinctive V16 sound while meeting increasingly stringent noise regulations has led to innovative solutions. These include the use of electronically controlled exhaust systems, which can modulate the engine's sound based on driving conditions and user preferences. Additionally, some manufacturers have explored the use of artificial sound enhancement to preserve the essence of the V16 acoustic signature in an era of quieter, more efficient engines.

Market Demand Analysis

The market demand for V16 engines and their distinctive acoustic signature has been evolving significantly in recent years. While V16 engines are not common in mass-market vehicles, they hold a unique position in luxury and high-performance segments. The demand for these engines is primarily driven by enthusiasts, collectors, and ultra-luxury vehicle manufacturers who value the exclusivity and prestige associated with V16 power plants.

In the luxury automotive sector, there is a growing appreciation for the auditory experience provided by high-end engines. The distinctive sound of a V16 engine has become a key selling point, appealing to customers who seek not just performance, but also a multisensory driving experience. This has led to increased focus on acoustic engineering in engine design, with manufacturers investing heavily in creating signature engine notes that enhance brand identity and emotional connection with the vehicle.

The marine industry represents another significant market for V16 engines, particularly in large yachts and commercial vessels. Here, the acoustic signature is crucial for both comfort and regulatory compliance. Owners and operators demand powerful engines that can deliver high performance while maintaining low noise and vibration levels, making the acoustic design of V16 engines a critical factor in this sector.

In the realm of motorsports and racing, although V16 engines are less common due to regulations, there is still a niche demand for their unique characteristics. The sound of a V16 engine at high revs is often described as unparalleled, attracting spectators and enhancing the overall racing experience. This has led to some specialized racing series and events featuring V16-powered vehicles, catering to a dedicated fan base.

The aviation industry, particularly in the private jet sector, has shown interest in V16 engines for their power-to-weight ratio and potential for quieter operation. As noise regulations become stricter at airports worldwide, the ability to design V16 engines with optimized acoustic profiles becomes increasingly valuable.

Interestingly, the distinctive sound of V16 engines has also found applications beyond transportation. In the entertainment and media industries, there is a demand for authentic engine sounds for use in films, video games, and simulations. Sound designers and foley artists seek to capture and reproduce the unique acoustic signature of V16 engines to enhance realism and audience engagement.

As environmental concerns grow, the market is seeing a shift towards more sustainable technologies. However, this has not diminished the demand for V16 engines in certain sectors. Instead, it has spurred innovation in acoustic design to meet stricter noise regulations while maintaining the characteristic sound that enthusiasts cherish. This has led to increased research and development in active sound design and noise cancellation technologies specific to V16 configurations.

In the luxury automotive sector, there is a growing appreciation for the auditory experience provided by high-end engines. The distinctive sound of a V16 engine has become a key selling point, appealing to customers who seek not just performance, but also a multisensory driving experience. This has led to increased focus on acoustic engineering in engine design, with manufacturers investing heavily in creating signature engine notes that enhance brand identity and emotional connection with the vehicle.

The marine industry represents another significant market for V16 engines, particularly in large yachts and commercial vessels. Here, the acoustic signature is crucial for both comfort and regulatory compliance. Owners and operators demand powerful engines that can deliver high performance while maintaining low noise and vibration levels, making the acoustic design of V16 engines a critical factor in this sector.

In the realm of motorsports and racing, although V16 engines are less common due to regulations, there is still a niche demand for their unique characteristics. The sound of a V16 engine at high revs is often described as unparalleled, attracting spectators and enhancing the overall racing experience. This has led to some specialized racing series and events featuring V16-powered vehicles, catering to a dedicated fan base.

The aviation industry, particularly in the private jet sector, has shown interest in V16 engines for their power-to-weight ratio and potential for quieter operation. As noise regulations become stricter at airports worldwide, the ability to design V16 engines with optimized acoustic profiles becomes increasingly valuable.

Interestingly, the distinctive sound of V16 engines has also found applications beyond transportation. In the entertainment and media industries, there is a demand for authentic engine sounds for use in films, video games, and simulations. Sound designers and foley artists seek to capture and reproduce the unique acoustic signature of V16 engines to enhance realism and audience engagement.

As environmental concerns grow, the market is seeing a shift towards more sustainable technologies. However, this has not diminished the demand for V16 engines in certain sectors. Instead, it has spurred innovation in acoustic design to meet stricter noise regulations while maintaining the characteristic sound that enthusiasts cherish. This has led to increased research and development in active sound design and noise cancellation technologies specific to V16 configurations.

Technical Challenges

The development of V16 engines and their distinctive acoustic signature presents several technical challenges that engineers and designers must overcome. One of the primary difficulties lies in managing the complex vibration patterns inherent to the V16 configuration. With 16 cylinders arranged in a V-shape, the engine produces intricate harmonic frequencies that can lead to increased noise and vibration if not properly addressed.

Balancing the engine is another significant challenge. The large number of moving parts in a V16 engine creates substantial reciprocating and rotating masses that must be carefully balanced to minimize vibration and ensure smooth operation. This balancing act becomes even more critical when considering the engine's acoustic signature, as any imbalance can contribute to unwanted noise and affect the desired sound profile.

The design of the exhaust system poses another technical hurdle. Engineers must create a system that not only efficiently expels exhaust gases but also contributes to the desired acoustic signature. This involves careful tuning of exhaust manifolds, pipes, and mufflers to achieve the right balance between performance and sound quality. The challenge lies in creating a system that enhances the distinctive V16 sound while meeting increasingly stringent noise regulations.

Fuel efficiency and emissions control present additional challenges in V16 engine design. The large displacement and high power output of these engines often result in increased fuel consumption and emissions. Engineers must implement advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve efficiency without compromising the engine's performance or acoustic characteristics.

The integration of modern electronic control systems adds another layer of complexity. These systems must be calibrated to manage the engine's performance, fuel delivery, and emissions while also contributing to the desired acoustic signature. This requires sophisticated algorithms and sensors to monitor and adjust various engine parameters in real-time, ensuring optimal performance and sound quality across different operating conditions.

Material selection and manufacturing processes also play a crucial role in addressing the technical challenges of V16 engine design. Engineers must choose materials that can withstand the high temperatures and pressures associated with these powerful engines while also contributing to weight reduction and sound management. Advanced manufacturing techniques, such as precision casting and 3D printing, may be required to produce complex components with the necessary tolerances and acoustic properties.

Lastly, the challenge of heat management cannot be overlooked. The high power output of V16 engines generates significant heat that must be efficiently dissipated to prevent thermal stress and maintain performance. Cooling system design must be optimized to manage heat while minimizing its impact on the engine's acoustic signature, often requiring innovative solutions in coolant flow and radiator design.

Balancing the engine is another significant challenge. The large number of moving parts in a V16 engine creates substantial reciprocating and rotating masses that must be carefully balanced to minimize vibration and ensure smooth operation. This balancing act becomes even more critical when considering the engine's acoustic signature, as any imbalance can contribute to unwanted noise and affect the desired sound profile.

The design of the exhaust system poses another technical hurdle. Engineers must create a system that not only efficiently expels exhaust gases but also contributes to the desired acoustic signature. This involves careful tuning of exhaust manifolds, pipes, and mufflers to achieve the right balance between performance and sound quality. The challenge lies in creating a system that enhances the distinctive V16 sound while meeting increasingly stringent noise regulations.

Fuel efficiency and emissions control present additional challenges in V16 engine design. The large displacement and high power output of these engines often result in increased fuel consumption and emissions. Engineers must implement advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve efficiency without compromising the engine's performance or acoustic characteristics.

The integration of modern electronic control systems adds another layer of complexity. These systems must be calibrated to manage the engine's performance, fuel delivery, and emissions while also contributing to the desired acoustic signature. This requires sophisticated algorithms and sensors to monitor and adjust various engine parameters in real-time, ensuring optimal performance and sound quality across different operating conditions.

Material selection and manufacturing processes also play a crucial role in addressing the technical challenges of V16 engine design. Engineers must choose materials that can withstand the high temperatures and pressures associated with these powerful engines while also contributing to weight reduction and sound management. Advanced manufacturing techniques, such as precision casting and 3D printing, may be required to produce complex components with the necessary tolerances and acoustic properties.

Lastly, the challenge of heat management cannot be overlooked. The high power output of V16 engines generates significant heat that must be efficiently dissipated to prevent thermal stress and maintain performance. Cooling system design must be optimized to manage heat while minimizing its impact on the engine's acoustic signature, often requiring innovative solutions in coolant flow and radiator design.

Current Sound Solutions

01 Engine acoustic signature analysis

Methods and systems for analyzing the acoustic signature of V16 engines, including techniques for capturing, processing, and interpreting sound data to identify engine characteristics, performance issues, or potential faults. This analysis can be used for diagnostics, maintenance, and optimization of engine operation.- Engine acoustic signature analysis: Methods and systems for analyzing the acoustic signature of V16 engines, including techniques for capturing, processing, and interpreting sound data to identify engine characteristics, performance issues, or potential faults. This analysis can be used for diagnostics, maintenance, and optimization of engine operation.

- Noise reduction and sound management: Techniques for reducing noise and managing the acoustic output of V16 engines, including the use of sound-absorbing materials, active noise control systems, and exhaust system modifications. These approaches aim to improve the overall sound quality and reduce unwanted noise emissions from the engine.

- Engine monitoring and diagnostics: Systems and methods for monitoring V16 engine performance and conducting diagnostics based on acoustic signatures. This includes the use of sensors, data analysis algorithms, and machine learning techniques to detect anomalies, predict maintenance needs, and optimize engine performance based on sound patterns.

- Acoustic-based engine control systems: Development of engine control systems that utilize acoustic feedback to adjust engine parameters in real-time. These systems can optimize fuel efficiency, reduce emissions, and enhance overall engine performance by analyzing and responding to the acoustic signature of the V16 engine during operation.

- Acoustic signature simulation and modeling: Advanced simulation and modeling techniques for predicting and analyzing the acoustic signature of V16 engines. These methods allow for virtual testing and optimization of engine designs, reducing development time and costs while improving acoustic performance.

02 Noise reduction and sound management

Techniques for reducing noise and managing the acoustic output of V16 engines, including the use of advanced materials, design modifications, and active noise control systems. These approaches aim to improve the overall sound quality and reduce unwanted noise emissions from the engine.Expand Specific Solutions03 Engine monitoring and diagnostics

Systems and methods for monitoring V16 engine performance and conducting diagnostics based on acoustic signatures. This includes the use of sensors, data analysis algorithms, and machine learning techniques to detect anomalies, predict maintenance needs, and optimize engine performance.Expand Specific Solutions04 Acoustic-based security and authentication

Utilization of V16 engine acoustic signatures for security and authentication purposes, such as vehicle identification, anti-theft systems, and access control. These methods leverage the unique sound characteristics of V16 engines to create acoustic fingerprints for verification and authorization.Expand Specific Solutions05 Acoustic modeling and simulation

Development of acoustic models and simulation techniques for V16 engines, enabling virtual testing, design optimization, and prediction of acoustic behavior. These tools help in refining engine designs, reducing development costs, and improving overall performance and sound quality.Expand Specific Solutions

Key Industry Players

The acoustic signature of V16 engines represents a niche market within the automotive and aerospace industries, currently in a mature stage of development. While the market size is relatively small, it holds significant value for luxury and high-performance vehicle manufacturers. Companies like Mercedes-Benz Group AG and AVL List GmbH have demonstrated advanced technical capabilities in V16 engine design, focusing on optimizing acoustic characteristics. Other players such as Honda Motor Co., Ltd. and Toyota Motor Corp. have also contributed to the field, albeit to a lesser extent. The technology's maturity is evident in its limited but specialized applications, with ongoing research aimed at enhancing performance and efficiency while maintaining the distinctive sound profile.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated approach to V16 engine acoustic signature design, focusing on both performance and luxury. Their technology involves advanced exhaust system tuning, utilizing variable valve timing and intelligent muffler designs to create a distinctive sound profile. The company employs computational fluid dynamics (CFD) simulations to optimize exhaust flow and acoustic properties[1]. Additionally, they have implemented active noise control systems that can enhance or suppress specific frequencies of the engine sound, allowing for a customizable auditory experience[3]. This technology not only preserves the iconic V16 sound but also ensures compliance with strict noise regulations[5].

Strengths: Luxurious and distinctive sound profile, customizable acoustic experience, compliance with regulations. Weaknesses: Complex and potentially costly system, may require frequent calibration and maintenance.

AVL List GmbH

Technical Solution: AVL List GmbH has developed a comprehensive approach to V16 engine acoustic signature design through their Advanced Simulation Technologies division. Their method combines 1D and 3D simulation techniques to predict and optimize engine acoustics. The company utilizes their proprietary software, AVL EXCITE, to simulate the entire powertrain dynamics and noise generation[2]. For V16 engines specifically, they have implemented a multi-physics approach that considers combustion dynamics, structural vibrations, and fluid-structure interactions. AVL's technology also incorporates psychoacoustic principles to ensure the engine sound is not only distinctive but also pleasing to the human ear[4]. They have recently introduced machine learning algorithms to further refine their acoustic predictions and design processes[6].

Strengths: Comprehensive simulation capabilities, integration of psychoacoustics, advanced machine learning implementation. Weaknesses: High computational requirements, potential over-reliance on simulations versus real-world testing.

Core Acoustic Innovations

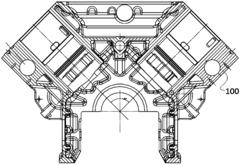

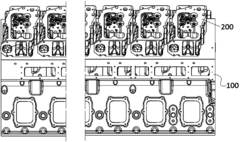

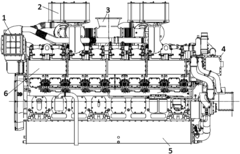

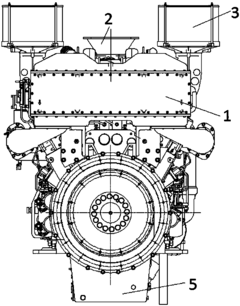

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

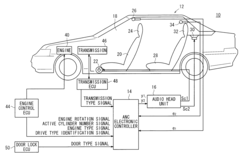

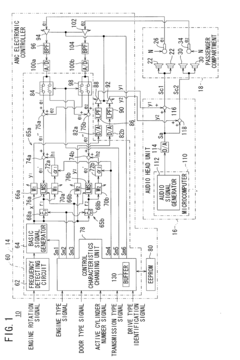

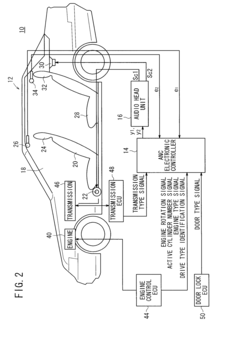

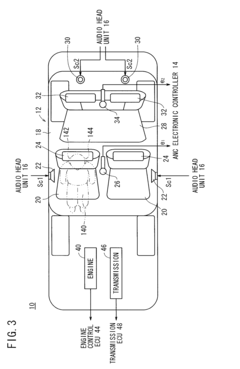

Active noise control apparatus

PatentInactiveUS20080240456A1

Innovation

- An ANC system with a control signal generator that adjusts control characteristics based on specification information from electronic control units (ECUs) via a control characteristics changing unit, allowing for adaptive changes in control parameters such as step size, frequency range, and amplification factors to ensure optimal silencing performance across various vehicle configurations.

Regulatory Considerations

The regulatory landscape surrounding V16 engines and their acoustic signatures is complex and multifaceted. Environmental regulations play a significant role in shaping the design and production of these engines. Many countries have implemented strict noise pollution laws that limit the permissible sound levels emitted by vehicles, including those with V16 engines. These regulations often specify maximum decibel levels for different operating conditions and times of day.

In the European Union, for instance, the Environmental Noise Directive (2002/49/EC) sets guidelines for assessing and managing environmental noise, including that produced by road vehicles. This directive has led to the implementation of noise maps and action plans in many urban areas, potentially affecting the use of V16 engines in certain locations.

Similarly, in the United States, the Noise Control Act of 1972 and subsequent amendments have established federal standards for noise emission levels of motor vehicles. The Environmental Protection Agency (EPA) has the authority to regulate noise pollution, which includes setting limits on vehicle noise emissions.

Furthermore, many local jurisdictions have their own noise ordinances that may impose additional restrictions on vehicle sound levels. These local regulations can vary significantly from one area to another, creating a patchwork of requirements that manufacturers must navigate.

Emissions regulations also indirectly impact the acoustic signature of V16 engines. As stricter emissions standards are implemented globally, manufacturers are compelled to develop more efficient engines and exhaust systems. These changes can alter the traditional sound profile of V16 engines, necessitating careful design considerations to maintain their distinctive acoustic characteristics while meeting regulatory requirements.

The automotive industry must also contend with regulations related to pedestrian safety. In some regions, there are requirements for electric and hybrid vehicles to produce artificial sounds at low speeds to alert pedestrians. While not directly applicable to V16 engines, these regulations demonstrate the increasing attention paid to vehicle acoustics in the regulatory sphere.

As environmental concerns continue to grow, it is likely that regulations affecting engine noise and emissions will become more stringent. This evolving regulatory landscape presents both challenges and opportunities for V16 engine designers. They must balance the desire to preserve the iconic sound of these engines with the need to comply with current and future regulations, potentially leading to innovative solutions in acoustic engineering and engine design.

In the European Union, for instance, the Environmental Noise Directive (2002/49/EC) sets guidelines for assessing and managing environmental noise, including that produced by road vehicles. This directive has led to the implementation of noise maps and action plans in many urban areas, potentially affecting the use of V16 engines in certain locations.

Similarly, in the United States, the Noise Control Act of 1972 and subsequent amendments have established federal standards for noise emission levels of motor vehicles. The Environmental Protection Agency (EPA) has the authority to regulate noise pollution, which includes setting limits on vehicle noise emissions.

Furthermore, many local jurisdictions have their own noise ordinances that may impose additional restrictions on vehicle sound levels. These local regulations can vary significantly from one area to another, creating a patchwork of requirements that manufacturers must navigate.

Emissions regulations also indirectly impact the acoustic signature of V16 engines. As stricter emissions standards are implemented globally, manufacturers are compelled to develop more efficient engines and exhaust systems. These changes can alter the traditional sound profile of V16 engines, necessitating careful design considerations to maintain their distinctive acoustic characteristics while meeting regulatory requirements.

The automotive industry must also contend with regulations related to pedestrian safety. In some regions, there are requirements for electric and hybrid vehicles to produce artificial sounds at low speeds to alert pedestrians. While not directly applicable to V16 engines, these regulations demonstrate the increasing attention paid to vehicle acoustics in the regulatory sphere.

As environmental concerns continue to grow, it is likely that regulations affecting engine noise and emissions will become more stringent. This evolving regulatory landscape presents both challenges and opportunities for V16 engine designers. They must balance the desire to preserve the iconic sound of these engines with the need to comply with current and future regulations, potentially leading to innovative solutions in acoustic engineering and engine design.

Environmental Impact

The acoustic signature of V16 engines has significant environmental implications that extend beyond mere performance considerations. These powerful engines, known for their distinctive sound, contribute to noise pollution in urban and rural areas alike. The low-frequency rumble and high-pitched whine characteristic of V16 engines can travel long distances, potentially disrupting wildlife habitats and affecting human communities.

In urban environments, the noise generated by V16 engines can contribute to overall ambient noise levels, which have been linked to various health issues, including stress, sleep disturbances, and cardiovascular problems. This is particularly concerning in densely populated areas where luxury vehicles equipped with V16 engines are more likely to be operated.

From an ecological perspective, the acoustic impact of V16 engines on wildlife cannot be overlooked. Many animal species rely on acoustic communication for survival, mating, and navigation. The intrusion of artificial sounds, especially those as distinctive as V16 engines, can mask natural sounds and disrupt ecosystems. This can lead to changes in animal behavior, breeding patterns, and even population dynamics.

However, it's important to note that the environmental impact of V16 engines extends beyond noise pollution. These engines are typically associated with high fuel consumption and increased emissions, contributing to air pollution and greenhouse gas emissions. As global efforts to combat climate change intensify, the continued use and development of V16 engines face scrutiny from environmental regulators and advocacy groups.

In response to these environmental concerns, engine designers and automotive manufacturers are exploring ways to mitigate the acoustic and environmental impact of V16 engines. This includes the development of advanced sound dampening technologies, active noise cancellation systems, and more efficient combustion processes. Some manufacturers are also investigating hybrid or electric powertrains that can complement or replace traditional V16 engines, potentially offering a compromise between performance and environmental responsibility.

The challenge for designers lies in balancing the iconic sound that enthusiasts associate with V16 engines against the growing demand for more environmentally friendly vehicles. This balance may involve innovative engineering solutions that preserve the essence of the V16 acoustic signature while significantly reducing its environmental footprint. As regulations tighten and consumer preferences evolve, the future of V16 engines will likely depend on the industry's ability to address these environmental concerns without compromising the unique auditory experience that defines these powerplants.

In urban environments, the noise generated by V16 engines can contribute to overall ambient noise levels, which have been linked to various health issues, including stress, sleep disturbances, and cardiovascular problems. This is particularly concerning in densely populated areas where luxury vehicles equipped with V16 engines are more likely to be operated.

From an ecological perspective, the acoustic impact of V16 engines on wildlife cannot be overlooked. Many animal species rely on acoustic communication for survival, mating, and navigation. The intrusion of artificial sounds, especially those as distinctive as V16 engines, can mask natural sounds and disrupt ecosystems. This can lead to changes in animal behavior, breeding patterns, and even population dynamics.

However, it's important to note that the environmental impact of V16 engines extends beyond noise pollution. These engines are typically associated with high fuel consumption and increased emissions, contributing to air pollution and greenhouse gas emissions. As global efforts to combat climate change intensify, the continued use and development of V16 engines face scrutiny from environmental regulators and advocacy groups.

In response to these environmental concerns, engine designers and automotive manufacturers are exploring ways to mitigate the acoustic and environmental impact of V16 engines. This includes the development of advanced sound dampening technologies, active noise cancellation systems, and more efficient combustion processes. Some manufacturers are also investigating hybrid or electric powertrains that can complement or replace traditional V16 engines, potentially offering a compromise between performance and environmental responsibility.

The challenge for designers lies in balancing the iconic sound that enthusiasts associate with V16 engines against the growing demand for more environmentally friendly vehicles. This balance may involve innovative engineering solutions that preserve the essence of the V16 acoustic signature while significantly reducing its environmental footprint. As regulations tighten and consumer preferences evolve, the future of V16 engines will likely depend on the industry's ability to address these environmental concerns without compromising the unique auditory experience that defines these powerplants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!