Synergies between V16 engines and light-duty electric vehicle hybrids

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16-EV Hybrid Synergy Background and Objectives

The synergy between V16 engines and light-duty electric vehicle hybrids represents a fascinating convergence of traditional high-performance combustion technology and cutting-edge electrification. This unique combination has its roots in the automotive industry's pursuit of both power and efficiency, a journey that began in the early 20th century with the development of powerful multi-cylinder engines and has now evolved to include hybrid powertrains.

V16 engines, known for their smooth operation and immense power output, have historically been reserved for luxury and high-performance vehicles. These engines reached their peak popularity in the 1930s, with iconic models from manufacturers like Cadillac and Marmon. However, their complexity, size, and fuel consumption led to a decline in their use over the following decades.

On the other hand, light-duty electric vehicle hybrids have gained significant traction since the late 1990s, driven by increasing environmental concerns and the need for improved fuel efficiency. These systems combine internal combustion engines with electric motors and battery packs to optimize energy use and reduce emissions.

The exploration of synergies between V16 engines and hybrid technology aims to address several key objectives. Primarily, it seeks to leverage the power and prestige of V16 engines while mitigating their inherent inefficiencies through electrification. This combination could potentially offer a best-of-both-worlds scenario for ultra-luxury and high-performance vehicle segments.

Another objective is to push the boundaries of hybrid technology integration in complex, high-output powertrains. By successfully marrying a V16 engine with hybrid systems, manufacturers can demonstrate their engineering prowess and pave the way for advanced hybrid solutions in other multi-cylinder configurations.

Furthermore, this synergy aims to explore new avenues for emissions reduction in high-performance vehicles. By incorporating hybrid technology, V16-powered vehicles could potentially meet increasingly stringent environmental regulations while maintaining their characteristic power output and driving experience.

The development of V16-EV hybrid systems also serves as a testbed for advanced power management and control systems. The complexity of coordinating a large, multi-cylinder engine with electric motors presents unique challenges and opportunities for innovation in powertrain control algorithms and energy distribution strategies.

Lastly, this technological exploration could lead to breakthroughs in thermal management and energy recovery systems. The heat generated by a V16 engine, coupled with the electrical systems of a hybrid powertrain, necessitates advanced cooling solutions and offers potential for novel energy recuperation techniques.

V16 engines, known for their smooth operation and immense power output, have historically been reserved for luxury and high-performance vehicles. These engines reached their peak popularity in the 1930s, with iconic models from manufacturers like Cadillac and Marmon. However, their complexity, size, and fuel consumption led to a decline in their use over the following decades.

On the other hand, light-duty electric vehicle hybrids have gained significant traction since the late 1990s, driven by increasing environmental concerns and the need for improved fuel efficiency. These systems combine internal combustion engines with electric motors and battery packs to optimize energy use and reduce emissions.

The exploration of synergies between V16 engines and hybrid technology aims to address several key objectives. Primarily, it seeks to leverage the power and prestige of V16 engines while mitigating their inherent inefficiencies through electrification. This combination could potentially offer a best-of-both-worlds scenario for ultra-luxury and high-performance vehicle segments.

Another objective is to push the boundaries of hybrid technology integration in complex, high-output powertrains. By successfully marrying a V16 engine with hybrid systems, manufacturers can demonstrate their engineering prowess and pave the way for advanced hybrid solutions in other multi-cylinder configurations.

Furthermore, this synergy aims to explore new avenues for emissions reduction in high-performance vehicles. By incorporating hybrid technology, V16-powered vehicles could potentially meet increasingly stringent environmental regulations while maintaining their characteristic power output and driving experience.

The development of V16-EV hybrid systems also serves as a testbed for advanced power management and control systems. The complexity of coordinating a large, multi-cylinder engine with electric motors presents unique challenges and opportunities for innovation in powertrain control algorithms and energy distribution strategies.

Lastly, this technological exploration could lead to breakthroughs in thermal management and energy recovery systems. The heat generated by a V16 engine, coupled with the electrical systems of a hybrid powertrain, necessitates advanced cooling solutions and offers potential for novel energy recuperation techniques.

Market Analysis for V16-EV Hybrid Vehicles

The market for V16-EV hybrid vehicles represents a niche but potentially lucrative segment within the automotive industry. This unique combination of a powerful V16 engine with electric vehicle technology caters to a specific consumer base that values both high performance and environmental consciousness.

Currently, the market for V16-EV hybrids is relatively small, primarily due to the limited production of V16 engines and the specialized nature of such vehicles. However, there is growing interest from luxury and ultra-luxury car manufacturers who see potential in this segment. These vehicles appeal to affluent consumers who desire the prestige and power of a V16 engine while also embracing the eco-friendly aspects of hybrid technology.

The target market for V16-EV hybrids consists mainly of high-net-worth individuals, car enthusiasts, and collectors. These consumers are willing to pay a premium for exclusive, high-performance vehicles that also offer improved fuel efficiency and reduced emissions compared to traditional V16-powered cars.

Market trends indicate a shift towards more sustainable luxury vehicles, with many premium brands investing in electrification. This trend aligns well with the concept of V16-EV hybrids, as they combine the allure of a powerful combustion engine with the benefits of electric propulsion.

The potential market size for V16-EV hybrids is estimated to be in the thousands of units annually, given the exclusivity and high price point of such vehicles. While this may seem small compared to mainstream vehicle segments, the high profit margins associated with ultra-luxury vehicles make it an attractive proposition for manufacturers.

Geographically, the primary markets for V16-EV hybrids are likely to be North America, Europe, and parts of Asia, particularly in countries with a strong luxury car market and a growing emphasis on environmental sustainability. Cities known for their concentration of wealth and car culture, such as Dubai, Monaco, and Beverly Hills, are expected to be key focal points for sales.

The market for V16-EV hybrids faces competition from other high-performance hybrid and electric vehicles, as well as traditional luxury combustion engine cars. However, the unique combination of a V16 engine with hybrid technology provides a distinct selling point that sets these vehicles apart in the ultra-luxury segment.

Looking ahead, the market for V16-EV hybrids is expected to evolve alongside advancements in electric vehicle technology and changing consumer preferences. As battery technology improves and emission regulations tighten, manufacturers may need to further optimize the balance between the V16 engine's power and the electric components' efficiency to maintain market relevance and meet regulatory requirements.

Currently, the market for V16-EV hybrids is relatively small, primarily due to the limited production of V16 engines and the specialized nature of such vehicles. However, there is growing interest from luxury and ultra-luxury car manufacturers who see potential in this segment. These vehicles appeal to affluent consumers who desire the prestige and power of a V16 engine while also embracing the eco-friendly aspects of hybrid technology.

The target market for V16-EV hybrids consists mainly of high-net-worth individuals, car enthusiasts, and collectors. These consumers are willing to pay a premium for exclusive, high-performance vehicles that also offer improved fuel efficiency and reduced emissions compared to traditional V16-powered cars.

Market trends indicate a shift towards more sustainable luxury vehicles, with many premium brands investing in electrification. This trend aligns well with the concept of V16-EV hybrids, as they combine the allure of a powerful combustion engine with the benefits of electric propulsion.

The potential market size for V16-EV hybrids is estimated to be in the thousands of units annually, given the exclusivity and high price point of such vehicles. While this may seem small compared to mainstream vehicle segments, the high profit margins associated with ultra-luxury vehicles make it an attractive proposition for manufacturers.

Geographically, the primary markets for V16-EV hybrids are likely to be North America, Europe, and parts of Asia, particularly in countries with a strong luxury car market and a growing emphasis on environmental sustainability. Cities known for their concentration of wealth and car culture, such as Dubai, Monaco, and Beverly Hills, are expected to be key focal points for sales.

The market for V16-EV hybrids faces competition from other high-performance hybrid and electric vehicles, as well as traditional luxury combustion engine cars. However, the unique combination of a V16 engine with hybrid technology provides a distinct selling point that sets these vehicles apart in the ultra-luxury segment.

Looking ahead, the market for V16-EV hybrids is expected to evolve alongside advancements in electric vehicle technology and changing consumer preferences. As battery technology improves and emission regulations tighten, manufacturers may need to further optimize the balance between the V16 engine's power and the electric components' efficiency to maintain market relevance and meet regulatory requirements.

Technical Challenges in V16-EV Hybrid Integration

The integration of V16 engines with light-duty electric vehicle hybrid systems presents several significant technical challenges. One of the primary obstacles is the sheer size and weight of V16 engines, which are typically designed for high-performance applications. Incorporating such a large engine into a light-duty vehicle chassis requires extensive redesign and reinforcement of the vehicle structure to accommodate the increased mass and dimensions.

Power management and distribution pose another critical challenge. Balancing the power output between the V16 engine and the electric motor(s) requires sophisticated control systems to optimize efficiency and performance. The complexity of this task is amplified by the need to seamlessly transition between different power sources and operating modes, such as electric-only, engine-only, and combined power delivery.

Thermal management is a significant concern in V16-EV hybrid integration. The heat generated by a V16 engine, combined with the thermal output of high-capacity batteries and electric motors, necessitates advanced cooling systems. These systems must be capable of efficiently dissipating heat from multiple sources while maintaining optimal operating temperatures for all components.

Packaging and space utilization present substantial hurdles. Fitting a V16 engine, electric motor(s), battery pack, and associated power electronics into a light-duty vehicle platform requires innovative design solutions. Engineers must optimize the layout to maintain proper weight distribution, ensure adequate passenger and cargo space, and meet safety standards.

Emissions control and fuel efficiency are paramount challenges in this integration. While the hybrid system can potentially improve overall efficiency, the large displacement of a V16 engine may counteract these gains. Developing strategies to minimize emissions and maximize fuel economy, particularly during urban driving cycles, requires advanced engine management systems and hybrid control algorithms.

Drivetrain integration poses unique challenges due to the torque characteristics of V16 engines and electric motors. Designing a transmission system that can effectively handle the high torque output of both power sources while providing smooth operation across various driving conditions is a complex engineering task.

Lastly, cost and manufacturability present significant obstacles. The complexity of integrating high-performance V16 engines with electric hybrid systems in light-duty vehicles leads to increased production costs. Developing manufacturing processes that can efficiently produce these complex powertrains at scale, while maintaining quality and reliability, is a major challenge for automotive manufacturers.

Power management and distribution pose another critical challenge. Balancing the power output between the V16 engine and the electric motor(s) requires sophisticated control systems to optimize efficiency and performance. The complexity of this task is amplified by the need to seamlessly transition between different power sources and operating modes, such as electric-only, engine-only, and combined power delivery.

Thermal management is a significant concern in V16-EV hybrid integration. The heat generated by a V16 engine, combined with the thermal output of high-capacity batteries and electric motors, necessitates advanced cooling systems. These systems must be capable of efficiently dissipating heat from multiple sources while maintaining optimal operating temperatures for all components.

Packaging and space utilization present substantial hurdles. Fitting a V16 engine, electric motor(s), battery pack, and associated power electronics into a light-duty vehicle platform requires innovative design solutions. Engineers must optimize the layout to maintain proper weight distribution, ensure adequate passenger and cargo space, and meet safety standards.

Emissions control and fuel efficiency are paramount challenges in this integration. While the hybrid system can potentially improve overall efficiency, the large displacement of a V16 engine may counteract these gains. Developing strategies to minimize emissions and maximize fuel economy, particularly during urban driving cycles, requires advanced engine management systems and hybrid control algorithms.

Drivetrain integration poses unique challenges due to the torque characteristics of V16 engines and electric motors. Designing a transmission system that can effectively handle the high torque output of both power sources while providing smooth operation across various driving conditions is a complex engineering task.

Lastly, cost and manufacturability present significant obstacles. The complexity of integrating high-performance V16 engines with electric hybrid systems in light-duty vehicles leads to increased production costs. Developing manufacturing processes that can efficiently produce these complex powertrains at scale, while maintaining quality and reliability, is a major challenge for automotive manufacturers.

Current V16-EV Hybrid Powertrain Solutions

01 Hybrid powertrain configurations for light-duty vehicles

Various hybrid powertrain configurations are designed for light-duty vehicles, combining internal combustion engines with electric motors. These systems aim to improve fuel efficiency and reduce emissions while maintaining performance. The configurations may include parallel, series, or power-split hybrid arrangements, optimizing the use of both power sources.- Hybrid powertrains combining V16 engines and electric motors: Integration of V16 internal combustion engines with electric motors in hybrid powertrains for light-duty vehicles. This combination aims to balance power output with improved fuel efficiency and reduced emissions. The system may include advanced power management and control strategies to optimize performance and energy usage.

- Energy management systems for V16 hybrid vehicles: Sophisticated energy management systems designed specifically for hybrid vehicles utilizing V16 engines. These systems coordinate power distribution between the combustion engine and electric motor(s), manage battery charging, and implement regenerative braking. They may also include adaptive algorithms to optimize efficiency based on driving conditions and patterns.

- Lightweight materials and design for V16 hybrid vehicles: Use of advanced lightweight materials and innovative design techniques to offset the weight of V16 engines in light-duty hybrid vehicles. This may include carbon fiber components, aluminum alloys, and optimized structural designs to improve overall vehicle efficiency and performance while maintaining the power advantages of a V16 engine.

- Electric assist systems for V16 engines: Development of electric assist systems specifically tailored for V16 engines in light-duty hybrid vehicles. These systems may include integrated starter-generators, electric superchargers, or torque-fill devices to complement the V16 engine's power characteristics and improve overall drivetrain efficiency and responsiveness.

- Emissions reduction technologies for V16 hybrid powertrains: Advanced emissions control systems and technologies specifically designed for V16 engines in hybrid configurations. This may include innovative catalytic converters, exhaust gas recirculation systems, and engine management strategies to minimize emissions while maintaining the performance characteristics of the V16 engine in a light-duty hybrid vehicle application.

02 Electric motor integration in V-engine layouts

Integration of electric motors into V-engine layouts, potentially including V16 configurations, for hybrid vehicles. This approach allows for compact packaging of both the internal combustion engine and electric propulsion components, maximizing space efficiency in light-duty vehicles while providing hybrid capabilities.Expand Specific Solutions03 Energy management and control systems for hybrid vehicles

Advanced energy management and control systems are developed for hybrid vehicles, including those with high-cylinder-count engines like V16s. These systems optimize power distribution between the internal combustion engine and electric motor(s), manage battery charging, and control vehicle operations to maximize efficiency and performance.Expand Specific Solutions04 Lightweight materials and design for hybrid powertrains

Use of lightweight materials and innovative design techniques in hybrid powertrains, particularly for light-duty vehicles. This approach helps offset the additional weight of hybrid components, improving overall vehicle efficiency and performance. Materials may include advanced alloys, composites, and optimized structural designs.Expand Specific Solutions05 Regenerative braking and energy recovery systems

Implementation of regenerative braking and energy recovery systems in light-duty hybrid vehicles. These systems capture kinetic energy during deceleration and braking, converting it to electrical energy for storage in the vehicle's battery. This technology improves overall energy efficiency and extends the electric driving range of hybrid vehicles.Expand Specific Solutions

Key Players in V16 and EV Hybrid Industries

The synergy between V16 engines and light-duty electric vehicle hybrids represents an emerging field in automotive technology, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for high-performance hybrid vehicles. Technical maturity is still evolving, with companies like GM Global Technology Operations, Hyundai Motor, and Ford Global Technologies leading research efforts. Other players such as Honda Motor, BMW, and Porsche are also contributing to advancements in this niche. The competition is intensifying as automakers seek to balance power and efficiency, with a focus on integrating V16 engines with electric powertrains for improved performance and reduced emissions in luxury and sports vehicle segments.

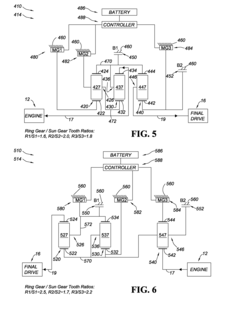

GM Global Technology Operations LLC

Technical Solution: GM has developed a hybrid powertrain system that combines a V16 engine with electric motors for light-duty vehicles. The system utilizes a split-power transmission architecture, where the V16 engine is primarily used for high-power demands and highway cruising, while the electric motors provide instant torque for acceleration and low-speed operation. The V16 engine is designed with cylinder deactivation technology, allowing it to operate as a V8 or even V4 for improved fuel efficiency when full power is not required[1]. The electric motors are integrated into the transmission, providing seamless power blending and regenerative braking capabilities[3].

Strengths: High power output for demanding applications, improved fuel efficiency through cylinder deactivation, seamless power blending. Weaknesses: Complexity of the system, potentially higher production costs, weight considerations for light-duty vehicles.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a unique hybrid system that pairs a downsized V16 engine with electric motors for light-duty vehicles. The V16 engine is designed with a compact layout and lightweight materials to minimize its footprint and weight. It employs advanced variable valve timing and direct injection technologies to optimize efficiency[2]. The hybrid system uses a power-split device that allows the V16 engine to operate at its most efficient points while the electric motors fill in the power gaps and provide low-speed propulsion. Hyundai's system also incorporates a high-capacity battery pack and intelligent power management software to maximize electric-only driving range[4].

Strengths: Compact design suitable for light-duty vehicles, high power-to-weight ratio, advanced efficiency technologies. Weaknesses: Potential reliability concerns with a complex V16 engine, higher manufacturing costs, cooling challenges in a compact package.

Core Innovations in V16-EV Hybrid Synergy

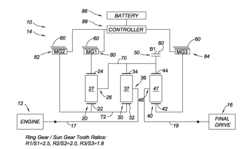

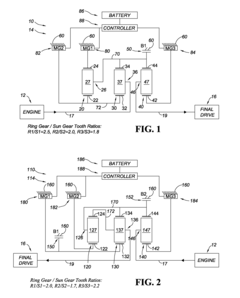

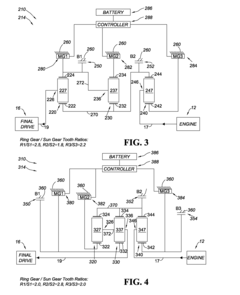

Hybrid powertrain having three planetary gearsets and brakes

PatentInactiveUS20080119314A1

Innovation

- A continuously-variable hybrid transmission system utilizing three planetary gear sets, three motor/generators, and brakes to enable series hybrid reverse driving, reducing battery power needs and optimizing motor/generator operation for efficient forward and reverse driving.

Environmental Impact Assessment

The integration of V16 engines with light-duty electric vehicle hybrids presents a unique opportunity to assess the environmental impact of this synergistic approach. This combination aims to leverage the power and performance of V16 engines while harnessing the efficiency and emissions benefits of electric propulsion systems.

One of the primary environmental considerations is the potential reduction in overall greenhouse gas emissions. By utilizing electric power for low-speed urban driving and the V16 engine for high-performance scenarios, this hybrid system could significantly decrease carbon dioxide emissions compared to traditional V16-powered vehicles. However, the exact reduction would depend on factors such as driving patterns, electric range, and the source of electricity used for charging.

Air quality improvements in urban areas are another potential benefit of this hybrid system. The ability to operate in all-electric mode for short distances could lead to reduced local air pollutants, including nitrogen oxides and particulate matter, which are particularly problematic in densely populated areas.

The environmental impact of battery production and disposal must also be considered. While the hybrid system may require smaller battery packs compared to fully electric vehicles, the manufacturing process still involves energy-intensive production and the use of rare earth materials. Proper recycling and disposal protocols would need to be established to mitigate long-term environmental effects.

Fuel efficiency improvements could lead to reduced overall fuel consumption, potentially decreasing the demand for fossil fuels and the associated environmental impacts of oil extraction and refining. However, this benefit may be partially offset by the increased complexity and resource requirements of manufacturing both a V16 engine and an electric powertrain.

Noise pollution is another aspect to consider. Electric operation could significantly reduce noise levels in urban environments, while the V16 engine would provide the desired auditory experience during high-performance driving scenarios. This dual-mode operation could help balance performance expectations with environmental concerns.

The lifecycle assessment of these hybrid vehicles would need to account for the production, use, and end-of-life phases. While the use phase may show improvements in emissions and efficiency, the increased complexity of the powertrain could lead to higher environmental impacts during production and potentially more challenging recycling processes.

In conclusion, the environmental impact of combining V16 engines with light-duty electric vehicle hybrids is multifaceted. While there are potential benefits in terms of emissions reduction and improved urban air quality, careful consideration must be given to the entire lifecycle of the vehicle to ensure a net positive environmental impact.

One of the primary environmental considerations is the potential reduction in overall greenhouse gas emissions. By utilizing electric power for low-speed urban driving and the V16 engine for high-performance scenarios, this hybrid system could significantly decrease carbon dioxide emissions compared to traditional V16-powered vehicles. However, the exact reduction would depend on factors such as driving patterns, electric range, and the source of electricity used for charging.

Air quality improvements in urban areas are another potential benefit of this hybrid system. The ability to operate in all-electric mode for short distances could lead to reduced local air pollutants, including nitrogen oxides and particulate matter, which are particularly problematic in densely populated areas.

The environmental impact of battery production and disposal must also be considered. While the hybrid system may require smaller battery packs compared to fully electric vehicles, the manufacturing process still involves energy-intensive production and the use of rare earth materials. Proper recycling and disposal protocols would need to be established to mitigate long-term environmental effects.

Fuel efficiency improvements could lead to reduced overall fuel consumption, potentially decreasing the demand for fossil fuels and the associated environmental impacts of oil extraction and refining. However, this benefit may be partially offset by the increased complexity and resource requirements of manufacturing both a V16 engine and an electric powertrain.

Noise pollution is another aspect to consider. Electric operation could significantly reduce noise levels in urban environments, while the V16 engine would provide the desired auditory experience during high-performance driving scenarios. This dual-mode operation could help balance performance expectations with environmental concerns.

The lifecycle assessment of these hybrid vehicles would need to account for the production, use, and end-of-life phases. While the use phase may show improvements in emissions and efficiency, the increased complexity of the powertrain could lead to higher environmental impacts during production and potentially more challenging recycling processes.

In conclusion, the environmental impact of combining V16 engines with light-duty electric vehicle hybrids is multifaceted. While there are potential benefits in terms of emissions reduction and improved urban air quality, careful consideration must be given to the entire lifecycle of the vehicle to ensure a net positive environmental impact.

Cost-Benefit Analysis of V16-EV Hybrid Systems

The cost-benefit analysis of V16-EV hybrid systems reveals a complex interplay of economic, environmental, and performance factors. Initial investment costs for integrating V16 engines with electric powertrains are substantial, primarily due to the complexity of merging high-performance combustion technology with advanced electric systems. However, these costs may be offset by potential long-term benefits.

Fuel efficiency improvements are a significant advantage of this hybrid configuration. The V16 engine can operate at its optimal efficiency range while the electric motor handles low-speed operations and assists during acceleration. This synergy can lead to reduced fuel consumption, especially in urban driving conditions, potentially resulting in considerable fuel cost savings over the vehicle's lifetime.

Maintenance costs present a mixed picture. While the V16 engine requires specialized maintenance due to its complexity, the electric components generally have lower maintenance requirements. The overall maintenance cost may be higher than conventional vehicles but could be offset by the increased durability and longevity of the hybrid system.

Performance benefits are a key selling point for V16-EV hybrids. The combination of a powerful V16 engine with instant electric torque can deliver exceptional acceleration and top speed, appealing to luxury and performance vehicle markets. This performance edge may justify premium pricing, potentially improving profit margins for manufacturers.

Environmental considerations play a crucial role in the cost-benefit analysis. While not as eco-friendly as fully electric vehicles, V16-EV hybrids can significantly reduce emissions compared to traditional V16-powered vehicles. This reduction may help manufacturers meet increasingly stringent environmental regulations, avoiding potential fines and improving brand image.

Market positioning is another important factor. V16-EV hybrids occupy a unique niche, blending high-performance luxury with eco-conscious technology. This positioning can attract affluent consumers seeking both power and environmental responsibility, potentially expanding the market reach of luxury vehicle manufacturers.

Research and development costs for V16-EV hybrid systems are considerable but may lead to technological advancements applicable to other vehicle segments. These innovations could provide long-term benefits through technology transfer and intellectual property rights.

In conclusion, while the initial costs of V16-EV hybrid systems are high, the potential benefits in terms of performance, fuel efficiency, and market positioning could justify the investment for certain vehicle categories, particularly in the luxury and high-performance segments.

Fuel efficiency improvements are a significant advantage of this hybrid configuration. The V16 engine can operate at its optimal efficiency range while the electric motor handles low-speed operations and assists during acceleration. This synergy can lead to reduced fuel consumption, especially in urban driving conditions, potentially resulting in considerable fuel cost savings over the vehicle's lifetime.

Maintenance costs present a mixed picture. While the V16 engine requires specialized maintenance due to its complexity, the electric components generally have lower maintenance requirements. The overall maintenance cost may be higher than conventional vehicles but could be offset by the increased durability and longevity of the hybrid system.

Performance benefits are a key selling point for V16-EV hybrids. The combination of a powerful V16 engine with instant electric torque can deliver exceptional acceleration and top speed, appealing to luxury and performance vehicle markets. This performance edge may justify premium pricing, potentially improving profit margins for manufacturers.

Environmental considerations play a crucial role in the cost-benefit analysis. While not as eco-friendly as fully electric vehicles, V16-EV hybrids can significantly reduce emissions compared to traditional V16-powered vehicles. This reduction may help manufacturers meet increasingly stringent environmental regulations, avoiding potential fines and improving brand image.

Market positioning is another important factor. V16-EV hybrids occupy a unique niche, blending high-performance luxury with eco-conscious technology. This positioning can attract affluent consumers seeking both power and environmental responsibility, potentially expanding the market reach of luxury vehicle manufacturers.

Research and development costs for V16-EV hybrid systems are considerable but may lead to technological advancements applicable to other vehicle segments. These innovations could provide long-term benefits through technology transfer and intellectual property rights.

In conclusion, while the initial costs of V16-EV hybrid systems are high, the potential benefits in terms of performance, fuel efficiency, and market positioning could justify the investment for certain vehicle categories, particularly in the luxury and high-performance segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!