Performance metrics comparison between V16 engines and other multi-cylinder configurations

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine configuration has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance aircraft, V16 engines have consistently pushed the boundaries of power, smoothness, and engineering prowess.

The earliest V16 engines appeared in the 1910s, primarily in concept cars and experimental aircraft. However, it wasn't until the 1930s that V16 engines gained prominence in the automotive industry. Luxury car manufacturers like Cadillac and Marmon introduced V16-powered vehicles, setting new standards for refinement and prestige.

During World War II, V16 engines found application in military aircraft, particularly in high-altitude fighters and bombers. The Daimler-Benz DB 604 and Rolls-Royce Griffon were notable examples, offering exceptional power-to-weight ratios and altitude performance.

Post-war, V16 engines saw limited use in automotive applications due to their complexity and cost. However, they continued to evolve in specialized fields such as marine propulsion and industrial power generation, where their smooth operation and high power output were highly valued.

In recent decades, V16 engines have experienced a resurgence in ultra-luxury and high-performance vehicles. Manufacturers like Bugatti and Cadillac have introduced modern V16 engines, leveraging advanced materials and technologies to achieve unprecedented levels of power and efficiency.

Compared to other multi-cylinder configurations, V16 engines offer several distinct advantages. Their inherent balance and smoothness surpass that of V8 and V12 engines, resulting in reduced vibration and enhanced refinement. The increased number of power strokes per revolution also contributes to more consistent power delivery and improved low-end torque.

However, V16 engines face challenges in terms of complexity, weight, and fuel efficiency. The additional cylinders and associated components increase manufacturing costs and maintenance requirements. These factors have limited their widespread adoption, particularly in an era of increasing focus on fuel economy and emissions reduction.

Despite these challenges, V16 engines continue to evolve, incorporating cutting-edge technologies such as variable valve timing, direct injection, and hybrid powertrains. These advancements aim to address efficiency concerns while maintaining the unique characteristics that make V16 engines desirable in certain applications.

As automotive technology progresses, the future of V16 engines remains uncertain. While they may continue to find niche applications in ultra-luxury and high-performance vehicles, broader market trends towards downsizing and electrification pose significant challenges to their long-term viability.

The earliest V16 engines appeared in the 1910s, primarily in concept cars and experimental aircraft. However, it wasn't until the 1930s that V16 engines gained prominence in the automotive industry. Luxury car manufacturers like Cadillac and Marmon introduced V16-powered vehicles, setting new standards for refinement and prestige.

During World War II, V16 engines found application in military aircraft, particularly in high-altitude fighters and bombers. The Daimler-Benz DB 604 and Rolls-Royce Griffon were notable examples, offering exceptional power-to-weight ratios and altitude performance.

Post-war, V16 engines saw limited use in automotive applications due to their complexity and cost. However, they continued to evolve in specialized fields such as marine propulsion and industrial power generation, where their smooth operation and high power output were highly valued.

In recent decades, V16 engines have experienced a resurgence in ultra-luxury and high-performance vehicles. Manufacturers like Bugatti and Cadillac have introduced modern V16 engines, leveraging advanced materials and technologies to achieve unprecedented levels of power and efficiency.

Compared to other multi-cylinder configurations, V16 engines offer several distinct advantages. Their inherent balance and smoothness surpass that of V8 and V12 engines, resulting in reduced vibration and enhanced refinement. The increased number of power strokes per revolution also contributes to more consistent power delivery and improved low-end torque.

However, V16 engines face challenges in terms of complexity, weight, and fuel efficiency. The additional cylinders and associated components increase manufacturing costs and maintenance requirements. These factors have limited their widespread adoption, particularly in an era of increasing focus on fuel economy and emissions reduction.

Despite these challenges, V16 engines continue to evolve, incorporating cutting-edge technologies such as variable valve timing, direct injection, and hybrid powertrains. These advancements aim to address efficiency concerns while maintaining the unique characteristics that make V16 engines desirable in certain applications.

As automotive technology progresses, the future of V16 engines remains uncertain. While they may continue to find niche applications in ultra-luxury and high-performance vehicles, broader market trends towards downsizing and electrification pose significant challenges to their long-term viability.

Market Demand Analysis

The market demand for V16 engines and other multi-cylinder configurations has been evolving significantly in recent years, driven by various factors including performance requirements, fuel efficiency standards, and environmental regulations. In the automotive sector, there has been a noticeable shift towards downsizing and turbocharging, which has reduced the demand for larger displacement engines like V16s in mainstream vehicles. However, the luxury and high-performance segments continue to show interest in V16 and other multi-cylinder configurations for their flagship models.

The marine industry remains a significant market for V16 engines, particularly in large yachts and commercial vessels where power output and reliability are paramount. These engines are valued for their ability to deliver high horsepower and torque in a relatively compact package, which is crucial for marine applications where space is often at a premium.

In the power generation sector, there is a growing demand for large multi-cylinder engines, including V16 configurations, for standby and prime power applications. This is driven by the need for reliable, high-output power sources in data centers, hospitals, and industrial facilities. The increasing frequency of extreme weather events and grid instability in some regions has further boosted the demand for robust backup power solutions.

The aviation industry, while not a major consumer of V16 engines, continues to utilize various multi-cylinder configurations in certain niche applications, such as vintage aircraft restoration and specialized military projects. However, the trend in commercial aviation leans towards more fuel-efficient turbofan engines.

Market analysis indicates that while the overall volume demand for V16 engines may be declining in some sectors, there is still a strong niche market that values their unique performance characteristics. The racing and motorsport industry, for instance, continues to push the boundaries of engine design, experimenting with various cylinder configurations to achieve optimal performance metrics.

Emerging markets, particularly in developing countries with less stringent emissions regulations, present potential growth opportunities for V16 and other large multi-cylinder engines. These markets often prioritize raw power and durability over fuel efficiency, aligning well with the strengths of larger engine configurations.

The global trend towards electrification and hybrid powertrains is impacting the market for all internal combustion engines, including V16s. However, this transition is creating new opportunities for innovative engine designs that can complement electric motors in hybrid systems, potentially leading to novel applications of multi-cylinder configurations in the future.

The marine industry remains a significant market for V16 engines, particularly in large yachts and commercial vessels where power output and reliability are paramount. These engines are valued for their ability to deliver high horsepower and torque in a relatively compact package, which is crucial for marine applications where space is often at a premium.

In the power generation sector, there is a growing demand for large multi-cylinder engines, including V16 configurations, for standby and prime power applications. This is driven by the need for reliable, high-output power sources in data centers, hospitals, and industrial facilities. The increasing frequency of extreme weather events and grid instability in some regions has further boosted the demand for robust backup power solutions.

The aviation industry, while not a major consumer of V16 engines, continues to utilize various multi-cylinder configurations in certain niche applications, such as vintage aircraft restoration and specialized military projects. However, the trend in commercial aviation leans towards more fuel-efficient turbofan engines.

Market analysis indicates that while the overall volume demand for V16 engines may be declining in some sectors, there is still a strong niche market that values their unique performance characteristics. The racing and motorsport industry, for instance, continues to push the boundaries of engine design, experimenting with various cylinder configurations to achieve optimal performance metrics.

Emerging markets, particularly in developing countries with less stringent emissions regulations, present potential growth opportunities for V16 and other large multi-cylinder engines. These markets often prioritize raw power and durability over fuel efficiency, aligning well with the strengths of larger engine configurations.

The global trend towards electrification and hybrid powertrains is impacting the market for all internal combustion engines, including V16s. However, this transition is creating new opportunities for innovative engine designs that can complement electric motors in hybrid systems, potentially leading to novel applications of multi-cylinder configurations in the future.

Technical Challenges

The comparison of V16 engines with other multi-cylinder configurations presents several technical challenges. One of the primary difficulties lies in achieving optimal balance and reducing vibration in V16 engines. Due to their complex design and high number of cylinders, V16 engines require sophisticated balancing mechanisms to minimize vibrations and ensure smooth operation. This challenge becomes more pronounced when comparing them to smaller configurations like V8 or V12 engines, which inherently have better natural balance.

Another significant challenge is the increased complexity in the fuel delivery and ignition systems of V16 engines. With 16 cylinders to manage, ensuring precise fuel injection timing and ignition sequencing becomes more demanding. This complexity can lead to potential issues in maintaining consistent performance across all cylinders, especially when compared to engines with fewer cylinders.

Heat management poses a substantial challenge in V16 engines. The higher number of cylinders generates more heat, requiring advanced cooling systems to maintain optimal operating temperatures. This challenge is less pronounced in smaller engine configurations, making thermal management a critical factor in performance comparisons.

The weight and size of V16 engines present challenges in vehicle integration and overall performance metrics. Their larger dimensions and heavier weight can affect vehicle dynamics, weight distribution, and fuel efficiency. This aspect becomes particularly relevant when comparing V16 engines to more compact configurations like inline-six or V8 engines, which offer better power-to-weight ratios in many applications.

Fuel efficiency and emissions control are also significant challenges for V16 engines. The higher number of cylinders typically results in increased fuel consumption compared to smaller engine configurations. Meeting stringent emissions standards while maintaining high performance is more challenging with V16 engines, requiring advanced technologies in fuel management and exhaust treatment.

Manufacturing and maintenance complexities add to the technical challenges of V16 engines. The intricate design and higher component count make production more costly and time-consuming compared to simpler engine configurations. Additionally, maintenance and repair procedures are more complex, requiring specialized skills and tools, which can impact long-term reliability and operational costs.

Lastly, the challenge of optimizing power delivery and torque characteristics in V16 engines is significant. While they can produce high power outputs, ensuring smooth and efficient power delivery across a wide RPM range is more challenging compared to engines with fewer cylinders. This affects the overall drivability and performance feel, which are crucial factors in performance comparisons with other engine configurations.

Another significant challenge is the increased complexity in the fuel delivery and ignition systems of V16 engines. With 16 cylinders to manage, ensuring precise fuel injection timing and ignition sequencing becomes more demanding. This complexity can lead to potential issues in maintaining consistent performance across all cylinders, especially when compared to engines with fewer cylinders.

Heat management poses a substantial challenge in V16 engines. The higher number of cylinders generates more heat, requiring advanced cooling systems to maintain optimal operating temperatures. This challenge is less pronounced in smaller engine configurations, making thermal management a critical factor in performance comparisons.

The weight and size of V16 engines present challenges in vehicle integration and overall performance metrics. Their larger dimensions and heavier weight can affect vehicle dynamics, weight distribution, and fuel efficiency. This aspect becomes particularly relevant when comparing V16 engines to more compact configurations like inline-six or V8 engines, which offer better power-to-weight ratios in many applications.

Fuel efficiency and emissions control are also significant challenges for V16 engines. The higher number of cylinders typically results in increased fuel consumption compared to smaller engine configurations. Meeting stringent emissions standards while maintaining high performance is more challenging with V16 engines, requiring advanced technologies in fuel management and exhaust treatment.

Manufacturing and maintenance complexities add to the technical challenges of V16 engines. The intricate design and higher component count make production more costly and time-consuming compared to simpler engine configurations. Additionally, maintenance and repair procedures are more complex, requiring specialized skills and tools, which can impact long-term reliability and operational costs.

Lastly, the challenge of optimizing power delivery and torque characteristics in V16 engines is significant. While they can produce high power outputs, ensuring smooth and efficient power delivery across a wide RPM range is more challenging compared to engines with fewer cylinders. This affects the overall drivability and performance feel, which are crucial factors in performance comparisons with other engine configurations.

Current V16 Solutions

01 Performance monitoring and analysis

Systems and methods for monitoring and analyzing the performance of V16 engines, including real-time data collection, processing, and visualization of various engine metrics. These solutions enable engineers to assess engine efficiency, identify potential issues, and optimize performance.- Performance monitoring and analysis: Systems and methods for monitoring and analyzing the performance of V16 engines, including real-time data collection, processing, and visualization of various engine metrics. These solutions enable efficient tracking of engine parameters, facilitating optimization and troubleshooting.

- Fuel efficiency optimization: Techniques for improving fuel efficiency in V16 engines through advanced control systems, predictive algorithms, and adaptive engine management. These approaches aim to maximize power output while minimizing fuel consumption, leading to improved overall engine performance.

- Emissions reduction and environmental impact: Innovations focused on reducing emissions and environmental impact of V16 engines, including advanced exhaust treatment systems, combustion optimization, and integration of eco-friendly technologies to meet stringent environmental regulations while maintaining high performance.

- Engine diagnostics and predictive maintenance: Advanced diagnostic systems and predictive maintenance solutions for V16 engines, utilizing machine learning and data analytics to identify potential issues before they occur, optimize maintenance schedules, and minimize downtime.

- Power output and torque optimization: Methods and systems for maximizing power output and torque in V16 engines through innovative design improvements, advanced materials, and optimized combustion processes. These enhancements aim to push the boundaries of engine performance while maintaining reliability and efficiency.

02 Engine simulation and modeling

Advanced simulation and modeling techniques for V16 engines, allowing for virtual testing and optimization of engine designs. These tools help in predicting performance metrics, reducing development time, and improving overall engine efficiency before physical prototyping.Expand Specific Solutions03 Fuel efficiency and emissions control

Innovative technologies and strategies for improving fuel efficiency and reducing emissions in V16 engines. This includes advanced fuel injection systems, exhaust gas recirculation, and intelligent engine management systems to optimize performance while meeting stringent environmental regulations.Expand Specific Solutions04 Power output and torque optimization

Techniques for maximizing power output and torque in V16 engines, including advanced valve timing, turbocharging, and supercharging systems. These innovations aim to enhance the engine's performance metrics while maintaining reliability and durability.Expand Specific Solutions05 Diagnostic and predictive maintenance

Implementation of sophisticated diagnostic tools and predictive maintenance algorithms for V16 engines. These systems use machine learning and data analytics to predict potential failures, schedule maintenance, and ensure optimal engine performance throughout its lifecycle.Expand Specific Solutions

Key Manufacturers

The performance metrics comparison between V16 engines and other multi-cylinder configurations is currently in a mature stage of development, with a substantial market size driven by high-performance and luxury vehicle segments. The technology's maturity is evident in the involvement of major automotive players like Toyota Motor Corp., GM Global Technology Operations LLC, and Ford Global Technologies LLC. These companies, along with others such as Bayerische Motoren Werke AG and Ferrari SpA, have contributed significantly to refining V16 engine performance metrics, showcasing the technology's established presence in the industry. However, ongoing research and development efforts continue to focus on optimizing efficiency, power output, and emissions to meet evolving market demands and regulatory standards.

Guangxi Yuchai Machinery Co., Ltd.

Technical Solution: Guangxi Yuchai Machinery Co., Ltd. has developed a high-performance V16 diesel engine for marine and power generation applications. Their V16 engine utilizes advanced fuel injection systems and turbocharging technology to optimize combustion efficiency. The engine features a displacement of 155.7 liters and can produce up to 5,200 kW of power[1]. Compared to other multi-cylinder configurations, Yuchai's V16 engine offers superior power density and fuel efficiency. The company has implemented electronic control systems to manage engine parameters and emissions, allowing the V16 to meet stringent environmental regulations while maintaining high performance[2].

Strengths: High power output, improved fuel efficiency, and compliance with emissions standards. Weaknesses: Increased complexity and potentially higher manufacturing costs compared to smaller engine configurations.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corp. has focused on developing hybrid powertrains and more efficient smaller displacement engines rather than V16 configurations. Their approach emphasizes fuel efficiency and reduced emissions through technologies like variable valve timing, direct injection, and hybrid systems. Toyota's most powerful production engine is a V8, used in vehicles like the Lexus LC500, producing up to 471 horsepower[3]. For performance comparisons, Toyota has developed advanced simulation and testing methodologies to evaluate different engine configurations, including multi-cylinder setups. Their research includes analyzing power-to-weight ratios, fuel consumption, and emissions across various engine types to optimize performance and efficiency[4].

Strengths: Focus on fuel efficiency and emissions reduction, extensive experience in hybrid technology. Weaknesses: Limited experience with very high-displacement engines like V16s, potentially limiting performance in ultra-high-power applications.

Core V16 Innovations

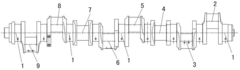

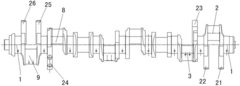

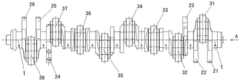

Crankshaft of 16-cylinder V-type engine and dynamic balance calibration method of crankshaft

PatentActiveCN104791367A

Innovation

- A 16-cylinder V-type engine crankshaft is designed, which has eight connecting rod journals, uses three sector-shaped balance blocks and eight annular equivalent balance rings. Through specific distribution and weight ratio, combined with the dynamic balance calibration method, Ensure the dynamic balance of the crankshaft is stable.

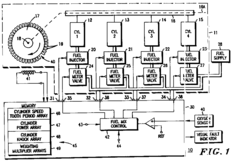

System for monitoring and/or controlling multiple cylinder engine performance

PatentInactiveEP0651148A3

Innovation

- A system that uses sensor means to monitor the speed-indicative signal of a driven member and determines the occurrence of knock by comparing the rate of change of the speed-indicative signal to predetermined threshold levels, and adjusts fuel delivery to individual cylinders to achieve power balancing while maintaining average fuel consumption, using weighting factors to assess performance criteria such as knock, power mismatch, and misfire.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and adoption of engine technologies, including V16 engines and other multi-cylinder configurations. These regulations have become increasingly stringent over the years, driven by environmental concerns and the need to reduce greenhouse gas emissions from the transportation sector.

In the context of V16 engines and their performance comparison with other multi-cylinder configurations, emissions regulations have a significant impact on design considerations and overall engine efficiency. The large displacement and high power output of V16 engines often result in higher fuel consumption and emissions, which can pose challenges in meeting strict regulatory standards.

Many countries and regions have implemented tiered emissions standards for various vehicle categories. For example, the European Union's Euro emissions standards and the United States Environmental Protection Agency's (EPA) emissions regulations set limits on pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These standards have become progressively more stringent, requiring manufacturers to invest in advanced technologies to reduce emissions.

The impact of emissions regulations on V16 engines and other multi-cylinder configurations can be observed in several areas. Firstly, manufacturers have had to implement sophisticated engine management systems and aftertreatment technologies to ensure compliance. This includes the use of catalytic converters, diesel particulate filters, and selective catalytic reduction (SCR) systems, which can affect engine performance and efficiency.

Furthermore, emissions regulations have led to a shift towards downsizing and turbocharging in engine design. This trend has resulted in smaller displacement engines achieving similar power outputs to larger naturally aspirated engines while producing fewer emissions. As a result, the prevalence of V16 engines in automotive applications has decreased, with manufacturers opting for more compact and efficient engine configurations.

The challenge of meeting emissions regulations has also spurred innovation in engine design and materials. Advanced combustion strategies, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion, have been developed to reduce emissions while maintaining performance. Additionally, the use of lightweight materials and improved thermal management techniques has helped enhance overall engine efficiency and reduce emissions.

In the realm of performance metrics, emissions regulations have influenced the way engine output is measured and reported. Manufacturers now focus on achieving a balance between power, fuel efficiency, and emissions compliance. This has led to the development of more sophisticated testing procedures and the inclusion of emissions-related metrics in overall engine performance evaluations.

As emissions regulations continue to evolve, the future of V16 engines and other high-cylinder count configurations in mainstream applications remains uncertain. However, these engines may still find niche applications in specialized vehicles where their unique performance characteristics outweigh emissions concerns, provided they can meet regulatory requirements through advanced technologies and design optimizations.

In the context of V16 engines and their performance comparison with other multi-cylinder configurations, emissions regulations have a significant impact on design considerations and overall engine efficiency. The large displacement and high power output of V16 engines often result in higher fuel consumption and emissions, which can pose challenges in meeting strict regulatory standards.

Many countries and regions have implemented tiered emissions standards for various vehicle categories. For example, the European Union's Euro emissions standards and the United States Environmental Protection Agency's (EPA) emissions regulations set limits on pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These standards have become progressively more stringent, requiring manufacturers to invest in advanced technologies to reduce emissions.

The impact of emissions regulations on V16 engines and other multi-cylinder configurations can be observed in several areas. Firstly, manufacturers have had to implement sophisticated engine management systems and aftertreatment technologies to ensure compliance. This includes the use of catalytic converters, diesel particulate filters, and selective catalytic reduction (SCR) systems, which can affect engine performance and efficiency.

Furthermore, emissions regulations have led to a shift towards downsizing and turbocharging in engine design. This trend has resulted in smaller displacement engines achieving similar power outputs to larger naturally aspirated engines while producing fewer emissions. As a result, the prevalence of V16 engines in automotive applications has decreased, with manufacturers opting for more compact and efficient engine configurations.

The challenge of meeting emissions regulations has also spurred innovation in engine design and materials. Advanced combustion strategies, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion, have been developed to reduce emissions while maintaining performance. Additionally, the use of lightweight materials and improved thermal management techniques has helped enhance overall engine efficiency and reduce emissions.

In the realm of performance metrics, emissions regulations have influenced the way engine output is measured and reported. Manufacturers now focus on achieving a balance between power, fuel efficiency, and emissions compliance. This has led to the development of more sophisticated testing procedures and the inclusion of emissions-related metrics in overall engine performance evaluations.

As emissions regulations continue to evolve, the future of V16 engines and other high-cylinder count configurations in mainstream applications remains uncertain. However, these engines may still find niche applications in specialized vehicles where their unique performance characteristics outweigh emissions concerns, provided they can meet regulatory requirements through advanced technologies and design optimizations.

Fuel Efficiency Trends

The fuel efficiency trends of V16 engines compared to other multi-cylinder configurations have shown significant evolution over the years. Historically, V16 engines were known for their high power output but relatively poor fuel economy due to their large displacement and complex design.

In recent decades, advancements in engine technology have led to improvements in fuel efficiency across all engine types, including V16 configurations. However, the rate of improvement has varied between different cylinder arrangements. V16 engines have generally lagged behind smaller configurations in terms of fuel efficiency gains.

Modern V8 and V12 engines have demonstrated more substantial improvements in fuel economy, often surpassing V16 engines in this aspect. This is partly due to the wider adoption and refinement of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in these more common configurations.

Turbocharging and supercharging have played a crucial role in enhancing the fuel efficiency of multi-cylinder engines. These forced induction methods have allowed smaller displacement engines to achieve power outputs comparable to larger naturally aspirated engines while consuming less fuel. V16 engines have benefited from these technologies as well, but their inherent complexity has limited the extent of efficiency gains.

The automotive industry's shift towards electrification and hybrid powertrains has further impacted fuel efficiency trends. Hybrid systems have been more readily integrated into smaller engine configurations, providing significant fuel economy improvements. V16 engines, primarily used in ultra-luxury and high-performance applications, have seen limited hybridization, thus missing out on some of these efficiency benefits.

Emissions regulations have also driven fuel efficiency improvements across all engine types. Manufacturers have been compelled to optimize combustion processes and implement advanced exhaust after-treatment systems. While these measures have improved the fuel economy of V16 engines, the inherent challenges in managing emissions from such large displacement powerplants have often resulted in less dramatic efficiency gains compared to smaller engine configurations.

In conclusion, while V16 engines have seen improvements in fuel efficiency, they have generally not kept pace with the advancements seen in other multi-cylinder configurations. The focus on downsizing and electrification in the automotive industry has favored smaller, more efficient engine designs, leaving V16 engines primarily in niche applications where fuel economy is not the primary concern.

In recent decades, advancements in engine technology have led to improvements in fuel efficiency across all engine types, including V16 configurations. However, the rate of improvement has varied between different cylinder arrangements. V16 engines have generally lagged behind smaller configurations in terms of fuel efficiency gains.

Modern V8 and V12 engines have demonstrated more substantial improvements in fuel economy, often surpassing V16 engines in this aspect. This is partly due to the wider adoption and refinement of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in these more common configurations.

Turbocharging and supercharging have played a crucial role in enhancing the fuel efficiency of multi-cylinder engines. These forced induction methods have allowed smaller displacement engines to achieve power outputs comparable to larger naturally aspirated engines while consuming less fuel. V16 engines have benefited from these technologies as well, but their inherent complexity has limited the extent of efficiency gains.

The automotive industry's shift towards electrification and hybrid powertrains has further impacted fuel efficiency trends. Hybrid systems have been more readily integrated into smaller engine configurations, providing significant fuel economy improvements. V16 engines, primarily used in ultra-luxury and high-performance applications, have seen limited hybridization, thus missing out on some of these efficiency benefits.

Emissions regulations have also driven fuel efficiency improvements across all engine types. Manufacturers have been compelled to optimize combustion processes and implement advanced exhaust after-treatment systems. While these measures have improved the fuel economy of V16 engines, the inherent challenges in managing emissions from such large displacement powerplants have often resulted in less dramatic efficiency gains compared to smaller engine configurations.

In conclusion, while V16 engines have seen improvements in fuel efficiency, they have generally not kept pace with the advancements seen in other multi-cylinder configurations. The focus on downsizing and electrification in the automotive industry has favored smaller, more efficient engine designs, leaving V16 engines primarily in niche applications where fuel economy is not the primary concern.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!