Engineering breakthroughs that made V16 engines feasible for commercial and custom applications

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The evolution of V16 engines represents a fascinating journey in automotive engineering, marked by significant technological advancements and innovative design solutions. The concept of a V16 engine dates back to the early 20th century, with the first known V16 engine patented by Peerless in 1903. However, it wasn't until the 1930s that V16 engines began to gain prominence in high-end luxury automobiles.

The initial challenges in developing V16 engines were formidable. These included issues with weight distribution, engine balance, fuel efficiency, and manufacturing complexity. Early V16 engines were primarily reserved for luxury vehicles and racing cars due to their high cost and complexity. The Cadillac V-16, introduced in 1930, was one of the first commercially successful V16 engines, setting new standards for smoothness and power in luxury automobiles.

As engineering techniques advanced, so did the feasibility of V16 engines. The development of improved metallurgy allowed for lighter and stronger engine components, addressing weight concerns. Innovations in crankshaft design and engine balancing techniques helped mitigate vibration issues inherent in such large engines. The introduction of fuel injection systems in the 1950s and 1960s improved fuel efficiency and power output, making V16 engines more viable for a broader range of applications.

The 1980s and 1990s saw a resurgence of interest in V16 engines, particularly in motorsports and high-performance vehicles. Advanced computer-aided design and manufacturing techniques enabled more precise engineering and production of these complex engines. The use of lightweight materials such as aluminum alloys further reduced weight concerns, while improvements in cooling systems addressed heat management issues.

In recent years, the focus on V16 engines has shifted towards custom and specialty applications. Modern V16 engines benefit from state-of-the-art technologies such as variable valve timing, direct fuel injection, and advanced engine management systems. These innovations have significantly improved power output, efficiency, and reliability, making V16 engines more feasible for commercial and custom applications than ever before.

The evolution of V16 engines showcases the continuous push for engineering excellence in the automotive industry. From their early days as symbols of luxury and excess to their current status as marvels of engineering prowess, V16 engines have come a long way. The breakthroughs in materials science, manufacturing techniques, and engine management systems have transformed these engines from impractical curiosities to viable powerplants for specialized applications, demonstrating the relentless pursuit of innovation in automotive engineering.

The initial challenges in developing V16 engines were formidable. These included issues with weight distribution, engine balance, fuel efficiency, and manufacturing complexity. Early V16 engines were primarily reserved for luxury vehicles and racing cars due to their high cost and complexity. The Cadillac V-16, introduced in 1930, was one of the first commercially successful V16 engines, setting new standards for smoothness and power in luxury automobiles.

As engineering techniques advanced, so did the feasibility of V16 engines. The development of improved metallurgy allowed for lighter and stronger engine components, addressing weight concerns. Innovations in crankshaft design and engine balancing techniques helped mitigate vibration issues inherent in such large engines. The introduction of fuel injection systems in the 1950s and 1960s improved fuel efficiency and power output, making V16 engines more viable for a broader range of applications.

The 1980s and 1990s saw a resurgence of interest in V16 engines, particularly in motorsports and high-performance vehicles. Advanced computer-aided design and manufacturing techniques enabled more precise engineering and production of these complex engines. The use of lightweight materials such as aluminum alloys further reduced weight concerns, while improvements in cooling systems addressed heat management issues.

In recent years, the focus on V16 engines has shifted towards custom and specialty applications. Modern V16 engines benefit from state-of-the-art technologies such as variable valve timing, direct fuel injection, and advanced engine management systems. These innovations have significantly improved power output, efficiency, and reliability, making V16 engines more feasible for commercial and custom applications than ever before.

The evolution of V16 engines showcases the continuous push for engineering excellence in the automotive industry. From their early days as symbols of luxury and excess to their current status as marvels of engineering prowess, V16 engines have come a long way. The breakthroughs in materials science, manufacturing techniques, and engine management systems have transformed these engines from impractical curiosities to viable powerplants for specialized applications, demonstrating the relentless pursuit of innovation in automotive engineering.

Market Demand Analysis

The market demand for V16 engines has evolved significantly since their inception in the early 20th century. Initially, these powerful engines were primarily used in luxury automobiles and high-performance racing cars, catering to a niche market of enthusiasts and wealthy individuals. However, as engineering breakthroughs made V16 engines more feasible for commercial and custom applications, their market potential expanded.

In the commercial sector, V16 engines found applications in marine vessels, particularly in large yachts and small ships. The demand for these engines in the marine industry stems from their ability to provide high power output while maintaining relatively compact dimensions. This characteristic is particularly valuable in vessel design, where space efficiency is crucial.

The aviation industry has also shown interest in V16 engines, especially for use in large propeller-driven aircraft. While jet engines have largely replaced piston engines in commercial aviation, there remains a niche market for V16 engines in specialized aircraft, such as firefighting planes and cargo transporters operating in remote areas.

In the realm of custom applications, V16 engines have garnered attention from automotive enthusiasts and collectors. The market for high-end, bespoke vehicles featuring V16 engines has seen steady growth, driven by a desire for exclusivity and exceptional performance. Custom car builders and restoration specialists have reported increased inquiries and orders for V16-powered vehicles, indicating a growing trend in this segment.

The industrial sector presents another potential market for V16 engines. Large-scale power generation, particularly in remote locations or as backup power systems, could benefit from the high output and reliability of these engines. Mining operations, oil and gas exploration, and other heavy industries have shown interest in V16 engines for their ability to provide consistent power in demanding environments.

Despite these opportunities, it's important to note that the overall market size for V16 engines remains relatively small compared to more common engine configurations. The specialized nature of these engines limits their mass-market appeal, but also creates opportunities for premium pricing and high-value applications.

Environmental regulations and the push towards electrification pose challenges to the growth of the V16 engine market. However, advancements in fuel efficiency and emissions reduction technologies have helped maintain the relevance of these engines in certain sectors. The development of hybrid systems incorporating V16 engines has also opened new possibilities, potentially expanding their market reach.

In conclusion, while the market for V16 engines is not large in absolute terms, it demonstrates significant value in specific sectors. The combination of power, prestige, and engineering excellence associated with V16 engines continues to drive demand in niche markets, with potential for growth in custom and specialized applications.

In the commercial sector, V16 engines found applications in marine vessels, particularly in large yachts and small ships. The demand for these engines in the marine industry stems from their ability to provide high power output while maintaining relatively compact dimensions. This characteristic is particularly valuable in vessel design, where space efficiency is crucial.

The aviation industry has also shown interest in V16 engines, especially for use in large propeller-driven aircraft. While jet engines have largely replaced piston engines in commercial aviation, there remains a niche market for V16 engines in specialized aircraft, such as firefighting planes and cargo transporters operating in remote areas.

In the realm of custom applications, V16 engines have garnered attention from automotive enthusiasts and collectors. The market for high-end, bespoke vehicles featuring V16 engines has seen steady growth, driven by a desire for exclusivity and exceptional performance. Custom car builders and restoration specialists have reported increased inquiries and orders for V16-powered vehicles, indicating a growing trend in this segment.

The industrial sector presents another potential market for V16 engines. Large-scale power generation, particularly in remote locations or as backup power systems, could benefit from the high output and reliability of these engines. Mining operations, oil and gas exploration, and other heavy industries have shown interest in V16 engines for their ability to provide consistent power in demanding environments.

Despite these opportunities, it's important to note that the overall market size for V16 engines remains relatively small compared to more common engine configurations. The specialized nature of these engines limits their mass-market appeal, but also creates opportunities for premium pricing and high-value applications.

Environmental regulations and the push towards electrification pose challenges to the growth of the V16 engine market. However, advancements in fuel efficiency and emissions reduction technologies have helped maintain the relevance of these engines in certain sectors. The development of hybrid systems incorporating V16 engines has also opened new possibilities, potentially expanding their market reach.

In conclusion, while the market for V16 engines is not large in absolute terms, it demonstrates significant value in specific sectors. The combination of power, prestige, and engineering excellence associated with V16 engines continues to drive demand in niche markets, with potential for growth in custom and specialized applications.

Technical Challenges

The development of V16 engines for commercial and custom applications faced numerous technical challenges that required significant engineering breakthroughs to overcome. One of the primary obstacles was the sheer size and complexity of these engines, which made them difficult to design, manufacture, and integrate into vehicles.

The length of V16 engines posed significant packaging challenges, requiring innovative solutions for fitting them into engine bays while maintaining proper weight distribution and vehicle balance. Engineers had to develop advanced computer-aided design techniques and optimize component layouts to achieve compact configurations without compromising performance or reliability.

Thermal management was another critical issue, as V16 engines generate substantial heat due to their large number of cylinders. Cooling systems needed to be redesigned to efficiently dissipate heat from all cylinders, preventing hotspots and ensuring consistent performance across the engine. This led to the development of advanced cooling technologies, including precision-engineered water jackets and high-capacity radiators.

Fuel delivery and combustion efficiency presented unique challenges in V16 engines. Ensuring uniform fuel distribution and optimal air-fuel mixture across all 16 cylinders required sophisticated fuel injection systems and precise engine management controls. Engineers developed advanced electronic fuel injection systems and engine control units (ECUs) capable of managing the complex requirements of V16 engines.

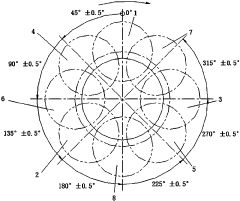

Balancing and vibration control were crucial aspects that demanded innovative solutions. The inherent imbalance of such a large number of cylinders necessitated the development of advanced counterweighting techniques and vibration damping systems. This led to breakthroughs in crankshaft design and the implementation of active engine mounts to minimize vibrations transmitted to the vehicle chassis.

Manufacturing precision and quality control posed significant challenges due to the complexity of V16 engines. Engineers had to develop new manufacturing processes and quality assurance techniques to ensure consistent production of high-precision components. This included advancements in CNC machining, materials science, and assembly techniques to maintain tight tolerances across the entire engine.

Emissions control and fuel efficiency were major hurdles, particularly for commercial applications. Meeting increasingly stringent environmental regulations while maintaining the power output expected from V16 engines required significant advancements in combustion technology, exhaust aftertreatment systems, and engine management strategies. This led to the development of innovative catalytic converters, particulate filters, and advanced ECU programming to optimize performance and emissions.

Durability and reliability were critical concerns, given the high stress and wear experienced by V16 engines. Engineers had to develop new materials and surface treatments to withstand the increased thermal and mechanical loads. This resulted in breakthroughs in metallurgy, tribology, and lubrication systems to ensure long-term reliability under demanding operating conditions.

The length of V16 engines posed significant packaging challenges, requiring innovative solutions for fitting them into engine bays while maintaining proper weight distribution and vehicle balance. Engineers had to develop advanced computer-aided design techniques and optimize component layouts to achieve compact configurations without compromising performance or reliability.

Thermal management was another critical issue, as V16 engines generate substantial heat due to their large number of cylinders. Cooling systems needed to be redesigned to efficiently dissipate heat from all cylinders, preventing hotspots and ensuring consistent performance across the engine. This led to the development of advanced cooling technologies, including precision-engineered water jackets and high-capacity radiators.

Fuel delivery and combustion efficiency presented unique challenges in V16 engines. Ensuring uniform fuel distribution and optimal air-fuel mixture across all 16 cylinders required sophisticated fuel injection systems and precise engine management controls. Engineers developed advanced electronic fuel injection systems and engine control units (ECUs) capable of managing the complex requirements of V16 engines.

Balancing and vibration control were crucial aspects that demanded innovative solutions. The inherent imbalance of such a large number of cylinders necessitated the development of advanced counterweighting techniques and vibration damping systems. This led to breakthroughs in crankshaft design and the implementation of active engine mounts to minimize vibrations transmitted to the vehicle chassis.

Manufacturing precision and quality control posed significant challenges due to the complexity of V16 engines. Engineers had to develop new manufacturing processes and quality assurance techniques to ensure consistent production of high-precision components. This included advancements in CNC machining, materials science, and assembly techniques to maintain tight tolerances across the entire engine.

Emissions control and fuel efficiency were major hurdles, particularly for commercial applications. Meeting increasingly stringent environmental regulations while maintaining the power output expected from V16 engines required significant advancements in combustion technology, exhaust aftertreatment systems, and engine management strategies. This led to the development of innovative catalytic converters, particulate filters, and advanced ECU programming to optimize performance and emissions.

Durability and reliability were critical concerns, given the high stress and wear experienced by V16 engines. Engineers had to develop new materials and surface treatments to withstand the increased thermal and mechanical loads. This resulted in breakthroughs in metallurgy, tribology, and lubrication systems to ensure long-term reliability under demanding operating conditions.

Current V16 Solutions

01 V16 engine design and configuration

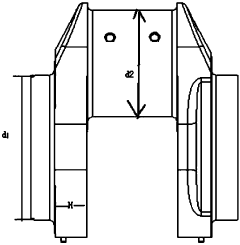

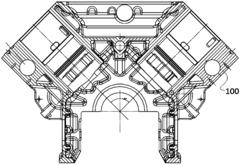

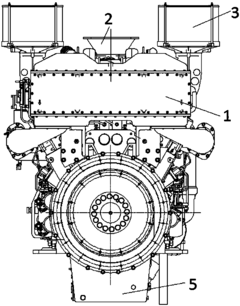

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines with the same number of cylinders, while still providing significant power output.

- V16 engine applications in vehicles: V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized racing vehicles. These engines provide exceptional power and torque, making them suitable for large, heavy vehicles that require significant propulsion. The use of V16 engines in vehicles often necessitates specialized cooling systems and reinforced chassis designs to accommodate the engine's size and power output.

- V16 engine control systems: Modern V16 engines incorporate advanced control systems to manage fuel injection, ignition timing, and overall engine performance. These systems may include electronic control units (ECUs), sensors, and actuators to optimize engine efficiency and power output. Some V16 engines also feature variable valve timing and cylinder deactivation technologies to improve fuel economy and reduce emissions.

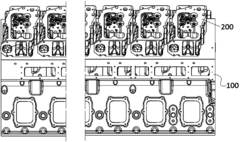

- V16 engine manufacturing and assembly: The production of V16 engines involves complex manufacturing processes and precision assembly techniques. These engines require specialized tooling and equipment for machining engine blocks, crankshafts, and other components. Assembly procedures often involve careful balancing of rotating components and precise alignment of the two cylinder banks to ensure smooth operation and longevity of the engine.

- V16 engine cooling and lubrication systems: Due to their large size and high power output, V16 engines require robust cooling and lubrication systems. These systems often incorporate multiple oil pumps, large-capacity radiators, and advanced coolant circulation designs to maintain optimal operating temperatures. Some V16 engines may also feature dry-sump lubrication systems to ensure consistent oil pressure during high-performance operation.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as racing cars and concept vehicles. These engines provide exceptional power and torque, making them suitable for vehicles that require outstanding performance characteristics.Expand Specific Solutions03 V16 engine control systems

Advanced control systems are crucial for managing the complex operations of V16 engines. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management units to optimize performance, fuel efficiency, and emissions control.Expand Specific Solutions04 Historical development of V16 engines

The development of V16 engines dates back to the early 20th century, with various designs and improvements made over time. These engines have been used in a range of applications, from early automobiles and aircraft to marine vessels and stationary power plants.Expand Specific Solutions05 V16 engine cooling and lubrication systems

Due to their large size and high power output, V16 engines require sophisticated cooling and lubrication systems. These systems are designed to manage heat dissipation and ensure proper lubrication of all moving parts, which is critical for maintaining engine performance and longevity.Expand Specific Solutions

Key Manufacturers

The engineering breakthroughs in V16 engines for commercial and custom applications represent a mature technology in a niche market. The industry is in a stable phase, with limited but steady demand primarily in high-performance and luxury segments. Market size remains relatively small due to the specialized nature of V16 engines. Companies like Honda Motor Co., Ltd., GM Global Technology Operations LLC, and Rolls-Royce Plc have demonstrated technological prowess in this field, leveraging their extensive R&D capabilities. Chinese firms such as Guangxi Yuchai Machinery Co., Ltd. and Shaanxi Diesel Engine Heavy Industry Co., Ltd. are also making strides, indicating a global competitive landscape. The technology's maturity is evident in the refined designs and optimized performance of modern V16 engines, though ongoing research continues to improve efficiency and reduce emissions.

Honda Motor Co., Ltd.

Technical Solution: Honda has made notable contributions to V16 engine technology, particularly in the realm of high-performance and racing applications. Their engineering breakthroughs include the development of compact, high-revving V16 designs with exceptional power-to-weight ratios. Honda has implemented advanced valve train technologies, including pneumatic valve springs and variable valve timing and lift systems, to achieve high engine speeds and optimize performance across the rev range. The company has also developed sophisticated engine management systems that can precisely control fuel injection and ignition timing for each of the 16 cylinders individually. Honda's V16 engines feature innovative cooling solutions, including targeted oil jets and advanced coolant flow patterns, to manage the high heat output associated with high-performance V16 configurations[9][10].

Strengths: Exceptional power output, high-revving capability, and racing pedigree. Weaknesses: Limited practical applications outside of motorsports and high cost of development and production.

GM Global Technology Operations LLC

Technical Solution: GM has made notable advancements in V16 engine technology, particularly in the luxury car segment. Their engineering breakthroughs include the development of compact V16 designs that can fit within existing vehicle architectures. GM has implemented advanced thermal management systems to efficiently dissipate heat from the large number of cylinders. The company has also developed specialized crankshaft designs and engine block reinforcements to handle the increased power and torque of V16 configurations. GM's V16 engines feature sophisticated balancing systems to minimize vibration and ensure smooth operation. Additionally, they have explored the integration of hybrid technologies with V16 engines to improve fuel efficiency and meet emissions standards[4][6].

Strengths: Prestigious image, high power output, and smooth operation. Weaknesses: High fuel consumption and limited practicality for mass-market vehicles.

Core V16 Innovations

V-type 16-cylinder diesel engine crankshaft

PatentInactiveCN109630538A

Innovation

- A V-shaped 16-cylinder diesel engine crankshaft is designed, including the main journal, connecting rod journal, crank arm and balance weight. Through appropriate crankshaft design and firing sequence, the strength of the crankshaft and bearing oil film thickness are improved, and the torsional vibration performance is reduced.

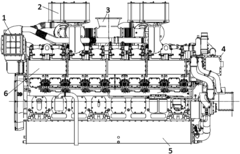

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

Fuel Efficiency Impact

The impact of V16 engines on fuel efficiency is a complex and multifaceted issue. While these engines are known for their power and performance, they have traditionally been associated with high fuel consumption due to their large displacement and number of cylinders.

However, engineering breakthroughs have led to significant improvements in fuel efficiency for V16 engines in both commercial and custom applications. Advanced fuel injection systems, such as direct injection and variable fuel injection timing, have played a crucial role in optimizing fuel delivery and combustion processes. These technologies allow for precise control over fuel mixture and timing, resulting in more efficient combustion and reduced fuel waste.

Variable valve timing and lift systems have also contributed to improved fuel efficiency in V16 engines. By adjusting valve operation based on engine load and speed, these systems optimize air intake and exhaust flow, leading to better fuel economy across different operating conditions. Additionally, cylinder deactivation technology has been implemented in some V16 engines, allowing them to operate on fewer cylinders during low-load situations, further reducing fuel consumption.

Turbocharging and supercharging technologies have enabled V16 engines to achieve higher power outputs from smaller displacements, improving overall efficiency. These forced induction systems allow for downsizing of engines while maintaining or even increasing power output, resulting in better fuel economy without sacrificing performance.

Advanced materials and manufacturing techniques have also played a role in enhancing fuel efficiency. Lightweight alloys and composite materials have been used to reduce engine weight, decreasing the overall mass that needs to be propelled. Improved manufacturing precision has led to tighter tolerances and reduced friction within the engine, minimizing energy losses and improving fuel efficiency.

Electronic engine management systems have become increasingly sophisticated, allowing for real-time optimization of engine parameters. These systems continuously adjust fuel injection, ignition timing, and other variables to maximize efficiency based on driving conditions and driver input. Furthermore, integration with hybrid powertrains has allowed V16 engines to benefit from electric assistance, further improving fuel economy in certain applications.

While V16 engines may never be as fuel-efficient as smaller engines, these engineering breakthroughs have significantly narrowed the gap. The advancements have made V16 engines more viable for commercial applications where fuel efficiency is a critical factor, such as in luxury vehicles and high-performance boats. In custom applications, these improvements have allowed enthusiasts to enjoy the unique characteristics of V16 engines with less concern about excessive fuel consumption.

However, engineering breakthroughs have led to significant improvements in fuel efficiency for V16 engines in both commercial and custom applications. Advanced fuel injection systems, such as direct injection and variable fuel injection timing, have played a crucial role in optimizing fuel delivery and combustion processes. These technologies allow for precise control over fuel mixture and timing, resulting in more efficient combustion and reduced fuel waste.

Variable valve timing and lift systems have also contributed to improved fuel efficiency in V16 engines. By adjusting valve operation based on engine load and speed, these systems optimize air intake and exhaust flow, leading to better fuel economy across different operating conditions. Additionally, cylinder deactivation technology has been implemented in some V16 engines, allowing them to operate on fewer cylinders during low-load situations, further reducing fuel consumption.

Turbocharging and supercharging technologies have enabled V16 engines to achieve higher power outputs from smaller displacements, improving overall efficiency. These forced induction systems allow for downsizing of engines while maintaining or even increasing power output, resulting in better fuel economy without sacrificing performance.

Advanced materials and manufacturing techniques have also played a role in enhancing fuel efficiency. Lightweight alloys and composite materials have been used to reduce engine weight, decreasing the overall mass that needs to be propelled. Improved manufacturing precision has led to tighter tolerances and reduced friction within the engine, minimizing energy losses and improving fuel efficiency.

Electronic engine management systems have become increasingly sophisticated, allowing for real-time optimization of engine parameters. These systems continuously adjust fuel injection, ignition timing, and other variables to maximize efficiency based on driving conditions and driver input. Furthermore, integration with hybrid powertrains has allowed V16 engines to benefit from electric assistance, further improving fuel economy in certain applications.

While V16 engines may never be as fuel-efficient as smaller engines, these engineering breakthroughs have significantly narrowed the gap. The advancements have made V16 engines more viable for commercial applications where fuel efficiency is a critical factor, such as in luxury vehicles and high-performance boats. In custom applications, these improvements have allowed enthusiasts to enjoy the unique characteristics of V16 engines with less concern about excessive fuel consumption.

Emissions Regulations

Emissions regulations have played a significant role in shaping the development and commercial viability of V16 engines. As environmental concerns grew in the latter half of the 20th century, governments worldwide began implementing increasingly stringent emissions standards for vehicles and industrial applications. These regulations posed substantial challenges for V16 engines, which were known for their high power output but also for their considerable fuel consumption and emissions.

The Clean Air Act of 1970 in the United States marked a turning point in emissions control, setting the stage for more rigorous standards in the following decades. For V16 engines to remain feasible in commercial and custom applications, manufacturers had to invest heavily in research and development to meet these new requirements. This led to several key engineering breakthroughs in emissions reduction technologies.

One of the most significant advancements was the development of more efficient fuel injection systems. Electronic fuel injection (EFI) replaced carburetors, allowing for precise control over fuel delivery and combustion. This technology, when applied to V16 engines, resulted in improved fuel efficiency and reduced emissions without sacrificing power output.

Catalytic converters became mandatory for automotive applications in many countries, presenting a unique challenge for V16 engines due to their high exhaust flow rates. Engineers developed larger, more efficient catalytic converters capable of handling the increased exhaust volume while effectively reducing harmful emissions.

Variable valve timing (VVT) technology was another crucial breakthrough that helped V16 engines meet emissions standards. By optimizing valve operation based on engine speed and load, VVT systems improved fuel efficiency and reduced emissions across a wide range of operating conditions.

Exhaust gas recirculation (EGR) systems were adapted for use in V16 engines, helping to lower nitrogen oxide (NOx) emissions by recirculating a portion of the exhaust gases back into the combustion chamber. This technology required careful calibration to maintain performance while meeting emissions targets.

Advanced engine management systems and onboard diagnostics played a vital role in ensuring V16 engines could comply with emissions regulations. These systems continuously monitor and adjust engine parameters to optimize performance and emissions control, allowing for real-time adaptations to varying operating conditions.

In the realm of custom applications, particularly in the marine and luxury automotive sectors, engineers developed innovative solutions to balance performance with emissions compliance. This included the use of lightweight materials and advanced aerodynamics to improve overall efficiency, indirectly supporting emissions reduction efforts.

As emissions regulations continue to evolve, the future of V16 engines in commercial and custom applications will depend on ongoing engineering innovations. The integration of hybrid technologies and the potential for alternative fuels may provide new avenues for V16 engines to meet increasingly stringent environmental standards while maintaining their distinctive power and prestige.

The Clean Air Act of 1970 in the United States marked a turning point in emissions control, setting the stage for more rigorous standards in the following decades. For V16 engines to remain feasible in commercial and custom applications, manufacturers had to invest heavily in research and development to meet these new requirements. This led to several key engineering breakthroughs in emissions reduction technologies.

One of the most significant advancements was the development of more efficient fuel injection systems. Electronic fuel injection (EFI) replaced carburetors, allowing for precise control over fuel delivery and combustion. This technology, when applied to V16 engines, resulted in improved fuel efficiency and reduced emissions without sacrificing power output.

Catalytic converters became mandatory for automotive applications in many countries, presenting a unique challenge for V16 engines due to their high exhaust flow rates. Engineers developed larger, more efficient catalytic converters capable of handling the increased exhaust volume while effectively reducing harmful emissions.

Variable valve timing (VVT) technology was another crucial breakthrough that helped V16 engines meet emissions standards. By optimizing valve operation based on engine speed and load, VVT systems improved fuel efficiency and reduced emissions across a wide range of operating conditions.

Exhaust gas recirculation (EGR) systems were adapted for use in V16 engines, helping to lower nitrogen oxide (NOx) emissions by recirculating a portion of the exhaust gases back into the combustion chamber. This technology required careful calibration to maintain performance while meeting emissions targets.

Advanced engine management systems and onboard diagnostics played a vital role in ensuring V16 engines could comply with emissions regulations. These systems continuously monitor and adjust engine parameters to optimize performance and emissions control, allowing for real-time adaptations to varying operating conditions.

In the realm of custom applications, particularly in the marine and luxury automotive sectors, engineers developed innovative solutions to balance performance with emissions compliance. This included the use of lightweight materials and advanced aerodynamics to improve overall efficiency, indirectly supporting emissions reduction efforts.

As emissions regulations continue to evolve, the future of V16 engines in commercial and custom applications will depend on ongoing engineering innovations. The integration of hybrid technologies and the potential for alternative fuels may provide new avenues for V16 engines to meet increasingly stringent environmental standards while maintaining their distinctive power and prestige.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!