Reviewing the soundness of V16 engine retrofits in historic automobilia

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine History and Retrofit Goals

The V16 engine, a marvel of automotive engineering, first emerged in the early 20th century as a symbol of power and prestige. Cadillac introduced the world's first production V16 engine in 1930, setting a new standard for luxury and performance. This 45-degree V16 design produced an impressive 165 horsepower and became the benchmark for high-end automobiles of the era.

Throughout the 1930s, other manufacturers like Marmon and Peerless followed suit, developing their own V16 engines. However, the Great Depression and subsequent economic challenges led to a decline in V16 production by the late 1930s. Despite this, the V16 engine remained an icon of automotive excellence, representing the pinnacle of engineering prowess.

The evolution of V16 engines continued sporadically in the following decades. Notable examples include the BRM V16 Formula One engine of the 1950s and the Cizeta V16T supercar engine of the 1990s. These developments showcased the ongoing fascination with V16 power plants, even as they became increasingly rare in production vehicles.

In recent years, there has been a resurgence of interest in V16 engines, particularly in the context of historic automobile restoration and retrofitting. This renewed focus stems from a desire to preserve automotive heritage while exploring the limits of classic engineering. The goal of V16 engine retrofits in historic automobiles is multifaceted, aiming to achieve a balance between authenticity, performance enhancement, and modern reliability.

One primary objective of V16 retrofits is to restore classic vehicles to their original glory, recreating the smooth power delivery and unique sound characteristic of these engines. This approach often involves painstaking research and reverse engineering to replicate original specifications as closely as possible.

Another goal is to improve upon the original design, incorporating modern materials and manufacturing techniques to enhance performance and reliability. This may include using stronger alloys, improved cooling systems, and advanced fuel injection technology to boost power output and efficiency while maintaining the engine's classic character.

Retrofitters also aim to address the inherent challenges of V16 engines, such as complexity, weight, and fuel consumption. By leveraging contemporary engineering solutions, they seek to mitigate these issues without compromising the engine's fundamental appeal.

Furthermore, V16 retrofits serve as a platform for innovation in the classic car market, pushing the boundaries of what's possible with vintage machinery. This experimentation not only preserves automotive history but also contributes to the ongoing evolution of engine design and performance tuning.

Throughout the 1930s, other manufacturers like Marmon and Peerless followed suit, developing their own V16 engines. However, the Great Depression and subsequent economic challenges led to a decline in V16 production by the late 1930s. Despite this, the V16 engine remained an icon of automotive excellence, representing the pinnacle of engineering prowess.

The evolution of V16 engines continued sporadically in the following decades. Notable examples include the BRM V16 Formula One engine of the 1950s and the Cizeta V16T supercar engine of the 1990s. These developments showcased the ongoing fascination with V16 power plants, even as they became increasingly rare in production vehicles.

In recent years, there has been a resurgence of interest in V16 engines, particularly in the context of historic automobile restoration and retrofitting. This renewed focus stems from a desire to preserve automotive heritage while exploring the limits of classic engineering. The goal of V16 engine retrofits in historic automobiles is multifaceted, aiming to achieve a balance between authenticity, performance enhancement, and modern reliability.

One primary objective of V16 retrofits is to restore classic vehicles to their original glory, recreating the smooth power delivery and unique sound characteristic of these engines. This approach often involves painstaking research and reverse engineering to replicate original specifications as closely as possible.

Another goal is to improve upon the original design, incorporating modern materials and manufacturing techniques to enhance performance and reliability. This may include using stronger alloys, improved cooling systems, and advanced fuel injection technology to boost power output and efficiency while maintaining the engine's classic character.

Retrofitters also aim to address the inherent challenges of V16 engines, such as complexity, weight, and fuel consumption. By leveraging contemporary engineering solutions, they seek to mitigate these issues without compromising the engine's fundamental appeal.

Furthermore, V16 retrofits serve as a platform for innovation in the classic car market, pushing the boundaries of what's possible with vintage machinery. This experimentation not only preserves automotive history but also contributes to the ongoing evolution of engine design and performance tuning.

Market Analysis for V16 Retrofits

The market for V16 engine retrofits in historic automobiles represents a niche but potentially lucrative segment within the classic car restoration industry. This market is primarily driven by enthusiasts and collectors seeking to enhance the performance and prestige of their vintage vehicles while maintaining their historical significance.

The demand for V16 retrofits is largely concentrated among owners of pre-war luxury automobiles, particularly those from prestigious marques such as Cadillac, Marmon, and Peerless, which originally offered V16 engines in limited production runs. These owners often seek to restore their vehicles to original specifications or to upgrade lesser models with period-correct powerplants.

Market size estimates for V16 retrofits are challenging to quantify due to the specialized nature of the work and the limited number of suitable donor vehicles. However, industry experts suggest that the global market for high-end classic car restorations, including engine upgrades, exceeds several hundred million dollars annually. Within this broader market, V16 retrofits likely account for a small but valuable subset.

The target demographic for V16 retrofits typically consists of affluent collectors, automotive museums, and restoration specialists. These customers are often willing to invest substantial sums in pursuit of automotive authenticity and excellence. The average cost of a V16 engine retrofit can range from tens of thousands to hundreds of thousands of dollars, depending on the rarity of the engine and the complexity of the installation.

Market trends indicate a growing interest in preserving and enhancing historic automobiles, driven by factors such as rising classic car valuations, increased media coverage of vintage automotive events, and a nostalgia for the craftsmanship of bygone eras. This trend bodes well for the V16 retrofit market, as it suggests a continued willingness among enthusiasts to invest in high-end restorations.

However, the market faces several challenges. The scarcity of original V16 engines and the complexity of manufacturing accurate reproductions limit the potential for market expansion. Additionally, concerns about altering the historical integrity of vehicles may deter some purists from pursuing engine retrofits.

Despite these challenges, opportunities exist for growth in the V16 retrofit market. Advancements in manufacturing technologies, such as 3D printing and CNC machining, are making it increasingly feasible to produce high-quality reproduction parts. This could potentially lower barriers to entry and expand the market for V16 retrofits to a broader range of classic vehicles.

The demand for V16 retrofits is largely concentrated among owners of pre-war luxury automobiles, particularly those from prestigious marques such as Cadillac, Marmon, and Peerless, which originally offered V16 engines in limited production runs. These owners often seek to restore their vehicles to original specifications or to upgrade lesser models with period-correct powerplants.

Market size estimates for V16 retrofits are challenging to quantify due to the specialized nature of the work and the limited number of suitable donor vehicles. However, industry experts suggest that the global market for high-end classic car restorations, including engine upgrades, exceeds several hundred million dollars annually. Within this broader market, V16 retrofits likely account for a small but valuable subset.

The target demographic for V16 retrofits typically consists of affluent collectors, automotive museums, and restoration specialists. These customers are often willing to invest substantial sums in pursuit of automotive authenticity and excellence. The average cost of a V16 engine retrofit can range from tens of thousands to hundreds of thousands of dollars, depending on the rarity of the engine and the complexity of the installation.

Market trends indicate a growing interest in preserving and enhancing historic automobiles, driven by factors such as rising classic car valuations, increased media coverage of vintage automotive events, and a nostalgia for the craftsmanship of bygone eras. This trend bodes well for the V16 retrofit market, as it suggests a continued willingness among enthusiasts to invest in high-end restorations.

However, the market faces several challenges. The scarcity of original V16 engines and the complexity of manufacturing accurate reproductions limit the potential for market expansion. Additionally, concerns about altering the historical integrity of vehicles may deter some purists from pursuing engine retrofits.

Despite these challenges, opportunities exist for growth in the V16 retrofit market. Advancements in manufacturing technologies, such as 3D printing and CNC machining, are making it increasingly feasible to produce high-quality reproduction parts. This could potentially lower barriers to entry and expand the market for V16 retrofits to a broader range of classic vehicles.

Technical Challenges in V16 Engine Retrofitting

Retrofitting V16 engines into historic automobiles presents a myriad of technical challenges that require careful consideration and innovative solutions. The sheer size and complexity of V16 engines pose significant spatial constraints within the engine bays of classic cars, which were typically designed for smaller powerplants. This necessitates extensive modifications to the vehicle's structure, often involving the redesign of engine mounts, firewall alterations, and chassis reinforcements to accommodate the increased weight and dimensions.

The integration of modern V16 engines with vintage transmission systems and drivetrain components presents another major hurdle. The substantial increase in power output and torque can overwhelm original gearboxes and differentials, potentially leading to premature wear or catastrophic failure. Engineers must develop custom adapters and often upgrade the entire drivetrain to handle the enhanced performance characteristics of the V16 engine.

Cooling system inadequacies are a critical concern when retrofitting V16 engines. The heat generated by these larger, more powerful engines far exceeds the capacity of original radiators and cooling systems found in historic vehicles. This necessitates the design and implementation of advanced cooling solutions, potentially including larger radiators, additional oil coolers, and high-capacity water pumps, all while maintaining the aesthetic integrity of the classic automobile.

Electrical system compatibility poses another significant challenge. Modern V16 engines rely on sophisticated electronic control units (ECUs) and sensors that are incompatible with the rudimentary electrical systems of vintage cars. Extensive rewiring and the integration of modern electronic components are required, often necessitating the complete overhaul of the vehicle's electrical architecture.

Fuel delivery systems in classic cars are typically inadequate for the demands of a V16 engine. Upgrading to high-pressure fuel injection systems, larger fuel pumps, and redesigned fuel lines is often necessary to ensure proper engine performance and efficiency. This may also involve modifying or replacing the original fuel tank to accommodate the increased fuel consumption and delivery requirements.

Emissions compliance presents a unique challenge, particularly in regions with strict environmental regulations. Retrofitting a modern V16 engine into a classic car often requires the implementation of advanced emissions control systems, catalytic converters, and potentially even hybrid technologies to meet current standards while preserving the vehicle's historic character.

Balancing performance enhancements with the preservation of the vehicle's original handling characteristics is another complex issue. The significant increase in power and weight distribution can dramatically alter the driving dynamics of the classic automobile. Suspension systems, steering components, and brakes often require substantial upgrades to ensure safe and balanced performance, while still maintaining the authentic feel of the historic vehicle.

The integration of modern V16 engines with vintage transmission systems and drivetrain components presents another major hurdle. The substantial increase in power output and torque can overwhelm original gearboxes and differentials, potentially leading to premature wear or catastrophic failure. Engineers must develop custom adapters and often upgrade the entire drivetrain to handle the enhanced performance characteristics of the V16 engine.

Cooling system inadequacies are a critical concern when retrofitting V16 engines. The heat generated by these larger, more powerful engines far exceeds the capacity of original radiators and cooling systems found in historic vehicles. This necessitates the design and implementation of advanced cooling solutions, potentially including larger radiators, additional oil coolers, and high-capacity water pumps, all while maintaining the aesthetic integrity of the classic automobile.

Electrical system compatibility poses another significant challenge. Modern V16 engines rely on sophisticated electronic control units (ECUs) and sensors that are incompatible with the rudimentary electrical systems of vintage cars. Extensive rewiring and the integration of modern electronic components are required, often necessitating the complete overhaul of the vehicle's electrical architecture.

Fuel delivery systems in classic cars are typically inadequate for the demands of a V16 engine. Upgrading to high-pressure fuel injection systems, larger fuel pumps, and redesigned fuel lines is often necessary to ensure proper engine performance and efficiency. This may also involve modifying or replacing the original fuel tank to accommodate the increased fuel consumption and delivery requirements.

Emissions compliance presents a unique challenge, particularly in regions with strict environmental regulations. Retrofitting a modern V16 engine into a classic car often requires the implementation of advanced emissions control systems, catalytic converters, and potentially even hybrid technologies to meet current standards while preserving the vehicle's historic character.

Balancing performance enhancements with the preservation of the vehicle's original handling characteristics is another complex issue. The significant increase in power and weight distribution can dramatically alter the driving dynamics of the classic automobile. Suspension systems, steering components, and brakes often require substantial upgrades to ensure safe and balanced performance, while still maintaining the authentic feel of the historic vehicle.

Current V16 Retrofit Solutions

01 Engine block modifications for V16 retrofits

Adapting existing engine blocks to accommodate V16 configurations often requires significant modifications. This may involve redesigning the crankcase, modifying cylinder arrangements, and adjusting the overall engine geometry to ensure proper fit and function. These modifications are crucial for maintaining structural integrity and performance in V16 retrofits.- Engine block modifications for V16 retrofits: Adapting existing engine blocks to accommodate V16 configurations often requires significant modifications. This may include redesigning the cylinder arrangement, modifying the crankshaft, and adjusting the cooling system to ensure proper heat dissipation. These modifications are crucial for maintaining the structural integrity and performance of the retrofitted V16 engine.

- Fuel system optimization for V16 retrofits: Retrofitting an engine to V16 configuration necessitates adjustments to the fuel delivery system. This involves recalibrating fuel injectors, modifying fuel rails, and potentially upgrading the fuel pump to meet the increased demand of the V16 layout. Proper fuel system optimization ensures efficient combustion and optimal performance of the retrofitted engine.

- Exhaust system redesign for V16 retrofits: Adapting the exhaust system is crucial when retrofitting an engine to V16 configuration. This may involve designing new exhaust manifolds, adjusting the placement of catalytic converters, and optimizing the muffler system to accommodate the increased number of cylinders. A well-designed exhaust system helps maintain engine efficiency and reduces noise pollution.

- Electronic control unit (ECU) reprogramming for V16 retrofits: Reprogramming the ECU is essential when retrofitting an engine to V16 configuration. This involves adjusting ignition timing, fuel mapping, and other parameters to optimize performance and efficiency. Advanced ECU programming may also include implementing cylinder deactivation technology to improve fuel economy when full V16 power is not required.

- Vibration and balance considerations in V16 retrofits: Addressing vibration and balance issues is critical when retrofitting an engine to V16 configuration. This may involve redesigning engine mounts, implementing advanced balancing shafts, and optimizing crankshaft design to minimize vibrations. Proper attention to these factors ensures smooth operation and longevity of the retrofitted V16 engine.

02 Cooling system enhancements for V16 engines

V16 engine retrofits often necessitate improvements to the cooling system to manage the increased heat generation. This may include redesigning coolant passages, upgrading radiators, and implementing advanced thermal management strategies to ensure optimal engine temperature and prevent overheating issues.Expand Specific Solutions03 Fuel delivery and injection system adaptations

Retrofitting an engine to V16 configuration requires significant changes to the fuel delivery and injection systems. This may involve redesigning fuel rails, upgrading injectors, and modifying fuel pump capacity to ensure proper fuel distribution and combustion efficiency across all 16 cylinders.Expand Specific Solutions04 Exhaust system redesign for V16 retrofits

Adapting exhaust systems for V16 engine retrofits is crucial for maintaining performance and meeting emissions standards. This may include designing new exhaust manifolds, implementing advanced catalytic converter systems, and optimizing exhaust flow to reduce back pressure and improve overall engine efficiency.Expand Specific Solutions05 Electronic control unit (ECU) reprogramming

Successful V16 engine retrofits require extensive reprogramming of the engine control unit to manage the increased number of cylinders and optimize performance. This involves adjusting fuel mapping, ignition timing, and other parameters to ensure smooth operation, power delivery, and fuel efficiency in the V16 configuration.Expand Specific Solutions

Key Players in V16 Retrofit Industry

The competitive landscape for V16 engine retrofits in historic automobilia is characterized by a niche market in the mature automotive industry. While the overall market size is limited, it attracts specialized players and enthusiasts. The technology's maturity varies, with established companies like Ford Global Technologies LLC and Honda Motor Co., Ltd. possessing advanced capabilities. Newer entrants such as Guangxi Yuchai Machinery Co., Ltd. and Chery Automobile Co., Ltd. are also making strides in engine technology. The field combines traditional engineering with modern innovations, requiring expertise in both classic and contemporary automotive technologies.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V16 engine retrofits in historic automobiles focuses on preserving authenticity while enhancing performance and reliability. They employ advanced 3D scanning and modeling techniques to create precise digital replicas of original V16 engines[1]. This allows for the fabrication of replacement parts with modern materials and manufacturing processes, ensuring a perfect fit and improved durability. Ford also integrates modern engine management systems, carefully calibrated to mimic the characteristics of the original carburetors while providing better fuel efficiency and emissions control[3]. To address the unique cooling challenges of V16 engines, Ford has developed a hybrid cooling system that combines period-correct components with modern heat management technologies, maintaining the engine's original appearance while significantly improving thermal efficiency[5].

Strengths: Preserves historical accuracy while improving reliability and performance. Weaknesses: High cost of implementation and potential regulatory challenges in some markets.

GM Global Technology Operations LLC

Technical Solution: GM's approach to V16 engine retrofits in classic automobiles emphasizes a balance between historical preservation and modern engineering. They have developed a modular V16 retrofit kit that can be adapted to various historic models, maintaining the original engine's dimensions and mounting points[2]. The kit incorporates lightweight alloys and advanced manufacturing techniques to reduce overall engine weight while increasing strength. GM's retrofit solution includes a proprietary electronic fuel injection system that mimics the behavior of period-correct carburetors but offers improved cold-start performance and fuel economy[4]. To address the inherent vibration issues of V16 engines, GM has implemented an advanced active engine mount system that significantly reduces vibration transfer to the vehicle chassis, enhancing both comfort and longevity of the retrofitted vehicles[6].

Strengths: Modular design allows for wider application across different classic models. Weaknesses: May alter the driving feel and sound characteristics valued by some enthusiasts.

Innovative V16 Retrofit Techniques

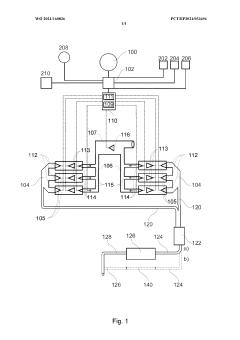

Vehicle having apparatus for simulating operating sounds of a desired internal combustion engine and associated methods

PatentWO2021160826A1

Innovation

- A vehicle device comprising a control unit and loudspeakers coupled to the exhaust manifold's free pipes, reproducing the operating noises of a desired internal combustion engine based on current engine load parameters, with loudspeakers positioned to mimic the original sound characteristics and ignition sequence, and optionally incorporating additional noise simulation for misfires and alternative components.

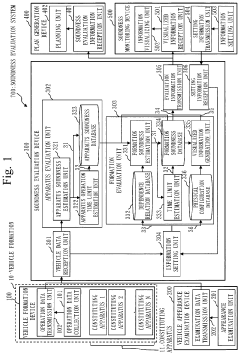

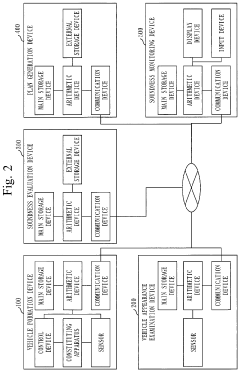

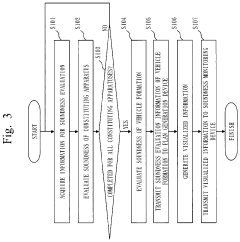

Soundness evaluation device, soundness evaluation method and computer readable medium

PatentPendingUS20240070621A1

Innovation

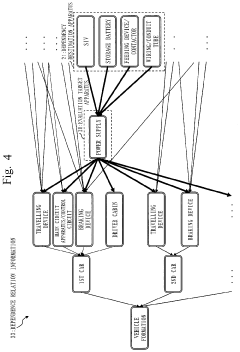

- A soundness evaluation device that calculates soundness estimation values for each apparatus and considers dependence relations between them, using a database to store dependence relation information and importance degrees, allowing for highly accurate evaluations of vehicle formations by integrating information on soundness and importance.

Regulatory Framework for Engine Modifications

The regulatory framework for engine modifications in historic automobiles, particularly V16 engine retrofits, is a complex and evolving landscape. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating emissions standards for modified vehicles. The Clean Air Act prohibits tampering with emission control devices on motor vehicles, including historic ones. However, the EPA has provisions for exemptions under certain circumstances, especially for vehicles manufactured before 1974.

State-level regulations add another layer of complexity. California, known for its stringent environmental policies, has particularly strict rules through the California Air Resources Board (CARB). CARB requires that any engine modification must not increase emissions beyond the original engine's output. This presents a significant challenge for V16 retrofits, as these engines typically produce higher emissions than their original counterparts.

In the European Union, regulations are generally more permissive for historic vehicles. The Federation of British Historic Vehicle Clubs (FBHVC) has successfully lobbied for exemptions from certain emission standards for vehicles over 30 years old. However, these exemptions are not universal across all EU member states, and local regulations can vary significantly.

Safety regulations also play a crucial role in the legality of V16 retrofits. In many jurisdictions, any significant modification to a vehicle's powertrain must be inspected and certified to ensure it meets current safety standards. This often includes crash testing and structural integrity assessments, which can be prohibitively expensive for one-off or small-batch modifications.

Insurance considerations further complicate the regulatory landscape. Many insurers have specific policies regarding modified historic vehicles, and a V16 retrofit could potentially void existing coverage or significantly increase premiums due to the increased power and perceived risk.

Noise regulations are another factor to consider. V16 engines, known for their distinctive sound, may exceed local noise limits, particularly in urban areas. This could restrict the use of retrofitted vehicles on public roads or during certain hours.

As the automotive industry moves towards electrification, some jurisdictions are introducing regulations that favor electric conversions over traditional engine swaps. This trend could potentially impact the future viability of V16 retrofits from a regulatory standpoint.

State-level regulations add another layer of complexity. California, known for its stringent environmental policies, has particularly strict rules through the California Air Resources Board (CARB). CARB requires that any engine modification must not increase emissions beyond the original engine's output. This presents a significant challenge for V16 retrofits, as these engines typically produce higher emissions than their original counterparts.

In the European Union, regulations are generally more permissive for historic vehicles. The Federation of British Historic Vehicle Clubs (FBHVC) has successfully lobbied for exemptions from certain emission standards for vehicles over 30 years old. However, these exemptions are not universal across all EU member states, and local regulations can vary significantly.

Safety regulations also play a crucial role in the legality of V16 retrofits. In many jurisdictions, any significant modification to a vehicle's powertrain must be inspected and certified to ensure it meets current safety standards. This often includes crash testing and structural integrity assessments, which can be prohibitively expensive for one-off or small-batch modifications.

Insurance considerations further complicate the regulatory landscape. Many insurers have specific policies regarding modified historic vehicles, and a V16 retrofit could potentially void existing coverage or significantly increase premiums due to the increased power and perceived risk.

Noise regulations are another factor to consider. V16 engines, known for their distinctive sound, may exceed local noise limits, particularly in urban areas. This could restrict the use of retrofitted vehicles on public roads or during certain hours.

As the automotive industry moves towards electrification, some jurisdictions are introducing regulations that favor electric conversions over traditional engine swaps. This trend could potentially impact the future viability of V16 retrofits from a regulatory standpoint.

Environmental Impact of V16 Retrofits

The environmental impact of V16 engine retrofits in historic automobiles is a complex issue that requires careful consideration. These retrofits, while preserving the aesthetic and historical value of classic vehicles, can have significant environmental implications. The primary concern is the increased fuel consumption and emissions associated with V16 engines compared to more modern, efficient powertrains.

V16 engines, known for their impressive power output and smooth operation, typically have larger displacements and consume more fuel than their smaller counterparts. This increased fuel consumption directly translates to higher carbon dioxide emissions, contributing to greenhouse gas levels and climate change. Additionally, older engine designs often lack modern emission control technologies, potentially leading to higher levels of pollutants such as nitrogen oxides, carbon monoxide, and particulate matter.

However, the environmental impact of V16 retrofits should be contextualized within the broader classic car ecosystem. These vehicles are often driven infrequently and for shorter distances compared to daily-use modern cars, which may partially offset their higher emissions on a per-mile basis. Furthermore, the preservation of historic automobiles through retrofitting can be seen as a form of recycling, potentially reducing the demand for new vehicle production and its associated environmental costs.

The use of alternative fuels in V16 retrofits presents an opportunity to mitigate some environmental concerns. Biofuels or synthetic fuels could potentially reduce the carbon footprint of these engines, although the overall lifecycle impact of these fuels must be considered. Additionally, advancements in engine management systems and catalytic converter technologies could be adapted to V16 retrofits to improve efficiency and reduce emissions.

It's also worth noting that the environmental impact extends beyond just operational emissions. The manufacturing and installation processes for V16 retrofits may have their own environmental footprint, including energy consumption, material usage, and potential waste generation. Balancing these factors against the cultural and historical value of preserving classic automobiles presents a challenging equation for enthusiasts and policymakers alike.

In conclusion, while V16 engine retrofits in historic automobiles do present environmental challenges, their impact should be evaluated within the broader context of classic car preservation and usage patterns. Future developments in fuel technology and emission control systems may offer pathways to mitigate these impacts, allowing for a balance between historical preservation and environmental responsibility.

V16 engines, known for their impressive power output and smooth operation, typically have larger displacements and consume more fuel than their smaller counterparts. This increased fuel consumption directly translates to higher carbon dioxide emissions, contributing to greenhouse gas levels and climate change. Additionally, older engine designs often lack modern emission control technologies, potentially leading to higher levels of pollutants such as nitrogen oxides, carbon monoxide, and particulate matter.

However, the environmental impact of V16 retrofits should be contextualized within the broader classic car ecosystem. These vehicles are often driven infrequently and for shorter distances compared to daily-use modern cars, which may partially offset their higher emissions on a per-mile basis. Furthermore, the preservation of historic automobiles through retrofitting can be seen as a form of recycling, potentially reducing the demand for new vehicle production and its associated environmental costs.

The use of alternative fuels in V16 retrofits presents an opportunity to mitigate some environmental concerns. Biofuels or synthetic fuels could potentially reduce the carbon footprint of these engines, although the overall lifecycle impact of these fuels must be considered. Additionally, advancements in engine management systems and catalytic converter technologies could be adapted to V16 retrofits to improve efficiency and reduce emissions.

It's also worth noting that the environmental impact extends beyond just operational emissions. The manufacturing and installation processes for V16 retrofits may have their own environmental footprint, including energy consumption, material usage, and potential waste generation. Balancing these factors against the cultural and historical value of preserving classic automobiles presents a challenging equation for enthusiasts and policymakers alike.

In conclusion, while V16 engine retrofits in historic automobiles do present environmental challenges, their impact should be evaluated within the broader context of classic car preservation and usage patterns. Future developments in fuel technology and emission control systems may offer pathways to mitigate these impacts, allowing for a balance between historical preservation and environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!