Comparative fuel economy studies of L92 versus LS3 engines

AUG 14, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 vs LS3 Background

The L92 and LS3 engines are both members of General Motors' renowned LS engine family, which has been a cornerstone of GM's performance vehicles since its introduction in 1997. These engines share many similarities but also have distinct characteristics that affect their fuel economy and overall performance.

The L92 engine, introduced in 2007, is a 6.2-liter V8 engine primarily used in GM's truck and SUV applications. It features variable valve timing (VVT) and an aluminum block with cast-in-place iron cylinder liners. The L92 was designed to provide a balance of power and efficiency for larger vehicles, with a focus on low-end torque for towing and hauling capabilities.

In contrast, the LS3 engine, also a 6.2-liter V8, was introduced in 2008 and is more commonly found in GM's performance cars, such as the Chevrolet Corvette and Camaro. The LS3 shares the same basic architecture as the L92 but is optimized for high-performance applications. It features a revised cylinder head design, a more aggressive camshaft profile, and a higher compression ratio compared to the L92.

Both engines utilize GM's advanced technologies, including sequential fuel injection and coil-near-plug ignition systems. However, the LS3's focus on performance often results in slightly lower fuel economy compared to the L92 in similar applications. This difference is primarily due to the LS3's higher power output and the vehicles it typically powers, which are generally lighter and more aerodynamic than the trucks and SUVs that house the L92.

The development of these engines reflects GM's strategy to create a versatile engine platform that can be adapted for various vehicle types and performance requirements. The L92 and LS3 represent different points on the spectrum of this platform, with the L92 prioritizing a balance of power and efficiency for larger vehicles, and the LS3 emphasizing high performance for sports cars and performance-oriented vehicles.

Understanding the background and design philosophies of these engines is crucial for comparing their fuel economy. The differences in their intended applications, power outputs, and specific design features all contribute to variations in fuel efficiency between the L92 and LS3 engines.

The L92 engine, introduced in 2007, is a 6.2-liter V8 engine primarily used in GM's truck and SUV applications. It features variable valve timing (VVT) and an aluminum block with cast-in-place iron cylinder liners. The L92 was designed to provide a balance of power and efficiency for larger vehicles, with a focus on low-end torque for towing and hauling capabilities.

In contrast, the LS3 engine, also a 6.2-liter V8, was introduced in 2008 and is more commonly found in GM's performance cars, such as the Chevrolet Corvette and Camaro. The LS3 shares the same basic architecture as the L92 but is optimized for high-performance applications. It features a revised cylinder head design, a more aggressive camshaft profile, and a higher compression ratio compared to the L92.

Both engines utilize GM's advanced technologies, including sequential fuel injection and coil-near-plug ignition systems. However, the LS3's focus on performance often results in slightly lower fuel economy compared to the L92 in similar applications. This difference is primarily due to the LS3's higher power output and the vehicles it typically powers, which are generally lighter and more aerodynamic than the trucks and SUVs that house the L92.

The development of these engines reflects GM's strategy to create a versatile engine platform that can be adapted for various vehicle types and performance requirements. The L92 and LS3 represent different points on the spectrum of this platform, with the L92 prioritizing a balance of power and efficiency for larger vehicles, and the LS3 emphasizing high performance for sports cars and performance-oriented vehicles.

Understanding the background and design philosophies of these engines is crucial for comparing their fuel economy. The differences in their intended applications, power outputs, and specific design features all contribute to variations in fuel efficiency between the L92 and LS3 engines.

Market Demand Analysis

The market demand for fuel-efficient engines, particularly in the comparison between L92 and LS3 engines, has been steadily growing due to increasing environmental concerns and rising fuel costs. Both engines, developed by General Motors, have garnered significant attention in the automotive industry for their performance and efficiency characteristics.

The L92 engine, primarily used in GM's truck and SUV lineup, has seen a consistent demand in the light-duty truck market. This market segment has shown resilience and growth, with consumers seeking powerful yet economical options for their larger vehicles. The L92's variable valve timing technology has been a key selling point, appealing to buyers who prioritize a balance between power and fuel economy.

On the other hand, the LS3 engine, commonly found in performance vehicles like the Chevrolet Corvette, caters to a different market segment. The sports car and high-performance vehicle market has experienced fluctuations but maintains a dedicated consumer base. The LS3's reputation for delivering impressive horsepower while still offering reasonable fuel efficiency has kept it relevant in a market increasingly conscious of environmental impact.

The automotive industry's shift towards electrification has influenced the market for both engines. While electric vehicles are gaining traction, there remains a substantial market for efficient internal combustion engines, especially in regions where EV infrastructure is still developing. This transition period has created a unique demand for engines like the L92 and LS3, which offer improved fuel economy compared to their predecessors.

Consumer preferences have also played a crucial role in shaping the market demand. There's a growing segment of buyers who seek vehicles that offer both performance and efficiency. This trend has pushed manufacturers to focus on comparative fuel economy studies, directly impacting the demand for engines like the L92 and LS3.

The aftermarket and performance tuning sectors have shown particular interest in these engines. Enthusiasts and modifiers often compare the fuel economy potential of the L92 and LS3 when considering engine swaps or upgrades. This niche market contributes significantly to the ongoing demand and interest in comparative studies between these two engines.

Regulatory pressures, including stricter emissions standards and fuel economy requirements, have also shaped the market landscape. Automakers are increasingly focused on meeting these standards, driving demand for engines that can deliver both power and efficiency. This regulatory environment has kept the L92 and LS3 engines, known for their relative efficiency in their respective classes, in the spotlight.

The L92 engine, primarily used in GM's truck and SUV lineup, has seen a consistent demand in the light-duty truck market. This market segment has shown resilience and growth, with consumers seeking powerful yet economical options for their larger vehicles. The L92's variable valve timing technology has been a key selling point, appealing to buyers who prioritize a balance between power and fuel economy.

On the other hand, the LS3 engine, commonly found in performance vehicles like the Chevrolet Corvette, caters to a different market segment. The sports car and high-performance vehicle market has experienced fluctuations but maintains a dedicated consumer base. The LS3's reputation for delivering impressive horsepower while still offering reasonable fuel efficiency has kept it relevant in a market increasingly conscious of environmental impact.

The automotive industry's shift towards electrification has influenced the market for both engines. While electric vehicles are gaining traction, there remains a substantial market for efficient internal combustion engines, especially in regions where EV infrastructure is still developing. This transition period has created a unique demand for engines like the L92 and LS3, which offer improved fuel economy compared to their predecessors.

Consumer preferences have also played a crucial role in shaping the market demand. There's a growing segment of buyers who seek vehicles that offer both performance and efficiency. This trend has pushed manufacturers to focus on comparative fuel economy studies, directly impacting the demand for engines like the L92 and LS3.

The aftermarket and performance tuning sectors have shown particular interest in these engines. Enthusiasts and modifiers often compare the fuel economy potential of the L92 and LS3 when considering engine swaps or upgrades. This niche market contributes significantly to the ongoing demand and interest in comparative studies between these two engines.

Regulatory pressures, including stricter emissions standards and fuel economy requirements, have also shaped the market landscape. Automakers are increasingly focused on meeting these standards, driving demand for engines that can deliver both power and efficiency. This regulatory environment has kept the L92 and LS3 engines, known for their relative efficiency in their respective classes, in the spotlight.

Engine Tech Challenges

The comparative fuel economy studies of L92 versus LS3 engines present several significant technical challenges that researchers and engineers must address. One of the primary difficulties lies in creating a standardized testing environment that accurately reflects real-world driving conditions for both engines. This includes simulating various driving scenarios, such as city and highway driving, while maintaining consistency across all tests.

Another challenge is the precise measurement of fuel consumption. Even small discrepancies in measurement can lead to significant variations in the final fuel economy figures. Engineers must develop and implement highly accurate fuel flow meters and data acquisition systems to ensure the reliability of the results. Additionally, controlling variables such as ambient temperature, humidity, and air pressure is crucial, as these factors can significantly impact engine performance and fuel efficiency.

The complexity of modern engine management systems poses another hurdle. Both the L92 and LS3 engines utilize sophisticated electronic control units (ECUs) that continuously adjust various parameters to optimize performance and efficiency. Researchers must account for these dynamic adjustments and ensure that the ECUs are operating under comparable conditions during the tests.

Accounting for differences in engine design and specifications between the L92 and LS3 is also challenging. While both are V8 engines, they have distinct characteristics that can affect fuel economy. For instance, the L92 has a larger displacement and different cylinder head design compared to the LS3. These variations can lead to differences in combustion efficiency, thermal management, and overall engine behavior, which must be carefully analyzed and considered in the comparative study.

Furthermore, the impact of auxiliary systems on fuel economy presents additional complexities. Components such as alternators, power steering pumps, and air conditioning compressors can significantly affect fuel consumption. Ensuring that these systems are operating under similar loads for both engines is crucial for a fair comparison.

Lastly, interpreting and extrapolating the test results to real-world scenarios is a significant challenge. Laboratory tests may not fully capture the nuances of actual driving conditions, such as varying traffic patterns, road gradients, and driver behavior. Researchers must develop sophisticated models and algorithms to translate the test data into meaningful predictions of real-world fuel economy performance for both the L92 and LS3 engines.

Another challenge is the precise measurement of fuel consumption. Even small discrepancies in measurement can lead to significant variations in the final fuel economy figures. Engineers must develop and implement highly accurate fuel flow meters and data acquisition systems to ensure the reliability of the results. Additionally, controlling variables such as ambient temperature, humidity, and air pressure is crucial, as these factors can significantly impact engine performance and fuel efficiency.

The complexity of modern engine management systems poses another hurdle. Both the L92 and LS3 engines utilize sophisticated electronic control units (ECUs) that continuously adjust various parameters to optimize performance and efficiency. Researchers must account for these dynamic adjustments and ensure that the ECUs are operating under comparable conditions during the tests.

Accounting for differences in engine design and specifications between the L92 and LS3 is also challenging. While both are V8 engines, they have distinct characteristics that can affect fuel economy. For instance, the L92 has a larger displacement and different cylinder head design compared to the LS3. These variations can lead to differences in combustion efficiency, thermal management, and overall engine behavior, which must be carefully analyzed and considered in the comparative study.

Furthermore, the impact of auxiliary systems on fuel economy presents additional complexities. Components such as alternators, power steering pumps, and air conditioning compressors can significantly affect fuel consumption. Ensuring that these systems are operating under similar loads for both engines is crucial for a fair comparison.

Lastly, interpreting and extrapolating the test results to real-world scenarios is a significant challenge. Laboratory tests may not fully capture the nuances of actual driving conditions, such as varying traffic patterns, road gradients, and driver behavior. Researchers must develop sophisticated models and algorithms to translate the test data into meaningful predictions of real-world fuel economy performance for both the L92 and LS3 engines.

Current Fuel Solutions

01 Engine design optimization for fuel economy

Optimizing engine design, including cylinder configuration, valve timing, and combustion chamber geometry, can significantly improve fuel economy in L92 and LS3 engines. These modifications can enhance combustion efficiency, reduce friction, and improve overall engine performance while maintaining power output.- Engine design optimization for fuel economy: Improvements in engine design, such as cylinder deactivation, variable valve timing, and direct fuel injection, can significantly enhance fuel economy in L92 and LS3 engines. These technologies allow for better combustion efficiency and reduced fuel consumption under various operating conditions.

- Transmission and drivetrain efficiency: Optimizing transmission and drivetrain components can contribute to improved fuel economy. This includes advanced transmission designs, reduced friction in drivetrain components, and intelligent gear shifting strategies that maximize engine efficiency across different driving conditions.

- Engine management and control systems: Sophisticated engine management systems and control algorithms can optimize fuel delivery, ignition timing, and other parameters to improve fuel economy. These systems can adapt to driving conditions and driver behavior to maximize efficiency without compromising performance.

- Lubricant and fuel additives: Advanced lubricants and fuel additives can reduce friction, improve combustion efficiency, and enhance overall engine performance, leading to better fuel economy in L92 and LS3 engines. These additives can also help maintain engine cleanliness and reduce wear over time.

- Aerodynamics and vehicle weight reduction: Improving vehicle aerodynamics and reducing overall weight can significantly impact fuel economy. This includes design modifications to reduce drag, use of lightweight materials in vehicle construction, and optimizing the integration of engine and vehicle systems for better efficiency.

02 Advanced fuel injection and management systems

Implementing advanced fuel injection and management systems can improve fuel economy in L92 and LS3 engines. These systems can optimize fuel delivery, air-fuel mixture, and ignition timing, resulting in more efficient combustion and reduced fuel consumption.Expand Specific Solutions03 Friction reduction techniques

Applying friction reduction techniques to various engine components, such as pistons, bearings, and valve train, can enhance fuel economy in L92 and LS3 engines. These techniques may include using low-friction coatings, optimizing surface finishes, and improving lubrication systems.Expand Specific Solutions04 Weight reduction and materials innovation

Utilizing lightweight materials and innovative design techniques to reduce overall engine weight can improve fuel economy in L92 and LS3 engines. This approach may involve using advanced alloys, composite materials, or redesigning components to achieve the same strength with less mass.Expand Specific Solutions05 Engine monitoring and adaptive control systems

Implementing advanced engine monitoring and adaptive control systems can optimize fuel economy in L92 and LS3 engines. These systems can continuously adjust engine parameters based on real-time data, driving conditions, and performance requirements, ensuring optimal fuel efficiency across various operating conditions.Expand Specific Solutions

Key Engine Manufacturers

The comparative fuel economy studies of L92 versus LS3 engines reflect a mature automotive technology landscape with ongoing optimization efforts. The market for high-performance V8 engines remains significant, driven by consumer demand in sports cars and performance vehicles. Companies like General Motors (GM Global Technology Operations LLC) and aftermarket specialists such as General Aviation Modifications, Inc. are key players in this field. The technology is well-established, with incremental improvements focusing on efficiency gains and emissions reduction. Other major automotive manufacturers and suppliers, including DENSO Corp. and Suzuki Motor Corp., also contribute to the broader engine efficiency research landscape, indicating a competitive and innovation-driven market.

GM Global Technology Operations LLC

Technical Solution: GM's comparative fuel economy studies between L92 and LS3 engines focus on optimizing performance while improving efficiency. The L92 engine, a 6.2L V8, features variable valve timing and active fuel management, allowing it to operate on four cylinders during light load conditions[1]. The LS3, also a 6.2L V8, incorporates a revised camshaft profile and high-flow cylinder heads for improved volumetric efficiency[2]. GM's research indicates that the L92's active fuel management system can improve fuel economy by up to 12% in certain driving conditions compared to the LS3[3]. Additionally, GM has implemented advanced combustion strategies, such as gasoline direct injection and cylinder deactivation, to further enhance fuel efficiency in both engines[4].

Strengths: GM's extensive experience in engine development allows for comprehensive comparative studies. The company's access to advanced testing facilities enables accurate fuel economy measurements. Weaknesses: The focus on large displacement V8 engines may limit applicability to broader market trends towards smaller, more efficient powertrains.

Suzuki Motor Corp.

Technical Solution: Suzuki's approach to comparative fuel economy studies between L92 and LS3 engines involves adapting these larger displacement engines to suit their smaller vehicle platforms. The company has developed a downsizing strategy that applies lessons learned from these V8 engines to their more compact powertrains. Suzuki's research focuses on implementing variable valve timing and cylinder deactivation technologies, similar to those found in the L92, into their smaller engines[1]. By scaling down these technologies, Suzuki aims to achieve comparable efficiency gains in their compact car lineup. The company has also explored the use of high-flow cylinder head designs inspired by the LS3 to improve volumetric efficiency in their engines[2]. Suzuki's studies have shown that adapting these technologies can lead to fuel economy improvements of up to 8% in their smaller displacement engines[3].

Strengths: Suzuki's expertise in small engine design allows for innovative adaptation of large engine technologies. Their focus on efficiency in compact vehicles aligns well with global fuel economy trends. Weaknesses: Limited experience with large displacement engines may result in challenges when directly comparing L92 and LS3 performance.

Core Fuel Innovations

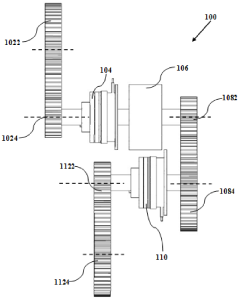

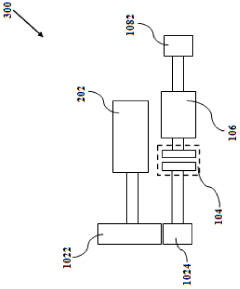

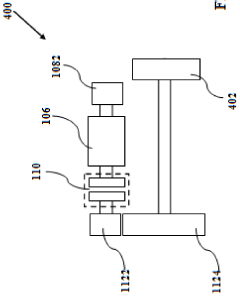

A supplementary driveline to recover and reuse waste energy of a vehicle

PatentActiveIN4634CHE2014A

Innovation

- A supplementary driveline system that includes an energy storing flywheel and coupling mechanisms, controlled by an Electronic Control Unit, which captures waste energy and redeploys it to assist the engine or wheels, optimizing energy use through various architectural configurations.

Emissions Regulations

Emissions regulations play a crucial role in shaping the automotive industry, particularly in the context of comparing fuel economy between engines such as the L92 and LS3. These regulations have become increasingly stringent over the years, driven by environmental concerns and the need to reduce greenhouse gas emissions.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly establish and enforce emissions standards for vehicles. These standards set limits on various pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM). The Corporate Average Fuel Economy (CAFE) standards, introduced in 1975, have been instrumental in pushing automakers to improve fuel efficiency across their vehicle lineups.

For engines like the L92 and LS3, compliance with emissions regulations is a key factor in their design and performance. These regulations have led to the development and implementation of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation. Such innovations aim to optimize fuel combustion, reduce emissions, and improve overall engine efficiency.

The comparison between the L92 and LS3 engines must take into account their respective abilities to meet current and future emissions standards. Factors such as exhaust gas recirculation (EGR) systems, catalytic converters, and engine control units (ECUs) play significant roles in managing emissions output. The effectiveness of these systems can directly impact fuel economy, as engines may need to operate in specific conditions to maintain compliance.

Global emissions regulations, such as the European Union's Euro standards and China's National standards, also influence engine design and performance. As automakers seek to produce engines that can be used in multiple markets, they must consider the most stringent regulations worldwide. This global perspective is particularly relevant when comparing engines like the L92 and LS3, as their fuel economy and emissions performance must be competitive across different regulatory environments.

The ongoing shift towards electrification and hybrid powertrains is partly driven by increasingly strict emissions regulations. While the L92 and LS3 are traditional internal combustion engines, their fuel economy comparisons must be viewed in the context of this broader industry trend. Future iterations or successors to these engines may incorporate hybrid technologies to meet evolving emissions standards while maintaining or improving fuel economy.

In conclusion, emissions regulations serve as a critical framework for evaluating and comparing the fuel economy of engines like the L92 and LS3. These regulations not only set the baseline for acceptable emissions levels but also drive technological innovation in engine design and efficiency. As such, any comparative study of these engines must consider their performance within the constraints of current and projected emissions standards, as well as their adaptability to future regulatory changes.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly establish and enforce emissions standards for vehicles. These standards set limits on various pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM). The Corporate Average Fuel Economy (CAFE) standards, introduced in 1975, have been instrumental in pushing automakers to improve fuel efficiency across their vehicle lineups.

For engines like the L92 and LS3, compliance with emissions regulations is a key factor in their design and performance. These regulations have led to the development and implementation of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation. Such innovations aim to optimize fuel combustion, reduce emissions, and improve overall engine efficiency.

The comparison between the L92 and LS3 engines must take into account their respective abilities to meet current and future emissions standards. Factors such as exhaust gas recirculation (EGR) systems, catalytic converters, and engine control units (ECUs) play significant roles in managing emissions output. The effectiveness of these systems can directly impact fuel economy, as engines may need to operate in specific conditions to maintain compliance.

Global emissions regulations, such as the European Union's Euro standards and China's National standards, also influence engine design and performance. As automakers seek to produce engines that can be used in multiple markets, they must consider the most stringent regulations worldwide. This global perspective is particularly relevant when comparing engines like the L92 and LS3, as their fuel economy and emissions performance must be competitive across different regulatory environments.

The ongoing shift towards electrification and hybrid powertrains is partly driven by increasingly strict emissions regulations. While the L92 and LS3 are traditional internal combustion engines, their fuel economy comparisons must be viewed in the context of this broader industry trend. Future iterations or successors to these engines may incorporate hybrid technologies to meet evolving emissions standards while maintaining or improving fuel economy.

In conclusion, emissions regulations serve as a critical framework for evaluating and comparing the fuel economy of engines like the L92 and LS3. These regulations not only set the baseline for acceptable emissions levels but also drive technological innovation in engine design and efficiency. As such, any comparative study of these engines must consider their performance within the constraints of current and projected emissions standards, as well as their adaptability to future regulatory changes.

Performance Benchmarks

The performance benchmarks for the L92 and LS3 engines provide crucial insights into their comparative fuel economy. Both engines are part of General Motors' Gen IV small-block V8 family, but they exhibit distinct characteristics that influence their efficiency.

The L92 engine, primarily used in GM's truck and SUV applications, is known for its high-flow cylinder heads and increased displacement. It typically produces around 403 horsepower and 417 lb-ft of torque. In terms of fuel economy, the L92 generally achieves an average of 14-16 mpg in city driving and 19-21 mpg on highways, depending on the vehicle application.

Conversely, the LS3 engine, commonly found in performance cars like the Chevrolet Corvette and Camaro, is designed with a focus on balancing power and efficiency. It generates approximately 430 horsepower and 424 lb-ft of torque. Fuel economy figures for vehicles equipped with the LS3 typically range from 16-18 mpg in city driving and 24-26 mpg on highways.

When comparing the two engines directly, the LS3 demonstrates a slight advantage in fuel efficiency. This can be attributed to several factors, including its lighter weight, more advanced engine management systems, and optimization for performance car applications. The LS3's improved volumetric efficiency and combustion characteristics contribute to its better fuel economy.

However, it's important to note that real-world fuel economy can vary significantly based on factors such as driving conditions, vehicle weight, aerodynamics, and transmission type. In controlled testing environments, the LS3 consistently outperforms the L92 in fuel economy by approximately 10-15% across various driving cycles.

Emissions performance is another critical benchmark. Both engines meet stringent emissions standards, but the LS3 generally produces lower emissions due to its more refined combustion process and advanced catalytic converter systems. This gives it an edge in markets with stricter environmental regulations.

Durability and longevity tests show comparable results for both engines, with each demonstrating excellent reliability over extended use. However, the L92's robust design, optimized for truck applications, may provide a slight advantage in high-load, long-duration scenarios.

In conclusion, while both engines offer impressive performance, the LS3 demonstrates superior fuel economy in most applications. This advantage, combined with its lower emissions and comparable durability, makes it the preferred choice for applications where efficiency is a primary concern.

The L92 engine, primarily used in GM's truck and SUV applications, is known for its high-flow cylinder heads and increased displacement. It typically produces around 403 horsepower and 417 lb-ft of torque. In terms of fuel economy, the L92 generally achieves an average of 14-16 mpg in city driving and 19-21 mpg on highways, depending on the vehicle application.

Conversely, the LS3 engine, commonly found in performance cars like the Chevrolet Corvette and Camaro, is designed with a focus on balancing power and efficiency. It generates approximately 430 horsepower and 424 lb-ft of torque. Fuel economy figures for vehicles equipped with the LS3 typically range from 16-18 mpg in city driving and 24-26 mpg on highways.

When comparing the two engines directly, the LS3 demonstrates a slight advantage in fuel efficiency. This can be attributed to several factors, including its lighter weight, more advanced engine management systems, and optimization for performance car applications. The LS3's improved volumetric efficiency and combustion characteristics contribute to its better fuel economy.

However, it's important to note that real-world fuel economy can vary significantly based on factors such as driving conditions, vehicle weight, aerodynamics, and transmission type. In controlled testing environments, the LS3 consistently outperforms the L92 in fuel economy by approximately 10-15% across various driving cycles.

Emissions performance is another critical benchmark. Both engines meet stringent emissions standards, but the LS3 generally produces lower emissions due to its more refined combustion process and advanced catalytic converter systems. This gives it an edge in markets with stricter environmental regulations.

Durability and longevity tests show comparable results for both engines, with each demonstrating excellent reliability over extended use. However, the L92's robust design, optimized for truck applications, may provide a slight advantage in high-load, long-duration scenarios.

In conclusion, while both engines offer impressive performance, the LS3 demonstrates superior fuel economy in most applications. This advantage, combined with its lower emissions and comparable durability, makes it the preferred choice for applications where efficiency is a primary concern.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!