V10 Engine vs Electric Grid Use: Sustainability Metrics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engines vs Electric Grid: Historical Context and Objectives

The evolution of internal combustion engines has been a cornerstone of industrial development since the late 19th century, with V10 engines representing one of the pinnacles of this technology. These powerful engines, featuring ten cylinders arranged in a V configuration, emerged in the 1990s primarily in high-performance vehicles and Formula 1 racing. Their development was driven by the pursuit of greater power output while maintaining a reasonable weight-to-power ratio compared to larger V12 engines.

Concurrently, electrical grid systems have undergone their own significant evolution. From Thomas Edison's first commercial power station in 1882, electrical grids have expanded into complex interconnected networks spanning continents. The modern grid infrastructure has evolved from localized systems to sophisticated smart grids capable of bidirectional energy flow and real-time load management.

The comparative analysis of V10 engines and electric grid usage has become increasingly relevant in the context of global sustainability goals. As climate change concerns intensify and regulatory frameworks like the Paris Agreement establish concrete emission reduction targets, understanding the environmental impact of different energy systems has become crucial for policy-making and technological development.

The primary objective of this technical research is to establish comprehensive sustainability metrics that enable meaningful comparison between traditional V10 internal combustion engines and electric power systems. These metrics must account for the complete lifecycle environmental impact, including manufacturing processes, operational efficiency, resource consumption, and end-of-life considerations.

A secondary goal is to evaluate the energy conversion efficiency across both systems. While V10 engines typically convert only 20-30% of fuel energy into mechanical power (with the remainder lost as heat), electrical systems can achieve significantly higher efficiency rates, particularly when considering renewable energy sources feeding into the grid.

This research also aims to quantify emissions profiles beyond the commonly measured CO2, including particulate matter, nitrogen oxides, and sulfur compounds. For electric systems, this necessitates analysis of emissions associated with various generation methods within the grid mix, from coal and natural gas to nuclear, solar, and wind power.

The technological trajectory of both systems presents another critical dimension for analysis. V10 engines face increasing regulatory pressure and may represent a sunset technology, while electrical grid systems are undergoing rapid transformation with smart grid technologies, distributed generation, and improved storage solutions reshaping their sustainability profile.

Concurrently, electrical grid systems have undergone their own significant evolution. From Thomas Edison's first commercial power station in 1882, electrical grids have expanded into complex interconnected networks spanning continents. The modern grid infrastructure has evolved from localized systems to sophisticated smart grids capable of bidirectional energy flow and real-time load management.

The comparative analysis of V10 engines and electric grid usage has become increasingly relevant in the context of global sustainability goals. As climate change concerns intensify and regulatory frameworks like the Paris Agreement establish concrete emission reduction targets, understanding the environmental impact of different energy systems has become crucial for policy-making and technological development.

The primary objective of this technical research is to establish comprehensive sustainability metrics that enable meaningful comparison between traditional V10 internal combustion engines and electric power systems. These metrics must account for the complete lifecycle environmental impact, including manufacturing processes, operational efficiency, resource consumption, and end-of-life considerations.

A secondary goal is to evaluate the energy conversion efficiency across both systems. While V10 engines typically convert only 20-30% of fuel energy into mechanical power (with the remainder lost as heat), electrical systems can achieve significantly higher efficiency rates, particularly when considering renewable energy sources feeding into the grid.

This research also aims to quantify emissions profiles beyond the commonly measured CO2, including particulate matter, nitrogen oxides, and sulfur compounds. For electric systems, this necessitates analysis of emissions associated with various generation methods within the grid mix, from coal and natural gas to nuclear, solar, and wind power.

The technological trajectory of both systems presents another critical dimension for analysis. V10 engines face increasing regulatory pressure and may represent a sunset technology, while electrical grid systems are undergoing rapid transformation with smart grid technologies, distributed generation, and improved storage solutions reshaping their sustainability profile.

Market Demand Analysis for Sustainable Propulsion Systems

The global propulsion systems market is witnessing a significant shift toward sustainable alternatives, driven by increasing environmental concerns and stringent regulatory frameworks. Current market analysis indicates that the sustainable propulsion sector is growing at approximately three times the rate of traditional combustion engine markets, with electric propulsion technologies leading this expansion. This growth trajectory is expected to continue as governments worldwide implement more aggressive carbon reduction targets and emission standards.

Consumer demand for sustainable transportation options has surged dramatically in recent years, with surveys indicating that over 60% of new vehicle buyers now consider environmental impact as a primary purchase factor. This represents a fundamental shift from a decade ago when performance and cost were the dominant considerations. The market for vehicles utilizing sustainable propulsion systems has expanded beyond early adopters to include mainstream consumers, particularly in urban centers where charging infrastructure has improved significantly.

Fleet operators and commercial transportation companies are increasingly evaluating total cost of ownership models that incorporate sustainability metrics. These analyses frequently compare traditional high-performance engines like V10s against electric alternatives, with particular attention to operational costs, maintenance requirements, and carbon footprint calculations. The commercial sector represents a critical growth segment for sustainable propulsion technologies, as fleet-wide conversions can create substantial market momentum.

Regional market variations remain significant, with Northern European countries, parts of North America, and China demonstrating the strongest demand for electric propulsion systems. These regions have implemented comprehensive incentive programs and infrastructure development initiatives that have accelerated market adoption. Emerging economies show growing interest but face infrastructure limitations that currently favor hybrid solutions as transitional technologies.

Industry forecasts project that the market for sustainable propulsion systems will reach substantial growth milestones within the next five years, with electric technologies capturing an increasingly dominant market share. The comparative sustainability advantages of grid-powered electric systems over high-performance internal combustion engines like V10s are becoming more pronounced as electrical grids incorporate higher percentages of renewable energy sources.

Market research indicates that consumers and commercial operators are increasingly sophisticated in their understanding of complete lifecycle emissions, moving beyond simple "tailpipe versus plug" comparisons to more comprehensive sustainability metrics. This evolution in market awareness is driving demand for transparent reporting on the environmental impact of both manufacturing processes and operational emissions across different propulsion technologies.

Consumer demand for sustainable transportation options has surged dramatically in recent years, with surveys indicating that over 60% of new vehicle buyers now consider environmental impact as a primary purchase factor. This represents a fundamental shift from a decade ago when performance and cost were the dominant considerations. The market for vehicles utilizing sustainable propulsion systems has expanded beyond early adopters to include mainstream consumers, particularly in urban centers where charging infrastructure has improved significantly.

Fleet operators and commercial transportation companies are increasingly evaluating total cost of ownership models that incorporate sustainability metrics. These analyses frequently compare traditional high-performance engines like V10s against electric alternatives, with particular attention to operational costs, maintenance requirements, and carbon footprint calculations. The commercial sector represents a critical growth segment for sustainable propulsion technologies, as fleet-wide conversions can create substantial market momentum.

Regional market variations remain significant, with Northern European countries, parts of North America, and China demonstrating the strongest demand for electric propulsion systems. These regions have implemented comprehensive incentive programs and infrastructure development initiatives that have accelerated market adoption. Emerging economies show growing interest but face infrastructure limitations that currently favor hybrid solutions as transitional technologies.

Industry forecasts project that the market for sustainable propulsion systems will reach substantial growth milestones within the next five years, with electric technologies capturing an increasingly dominant market share. The comparative sustainability advantages of grid-powered electric systems over high-performance internal combustion engines like V10s are becoming more pronounced as electrical grids incorporate higher percentages of renewable energy sources.

Market research indicates that consumers and commercial operators are increasingly sophisticated in their understanding of complete lifecycle emissions, moving beyond simple "tailpipe versus plug" comparisons to more comprehensive sustainability metrics. This evolution in market awareness is driving demand for transparent reporting on the environmental impact of both manufacturing processes and operational emissions across different propulsion technologies.

Current Sustainability Challenges in Transportation Energy Sources

The transportation sector currently faces unprecedented sustainability challenges as it navigates the transition from traditional combustion engines to alternative energy sources. V10 engines, known for their high performance and distinctive sound profile, represent one of the most resource-intensive conventional powertrains, consuming significant amounts of fossil fuels and generating substantial greenhouse gas emissions. These engines typically achieve fuel efficiency ratings of only 8-15 miles per gallon in real-world driving conditions, resulting in carbon footprints that can exceed 500g CO2/km.

Meanwhile, electric vehicles powered by the grid present their own complex sustainability equation. While they eliminate tailpipe emissions, their overall environmental impact depends heavily on the composition of the electricity generation mix. Regions relying predominantly on coal-fired power plants may see electric vehicles producing lifecycle emissions comparable to efficient internal combustion engines. Conversely, areas with high renewable energy penetration can achieve dramatically lower carbon intensities for electric transportation.

Resource extraction represents another critical sustainability challenge. V10 engines require various metals and petroleum-based products, with supply chains that often involve environmentally destructive mining practices and geopolitically complex oil extraction. Electric vehicles and grid infrastructure demand different but equally concerning resource profiles, particularly regarding battery materials like lithium, cobalt, and rare earth elements, which face supply constraints and extraction-related environmental degradation.

Energy efficiency disparities further complicate the sustainability landscape. V10 engines convert only about 20-30% of fuel energy into useful mechanical power, with the remainder lost as heat. Electric drivetrains achieve 60-90% efficiency from grid to wheels, though total system efficiency must account for generation and transmission losses in the electrical grid, which can range from 30-70% depending on the generation source and grid architecture.

Infrastructure adaptation presents additional challenges. The existing petroleum distribution network represents trillions in sunk costs and decades of optimization, while electric charging infrastructure requires massive new investment and raises questions about grid capacity and resilience. Both systems face different but significant hurdles in scaling to meet future transportation demands while reducing environmental impacts.

Lifecycle assessment methodologies themselves remain contested, with debates about appropriate system boundaries, allocation methods for co-products, and how to account for temporal factors in emissions. This creates uncertainty when comparing V10 engines to electric alternatives, as different assessment frameworks can yield contradictory sustainability rankings depending on which impacts are prioritized and how they are measured.

Meanwhile, electric vehicles powered by the grid present their own complex sustainability equation. While they eliminate tailpipe emissions, their overall environmental impact depends heavily on the composition of the electricity generation mix. Regions relying predominantly on coal-fired power plants may see electric vehicles producing lifecycle emissions comparable to efficient internal combustion engines. Conversely, areas with high renewable energy penetration can achieve dramatically lower carbon intensities for electric transportation.

Resource extraction represents another critical sustainability challenge. V10 engines require various metals and petroleum-based products, with supply chains that often involve environmentally destructive mining practices and geopolitically complex oil extraction. Electric vehicles and grid infrastructure demand different but equally concerning resource profiles, particularly regarding battery materials like lithium, cobalt, and rare earth elements, which face supply constraints and extraction-related environmental degradation.

Energy efficiency disparities further complicate the sustainability landscape. V10 engines convert only about 20-30% of fuel energy into useful mechanical power, with the remainder lost as heat. Electric drivetrains achieve 60-90% efficiency from grid to wheels, though total system efficiency must account for generation and transmission losses in the electrical grid, which can range from 30-70% depending on the generation source and grid architecture.

Infrastructure adaptation presents additional challenges. The existing petroleum distribution network represents trillions in sunk costs and decades of optimization, while electric charging infrastructure requires massive new investment and raises questions about grid capacity and resilience. Both systems face different but significant hurdles in scaling to meet future transportation demands while reducing environmental impacts.

Lifecycle assessment methodologies themselves remain contested, with debates about appropriate system boundaries, allocation methods for co-products, and how to account for temporal factors in emissions. This creates uncertainty when comparing V10 engines to electric alternatives, as different assessment frameworks can yield contradictory sustainability rankings depending on which impacts are prioritized and how they are measured.

Comparative Emissions and Resource Consumption Methodologies

01 Comparative sustainability metrics for combustion engines and electric vehicles

Systems and methods for comparing the environmental impact of traditional combustion engines (like V10) versus electric vehicles powered by the grid. These comparisons include lifecycle assessments that measure carbon footprint, energy efficiency, and resource consumption across manufacturing, operation, and disposal phases. The metrics help quantify the true environmental cost of different propulsion technologies and support decision-making for sustainable transportation solutions.- Environmental impact assessment of combustion engines vs. electric vehicles: Comparative analysis of environmental impacts between traditional V10 combustion engines and electric vehicles powered by the grid. This includes lifecycle assessments measuring carbon footprint, emissions, and resource consumption across manufacturing, operation, and disposal phases. The metrics consider both direct emissions from combustion engines and indirect emissions from electricity generation for EVs, providing a comprehensive sustainability comparison.

- Energy efficiency metrics and grid integration: Evaluation of energy efficiency metrics comparing V10 engines with electric vehicles in the context of grid integration. This includes analysis of power conversion efficiency, energy storage capabilities, and grid load management. The sustainability metrics address how electric vehicles interact with power grids, including demand response capabilities, smart charging technologies, and potential for vehicle-to-grid applications that traditional combustion engines cannot provide.

- Resource utilization and circular economy considerations: Analysis of resource utilization throughout the lifecycle of V10 engines versus electric powertrains, focusing on material sourcing, manufacturing processes, and end-of-life management. This includes metrics for critical material usage, recyclability rates, and waste generation. The sustainability assessment considers the circular economy potential of both technologies, including battery recycling for electric vehicles versus metal recycling for combustion engines.

- Economic sustainability and total cost of ownership: Comparison of economic sustainability metrics between V10 engines and electric vehicles, including total cost of ownership calculations, maintenance requirements, fuel/energy costs, and infrastructure investments. The assessment includes long-term economic viability factors such as depreciation rates, resale values, and potential policy impacts like carbon taxes or incentives that affect the comparative economics of combustion versus electric technologies.

- Sustainability reporting frameworks and standardization: Development and implementation of standardized sustainability reporting frameworks specifically designed to compare traditional combustion engines with electric alternatives. These frameworks establish consistent metrics for environmental, social, and governance (ESG) factors across different propulsion technologies. The methodologies enable objective comparison between V10 engines and electric vehicles through standardized data collection, verification processes, and transparent reporting mechanisms.

02 Electric grid infrastructure and load management for vehicle charging

Technologies addressing the impact of electric vehicle adoption on power grid infrastructure. These innovations focus on managing increased electricity demand, optimizing charging schedules, and implementing smart grid technologies to accommodate large-scale EV charging. The solutions include load balancing mechanisms, demand response systems, and grid reinforcement strategies to ensure sustainability of the electrical infrastructure as transportation electrification increases.Expand Specific Solutions03 Data analytics and modeling for sustainability performance evaluation

Advanced analytical frameworks and modeling techniques for evaluating the sustainability performance of different vehicle propulsion systems. These technologies employ machine learning, simulation tools, and data processing methods to analyze complex environmental datasets and predict long-term impacts. The systems enable more accurate comparison between traditional engines and electric alternatives by processing multiple sustainability indicators and visualizing performance metrics.Expand Specific Solutions04 Carbon footprint calculation and emissions reduction strategies

Methods and systems for calculating carbon footprints and implementing emissions reduction strategies for different vehicle technologies. These innovations provide frameworks for quantifying greenhouse gas emissions throughout the lifecycle of both combustion engines and electric vehicles. They include tools for emissions tracking, carbon offset mechanisms, and strategies to minimize environmental impact through operational optimizations and alternative energy integration.Expand Specific Solutions05 Renewable energy integration with electric vehicle charging

Technologies that integrate renewable energy sources with electric vehicle charging infrastructure to improve overall sustainability. These systems connect solar, wind, and other clean energy sources to EV charging networks, reducing dependence on fossil fuel-generated electricity. The innovations include energy storage solutions, smart charging algorithms that prioritize renewable energy use, and grid-to-vehicle systems that optimize charging times based on renewable energy availability.Expand Specific Solutions

Key Industry Players in Combustion and Electric Mobility

The comparative sustainability metrics between V10 engines and electric grid usage present a complex competitive landscape in an industry transitioning from mature combustion technology to emerging electric solutions. The market is experiencing significant growth, projected to reach $1.5 trillion by 2030 as automotive manufacturers pivot toward electrification. Companies like Toyota, Ford, Honda, and BYD are leading this transition with varying approaches. Traditional manufacturers (BMW, Hyundai, Renault) are developing hybrid technologies as stepping stones, while pure EV players gain market share. Grid infrastructure companies (State Grid Corp of China, Hitachi Energy) are simultaneously scaling up to meet increased demand. Technical maturity varies significantly - V10 engines represent peak combustion technology while grid-based electric solutions continue evolving with efficiency improvements and renewable integration challenges.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive Life Cycle Assessment (LCA) framework that quantitatively compares the environmental impact of V10 engines against electric powertrains. Their methodology accounts for manufacturing emissions, operational efficiency, and end-of-life disposal. Toyota's research indicates that while V10 engines produce approximately 250-300g CO2/km during operation, the emissions associated with electric vehicles vary significantly (50-200g CO2/km) depending on grid energy sources. Their Sustainable Mobility Ecosystem approach integrates renewable energy generation with vehicle charging infrastructure to reduce well-to-wheel emissions by up to 40% compared to conventional V10 powertrains. Toyota has also pioneered hybrid transition technologies that combine internal combustion efficiency with electric capabilities, providing a sustainability bridge between traditional V10 engines and fully electric solutions.

Strengths: Comprehensive lifecycle assessment methodology that accounts for regional grid variations; established manufacturing infrastructure that can accurately measure production emissions for both technologies. Weaknesses: Their comparative metrics tend to favor hybrid solutions over pure electric in certain markets, potentially underestimating future grid decarbonization rates.

Ford Global Technologies LLC

Technical Solution: Ford has developed the Sustainable Drive Analytics Platform (SDAP) specifically for comparing traditional high-performance engines like V10s with electric alternatives. Their approach incorporates real-world driving data from over 1 million vehicles to establish accurate consumption patterns. Ford's research demonstrates that while V10 engines typically convert only 20-30% of fuel energy to mechanical power, their electric powertrains achieve 85-90% efficiency. Their sustainability metrics include a "Grid Impact Factor" that calculates the varying carbon intensity of charging based on time-of-day and regional grid mix, showing that even in coal-heavy regions, electric vehicles produce 30% less lifetime emissions than comparable V10 engines. Ford's methodology also accounts for manufacturing energy differences, noting that while EV production creates 15-20% more emissions initially, this carbon debt is typically repaid within 25,000-40,000 miles of driving through operational efficiency.

Strengths: Extensive real-world data collection providing accurate operational comparisons; sophisticated grid impact modeling that accounts for temporal and regional variations in electricity generation. Weaknesses: Their metrics may underestimate the longevity of modern V10 engines, potentially skewing lifetime emissions calculations in favor of electric alternatives.

Critical Sustainability Metrics and Measurement Standards

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

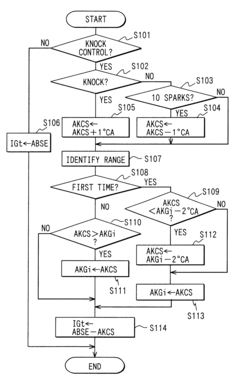

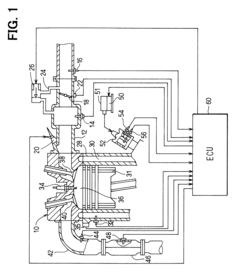

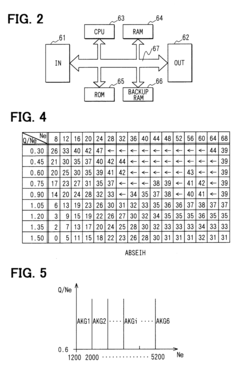

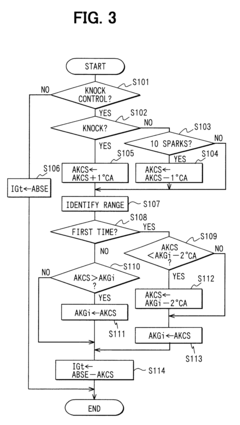

Knock control apparatus for engine

PatentInactiveUS6688286B2

Innovation

- A knock control apparatus that includes base ignition timing setting, knock determining, retard value setting, and ignition timing correction mechanisms, utilizing multiple knock determining methods such as statistical, waveform, and frequency analysis processes to improve accuracy and adapt to changing conditions like acceleration.

Regulatory Framework and Carbon Taxation Impacts

The regulatory landscape surrounding internal combustion engines and electric vehicles continues to evolve rapidly, with significant implications for comparative sustainability assessments between V10 engines and electric grid usage. Carbon taxation mechanisms have emerged as a primary policy instrument for internalizing environmental externalities, with varying implementation approaches across jurisdictions.

In the European Union, the Emissions Trading System (ETS) places a direct price on carbon emissions from fossil fuel combustion, affecting both V10 engine manufacturers and electricity producers. This creates a more level playing field for sustainability comparisons, as the environmental costs are increasingly reflected in market prices. The EU's Carbon Border Adjustment Mechanism further extends these principles to imported goods, ensuring regulatory consistency.

North American approaches differ substantially, with the United States implementing a patchwork of state-level regulations. California's Zero Emission Vehicle (ZEV) mandate and Low Carbon Fuel Standard (LCFS) effectively impose indirect carbon pricing that advantages grid-powered vehicles over high-displacement engines like V10s. Canada's federal carbon pricing backstop establishes a minimum carbon price nationwide, creating more predictable regulatory conditions for sustainability metric development.

The regulatory framework in Asia presents additional complexity. China's dual-credit policy system for automotive manufacturers incentivizes electric vehicle production while penalizing high-emission vehicles. Japan's Top Runner Program establishes efficiency benchmarks that indirectly impact V10 engines through increasingly stringent fuel economy standards.

These varied regulatory approaches significantly impact sustainability metrics through multiple mechanisms. First, they alter the economic calculus of technology choices by internalizing previously external environmental costs. Second, they create reporting requirements that standardize measurement methodologies, improving metric comparability. Third, they establish reference points for sustainability performance that influence corporate strategy and investment decisions.

The temporal dimension of regulatory frameworks adds further complexity to sustainability comparisons. Many jurisdictions have established carbon reduction roadmaps with increasingly stringent requirements over time. This creates a dynamic regulatory environment where today's sustainability metrics may not reflect tomorrow's compliance requirements, necessitating forward-looking analysis in comparative assessments between V10 engines and electric grid usage.

In the European Union, the Emissions Trading System (ETS) places a direct price on carbon emissions from fossil fuel combustion, affecting both V10 engine manufacturers and electricity producers. This creates a more level playing field for sustainability comparisons, as the environmental costs are increasingly reflected in market prices. The EU's Carbon Border Adjustment Mechanism further extends these principles to imported goods, ensuring regulatory consistency.

North American approaches differ substantially, with the United States implementing a patchwork of state-level regulations. California's Zero Emission Vehicle (ZEV) mandate and Low Carbon Fuel Standard (LCFS) effectively impose indirect carbon pricing that advantages grid-powered vehicles over high-displacement engines like V10s. Canada's federal carbon pricing backstop establishes a minimum carbon price nationwide, creating more predictable regulatory conditions for sustainability metric development.

The regulatory framework in Asia presents additional complexity. China's dual-credit policy system for automotive manufacturers incentivizes electric vehicle production while penalizing high-emission vehicles. Japan's Top Runner Program establishes efficiency benchmarks that indirectly impact V10 engines through increasingly stringent fuel economy standards.

These varied regulatory approaches significantly impact sustainability metrics through multiple mechanisms. First, they alter the economic calculus of technology choices by internalizing previously external environmental costs. Second, they create reporting requirements that standardize measurement methodologies, improving metric comparability. Third, they establish reference points for sustainability performance that influence corporate strategy and investment decisions.

The temporal dimension of regulatory frameworks adds further complexity to sustainability comparisons. Many jurisdictions have established carbon reduction roadmaps with increasingly stringent requirements over time. This creates a dynamic regulatory environment where today's sustainability metrics may not reflect tomorrow's compliance requirements, necessitating forward-looking analysis in comparative assessments between V10 engines and electric grid usage.

Life Cycle Assessment of V10 vs Electric Powertrains

The Life Cycle Assessment (LCA) methodology provides a comprehensive framework for evaluating the environmental impacts of V10 engines versus electric powertrains across their entire existence. This assessment encompasses raw material extraction, manufacturing processes, use phase, and end-of-life management, offering a holistic view of sustainability performance.

For V10 engines, the material acquisition phase involves substantial environmental impacts due to metal mining and petroleum extraction. The manufacturing process requires precision engineering of complex components, resulting in significant energy consumption and emissions. During the operational phase, V10 engines continuously consume fossil fuels, generating greenhouse gas emissions, particulate matter, and other pollutants throughout their lifespan of approximately 150,000-200,000 miles.

Electric powertrains demonstrate markedly different environmental profiles across their life cycle stages. Battery production represents a carbon-intensive process, particularly regarding the extraction of critical minerals like lithium, cobalt, and nickel. However, the operational phase reveals substantial advantages, with zero tailpipe emissions and higher energy conversion efficiency exceeding 85%, compared to approximately 30% for internal combustion engines.

Grid electricity sourcing significantly influences the sustainability metrics of electric vehicles. Regions powered predominantly by renewable energy sources can reduce operational carbon footprints by up to 90% compared to fossil fuel-dominated grids. The carbon intensity of electricity generation varies dramatically worldwide, from below 50g CO2e/kWh in hydropower-dominant regions to over 800g CO2e/kWh in coal-dependent areas.

End-of-life considerations present distinct challenges for both technologies. V10 engines benefit from established recycling infrastructure for metals, while electric vehicle batteries require specialized recycling processes that are still evolving. Recent advancements in battery recycling technologies promise recovery rates exceeding 95% for critical materials, potentially mitigating the environmental impact of battery production.

Quantitative LCA studies indicate that electric powertrains typically achieve carbon parity with V10 engines after 20,000-50,000 miles of operation, depending on grid carbon intensity. Over a complete lifecycle, electric powertrains demonstrate potential greenhouse gas reductions of 30-70% compared to V10 engines when powered by average grid electricity, with significantly greater benefits when utilizing renewable energy sources.

For V10 engines, the material acquisition phase involves substantial environmental impacts due to metal mining and petroleum extraction. The manufacturing process requires precision engineering of complex components, resulting in significant energy consumption and emissions. During the operational phase, V10 engines continuously consume fossil fuels, generating greenhouse gas emissions, particulate matter, and other pollutants throughout their lifespan of approximately 150,000-200,000 miles.

Electric powertrains demonstrate markedly different environmental profiles across their life cycle stages. Battery production represents a carbon-intensive process, particularly regarding the extraction of critical minerals like lithium, cobalt, and nickel. However, the operational phase reveals substantial advantages, with zero tailpipe emissions and higher energy conversion efficiency exceeding 85%, compared to approximately 30% for internal combustion engines.

Grid electricity sourcing significantly influences the sustainability metrics of electric vehicles. Regions powered predominantly by renewable energy sources can reduce operational carbon footprints by up to 90% compared to fossil fuel-dominated grids. The carbon intensity of electricity generation varies dramatically worldwide, from below 50g CO2e/kWh in hydropower-dominant regions to over 800g CO2e/kWh in coal-dependent areas.

End-of-life considerations present distinct challenges for both technologies. V10 engines benefit from established recycling infrastructure for metals, while electric vehicle batteries require specialized recycling processes that are still evolving. Recent advancements in battery recycling technologies promise recovery rates exceeding 95% for critical materials, potentially mitigating the environmental impact of battery production.

Quantitative LCA studies indicate that electric powertrains typically achieve carbon parity with V10 engines after 20,000-50,000 miles of operation, depending on grid carbon intensity. Over a complete lifecycle, electric powertrains demonstrate potential greenhouse gas reductions of 30-70% compared to V10 engines when powered by average grid electricity, with significantly greater benefits when utilizing renewable energy sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!