Comparing Laser Welding and Riveting for Aircraft Assembly

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aircraft Assembly Technology Evolution and Objectives

Aircraft assembly has undergone significant technological evolution since the early days of aviation. Initially, aircraft structures were primarily assembled using mechanical fastening methods, with riveting emerging as the dominant technique by the mid-20th century. This traditional approach has been the backbone of aircraft manufacturing for decades, offering reliability and well-established certification pathways. The evolution of riveting itself has seen advancements from manual processes to automated systems, improving precision and reducing labor intensity.

The 1980s marked the beginning of exploration into alternative joining technologies, with adhesive bonding gaining traction for specific applications. However, the transformative shift began in the late 1990s with the introduction of laser welding technologies in aerospace manufacturing. This represented a paradigm shift in assembly philosophy, moving from mechanical fastening toward more integrated structural connections.

The 2000s witnessed accelerated development in laser welding capabilities, with significant improvements in beam quality, control systems, and process monitoring. Concurrently, advanced riveting technologies evolved to maintain relevance, incorporating computer-controlled precision and novel materials. This technological duality has created a complex landscape where manufacturers must carefully evaluate joining methods based on specific requirements.

Current technological objectives in aircraft assembly center around several key imperatives. Weight reduction remains paramount, with manufacturers seeking to minimize structural mass without compromising safety. This drives interest in laser welding, which eliminates the need for additional fastening components. Simultaneously, production efficiency has become increasingly critical as manufacturers face pressure to increase output rates while maintaining quality standards.

Long-term durability represents another crucial objective, particularly given the extended service life of modern aircraft. Assembly technologies must demonstrate reliability over decades of operation under varying environmental conditions. Additionally, environmental sustainability has emerged as a significant consideration, with manufacturers evaluating the ecological footprint of different assembly methods throughout their lifecycle.

The industry now stands at a technological crossroads, with both riveting and laser welding offering distinct advantages. The objective of contemporary research is not necessarily to determine a universal superior method, but rather to develop a comprehensive understanding of where each technology excels, enabling optimized hybrid approaches that leverage the strengths of both techniques while mitigating their respective limitations.

The 1980s marked the beginning of exploration into alternative joining technologies, with adhesive bonding gaining traction for specific applications. However, the transformative shift began in the late 1990s with the introduction of laser welding technologies in aerospace manufacturing. This represented a paradigm shift in assembly philosophy, moving from mechanical fastening toward more integrated structural connections.

The 2000s witnessed accelerated development in laser welding capabilities, with significant improvements in beam quality, control systems, and process monitoring. Concurrently, advanced riveting technologies evolved to maintain relevance, incorporating computer-controlled precision and novel materials. This technological duality has created a complex landscape where manufacturers must carefully evaluate joining methods based on specific requirements.

Current technological objectives in aircraft assembly center around several key imperatives. Weight reduction remains paramount, with manufacturers seeking to minimize structural mass without compromising safety. This drives interest in laser welding, which eliminates the need for additional fastening components. Simultaneously, production efficiency has become increasingly critical as manufacturers face pressure to increase output rates while maintaining quality standards.

Long-term durability represents another crucial objective, particularly given the extended service life of modern aircraft. Assembly technologies must demonstrate reliability over decades of operation under varying environmental conditions. Additionally, environmental sustainability has emerged as a significant consideration, with manufacturers evaluating the ecological footprint of different assembly methods throughout their lifecycle.

The industry now stands at a technological crossroads, with both riveting and laser welding offering distinct advantages. The objective of contemporary research is not necessarily to determine a universal superior method, but rather to develop a comprehensive understanding of where each technology excels, enabling optimized hybrid approaches that leverage the strengths of both techniques while mitigating their respective limitations.

Market Demand Analysis for Advanced Aircraft Joining Methods

The global aircraft manufacturing industry is experiencing a significant shift towards more efficient, lightweight, and cost-effective assembly methods. Current market analysis indicates that advanced joining technologies, particularly laser welding and riveting, are becoming increasingly critical in determining competitive advantages among aircraft manufacturers. The market for these technologies is projected to grow substantially, driven by the expanding commercial aircraft sector which is expected to deliver approximately 40,000 new aircraft over the next two decades.

Traditional riveting has dominated aircraft assembly for decades, representing over 80% of structural joining methods in commercial aircraft production. However, market demand for laser welding solutions has grown at a compound annual rate exceeding 7% since 2018, reflecting the industry's push toward weight reduction and manufacturing efficiency. This trend is particularly pronounced in regions with advanced aerospace manufacturing capabilities such as North America, Western Europe, and increasingly, East Asia.

Market research reveals that airlines and aircraft operators are prioritizing fuel efficiency as a primary purchasing criterion, directly influencing manufacturers to adopt joining technologies that reduce structural weight. Each 1% reduction in aircraft weight translates to approximately 1.5% fuel savings over the aircraft's operational lifetime, creating substantial economic incentives for advanced joining methods that can reduce weight compared to conventional riveting.

The defense aerospace sector presents another significant market driver, with military aircraft programs increasingly specifying advanced joining technologies to enhance performance characteristics and reduce radar signatures. This segment values the precision and minimal distortion offered by laser welding for critical components, creating a premium market segment with less price sensitivity than commercial applications.

Supply chain considerations are reshaping market demand patterns as well. Aircraft manufacturers are increasingly seeking joining technologies that reduce parts count, simplify assembly sequences, and decrease reliance on manual labor. This trend favors automated laser welding systems that can join larger, more complex subassemblies with fewer fasteners and reduced touch labor hours.

Regional market analysis shows varying adoption rates, with European manufacturers generally leading in laser welding implementation, while North American producers maintain a balanced approach incorporating both advanced riveting and selective laser welding. Emerging aerospace manufacturing hubs in Asia are making significant investments in both technologies, positioning themselves to serve growing regional demand while developing export capabilities.

Customer feedback from aircraft operators indicates growing acceptance of laser-welded structures, overcoming historical concerns about inspection and repair. This shift in market perception is expanding the potential applications for laser welding beyond non-critical structures to primary airframe components, representing a significant expansion of the addressable market.

Traditional riveting has dominated aircraft assembly for decades, representing over 80% of structural joining methods in commercial aircraft production. However, market demand for laser welding solutions has grown at a compound annual rate exceeding 7% since 2018, reflecting the industry's push toward weight reduction and manufacturing efficiency. This trend is particularly pronounced in regions with advanced aerospace manufacturing capabilities such as North America, Western Europe, and increasingly, East Asia.

Market research reveals that airlines and aircraft operators are prioritizing fuel efficiency as a primary purchasing criterion, directly influencing manufacturers to adopt joining technologies that reduce structural weight. Each 1% reduction in aircraft weight translates to approximately 1.5% fuel savings over the aircraft's operational lifetime, creating substantial economic incentives for advanced joining methods that can reduce weight compared to conventional riveting.

The defense aerospace sector presents another significant market driver, with military aircraft programs increasingly specifying advanced joining technologies to enhance performance characteristics and reduce radar signatures. This segment values the precision and minimal distortion offered by laser welding for critical components, creating a premium market segment with less price sensitivity than commercial applications.

Supply chain considerations are reshaping market demand patterns as well. Aircraft manufacturers are increasingly seeking joining technologies that reduce parts count, simplify assembly sequences, and decrease reliance on manual labor. This trend favors automated laser welding systems that can join larger, more complex subassemblies with fewer fasteners and reduced touch labor hours.

Regional market analysis shows varying adoption rates, with European manufacturers generally leading in laser welding implementation, while North American producers maintain a balanced approach incorporating both advanced riveting and selective laser welding. Emerging aerospace manufacturing hubs in Asia are making significant investments in both technologies, positioning themselves to serve growing regional demand while developing export capabilities.

Customer feedback from aircraft operators indicates growing acceptance of laser-welded structures, overcoming historical concerns about inspection and repair. This shift in market perception is expanding the potential applications for laser welding beyond non-critical structures to primary airframe components, representing a significant expansion of the addressable market.

Current State and Challenges in Aircraft Assembly Technologies

Aircraft assembly has traditionally relied on mechanical fastening methods, with riveting being the dominant technique for decades. Currently, over 80% of structural joints in commercial aircraft are created using rivets, which provide reliable and well-understood performance characteristics. However, this conventional approach faces significant challenges in modern aerospace manufacturing, particularly regarding production efficiency and weight optimization.

The riveting process remains labor-intensive, requiring precise hole drilling, surface preparation, and fastener installation. In high-volume production environments like those of Boeing and Airbus, this translates to thousands of work hours per aircraft. Additionally, each rivet adds incremental weight to the structure, with a typical wide-body commercial aircraft containing over 1.5 million fasteners, contributing significantly to the overall weight.

Laser welding technology has emerged as a promising alternative, with implementation increasing by approximately 15-20% in aerospace applications over the past decade. This technology offers potential weight reduction of 15-30% compared to riveted structures by eliminating fasteners and creating continuous joints. However, its adoption faces substantial technical barriers, particularly regarding the welding of aluminum alloys commonly used in aircraft structures.

The primary challenge for laser welding in aerospace applications is managing thermal effects in high-strength aluminum alloys. These materials are prone to hot cracking, porosity formation, and heat-affected zone weakening when subjected to intense localized heating. Current laser welding systems achieve approximately 70-85% of the joint strength compared to traditional riveted connections in aerospace-grade aluminum alloys.

Quality assurance presents another significant challenge. Riveted joints benefit from decades of standardization and well-established inspection protocols. In contrast, laser-welded joints require advanced non-destructive testing methods, including ultrasonic, radiographic, and thermographic techniques, which are still evolving for aerospace certification requirements.

Regulatory frameworks also pose barriers to widespread adoption of laser welding. Aviation authorities maintain stringent certification requirements, with the FAA and EASA requiring extensive testing and validation before approving new joining technologies for primary aircraft structures. This certification process typically spans 3-5 years and costs millions of dollars, creating significant inertia favoring established technologies.

Hybrid approaches are gaining traction, with manufacturers implementing selective laser welding for secondary structures while maintaining riveting for primary load-bearing components. This balanced approach allows incremental adoption while building confidence in the newer technology's long-term performance and reliability.

The riveting process remains labor-intensive, requiring precise hole drilling, surface preparation, and fastener installation. In high-volume production environments like those of Boeing and Airbus, this translates to thousands of work hours per aircraft. Additionally, each rivet adds incremental weight to the structure, with a typical wide-body commercial aircraft containing over 1.5 million fasteners, contributing significantly to the overall weight.

Laser welding technology has emerged as a promising alternative, with implementation increasing by approximately 15-20% in aerospace applications over the past decade. This technology offers potential weight reduction of 15-30% compared to riveted structures by eliminating fasteners and creating continuous joints. However, its adoption faces substantial technical barriers, particularly regarding the welding of aluminum alloys commonly used in aircraft structures.

The primary challenge for laser welding in aerospace applications is managing thermal effects in high-strength aluminum alloys. These materials are prone to hot cracking, porosity formation, and heat-affected zone weakening when subjected to intense localized heating. Current laser welding systems achieve approximately 70-85% of the joint strength compared to traditional riveted connections in aerospace-grade aluminum alloys.

Quality assurance presents another significant challenge. Riveted joints benefit from decades of standardization and well-established inspection protocols. In contrast, laser-welded joints require advanced non-destructive testing methods, including ultrasonic, radiographic, and thermographic techniques, which are still evolving for aerospace certification requirements.

Regulatory frameworks also pose barriers to widespread adoption of laser welding. Aviation authorities maintain stringent certification requirements, with the FAA and EASA requiring extensive testing and validation before approving new joining technologies for primary aircraft structures. This certification process typically spans 3-5 years and costs millions of dollars, creating significant inertia favoring established technologies.

Hybrid approaches are gaining traction, with manufacturers implementing selective laser welding for secondary structures while maintaining riveting for primary load-bearing components. This balanced approach allows incremental adoption while building confidence in the newer technology's long-term performance and reliability.

Comparative Analysis of Laser Welding vs Riveting Methods

01 Laser welding techniques for automotive applications

Laser welding technologies specifically designed for automotive manufacturing, including joining body panels, structural components, and powertrain parts. These techniques offer advantages such as high precision, reduced heat-affected zones, and the ability to join dissimilar materials. The processes often incorporate specialized fixtures and automated systems to ensure consistent weld quality and production efficiency in automotive assembly lines.- Laser welding techniques for automotive applications: Laser welding techniques specifically designed for automotive manufacturing, including joining body panels, structural components, and interior parts. These methods provide high precision, strength, and efficiency in automotive assembly processes, allowing for reduced weight and improved structural integrity. The techniques often incorporate specialized fixtures and automated systems to ensure consistent weld quality across high-volume production environments.

- Hybrid joining methods combining laser welding and riveting: Hybrid joining technologies that integrate laser welding with mechanical fastening methods like riveting to achieve superior joint strength and durability. These combined approaches leverage the advantages of both techniques - the speed and precision of laser welding with the mechanical reliability of riveting. Such hybrid methods are particularly valuable for joining dissimilar materials or in applications requiring redundant joining mechanisms for safety-critical components.

- Process control and monitoring systems for laser joining: Advanced monitoring and control systems designed to ensure quality and consistency in laser welding and riveting processes. These systems incorporate real-time feedback mechanisms, vision systems, thermal imaging, and AI-based analytics to detect defects, adjust parameters dynamically, and maintain optimal joining conditions. The technology enables improved process reliability, reduced scrap rates, and comprehensive documentation for quality assurance purposes.

- Specialized laser equipment for joining complex materials: Specialized laser equipment and configurations designed for joining challenging or advanced materials such as high-strength steels, aluminum alloys, composites, and multi-material assemblies. These systems feature tailored beam profiles, power modulation capabilities, and specialized optics to address the unique challenges presented by different material combinations. The equipment often incorporates pre- and post-processing capabilities to optimize surface conditions and joint properties.

- Automated and robotic systems for laser joining operations: Automated and robotic systems that integrate laser welding and riveting technologies into flexible manufacturing cells. These systems feature multi-axis robots, automated part handling, and sophisticated programming interfaces to enable complex joining operations with minimal human intervention. The automation solutions provide benefits including increased throughput, improved repeatability, enhanced worker safety, and the ability to perform joining operations in difficult-to-access locations.

02 Hybrid joining methods combining laser welding and riveting

Innovative joining techniques that combine laser welding with mechanical fastening methods like riveting to achieve superior joint strength and durability. These hybrid approaches leverage the advantages of both methods - the speed and precision of laser welding with the mechanical reliability of rivets. Such combinations are particularly effective for joining dissimilar materials or in applications requiring both sealing properties and mechanical strength.Expand Specific Solutions03 Laser welding equipment and control systems

Advanced laser welding equipment incorporating sophisticated control systems for precise energy delivery and process monitoring. These systems include beam shaping optics, real-time monitoring sensors, and adaptive control algorithms that adjust welding parameters based on feedback. The equipment often features integrated cooling systems, protective enclosures, and user-friendly interfaces for operator control and process optimization.Expand Specific Solutions04 Laser riveting processes and apparatus

Specialized processes and equipment for laser-assisted riveting, where laser energy is used to heat, form, or secure rivets in joining applications. These techniques can include laser softening of materials before riveting, laser-based rivet forming, or laser welding of rivet heads. The processes typically offer advantages in terms of speed, precision, and reduced mechanical stress on the joined components compared to conventional riveting methods.Expand Specific Solutions05 Material-specific laser joining technologies

Tailored laser welding and riveting technologies developed for specific material combinations, such as aluminum alloys, high-strength steels, or composite materials. These specialized approaches address the unique challenges presented by different materials, including thermal conductivity differences, melting point variations, and potential for intermetallic formation. The technologies often incorporate specific beam profiles, power modulation techniques, or supplementary processes to achieve optimal joint quality.Expand Specific Solutions

Key Industry Players in Aircraft Assembly Solutions

The aircraft assembly industry is currently in a mature growth phase, with laser welding technology emerging as a disruptive alternative to traditional riveting methods. The global market for aircraft assembly technologies is estimated at $15-20 billion annually, with significant growth potential as manufacturers seek efficiency improvements. Leading aerospace giants Airbus and Boeing are at the forefront of this technological transition, with Airbus Operations GmbH demonstrating advanced laser welding implementation in fuselage assembly. Other key players including Fraunhofer-Gesellschaft, IPG Photonics, and research institutions like Harbin Institute of Technology are driving innovation in laser welding technologies. While riveting remains the industry standard due to its proven reliability, laser welding is rapidly maturing with enhanced precision, reduced weight, and improved production efficiency.

Airbus Operations GmbH

Technical Solution: Airbus has developed advanced Laser Beam Welding (LBW) technology for aircraft assembly, particularly focusing on fuselage panels and structural components. Their proprietary Laser Welded Blanks (LWB) technology enables the joining of different aluminum alloy sheets with varying thicknesses, optimizing weight distribution while maintaining structural integrity. Airbus implements a hybrid approach combining laser welding for primary structures with selective riveting for critical load-bearing joints. Their WELDCOR (Welding of Corrosion Resistant Alloys) program specifically addresses challenges in welding aerospace-grade aluminum alloys by utilizing fiber-delivered YAG lasers with power outputs of 3-4kW and precise beam control systems. This technology has reduced assembly time by approximately 40% compared to traditional riveting processes while achieving weight savings of 15-20% in certain structural components.

Strengths: Significant weight reduction (15-20%), faster production cycles, reduced part count, and improved fatigue resistance in welded joints. Weaknesses: Higher initial capital investment, challenges with certain aluminum alloys prone to hot cracking, and requires more stringent quality control measures than conventional riveting.

The Boeing Co.

Technical Solution: Boeing has pioneered Friction Stir Welding (FSW) as an alternative to both conventional riveting and laser welding for aircraft assembly. Their approach integrates laser welding for specific applications while maintaining riveting for critical structural components. Boeing's Laser Welded Structural Assembly (LWSA) system employs high-power fiber lasers (6-10kW) with sophisticated seam tracking and real-time quality monitoring capabilities. For their 787 Dreamliner, Boeing developed a hybrid joining strategy where laser welding is used for longitudinal fuselage joints while advanced automated riveting systems handle circumferential joints. Their proprietary Laser Beam Welding Quality Assurance System (LBWQAS) incorporates multiple sensors including thermal cameras and spectroscopic analysis to ensure weld integrity. Boeing has reported approximately 30% reduction in assembly time and 10-15% weight savings in components where laser welding replaced traditional riveting techniques.

Strengths: Comprehensive quality control systems, proven implementation in production aircraft, and significant process time reduction. Weaknesses: Conservative approach limiting full exploitation of laser welding benefits, higher maintenance requirements for laser systems, and challenges with certain alloy combinations requiring specialized process parameters.

Technical Innovations in Aircraft Structural Joining

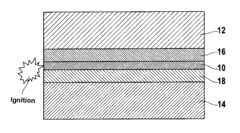

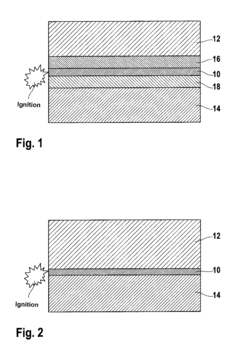

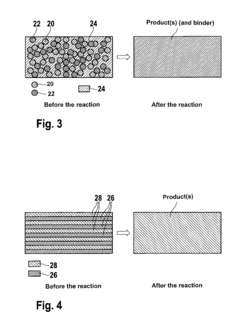

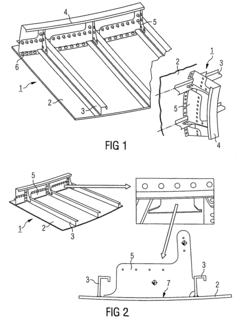

Joining method for joining components

PatentInactiveUS7975902B2

Innovation

- A method involving nano- or microstructured materials that initiate an exothermic reaction to connect components with lower heat introduction, allowing for the joining of diverse materials including metals, composites, and ceramics, using activation energy sources like electric energy or ultrasonic waves, and optionally incorporating connecting materials like solder.

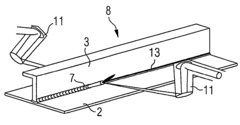

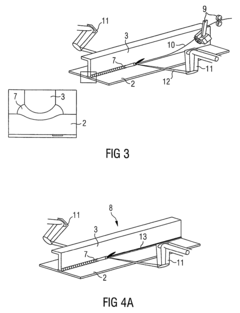

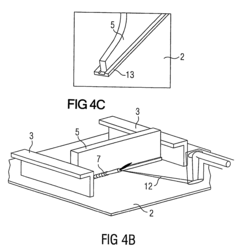

System and method for manufacturing welded structures, and a welding additive material for this purpose

PatentInactiveUS20060065643A1

Innovation

- A system and method using shaped welding additive materials, such as U- or L-profiled materials, pre-positioned between components to be welded, melted by heat sources like laser beams, to form high-quality welds with improved mechanical properties, eliminating the need for wire delivery devices and reducing defects like cracks and notches.

Weight and Structural Integrity Considerations

Weight considerations represent a critical factor in aircraft design and assembly, with every gram impacting fuel efficiency and operational costs. Laser welding offers significant weight reduction advantages compared to traditional riveting methods. When implemented properly, laser-welded joints eliminate the need for overlapping materials and fasteners, potentially reducing structural weight by 15-20% in specific applications. This weight reduction directly translates to improved fuel efficiency, with industry studies suggesting that a 100kg weight reduction can save approximately 2,500 liters of fuel annually per aircraft.

Structural integrity analysis reveals complex trade-offs between these joining technologies. Riveted joints have demonstrated reliable performance over decades of aviation history, with well-established fatigue behavior and damage tolerance characteristics. The discrete nature of riveted connections allows for controlled crack propagation paths, preventing catastrophic failures. Riveted structures typically exhibit progressive failure modes that provide visual indicators before critical failure occurs.

Laser welding, while offering seamless joints with excellent load distribution characteristics, introduces different structural considerations. Welded joints create heat-affected zones that may alter material properties and require careful management of residual stresses. Recent advancements in laser welding technology have significantly improved the fatigue performance of welded aluminum structures, with some studies showing comparable or superior fatigue life to riveted joints under certain loading conditions.

Damage tolerance assessment reveals that laser-welded structures may exhibit different crack propagation behavior compared to riveted assemblies. Without the stress concentration points created by fastener holes, welded structures can demonstrate improved resistance to crack initiation. However, once cracks form, they may propagate more rapidly through continuous welded sections without the crack-stopping features inherent in riveted designs.

Hybrid joining approaches are emerging as promising solutions that capitalize on the strengths of both technologies. These systems strategically implement laser welding in areas where weight reduction is critical, while maintaining riveted connections in high-stress zones or areas requiring regular inspection and maintenance. Such hybrid designs have demonstrated weight reductions of 8-12% compared to traditional riveted structures while maintaining equivalent or superior structural integrity.

The aerospace industry's gradual shift toward composite-metal hybrid structures further complicates the joining technology selection process, as laser welding and riveting interact differently with these advanced material systems. Ongoing research focuses on optimizing joining technologies for these next-generation aircraft structures to maximize both weight efficiency and structural performance.

Structural integrity analysis reveals complex trade-offs between these joining technologies. Riveted joints have demonstrated reliable performance over decades of aviation history, with well-established fatigue behavior and damage tolerance characteristics. The discrete nature of riveted connections allows for controlled crack propagation paths, preventing catastrophic failures. Riveted structures typically exhibit progressive failure modes that provide visual indicators before critical failure occurs.

Laser welding, while offering seamless joints with excellent load distribution characteristics, introduces different structural considerations. Welded joints create heat-affected zones that may alter material properties and require careful management of residual stresses. Recent advancements in laser welding technology have significantly improved the fatigue performance of welded aluminum structures, with some studies showing comparable or superior fatigue life to riveted joints under certain loading conditions.

Damage tolerance assessment reveals that laser-welded structures may exhibit different crack propagation behavior compared to riveted assemblies. Without the stress concentration points created by fastener holes, welded structures can demonstrate improved resistance to crack initiation. However, once cracks form, they may propagate more rapidly through continuous welded sections without the crack-stopping features inherent in riveted designs.

Hybrid joining approaches are emerging as promising solutions that capitalize on the strengths of both technologies. These systems strategically implement laser welding in areas where weight reduction is critical, while maintaining riveted connections in high-stress zones or areas requiring regular inspection and maintenance. Such hybrid designs have demonstrated weight reductions of 8-12% compared to traditional riveted structures while maintaining equivalent or superior structural integrity.

The aerospace industry's gradual shift toward composite-metal hybrid structures further complicates the joining technology selection process, as laser welding and riveting interact differently with these advanced material systems. Ongoing research focuses on optimizing joining technologies for these next-generation aircraft structures to maximize both weight efficiency and structural performance.

Environmental Impact and Sustainability Factors

The environmental impact of aircraft assembly methods has become increasingly important as the aviation industry faces pressure to reduce its carbon footprint. Laser welding demonstrates significant environmental advantages over traditional riveting processes. The elimination of thousands of rivets in a typical aircraft structure reduces raw material consumption by approximately 15-20%, directly decreasing the environmental burden associated with metal extraction and processing.

Energy consumption analysis reveals that laser welding systems, while requiring high power during operation, consume less total energy across the complete assembly lifecycle. Studies indicate that laser welding can reduce energy consumption by up to 30% compared to riveting when accounting for material production, assembly processes, and long-term aircraft operation. This efficiency stems from both the streamlined manufacturing process and the weight reduction in the final structure.

Waste generation presents another critical environmental consideration. Riveting processes generate substantial waste in the form of metal shavings, discarded rivets, and worn drilling tools. In contrast, laser welding produces minimal physical waste, with estimates suggesting a 40-60% reduction in manufacturing waste. Additionally, laser welding eliminates the need for potentially hazardous sealants often required with riveted joints to prevent fuel leakage and corrosion.

The reduced weight of laser-welded structures contributes significantly to sustainability throughout the aircraft lifecycle. Industry calculations indicate that every kilogram of weight saved on an aircraft translates to approximately 3,000 liters of fuel saved over a typical 20-year service life. Laser-welded structures can reduce aircraft weight by 2-5%, potentially saving millions of liters of fuel and preventing thousands of tons of carbon emissions per aircraft.

Chemical usage represents another environmental factor. Riveting processes often require multiple chemical treatments including cleaning agents, anti-corrosion compounds, and sealants. Laser welding significantly reduces the need for these chemicals, decreasing both environmental contamination risks and workplace hazardous material exposure. Recent environmental impact assessments estimate a 30-50% reduction in chemical usage when transitioning from riveting to laser welding processes.

End-of-life considerations also favor laser welding from a sustainability perspective. Laser-welded components can be more easily separated for recycling through targeted cutting processes, whereas riveted assemblies often require more complex disassembly procedures that can damage materials and reduce recycling efficiency. This advantage becomes increasingly important as aircraft manufacturers adopt circular economy principles and design for disassembly approaches.

Energy consumption analysis reveals that laser welding systems, while requiring high power during operation, consume less total energy across the complete assembly lifecycle. Studies indicate that laser welding can reduce energy consumption by up to 30% compared to riveting when accounting for material production, assembly processes, and long-term aircraft operation. This efficiency stems from both the streamlined manufacturing process and the weight reduction in the final structure.

Waste generation presents another critical environmental consideration. Riveting processes generate substantial waste in the form of metal shavings, discarded rivets, and worn drilling tools. In contrast, laser welding produces minimal physical waste, with estimates suggesting a 40-60% reduction in manufacturing waste. Additionally, laser welding eliminates the need for potentially hazardous sealants often required with riveted joints to prevent fuel leakage and corrosion.

The reduced weight of laser-welded structures contributes significantly to sustainability throughout the aircraft lifecycle. Industry calculations indicate that every kilogram of weight saved on an aircraft translates to approximately 3,000 liters of fuel saved over a typical 20-year service life. Laser-welded structures can reduce aircraft weight by 2-5%, potentially saving millions of liters of fuel and preventing thousands of tons of carbon emissions per aircraft.

Chemical usage represents another environmental factor. Riveting processes often require multiple chemical treatments including cleaning agents, anti-corrosion compounds, and sealants. Laser welding significantly reduces the need for these chemicals, decreasing both environmental contamination risks and workplace hazardous material exposure. Recent environmental impact assessments estimate a 30-50% reduction in chemical usage when transitioning from riveting to laser welding processes.

End-of-life considerations also favor laser welding from a sustainability perspective. Laser-welded components can be more easily separated for recycling through targeted cutting processes, whereas riveted assemblies often require more complex disassembly procedures that can damage materials and reduce recycling efficiency. This advantage becomes increasingly important as aircraft manufacturers adopt circular economy principles and design for disassembly approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!