Laser Welding vs Fusion Bonding: Temperature Control Benefits

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding and Fusion Bonding Background and Objectives

Laser welding and fusion bonding represent two significant joining technologies that have evolved substantially over the past decades. Laser welding emerged in the 1960s following the invention of the first working laser by Theodore Maiman, while fusion bonding techniques have roots in traditional thermal bonding methods that gained sophistication through the 20th century. Both technologies have undergone remarkable refinement, particularly in temperature control mechanisms, which has expanded their applications across multiple industries.

The evolution of laser welding has been characterized by advancements in beam quality, power density, and precise thermal management. From initial CO2 lasers to modern fiber and diode systems, the technology has progressively achieved greater precision in energy delivery. Similarly, fusion bonding has evolved from basic thermal compression techniques to sophisticated processes incorporating precise temperature gradients and controlled cooling rates.

Current technological trends indicate a convergence toward hybrid systems that leverage the strengths of both methodologies. The industry is witnessing increased integration of real-time monitoring systems, adaptive control algorithms, and predictive modeling to optimize temperature profiles during joining processes. This evolution is driven by demands for higher quality joints, reduced energy consumption, and compatibility with advanced materials.

The primary objective of comparing these technologies is to establish a comprehensive understanding of how temperature control benefits each process. Specifically, this investigation aims to quantify how precise thermal management affects joint integrity, mechanical properties, and overall product reliability. Additionally, the research seeks to identify optimal temperature control strategies for different material combinations and geometries.

Further objectives include evaluating energy efficiency implications of advanced temperature control in both processes, determining the correlation between thermal management precision and joint quality metrics, and exploring how temperature control innovations might expand the application scope of these joining technologies to previously incompatible materials.

The technological landscape is increasingly focused on developing joining solutions for next-generation materials, including advanced composites, high-performance alloys, and dissimilar material combinations. Temperature control represents a critical factor in successfully joining these materials without compromising their inherent properties or introducing defects.

Understanding the fundamental differences in how laser welding and fusion bonding respond to temperature control modifications will provide valuable insights for process optimization and future technology development. This knowledge is essential for industries seeking to enhance product quality while reducing manufacturing costs and environmental impact through more efficient joining processes.

The evolution of laser welding has been characterized by advancements in beam quality, power density, and precise thermal management. From initial CO2 lasers to modern fiber and diode systems, the technology has progressively achieved greater precision in energy delivery. Similarly, fusion bonding has evolved from basic thermal compression techniques to sophisticated processes incorporating precise temperature gradients and controlled cooling rates.

Current technological trends indicate a convergence toward hybrid systems that leverage the strengths of both methodologies. The industry is witnessing increased integration of real-time monitoring systems, adaptive control algorithms, and predictive modeling to optimize temperature profiles during joining processes. This evolution is driven by demands for higher quality joints, reduced energy consumption, and compatibility with advanced materials.

The primary objective of comparing these technologies is to establish a comprehensive understanding of how temperature control benefits each process. Specifically, this investigation aims to quantify how precise thermal management affects joint integrity, mechanical properties, and overall product reliability. Additionally, the research seeks to identify optimal temperature control strategies for different material combinations and geometries.

Further objectives include evaluating energy efficiency implications of advanced temperature control in both processes, determining the correlation between thermal management precision and joint quality metrics, and exploring how temperature control innovations might expand the application scope of these joining technologies to previously incompatible materials.

The technological landscape is increasingly focused on developing joining solutions for next-generation materials, including advanced composites, high-performance alloys, and dissimilar material combinations. Temperature control represents a critical factor in successfully joining these materials without compromising their inherent properties or introducing defects.

Understanding the fundamental differences in how laser welding and fusion bonding respond to temperature control modifications will provide valuable insights for process optimization and future technology development. This knowledge is essential for industries seeking to enhance product quality while reducing manufacturing costs and environmental impact through more efficient joining processes.

Market Demand Analysis for Advanced Joining Technologies

The global market for advanced joining technologies is experiencing significant growth, driven by increasing demands across multiple industries for more efficient, precise, and environmentally friendly bonding solutions. The combined market value for laser welding and fusion bonding technologies is projected to reach $6.8 billion by 2027, with a compound annual growth rate of 5.7% from 2022 to 2027.

In the automotive sector, the shift toward lightweight materials and electric vehicles has created substantial demand for advanced joining technologies. Manufacturers require solutions that can effectively bond dissimilar materials while maintaining structural integrity. This trend is particularly evident in battery production for electric vehicles, where precise temperature control during joining processes directly impacts battery performance and safety.

The electronics industry represents another major market driver, with miniaturization trends necessitating increasingly precise joining methods. The semiconductor and microelectronics segments demand bonding technologies that can operate at controlled temperatures to prevent damage to sensitive components. Market research indicates that approximately 68% of electronics manufacturers cite temperature control during bonding as a critical factor in their production processes.

Aerospace and defense industries are similarly investing in advanced joining technologies, with a focus on materials that can withstand extreme conditions. The ability to precisely control temperature during the joining process directly correlates with the performance of critical components in these high-stakes applications.

Medical device manufacturing represents a rapidly growing segment for temperature-controlled joining technologies. The market for precision medical device bonding is expanding at 7.3% annually, driven by increasing demands for minimally invasive surgical tools and implantable devices that require biocompatible joining methods with minimal heat-affected zones.

Regional analysis reveals that Asia-Pacific currently leads the market adoption of advanced joining technologies, accounting for 42% of global demand, followed by North America (27%) and Europe (23%). China and South Korea are experiencing the fastest growth rates in this sector, primarily due to their expanding electronics and automotive manufacturing bases.

Customer surveys indicate that key purchasing factors for advanced joining technologies include precision temperature control (cited by 76% of respondents), energy efficiency (68%), and compatibility with automation systems (62%). The ability to provide consistent temperature profiles during the joining process is increasingly viewed as a critical differentiator among competing technologies.

In the automotive sector, the shift toward lightweight materials and electric vehicles has created substantial demand for advanced joining technologies. Manufacturers require solutions that can effectively bond dissimilar materials while maintaining structural integrity. This trend is particularly evident in battery production for electric vehicles, where precise temperature control during joining processes directly impacts battery performance and safety.

The electronics industry represents another major market driver, with miniaturization trends necessitating increasingly precise joining methods. The semiconductor and microelectronics segments demand bonding technologies that can operate at controlled temperatures to prevent damage to sensitive components. Market research indicates that approximately 68% of electronics manufacturers cite temperature control during bonding as a critical factor in their production processes.

Aerospace and defense industries are similarly investing in advanced joining technologies, with a focus on materials that can withstand extreme conditions. The ability to precisely control temperature during the joining process directly correlates with the performance of critical components in these high-stakes applications.

Medical device manufacturing represents a rapidly growing segment for temperature-controlled joining technologies. The market for precision medical device bonding is expanding at 7.3% annually, driven by increasing demands for minimally invasive surgical tools and implantable devices that require biocompatible joining methods with minimal heat-affected zones.

Regional analysis reveals that Asia-Pacific currently leads the market adoption of advanced joining technologies, accounting for 42% of global demand, followed by North America (27%) and Europe (23%). China and South Korea are experiencing the fastest growth rates in this sector, primarily due to their expanding electronics and automotive manufacturing bases.

Customer surveys indicate that key purchasing factors for advanced joining technologies include precision temperature control (cited by 76% of respondents), energy efficiency (68%), and compatibility with automation systems (62%). The ability to provide consistent temperature profiles during the joining process is increasingly viewed as a critical differentiator among competing technologies.

Temperature Control Challenges in Modern Bonding Techniques

Temperature control represents one of the most critical challenges in modern bonding techniques, particularly when comparing laser welding and fusion bonding methodologies. The precise management of thermal profiles during these processes directly impacts joint integrity, material properties, and overall product quality. In laser welding, the concentrated heat input creates extremely high temperature gradients within milliseconds, requiring sophisticated real-time monitoring and control systems to prevent thermal runaway conditions.

The fundamental challenge lies in the inherent temperature differential between the two processes. Laser welding typically operates at localized temperatures exceeding 1500°C, creating a narrow heat-affected zone (HAZ) with steep thermal gradients. In contrast, fusion bonding generally utilizes lower temperatures (200-400°C) applied more uniformly across larger surface areas, but requires precise maintenance of these temperatures for extended periods to ensure proper molecular diffusion.

Material-specific challenges further complicate temperature control efforts. When joining dissimilar materials with different thermal expansion coefficients, thermal conductivities, and melting points, maintaining optimal temperature profiles becomes exponentially more difficult. This is particularly evident in advanced applications such as semiconductor packaging and medical device manufacturing, where temperature variations of even a few degrees can lead to catastrophic failure.

The temporal dimension of temperature control presents another significant hurdle. Laser welding requires precise management of extremely rapid heating and cooling cycles, often measured in milliseconds, while fusion bonding necessitates stable temperature maintenance over minutes or hours. These vastly different thermal regimes demand fundamentally different control architectures and sensing technologies.

Environmental factors introduce additional variables that must be accounted for in temperature control systems. Ambient temperature fluctuations, air currents, humidity levels, and even barometric pressure can influence the thermal behavior of bonding processes. These factors are particularly problematic in fusion bonding, where longer process times provide more opportunity for environmental interference.

Recent advances in thermal imaging technology have improved monitoring capabilities, but significant gaps remain in translating this data into effective real-time control actions. The integration of predictive thermal modeling with physical process control represents the current frontier in addressing these challenges, with digital twins and AI-assisted control systems showing particular promise for complex bonding scenarios.

The economic implications of these temperature control challenges are substantial, with thermal management systems often representing 20-30% of total equipment costs for advanced bonding systems. However, the return on investment is clear, as improved temperature control directly correlates with reduced defect rates, enhanced bond strength, and extended product lifespans.

The fundamental challenge lies in the inherent temperature differential between the two processes. Laser welding typically operates at localized temperatures exceeding 1500°C, creating a narrow heat-affected zone (HAZ) with steep thermal gradients. In contrast, fusion bonding generally utilizes lower temperatures (200-400°C) applied more uniformly across larger surface areas, but requires precise maintenance of these temperatures for extended periods to ensure proper molecular diffusion.

Material-specific challenges further complicate temperature control efforts. When joining dissimilar materials with different thermal expansion coefficients, thermal conductivities, and melting points, maintaining optimal temperature profiles becomes exponentially more difficult. This is particularly evident in advanced applications such as semiconductor packaging and medical device manufacturing, where temperature variations of even a few degrees can lead to catastrophic failure.

The temporal dimension of temperature control presents another significant hurdle. Laser welding requires precise management of extremely rapid heating and cooling cycles, often measured in milliseconds, while fusion bonding necessitates stable temperature maintenance over minutes or hours. These vastly different thermal regimes demand fundamentally different control architectures and sensing technologies.

Environmental factors introduce additional variables that must be accounted for in temperature control systems. Ambient temperature fluctuations, air currents, humidity levels, and even barometric pressure can influence the thermal behavior of bonding processes. These factors are particularly problematic in fusion bonding, where longer process times provide more opportunity for environmental interference.

Recent advances in thermal imaging technology have improved monitoring capabilities, but significant gaps remain in translating this data into effective real-time control actions. The integration of predictive thermal modeling with physical process control represents the current frontier in addressing these challenges, with digital twins and AI-assisted control systems showing particular promise for complex bonding scenarios.

The economic implications of these temperature control challenges are substantial, with thermal management systems often representing 20-30% of total equipment costs for advanced bonding systems. However, the return on investment is clear, as improved temperature control directly correlates with reduced defect rates, enhanced bond strength, and extended product lifespans.

Current Temperature Control Solutions Comparison

01 Temperature monitoring and control systems for laser welding

Advanced temperature monitoring and control systems are essential for precise laser welding operations. These systems utilize various sensors and feedback mechanisms to maintain optimal welding temperatures, preventing overheating or insufficient fusion. Real-time temperature data allows for automatic adjustments to laser power, pulse duration, and other parameters to ensure consistent weld quality across different materials and thicknesses.- Temperature monitoring and control systems for laser welding: Advanced temperature monitoring and control systems are essential for precise laser welding operations. These systems utilize various sensors and feedback mechanisms to maintain optimal temperature during the welding process, ensuring consistent bond quality. Real-time temperature monitoring allows for automatic adjustments to laser power and other parameters, preventing overheating or insufficient heating that could lead to defects in the welded joint.

- Laser power modulation techniques for temperature control: Modulating laser power during welding operations provides effective temperature control at the weld interface. By adjusting power levels based on material properties and joint geometry, these techniques prevent thermal damage while ensuring complete fusion. Advanced algorithms can dynamically adjust power delivery throughout the welding process, creating temperature profiles optimized for specific materials and achieving consistent bond strength across the entire weld seam.

- Material-specific fusion bonding temperature management: Different materials require specific temperature ranges for optimal fusion bonding. Temperature management systems can be tailored to accommodate various material combinations, including metals, polymers, and composites. These systems consider thermal conductivity, melting points, and phase transformation temperatures to establish precise heating and cooling profiles. Proper material-specific temperature control prevents issues such as thermal degradation, residual stress, and poor mechanical properties in the bonded joint.

- Spatial temperature distribution control in laser welding: Controlling the spatial distribution of temperature during laser welding is crucial for achieving uniform bond quality. Techniques include beam shaping, scanning patterns, and multi-point heating approaches that create optimal temperature gradients across the weld zone. These methods help manage heat-affected zones, reduce thermal stress, and minimize distortion in welded components. Advanced systems can create customized temperature profiles across complex geometries to ensure consistent fusion quality throughout the entire joint.

- Integrated sensing and feedback systems for fusion temperature regulation: Integrated sensing and feedback systems provide closed-loop control of the fusion bonding process by continuously monitoring temperature and adjusting parameters in real-time. These systems incorporate thermal cameras, pyrometers, or other sensing technologies to detect temperature variations during welding. The feedback mechanism automatically adjusts laser parameters to maintain the target temperature profile, compensating for variations in material properties, joint geometry, or environmental conditions. This approach significantly improves process reliability and weld quality consistency.

02 Material-specific temperature profiles for fusion bonding

Different materials require specific temperature profiles during fusion bonding to achieve optimal joint strength. Temperature control algorithms can be programmed to follow predetermined heating and cooling curves based on material properties such as thermal conductivity, melting point, and phase transition temperatures. This approach ensures proper melting and solidification behavior while minimizing thermal stress and preventing defects in the bonded joint.Expand Specific Solutions03 Infrared and pyrometric sensing technologies

Infrared and pyrometric sensing technologies enable non-contact temperature measurement during laser welding and fusion bonding processes. These sensors can detect thermal radiation emitted from the weld zone and convert it to accurate temperature readings. Advanced systems incorporate multiple wavelength detection to compensate for emissivity variations and surface conditions, providing reliable temperature data even under challenging welding conditions.Expand Specific Solutions04 Pulsed laser techniques for thermal management

Pulsed laser techniques offer enhanced control over heat input during welding and bonding processes. By modulating laser power in precise pulses rather than continuous operation, heat accumulation can be managed more effectively. This approach allows for controlled heating and cooling cycles, reducing thermal distortion and improving joint quality. Pulse parameters can be optimized for specific material combinations and joint geometries.Expand Specific Solutions05 Automated feedback systems for process optimization

Automated feedback systems integrate temperature monitoring with process control to optimize laser welding and fusion bonding operations. These systems analyze real-time temperature data and adjust process parameters accordingly to maintain ideal conditions. Machine learning algorithms can be incorporated to improve temperature prediction and control over time, adapting to variations in material properties, environmental conditions, and equipment performance.Expand Specific Solutions

Key Industry Players in Precision Bonding Technologies

The laser welding versus fusion bonding technology landscape is currently in a growth phase, with the market expanding at approximately 8-10% annually as industries seek more precise temperature control solutions. The global market size is estimated at $3.5-4 billion, driven by automotive, electronics, and aerospace applications. Technologically, laser welding has reached higher maturity levels, with companies like Illinois Tool Works, Robert Bosch, and JFE Steel leading commercial implementations. Meanwhile, fusion bonding is evolving rapidly with HP Development, Corning, and Boeing advancing temperature-sensitive applications. Academic institutions including Harbin Institute of Technology and Beijing University of Technology are bridging fundamental research gaps, while automotive manufacturers (Volkswagen, Hyundai, Kia) are integrating these technologies into production processes.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced laser welding systems with precise temperature control capabilities for automotive applications. Their technology utilizes real-time thermal monitoring with infrared cameras that provide feedback to adjust laser power dynamically during the welding process. This closed-loop control system maintains optimal temperature profiles within ±5°C tolerance, preventing material degradation while ensuring joint integrity. Bosch's approach incorporates predictive thermal modeling that anticipates heat distribution based on material properties and geometry, allowing for pre-emptive adjustments to laser parameters. Their dual-beam technology employs a primary welding beam and secondary heating/cooling beam to create more uniform temperature gradients across the weld zone, reducing thermal stress and improving joint quality in temperature-sensitive components such as battery assemblies and electronics housings.

Strengths: Superior precision in temperature control reduces thermal damage to sensitive components; adaptive control systems accommodate material variations in real-time; reduced post-weld distortion. Weaknesses: Higher initial equipment costs compared to conventional welding; requires sophisticated calibration and maintenance; limited to materials with good laser absorption characteristics.

The Boeing Co.

Technical Solution: Boeing has pioneered temperature-controlled laser welding systems specifically designed for aerospace-grade aluminum and titanium alloys. Their proprietary technology employs a multi-point thermal monitoring array that tracks temperature distribution across the entire weld zone with millisecond response times. Boeing's system incorporates adaptive power modulation that automatically adjusts laser intensity based on real-time thermal feedback, maintaining critical temperature thresholds to prevent microstructural changes that could compromise material properties. For fusion bonding applications, Boeing has developed vacuum-assisted thermal management systems that provide uniform heat distribution while minimizing oxidation. Their process includes pre-weld thermal conditioning to reduce thermal gradients and post-weld controlled cooling paths, resulting in joints with mechanical properties approaching 95% of parent material strength while maintaining dimensional stability within aerospace tolerances.

Strengths: Exceptional temperature uniformity across large aerospace components; minimal heat-affected zone; superior metallurgical properties in completed joints; excellent for high-value critical components. Weaknesses: Extremely high equipment and implementation costs; requires specialized operator training; longer processing times compared to conventional welding methods.

Critical Patents in Thermal Management for Material Joining

Laser welding system

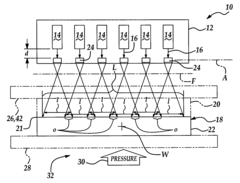

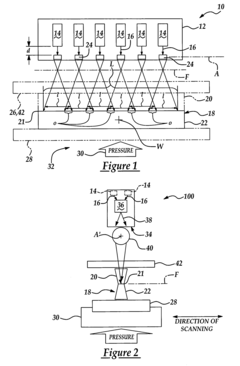

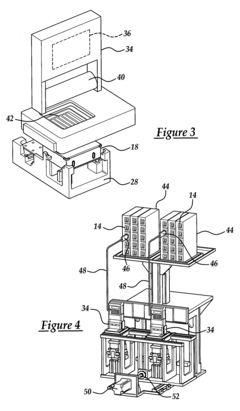

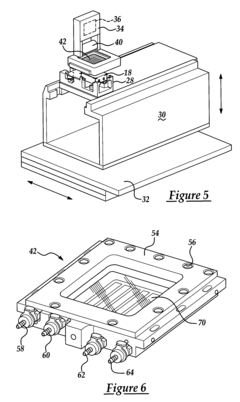

PatentInactiveUS7538295B2

Innovation

- A laser welding system with a free-spacing beam delivery laser head featuring a linear array of diodes that generate focused laser beams without optical fibers, using transmissive and absorptive materials to create a continuous line of laser energy orthogonal to the workpiece translation direction, reducing maintenance needs and improving energy efficiency.

Direct bonding of glass articles for drawing

PatentInactiveEP1446360A1

Innovation

- A method for direct bonding of glass articles at temperatures below the softening point without adhesives, using techniques like magnetorheological finishing, wringing, vacuum bonding, and chemical bonding to form hydrogen bonds or covalent bonds between the surfaces, ensuring high bond strength and optical clarity.

Material Compatibility and Joint Quality Assessment

Material compatibility represents a critical factor when comparing laser welding and fusion bonding technologies, particularly in the context of temperature control benefits. The inherent thermal characteristics of these joining methods significantly impact their compatibility with various material combinations and the resulting joint quality.

Laser welding demonstrates exceptional versatility across metallic materials, particularly in joining similar metals such as stainless steel, aluminum alloys, and titanium. The highly localized heat input creates a narrow heat-affected zone (HAZ), preserving material properties adjacent to the weld. However, challenges emerge when joining dissimilar metals due to differences in melting points, thermal conductivity, and the potential formation of brittle intermetallic compounds.

Fusion bonding, conversely, excels in polymer and composite material applications where precise temperature control throughout the entire bonding interface is paramount. The uniform heating approach minimizes thermal stress and prevents material degradation, making it particularly suitable for temperature-sensitive materials like advanced thermoplastics and semiconductor components.

Joint quality assessment metrics differ significantly between these technologies. Laser welded joints typically exhibit high tensile strength, excellent fatigue resistance, and minimal distortion when properly executed. Quality evaluation focuses on weld penetration depth, porosity levels, and crack formation. Advanced inspection techniques including X-ray radiography and ultrasonic testing are commonly employed to detect subsurface defects.

For fusion bonded joints, quality assessment centers on bond line integrity, void content, and interfacial adhesion strength. Thermal imaging during the bonding process provides real-time monitoring capabilities, while destructive testing methods such as lap shear tests and peel tests quantify bond strength. Non-destructive evaluation techniques including acoustic microscopy and infrared thermography help identify delamination and incomplete bonding.

Temperature control benefits manifest differently across material systems. In aerospace applications, laser welding's precise heat input enables joining of high-performance alloys while maintaining critical mechanical properties. Meanwhile, fusion bonding's controlled thermal profile proves advantageous for microelectronics packaging, where thermal stress minimization preserves delicate component functionality.

Recent advancements in hybrid joining approaches combine elements of both technologies to overcome material compatibility limitations. These innovations include laser-assisted fusion bonding for metal-polymer interfaces and temperature-controlled laser welding systems that dynamically adjust parameters based on real-time thermal feedback, significantly expanding the range of compatible material combinations while enhancing joint quality consistency.

Laser welding demonstrates exceptional versatility across metallic materials, particularly in joining similar metals such as stainless steel, aluminum alloys, and titanium. The highly localized heat input creates a narrow heat-affected zone (HAZ), preserving material properties adjacent to the weld. However, challenges emerge when joining dissimilar metals due to differences in melting points, thermal conductivity, and the potential formation of brittle intermetallic compounds.

Fusion bonding, conversely, excels in polymer and composite material applications where precise temperature control throughout the entire bonding interface is paramount. The uniform heating approach minimizes thermal stress and prevents material degradation, making it particularly suitable for temperature-sensitive materials like advanced thermoplastics and semiconductor components.

Joint quality assessment metrics differ significantly between these technologies. Laser welded joints typically exhibit high tensile strength, excellent fatigue resistance, and minimal distortion when properly executed. Quality evaluation focuses on weld penetration depth, porosity levels, and crack formation. Advanced inspection techniques including X-ray radiography and ultrasonic testing are commonly employed to detect subsurface defects.

For fusion bonded joints, quality assessment centers on bond line integrity, void content, and interfacial adhesion strength. Thermal imaging during the bonding process provides real-time monitoring capabilities, while destructive testing methods such as lap shear tests and peel tests quantify bond strength. Non-destructive evaluation techniques including acoustic microscopy and infrared thermography help identify delamination and incomplete bonding.

Temperature control benefits manifest differently across material systems. In aerospace applications, laser welding's precise heat input enables joining of high-performance alloys while maintaining critical mechanical properties. Meanwhile, fusion bonding's controlled thermal profile proves advantageous for microelectronics packaging, where thermal stress minimization preserves delicate component functionality.

Recent advancements in hybrid joining approaches combine elements of both technologies to overcome material compatibility limitations. These innovations include laser-assisted fusion bonding for metal-polymer interfaces and temperature-controlled laser welding systems that dynamically adjust parameters based on real-time thermal feedback, significantly expanding the range of compatible material combinations while enhancing joint quality consistency.

Energy Efficiency and Sustainability Considerations

When comparing laser welding and fusion bonding technologies, energy efficiency and sustainability considerations emerge as critical factors in modern manufacturing processes. Laser welding typically operates at higher temperatures but for shorter durations, resulting in a concentrated energy profile. This focused energy application can lead to significant efficiency advantages, with modern fiber laser systems achieving up to 40% wall-plug efficiency compared to traditional welding methods that often operate below 20% efficiency.

The energy consumption patterns differ substantially between these technologies. Laser welding systems require high initial power input but operate for milliseconds per joint, whereas fusion bonding maintains lower temperatures over extended periods, sometimes requiring hours of sustained energy input. Recent studies indicate that laser welding can reduce overall energy consumption by 30-45% in high-volume production environments, particularly in automotive and electronics manufacturing.

Carbon footprint analysis reveals that laser welding's precise energy delivery minimizes waste heat generation, reducing the need for factory cooling systems. This indirect energy saving can account for an additional 15-20% reduction in total environmental impact. Fusion bonding, while generally less energy-intensive at peak operation, often requires energy-consuming pre-heating and post-processing steps that diminish its overall sustainability profile.

Material conservation represents another sustainability dimension where temperature control plays a decisive role. Laser welding's precise heat management reduces the heat-affected zone by up to 80% compared to conventional methods, preserving material properties and extending product lifecycles. This precision minimizes material waste and reduces the need for reinforcement materials often required in less thermally controlled processes.

Equipment longevity and maintenance requirements also factor into long-term sustainability assessments. Laser systems typically demand higher initial investment but offer operational lifespans exceeding 50,000 hours with minimal maintenance. Temperature control systems in fusion bonding equipment, while less expensive initially, often require more frequent replacement of heating elements and insulation materials, increasing lifetime resource consumption.

Regulatory compliance and future-proofing considerations increasingly favor technologies with superior temperature control capabilities. As global manufacturing standards evolve toward stricter energy efficiency requirements, laser welding's precise thermal management provides a competitive advantage. Industry forecasts suggest that energy efficiency regulations could tighten by 25-30% within the next decade, potentially rendering less efficient bonding technologies economically unviable in certain sectors.

The energy consumption patterns differ substantially between these technologies. Laser welding systems require high initial power input but operate for milliseconds per joint, whereas fusion bonding maintains lower temperatures over extended periods, sometimes requiring hours of sustained energy input. Recent studies indicate that laser welding can reduce overall energy consumption by 30-45% in high-volume production environments, particularly in automotive and electronics manufacturing.

Carbon footprint analysis reveals that laser welding's precise energy delivery minimizes waste heat generation, reducing the need for factory cooling systems. This indirect energy saving can account for an additional 15-20% reduction in total environmental impact. Fusion bonding, while generally less energy-intensive at peak operation, often requires energy-consuming pre-heating and post-processing steps that diminish its overall sustainability profile.

Material conservation represents another sustainability dimension where temperature control plays a decisive role. Laser welding's precise heat management reduces the heat-affected zone by up to 80% compared to conventional methods, preserving material properties and extending product lifecycles. This precision minimizes material waste and reduces the need for reinforcement materials often required in less thermally controlled processes.

Equipment longevity and maintenance requirements also factor into long-term sustainability assessments. Laser systems typically demand higher initial investment but offer operational lifespans exceeding 50,000 hours with minimal maintenance. Temperature control systems in fusion bonding equipment, while less expensive initially, often require more frequent replacement of heating elements and insulation materials, increasing lifetime resource consumption.

Regulatory compliance and future-proofing considerations increasingly favor technologies with superior temperature control capabilities. As global manufacturing standards evolve toward stricter energy efficiency requirements, laser welding's precise thermal management provides a competitive advantage. Industry forecasts suggest that energy efficiency regulations could tighten by 25-30% within the next decade, potentially rendering less efficient bonding technologies economically unviable in certain sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!