Laser Welding in Jewelry Production: Precision Techniques

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Evolution and Objectives

Laser welding technology in jewelry production has evolved significantly over the past several decades, transforming from an experimental technique to an essential process in modern jewelry manufacturing. The journey began in the 1970s when laser technology was first adapted for precision metalwork, though these early systems were limited in power control and precision. By the 1990s, significant advancements in laser optics and power regulation allowed for more refined applications in the jewelry industry, enabling craftsmen to perform repairs and join delicate components with minimal thermal impact.

The 2000s marked a pivotal era with the introduction of pulsed Nd:YAG lasers specifically designed for jewelry applications, offering unprecedented control over weld parameters. This technological leap allowed jewelers to work with increasingly complex designs and a wider range of precious metals, including those previously considered challenging to weld such as platinum and titanium. The development of fiber laser technology in the late 2000s further revolutionized the field, providing enhanced beam quality and stability for even more precise welding operations.

Recent advancements have focused on miniaturization and integration, with compact desktop laser welding systems becoming accessible to smaller jewelry workshops and individual artisans. Modern systems incorporate sophisticated features such as high-definition visualization systems, programmable weld profiles, and automated positioning controls, democratizing access to this precision technology across the industry spectrum.

The primary objective of laser welding in jewelry production is to achieve seamless, high-strength joints while preserving the aesthetic integrity of the piece. This involves minimizing heat-affected zones, preventing material distortion, and eliminating the need for additional finishing work. Secondary objectives include increasing production efficiency, reducing material waste, and enabling the creation of designs that would be impossible using traditional joining methods.

Looking forward, the technical goals for laser welding in jewelry production are centered on further refinement of beam control technologies, development of adaptive systems that can automatically adjust parameters based on material properties, and integration with other digital manufacturing processes such as CAD/CAM and 3D printing. There is also significant interest in expanding the range of materials that can be effectively welded, particularly for emerging alternative metals and alloys in contemporary jewelry design.

The evolution trajectory suggests that future laser welding systems will likely incorporate artificial intelligence for parameter optimization, enhanced visualization technologies for sub-micron precision, and more sophisticated automation capabilities to support both mass production and bespoke craftsmanship in the jewelry industry.

The 2000s marked a pivotal era with the introduction of pulsed Nd:YAG lasers specifically designed for jewelry applications, offering unprecedented control over weld parameters. This technological leap allowed jewelers to work with increasingly complex designs and a wider range of precious metals, including those previously considered challenging to weld such as platinum and titanium. The development of fiber laser technology in the late 2000s further revolutionized the field, providing enhanced beam quality and stability for even more precise welding operations.

Recent advancements have focused on miniaturization and integration, with compact desktop laser welding systems becoming accessible to smaller jewelry workshops and individual artisans. Modern systems incorporate sophisticated features such as high-definition visualization systems, programmable weld profiles, and automated positioning controls, democratizing access to this precision technology across the industry spectrum.

The primary objective of laser welding in jewelry production is to achieve seamless, high-strength joints while preserving the aesthetic integrity of the piece. This involves minimizing heat-affected zones, preventing material distortion, and eliminating the need for additional finishing work. Secondary objectives include increasing production efficiency, reducing material waste, and enabling the creation of designs that would be impossible using traditional joining methods.

Looking forward, the technical goals for laser welding in jewelry production are centered on further refinement of beam control technologies, development of adaptive systems that can automatically adjust parameters based on material properties, and integration with other digital manufacturing processes such as CAD/CAM and 3D printing. There is also significant interest in expanding the range of materials that can be effectively welded, particularly for emerging alternative metals and alloys in contemporary jewelry design.

The evolution trajectory suggests that future laser welding systems will likely incorporate artificial intelligence for parameter optimization, enhanced visualization technologies for sub-micron precision, and more sophisticated automation capabilities to support both mass production and bespoke craftsmanship in the jewelry industry.

Market Demand for Precision Jewelry Welding

The global market for precision jewelry welding technologies has experienced significant growth over the past decade, driven primarily by increasing consumer demand for intricate and high-quality jewelry pieces. The luxury jewelry market, valued at approximately $230 billion in 2022, continues to expand at a steady annual rate of 5-7%, with precision manufacturing techniques becoming a critical differentiator for premium brands.

Consumer preferences have notably shifted toward more complex and personalized jewelry designs, creating substantial demand for advanced welding technologies that can accommodate intricate patterns and delicate gemstone settings. Market research indicates that over 65% of high-end jewelry consumers now prioritize craftsmanship quality and design precision when making purchasing decisions, compared to just 40% a decade ago.

The jewelry manufacturing sector has responded to these evolving preferences by increasingly adopting laser welding technologies. Industry surveys reveal that approximately 78% of medium to large jewelry manufacturers have invested in laser welding equipment within the past five years, representing a significant shift from traditional soldering methods. This transition is particularly pronounced in regions with established jewelry manufacturing hubs, including Italy, India, Thailand, and China.

From a regional perspective, North America and Europe currently represent the largest markets for precision jewelry welding technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is demonstrating the fastest growth rate, with annual market expansion exceeding 12% as manufacturers in countries like India and China rapidly modernize their production capabilities to meet international quality standards.

The economic advantages of laser welding are increasingly recognized across the industry. Manufacturers report production efficiency improvements of 30-40% when transitioning from traditional methods to laser welding systems, with corresponding reductions in material waste and rework requirements. These efficiency gains have become particularly valuable as precious metal prices continue to rise, making material conservation a priority for maintaining profit margins.

Environmental and regulatory factors are also influencing market demand. Stricter workplace safety regulations in major manufacturing regions have accelerated the adoption of laser welding, which produces fewer toxic fumes compared to traditional soldering methods. Additionally, growing consumer interest in sustainable and ethically produced jewelry has created market pressure for cleaner production techniques with reduced environmental impact.

Looking forward, market analysts project continued strong growth for precision jewelry welding technologies, with particular emphasis on systems offering enhanced automation capabilities, improved energy efficiency, and integration with digital design workflows. The market segment for compact, affordable laser welding systems targeted at small-scale artisanal jewelers is expected to emerge as a significant growth opportunity over the next five years.

Consumer preferences have notably shifted toward more complex and personalized jewelry designs, creating substantial demand for advanced welding technologies that can accommodate intricate patterns and delicate gemstone settings. Market research indicates that over 65% of high-end jewelry consumers now prioritize craftsmanship quality and design precision when making purchasing decisions, compared to just 40% a decade ago.

The jewelry manufacturing sector has responded to these evolving preferences by increasingly adopting laser welding technologies. Industry surveys reveal that approximately 78% of medium to large jewelry manufacturers have invested in laser welding equipment within the past five years, representing a significant shift from traditional soldering methods. This transition is particularly pronounced in regions with established jewelry manufacturing hubs, including Italy, India, Thailand, and China.

From a regional perspective, North America and Europe currently represent the largest markets for precision jewelry welding technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is demonstrating the fastest growth rate, with annual market expansion exceeding 12% as manufacturers in countries like India and China rapidly modernize their production capabilities to meet international quality standards.

The economic advantages of laser welding are increasingly recognized across the industry. Manufacturers report production efficiency improvements of 30-40% when transitioning from traditional methods to laser welding systems, with corresponding reductions in material waste and rework requirements. These efficiency gains have become particularly valuable as precious metal prices continue to rise, making material conservation a priority for maintaining profit margins.

Environmental and regulatory factors are also influencing market demand. Stricter workplace safety regulations in major manufacturing regions have accelerated the adoption of laser welding, which produces fewer toxic fumes compared to traditional soldering methods. Additionally, growing consumer interest in sustainable and ethically produced jewelry has created market pressure for cleaner production techniques with reduced environmental impact.

Looking forward, market analysts project continued strong growth for precision jewelry welding technologies, with particular emphasis on systems offering enhanced automation capabilities, improved energy efficiency, and integration with digital design workflows. The market segment for compact, affordable laser welding systems targeted at small-scale artisanal jewelers is expected to emerge as a significant growth opportunity over the next five years.

Current Laser Welding Technologies and Challenges

Laser welding technology in jewelry production has evolved significantly over the past two decades, transitioning from traditional soldering methods to more precise laser-based techniques. Currently, the industry predominantly utilizes Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers operating at 1064nm wavelength, which provide excellent energy absorption by most precious metals. These systems typically deliver power outputs ranging from 50W to 200W, with pulse durations between 0.5ms and 20ms, allowing jewelers to control heat input with remarkable precision.

Fiber laser systems have recently gained traction in high-end jewelry manufacturing, offering superior beam quality and stability compared to traditional Nd:YAG systems. These systems provide spot sizes as small as 0.1mm, enabling intricate welding operations on delicate jewelry components. The fiber delivery system also eliminates the need for complex mirror arrangements, resulting in more compact and maintenance-friendly equipment.

Despite technological advancements, several challenges persist in laser welding for jewelry production. Material reflectivity remains a significant obstacle, particularly with highly reflective metals like silver and platinum. These materials can reflect up to 90% of incident laser energy, necessitating higher power settings that risk thermal damage to surrounding areas. Various surface preparation techniques and specialized coatings are being explored to mitigate this issue.

Thermal management presents another critical challenge. The low thermal mass of fine jewelry components makes them susceptible to overheating and deformation. Current systems employ sophisticated thermal monitoring and pulsing strategies, but achieving consistent results across different geometries and material combinations remains problematic. The industry is actively researching adaptive control systems that can adjust laser parameters in real-time based on thermal feedback.

Alloy compatibility issues also complicate jewelry laser welding. Different gold alloys, for instance, exhibit varying thermal properties and melting points, making it difficult to establish universal welding parameters. This challenge is particularly evident in repair work, where identifying the exact composition of existing jewelry pieces can be problematic. Some manufacturers have developed material-specific parameter libraries, but these solutions remain proprietary and limited in scope.

Automation integration represents both a challenge and frontier in jewelry laser welding. While automated systems exist for standardized production, the artistic nature of custom jewelry creation has limited full automation adoption. Current hybrid approaches combine automated positioning systems with manual parameter control, but truly intelligent systems capable of adapting to unique jewelry designs remain elusive.

Fiber laser systems have recently gained traction in high-end jewelry manufacturing, offering superior beam quality and stability compared to traditional Nd:YAG systems. These systems provide spot sizes as small as 0.1mm, enabling intricate welding operations on delicate jewelry components. The fiber delivery system also eliminates the need for complex mirror arrangements, resulting in more compact and maintenance-friendly equipment.

Despite technological advancements, several challenges persist in laser welding for jewelry production. Material reflectivity remains a significant obstacle, particularly with highly reflective metals like silver and platinum. These materials can reflect up to 90% of incident laser energy, necessitating higher power settings that risk thermal damage to surrounding areas. Various surface preparation techniques and specialized coatings are being explored to mitigate this issue.

Thermal management presents another critical challenge. The low thermal mass of fine jewelry components makes them susceptible to overheating and deformation. Current systems employ sophisticated thermal monitoring and pulsing strategies, but achieving consistent results across different geometries and material combinations remains problematic. The industry is actively researching adaptive control systems that can adjust laser parameters in real-time based on thermal feedback.

Alloy compatibility issues also complicate jewelry laser welding. Different gold alloys, for instance, exhibit varying thermal properties and melting points, making it difficult to establish universal welding parameters. This challenge is particularly evident in repair work, where identifying the exact composition of existing jewelry pieces can be problematic. Some manufacturers have developed material-specific parameter libraries, but these solutions remain proprietary and limited in scope.

Automation integration represents both a challenge and frontier in jewelry laser welding. While automated systems exist for standardized production, the artistic nature of custom jewelry creation has limited full automation adoption. Current hybrid approaches combine automated positioning systems with manual parameter control, but truly intelligent systems capable of adapting to unique jewelry designs remain elusive.

Current Precision Laser Welding Solutions

01 Precision control systems for laser welding

Advanced control systems are essential for achieving high precision in laser welding operations. These systems incorporate real-time monitoring, feedback mechanisms, and precise positioning controls to maintain welding accuracy. Technologies such as computer vision, motion control algorithms, and automated calibration systems help to minimize deviations and ensure consistent weld quality across complex geometries.- Precision control systems for laser welding: Advanced control systems are essential for achieving high precision in laser welding operations. These systems incorporate real-time monitoring, feedback mechanisms, and precise positioning controls to ensure accurate welding results. By utilizing sophisticated algorithms and sensors, these control systems can adjust welding parameters dynamically, compensate for material variations, and maintain consistent weld quality throughout the process.

- Beam focusing and positioning technologies: Precision in laser welding heavily depends on accurate beam focusing and positioning technologies. These technologies include advanced optical systems, high-precision motion control platforms, and beam manipulation devices that enable precise control over the laser spot size, position, and energy distribution. Innovations in this area allow for welding of complex geometries, micro-scale components, and challenging material combinations with minimal heat-affected zones.

- Material-specific laser welding techniques: Different materials require specialized laser welding approaches to achieve optimal precision. These techniques involve tailored laser parameters, specific beam profiles, and customized process strategies for various materials including metals, alloys, polymers, and composites. By adapting the welding process to the specific thermal, optical, and mechanical properties of the materials, higher precision and stronger welds can be achieved while minimizing defects and distortion.

- Real-time monitoring and quality control systems: Real-time monitoring and quality control systems are crucial for maintaining precision in laser welding processes. These systems employ various sensors, cameras, and spectroscopic techniques to observe the welding process as it occurs, detecting anomalies and defects immediately. Advanced image processing algorithms and artificial intelligence can analyze the collected data to make instant adjustments to welding parameters, ensuring consistent quality and precision throughout the production run.

- Fixture and workpiece positioning innovations: Innovative fixture designs and workpiece positioning systems play a significant role in achieving high precision in laser welding. These innovations include adaptive clamping mechanisms, vibration isolation systems, and automated alignment tools that ensure the workpieces remain perfectly positioned during the welding process. By minimizing movement and maintaining precise alignment between the laser beam and the joint, these systems contribute significantly to weld quality, repeatability, and dimensional accuracy of the finished products.

02 Beam focusing and manipulation techniques

Specialized techniques for laser beam focusing and manipulation significantly enhance welding precision. These include adaptive optics, beam shaping technologies, and precision focusing mechanisms that can adjust the laser spot size and energy distribution. Advanced beam delivery systems allow for precise control of the laser energy at the welding point, enabling fine welds on miniature components and complex geometries.Expand Specific Solutions03 Fixture and positioning systems

Custom-designed fixtures and high-precision positioning systems are crucial for maintaining part alignment during laser welding. These systems incorporate micro-positioning stages, vibration isolation mechanisms, and specialized clamping devices to hold workpieces with minimal deviation. Advanced positioning systems can achieve sub-micron accuracy, ensuring that welded components maintain their dimensional specifications.Expand Specific Solutions04 Process monitoring and quality control

Real-time monitoring systems for laser welding processes enable immediate quality assessment and precision control. These systems utilize sensors, high-speed cameras, and spectroscopic analysis to detect deviations in weld parameters. Advanced algorithms process this data to make immediate adjustments to laser power, speed, and focus, ensuring consistent weld quality and preventing defects before they occur.Expand Specific Solutions05 Material-specific laser welding techniques

Specialized laser welding techniques have been developed for specific materials to enhance precision and joint quality. These techniques account for the unique thermal properties, reflectivity, and metallurgical characteristics of different materials. Pulse shaping, wavelength selection, and custom energy profiles are employed to optimize weld quality for challenging materials such as highly reflective metals, dissimilar material combinations, and heat-sensitive components.Expand Specific Solutions

Key Industry Players and Equipment Manufacturers

The laser welding jewelry production market is in a growth phase, characterized by increasing adoption of precision techniques across the industry. The global market is expanding steadily as manufacturers seek higher precision, efficiency, and quality in jewelry fabrication. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include TRUMPF Laser- und Systemtechnik, which provides specialized laser systems for jewelry applications, Progold SpA offering advanced alloy solutions, and Cheval Frères SAS with expertise in luxury microtechnology manufacturing. IPG Photonics contributes fiber laser technology, while Fraunhofer-Gesellschaft advances research in precision welding techniques. K2 Laser System and Laser Depth Dynamics represent specialized providers focusing on monitoring and control solutions for high-precision jewelry welding applications.

Progold SpA

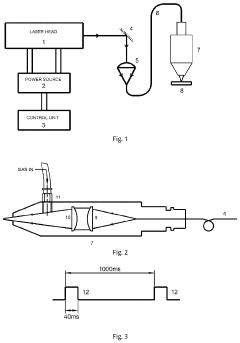

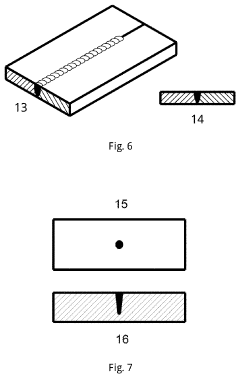

Technical Solution: Progold has developed an integrated laser welding approach specifically for jewelry manufacturing, combining their proprietary "GoldFuse" technology with specialized metallurgical expertise. Their systems feature variable pulse shaping capabilities with durations from 0.2ms to 50ms and peak powers up to 10kW, optimized for different precious metal alloys including specialized formulations of gold, platinum, and silver. Progold's technology incorporates a unique coaxial gas delivery system that provides inert gas shielding precisely at the weld point, preventing oxidation while maintaining visibility for the operator. Their workstations include high-resolution digital microscopes with up to 30x magnification and specialized illumination designed to enhance visibility of different metal surfaces. Progold has pioneered material-specific welding protocols based on extensive metallurgical research, with parameters optimized for maintaining the color consistency and mechanical properties of various jewelry alloys. Their latest innovation includes an AI-assisted parameter recommendation system that analyzes component geometry and material to suggest optimal welding settings.

Strengths: Deep metallurgical expertise specific to jewelry alloys; comprehensive training programs for jewelers transitioning to laser technology; excellent results maintaining color match in visible jewelry repairs. Weaknesses: More limited global service network compared to larger industrial laser manufacturers; fewer automation options for high-volume production; systems optimized primarily for precious metals with less versatility for other materials.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed the Jewel-Weld laser system specifically for the jewelry industry, featuring proprietary pulse-shaping technology that delivers precise energy control with 0.1ms resolution. Their system employs a dual-wavelength approach, combining 1064nm and 532nm lasers to optimize absorption characteristics across different precious metal alloys. ITW's technology incorporates a high-precision motion system with 5-axis control (X, Y, Z, rotation, and tilt) achieving positioning accuracy of ±3μm, enabling complex three-dimensional welding of intricate jewelry pieces. The company's patented "MetalMatch" software automatically identifies metal composition through spectroscopic analysis and adjusts welding parameters accordingly, reducing operator error by approximately 35%. Their latest systems feature integrated cooling technology that maintains consistent temperature at the weld site, preventing thermal distortion in delicate jewelry components and enabling work on heat-sensitive gemstone settings without risk of damage.

Strengths: Comprehensive material database optimized for jewelry alloys; intuitive touchscreen interface designed for jewelers without extensive technical training; excellent support network with specialized jewelry industry expertise. Weaknesses: Higher maintenance requirements compared to simpler systems; relatively large footprint for small jewelry workshops; premium pricing positioning limits accessibility for smaller operations.

Core Patents and Innovations in Jewelry Laser Welding

Laser welding method for enhanced weld quality and enhanced surface smoothness

PatentActiveUS20210354240A1

Innovation

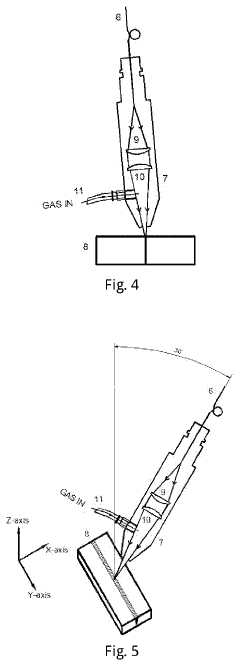

- A two-pass laser welding method using a high energy and long pulse Nd:YAG laser in the first pass with controlled peak power density below the evaporation threshold, followed by a second pass with a laser beam inclined at a specific angle and lower power density to achieve full depth penetration and surface smoothening, respectively.

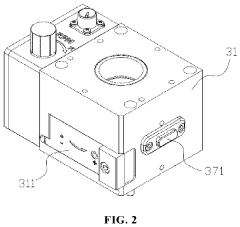

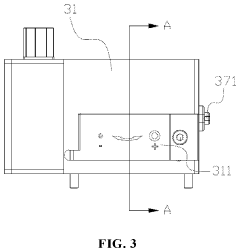

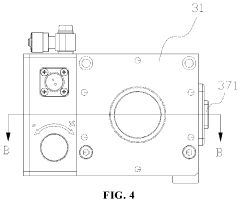

Lens assembly and laser welding head

PatentPendingUS20230330771A1

Innovation

- A lens assembly with a first and second optical path offset assembly, a drive mechanism, an elastic seal ring, and a locking mechanism, which allows for relative rotation between the assemblies to uniformly distribute energy and adjust the light spot size, enhancing precision and regulation range.

Material Compatibility and Metallurgical Considerations

Material compatibility represents a critical factor in laser welding for jewelry production, as different metals and alloys respond uniquely to laser energy. Gold alloys of varying karatage exhibit distinct thermal conductivity properties, with higher karat gold (22K-24K) requiring different laser parameters than lower karat varieties (10K-14K). The presence of alloying elements such as silver, copper, and zinc significantly influences weldability, with copper-rich alloys typically requiring more precise control to prevent brittleness at weld joints.

Platinum group metals present unique challenges due to their high melting points and reflectivity. Platinum (1,768°C melting point) and palladium (1,555°C) demand higher energy density settings compared to gold (1,064°C) or silver (961°C). The reflective properties of these metals necessitate specialized laser wavelengths to achieve optimal energy absorption and prevent beam deflection.

Metallurgical considerations extend to microstructural changes occurring during the rapid heating and cooling cycles characteristic of laser welding. The heat-affected zone (HAZ) typically experiences grain growth and potential phase transformations that can compromise mechanical properties if not properly controlled. In fine jewelry applications, minimizing the HAZ is essential for maintaining structural integrity and aesthetic qualities, particularly in pieces containing gemstones or intricate design elements.

Dissimilar metal joining represents another significant challenge in jewelry manufacturing. When welding gold to platinum or silver to white gold, intermetallic compounds may form at the interface, potentially leading to brittle joints susceptible to failure. Controlled energy input and precise positioning of the laser focal point become crucial to manage these metallurgical reactions and ensure strong, durable bonds.

Gemstone compatibility must also be considered when laser welding jewelry components near heat-sensitive materials. Thermal conductivity differences between metals and gemstones create risk zones where heat transfer must be carefully managed. Diamonds, with their excellent thermal conductivity, dissipate heat efficiently but can be damaged if directly exposed to laser energy. Conversely, emeralds, opals, and pearls have poor heat tolerance and require greater separation from weld zones or specialized heat-sinking fixtures during processing.

Surface preparation and fit-up quality significantly impact weld integrity across all material combinations. Oxide layers, contaminants, or poor joint alignment can lead to porosity, incomplete fusion, or cracking. Modern jewelry manufacturing protocols typically include rigorous cleaning procedures and precision fixturing to optimize material compatibility and ensure consistent metallurgical outcomes in laser-welded jewelry components.

Platinum group metals present unique challenges due to their high melting points and reflectivity. Platinum (1,768°C melting point) and palladium (1,555°C) demand higher energy density settings compared to gold (1,064°C) or silver (961°C). The reflective properties of these metals necessitate specialized laser wavelengths to achieve optimal energy absorption and prevent beam deflection.

Metallurgical considerations extend to microstructural changes occurring during the rapid heating and cooling cycles characteristic of laser welding. The heat-affected zone (HAZ) typically experiences grain growth and potential phase transformations that can compromise mechanical properties if not properly controlled. In fine jewelry applications, minimizing the HAZ is essential for maintaining structural integrity and aesthetic qualities, particularly in pieces containing gemstones or intricate design elements.

Dissimilar metal joining represents another significant challenge in jewelry manufacturing. When welding gold to platinum or silver to white gold, intermetallic compounds may form at the interface, potentially leading to brittle joints susceptible to failure. Controlled energy input and precise positioning of the laser focal point become crucial to manage these metallurgical reactions and ensure strong, durable bonds.

Gemstone compatibility must also be considered when laser welding jewelry components near heat-sensitive materials. Thermal conductivity differences between metals and gemstones create risk zones where heat transfer must be carefully managed. Diamonds, with their excellent thermal conductivity, dissipate heat efficiently but can be damaged if directly exposed to laser energy. Conversely, emeralds, opals, and pearls have poor heat tolerance and require greater separation from weld zones or specialized heat-sinking fixtures during processing.

Surface preparation and fit-up quality significantly impact weld integrity across all material combinations. Oxide layers, contaminants, or poor joint alignment can lead to porosity, incomplete fusion, or cracking. Modern jewelry manufacturing protocols typically include rigorous cleaning procedures and precision fixturing to optimize material compatibility and ensure consistent metallurgical outcomes in laser-welded jewelry components.

Quality Control and Certification Standards

Quality control in laser welding for jewelry production represents a critical component that ensures both the aesthetic appeal and structural integrity of finished pieces. The jewelry industry has established comprehensive certification standards that manufacturers must adhere to, particularly when implementing advanced technologies like laser welding. These standards typically encompass weld strength requirements, visual inspection criteria, and metallurgical compatibility assessments that vary based on the precious metals being joined.

The most widely recognized quality control framework comes from organizations such as the International Organization for Standardization (ISO), which has developed specific guidelines for jewelry manufacturing processes including ISO 11426 and ISO 11494 that address aspects of metal purity and joining techniques. Additionally, the World Jewellery Confederation (CIBJO) provides standards that specifically address laser welding quality expectations in fine jewelry production.

Implementation of these standards requires sophisticated testing methodologies. Non-destructive testing (NDT) techniques have become increasingly important, with ultrasonic testing and X-ray inspection allowing manufacturers to verify weld integrity without damaging valuable pieces. These methods can detect microscopic flaws such as micro-cracks, porosity, or incomplete fusion that might compromise the durability of the jewelry item.

Certification processes typically involve both in-process quality control and final product verification. During production, parameters such as laser power, pulse duration, spot size, and welding speed must be continuously monitored and documented. Many high-end jewelry manufacturers have implemented automated monitoring systems that record these parameters for each weld, creating a quality assurance trail that can be referenced for certification purposes.

The hallmarking system represents another critical aspect of quality certification in laser-welded jewelry. Countries have established specific requirements for hallmarking laser-welded pieces, ensuring that the welding process has not compromised the declared metal content or purity. In the European Union, for instance, the Convention on the Control and Marking of Articles of Precious Metals (known as the Hallmarking Convention) provides specific guidelines for testing and marking jewelry that has undergone joining processes including laser welding.

Training and certification of technicians who perform laser welding operations constitutes another dimension of quality control. Organizations like the Laser Institute of America (LIA) offer specialized certification programs for jewelry laser welding operators, ensuring that personnel possess the necessary skills to maintain quality standards. These certifications typically require both theoretical knowledge and practical demonstration of welding techniques specific to jewelry applications.

The most widely recognized quality control framework comes from organizations such as the International Organization for Standardization (ISO), which has developed specific guidelines for jewelry manufacturing processes including ISO 11426 and ISO 11494 that address aspects of metal purity and joining techniques. Additionally, the World Jewellery Confederation (CIBJO) provides standards that specifically address laser welding quality expectations in fine jewelry production.

Implementation of these standards requires sophisticated testing methodologies. Non-destructive testing (NDT) techniques have become increasingly important, with ultrasonic testing and X-ray inspection allowing manufacturers to verify weld integrity without damaging valuable pieces. These methods can detect microscopic flaws such as micro-cracks, porosity, or incomplete fusion that might compromise the durability of the jewelry item.

Certification processes typically involve both in-process quality control and final product verification. During production, parameters such as laser power, pulse duration, spot size, and welding speed must be continuously monitored and documented. Many high-end jewelry manufacturers have implemented automated monitoring systems that record these parameters for each weld, creating a quality assurance trail that can be referenced for certification purposes.

The hallmarking system represents another critical aspect of quality certification in laser-welded jewelry. Countries have established specific requirements for hallmarking laser-welded pieces, ensuring that the welding process has not compromised the declared metal content or purity. In the European Union, for instance, the Convention on the Control and Marking of Articles of Precious Metals (known as the Hallmarking Convention) provides specific guidelines for testing and marking jewelry that has undergone joining processes including laser welding.

Training and certification of technicians who perform laser welding operations constitutes another dimension of quality control. Organizations like the Laser Institute of America (LIA) offer specialized certification programs for jewelry laser welding operators, ensuring that personnel possess the necessary skills to maintain quality standards. These certifications typically require both theoretical knowledge and practical demonstration of welding techniques specific to jewelry applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!