How to Create a Seamless Finish in Laser Welding

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Technology Background and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from a niche industrial process to a mainstream manufacturing technique. The development trajectory has been characterized by continuous improvements in laser sources, from early CO2 and Nd:YAG lasers to modern fiber, disk, and diode lasers, each offering enhanced efficiency, precision, and control. This evolution has enabled increasingly sophisticated applications across automotive, aerospace, electronics, and medical device manufacturing sectors.

The pursuit of seamless finishes in laser welding represents a critical advancement in this technological progression. Traditionally, laser welding processes often resulted in visible seams, surface irregularities, and potential structural weaknesses at weld joints. These imperfections not only compromised aesthetic quality but also affected functional performance, particularly in high-stress applications or components requiring hermetic sealing.

Current technological trends in laser welding focus on achieving higher precision, greater process stability, and improved surface quality. Advanced beam shaping techniques, pulse modulation strategies, and hybrid welding approaches are emerging as promising methods for creating seamless finishes. Simultaneously, the integration of real-time monitoring systems and adaptive control algorithms is enabling more responsive and consistent welding processes.

The global push toward lightweight construction in transportation industries and miniaturization in electronics has intensified the demand for high-quality, seamless welds. These market drivers have accelerated research into novel laser welding techniques that can join dissimilar materials without compromising structural integrity or surface quality.

The primary technical objectives in creating seamless finishes include minimizing heat-affected zones, eliminating surface defects such as spatter and porosity, reducing post-processing requirements, and ensuring consistent mechanical properties across the weld joint. Additionally, there is growing emphasis on developing processes that maintain material properties while achieving aesthetic perfection.

Looking forward, the technology roadmap for seamless laser welding includes further refinement of beam control technologies, development of specialized filler materials, integration of machine learning for process optimization, and advancement of in-situ quality assurance methods. These developments aim to address current limitations while expanding the application scope of laser welding to more challenging material combinations and complex geometries.

The achievement of truly seamless finishes in laser welding represents not merely an aesthetic improvement but a fundamental enhancement in joining technology that promises to unlock new design possibilities and performance standards across multiple industries.

The pursuit of seamless finishes in laser welding represents a critical advancement in this technological progression. Traditionally, laser welding processes often resulted in visible seams, surface irregularities, and potential structural weaknesses at weld joints. These imperfections not only compromised aesthetic quality but also affected functional performance, particularly in high-stress applications or components requiring hermetic sealing.

Current technological trends in laser welding focus on achieving higher precision, greater process stability, and improved surface quality. Advanced beam shaping techniques, pulse modulation strategies, and hybrid welding approaches are emerging as promising methods for creating seamless finishes. Simultaneously, the integration of real-time monitoring systems and adaptive control algorithms is enabling more responsive and consistent welding processes.

The global push toward lightweight construction in transportation industries and miniaturization in electronics has intensified the demand for high-quality, seamless welds. These market drivers have accelerated research into novel laser welding techniques that can join dissimilar materials without compromising structural integrity or surface quality.

The primary technical objectives in creating seamless finishes include minimizing heat-affected zones, eliminating surface defects such as spatter and porosity, reducing post-processing requirements, and ensuring consistent mechanical properties across the weld joint. Additionally, there is growing emphasis on developing processes that maintain material properties while achieving aesthetic perfection.

Looking forward, the technology roadmap for seamless laser welding includes further refinement of beam control technologies, development of specialized filler materials, integration of machine learning for process optimization, and advancement of in-situ quality assurance methods. These developments aim to address current limitations while expanding the application scope of laser welding to more challenging material combinations and complex geometries.

The achievement of truly seamless finishes in laser welding represents not merely an aesthetic improvement but a fundamental enhancement in joining technology that promises to unlock new design possibilities and performance standards across multiple industries.

Market Demand for Seamless Welding Solutions

The global market for seamless welding solutions has experienced significant growth in recent years, driven primarily by increasing demands across automotive, aerospace, electronics, and medical device manufacturing sectors. The pursuit of perfect welds without visible seams or post-processing requirements has become a critical competitive advantage for manufacturers seeking to enhance product quality while reducing production costs.

In the automotive industry, the transition toward electric vehicles has intensified the need for high-precision welding solutions. Battery enclosures, motor components, and lightweight structural elements require welds that maintain both aesthetic appeal and structural integrity. Market research indicates that automotive manufacturers are willing to invest substantially in advanced laser welding technologies that can deliver seamless finishes, as these directly translate to higher perceived quality and customer satisfaction.

The aerospace sector presents another substantial market opportunity, with stringent requirements for weld quality and reliability. Components used in aircraft construction must meet exacting standards, where even minor imperfections can lead to catastrophic failures. The demand for seamless laser welding solutions in this sector is projected to grow steadily as manufacturers seek to improve safety margins while reducing weight through more precise joining technologies.

Consumer electronics manufacturers have emerged as significant adopters of seamless welding technologies, particularly for premium product lines where visible seams detract from perceived value. The miniaturization trend in electronics has further accelerated demand for precision welding capabilities that can join increasingly smaller components without visible seams or thermal damage to sensitive parts.

Medical device manufacturing represents one of the fastest-growing market segments for seamless welding solutions. The production of implantable devices, surgical instruments, and diagnostic equipment requires welds that not only appear flawless but also maintain biocompatibility and sterility. This sector's regulatory requirements create substantial barriers to entry but also ensure premium pricing for qualified welding solutions.

From a geographical perspective, developed markets in North America, Europe, and East Asia currently dominate demand for advanced welding technologies. However, emerging manufacturing hubs in Southeast Asia and Eastern Europe are showing accelerated adoption rates as they compete for high-value manufacturing contracts that require superior finish quality.

Cost considerations remain significant market drivers, with manufacturers increasingly evaluating the total cost of ownership rather than just equipment acquisition costs. Solutions that eliminate or reduce post-processing steps such as grinding, polishing, or finishing treatments demonstrate compelling return on investment despite higher initial implementation costs.

In the automotive industry, the transition toward electric vehicles has intensified the need for high-precision welding solutions. Battery enclosures, motor components, and lightweight structural elements require welds that maintain both aesthetic appeal and structural integrity. Market research indicates that automotive manufacturers are willing to invest substantially in advanced laser welding technologies that can deliver seamless finishes, as these directly translate to higher perceived quality and customer satisfaction.

The aerospace sector presents another substantial market opportunity, with stringent requirements for weld quality and reliability. Components used in aircraft construction must meet exacting standards, where even minor imperfections can lead to catastrophic failures. The demand for seamless laser welding solutions in this sector is projected to grow steadily as manufacturers seek to improve safety margins while reducing weight through more precise joining technologies.

Consumer electronics manufacturers have emerged as significant adopters of seamless welding technologies, particularly for premium product lines where visible seams detract from perceived value. The miniaturization trend in electronics has further accelerated demand for precision welding capabilities that can join increasingly smaller components without visible seams or thermal damage to sensitive parts.

Medical device manufacturing represents one of the fastest-growing market segments for seamless welding solutions. The production of implantable devices, surgical instruments, and diagnostic equipment requires welds that not only appear flawless but also maintain biocompatibility and sterility. This sector's regulatory requirements create substantial barriers to entry but also ensure premium pricing for qualified welding solutions.

From a geographical perspective, developed markets in North America, Europe, and East Asia currently dominate demand for advanced welding technologies. However, emerging manufacturing hubs in Southeast Asia and Eastern Europe are showing accelerated adoption rates as they compete for high-value manufacturing contracts that require superior finish quality.

Cost considerations remain significant market drivers, with manufacturers increasingly evaluating the total cost of ownership rather than just equipment acquisition costs. Solutions that eliminate or reduce post-processing steps such as grinding, polishing, or finishing treatments demonstrate compelling return on investment despite higher initial implementation costs.

Current Challenges in Laser Welding Finish Quality

Despite significant advancements in laser welding technology, achieving a truly seamless finish remains one of the most persistent challenges in industrial applications. Surface imperfections such as porosity, cracking, and uneven weld beads continue to plague manufacturers across automotive, aerospace, and medical device industries. These defects not only compromise aesthetic appeal but also potentially reduce structural integrity and functional performance of welded components.

The primary technical obstacles stem from multiple interrelated factors. Thermal management issues represent a significant hurdle, as excessive heat input can lead to material distortion, while insufficient heat may result in incomplete fusion. The heat-affected zone (HAZ) often exhibits different mechanical properties compared to the base material, creating visible transition areas that disrupt visual continuity.

Material compatibility presents another major challenge, particularly when joining dissimilar metals. Differences in thermal expansion coefficients, melting points, and chemical compositions can lead to brittle intermetallic compounds formation, compromising both appearance and strength. Even with compatible materials, variations in thickness and surface conditions can produce inconsistent weld quality.

Process parameter optimization remains exceedingly complex due to the multitude of variables involved. Laser power, welding speed, focal position, shielding gas composition, and beam characteristics must be precisely calibrated for each specific application. The narrow process window for optimal results leaves little margin for error, making consistent quality difficult to maintain in production environments.

Environmental factors further complicate matters, as ambient conditions including humidity, temperature, and air quality can influence weld quality. Contamination from oxides, oils, or other surface impurities frequently leads to porosity and inclusions that disrupt the seamless appearance of welds.

Monitoring and quality control systems still lack the sophistication needed for real-time detection and correction of all potential defects. Current inspection methods often rely on post-process evaluation, making immediate adjustments impossible and increasing production costs through rework or scrap.

Equipment limitations also contribute to finish quality issues. Beam stability, focus consistency, and motion control precision all affect weld uniformity. Even state-of-the-art systems experience drift over time, requiring frequent calibration to maintain optimal performance.

The industry's increasing demand for miniaturization and complex geometries further exacerbates these challenges, as smaller, more intricate components leave less room for error and require even greater precision in the welding process.

The primary technical obstacles stem from multiple interrelated factors. Thermal management issues represent a significant hurdle, as excessive heat input can lead to material distortion, while insufficient heat may result in incomplete fusion. The heat-affected zone (HAZ) often exhibits different mechanical properties compared to the base material, creating visible transition areas that disrupt visual continuity.

Material compatibility presents another major challenge, particularly when joining dissimilar metals. Differences in thermal expansion coefficients, melting points, and chemical compositions can lead to brittle intermetallic compounds formation, compromising both appearance and strength. Even with compatible materials, variations in thickness and surface conditions can produce inconsistent weld quality.

Process parameter optimization remains exceedingly complex due to the multitude of variables involved. Laser power, welding speed, focal position, shielding gas composition, and beam characteristics must be precisely calibrated for each specific application. The narrow process window for optimal results leaves little margin for error, making consistent quality difficult to maintain in production environments.

Environmental factors further complicate matters, as ambient conditions including humidity, temperature, and air quality can influence weld quality. Contamination from oxides, oils, or other surface impurities frequently leads to porosity and inclusions that disrupt the seamless appearance of welds.

Monitoring and quality control systems still lack the sophistication needed for real-time detection and correction of all potential defects. Current inspection methods often rely on post-process evaluation, making immediate adjustments impossible and increasing production costs through rework or scrap.

Equipment limitations also contribute to finish quality issues. Beam stability, focus consistency, and motion control precision all affect weld uniformity. Even state-of-the-art systems experience drift over time, requiring frequent calibration to maintain optimal performance.

The industry's increasing demand for miniaturization and complex geometries further exacerbates these challenges, as smaller, more intricate components leave less room for error and require even greater precision in the welding process.

Existing Seamless Finish Methodologies

01 Laser welding techniques for seamless joints

Advanced laser welding methods that create seamless joints with minimal visible seams. These techniques focus on precise control of laser parameters to achieve high-quality welds that require little to no post-processing. The welding process is optimized to create smooth transitions between joined materials, resulting in aesthetically pleasing finishes that appear seamless to the naked eye.- Laser welding techniques for seamless joints: Advanced laser welding methods that create joints with minimal or no visible seams. These techniques focus on precise control of laser parameters to achieve smooth transitions between welded parts. The process typically involves optimized beam focusing, power modulation, and controlled heat input to minimize distortion and create aesthetically pleasing connections that require little to no post-processing.

- Surface finishing methods for laser-welded joints: Post-welding treatments and processes specifically designed to enhance the appearance of laser-welded seams. These methods include polishing, grinding, heat treatment, and chemical processing to remove any visible weld lines or surface irregularities. The goal is to achieve a uniform surface texture and appearance that makes the welded joint indistinguishable from the surrounding material.

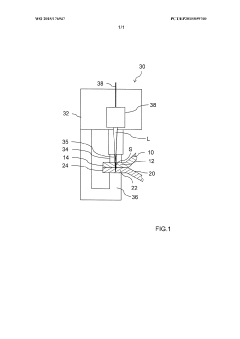

- Specialized laser welding equipment for seamless finishes: Custom-designed laser welding systems and components specifically engineered to produce seamless connections. These include specialized laser heads, beam delivery systems, and monitoring equipment that enable precise control over the welding process. The equipment often incorporates advanced features such as real-time feedback control, automated seam tracking, and integrated cooling systems to maintain consistent weld quality and appearance.

- Material-specific laser welding approaches for seamless results: Tailored laser welding techniques developed for specific materials to achieve invisible joints. These approaches consider the unique properties of different metals, alloys, and composites to determine optimal welding parameters. By accounting for factors such as thermal conductivity, melting point, and surface reflectivity, these methods produce welds with minimal distortion and excellent surface finish that blend seamlessly with the base material.

- Innovative joint designs for seamless laser welding: Novel joint configurations and preparation techniques that facilitate the creation of seamless welds. These designs focus on optimizing the interface between components to minimize gaps, ensure proper alignment, and reduce the visibility of the final weld. Approaches include specialized edge preparations, overlapping joints, and complementary geometries that, when combined with appropriate laser welding parameters, result in connections that appear continuous and uninterrupted.

02 Surface finishing methods for laser-welded joints

Post-welding surface treatment techniques specifically designed to enhance the appearance of laser-welded joints. These methods include polishing, grinding, and other finishing processes that remove any visible weld lines or imperfections. The goal is to create a uniform surface texture and appearance that makes the welded area indistinguishable from the surrounding material.Expand Specific Solutions03 Specialized laser welding equipment for seamless finishes

Custom-designed laser welding equipment and systems specifically engineered to produce seamless finishes. These systems incorporate advanced optics, precise positioning mechanisms, and specialized beam shaping technologies to achieve optimal weld quality. The equipment often includes integrated monitoring and control systems to ensure consistent results across various materials and geometries.Expand Specific Solutions04 Material-specific laser welding parameters for seamless results

Optimized laser welding parameters tailored to specific materials to achieve seamless finishes. These parameters include laser power, pulse duration, beam profile, and welding speed adjustments based on the thermal and mechanical properties of the materials being joined. The focus is on minimizing heat-affected zones and preventing distortion or discoloration that would compromise the seamless appearance.Expand Specific Solutions05 Automated inspection and quality control for seamless welds

Automated systems for inspecting and ensuring the quality of seamless laser welds. These systems employ various technologies such as machine vision, sensors, and artificial intelligence to detect imperfections that might affect the seamless appearance of the weld. Real-time monitoring during the welding process allows for immediate adjustments to maintain consistent quality and achieve truly seamless finishes.Expand Specific Solutions

Key Industry Players and Equipment Manufacturers

Laser welding technology for seamless finishes is currently in a mature growth phase, with the global market expected to reach $3.5 billion by 2025. The competitive landscape features established industrial leaders like TRUMPF Laser GmbH and IPG Photonics dominating high-precision applications, while automotive manufacturers including Audi, BMW, Toyota, and Nissan have integrated advanced laser welding into production lines. Fraunhofer-Gesellschaft leads research innovation, developing technologies that address common challenges in achieving seamless finishes. The technology has reached commercial maturity in automotive and manufacturing sectors, with companies like Bosch and Baosteel Tailored Blanks implementing specialized solutions for tailored blanks and precision components, demonstrating the technology's evolution from experimental to essential manufacturing process.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed comprehensive laser welding solutions focused on achieving seamless finishes through their advanced beam oscillation technology. Their researchers have pioneered high-frequency beam oscillation techniques that significantly improve weld pool stability and solidification characteristics. This approach enables precise control over the melt pool dynamics, reducing surface tension irregularities that typically cause weld bead unevenness[7]. Fraunhofer's dual-beam technology employs a leading beam for pre-heating and a trailing beam for controlled cooling, effectively eliminating micro-cracks and surface imperfections. Their process monitoring systems integrate multiple sensor technologies including high-speed thermal imaging, spectroscopy, and acoustic monitoring to detect and respond to process variations in real-time. For particularly challenging materials like zinc-coated steels, Fraunhofer has developed specialized venting techniques that allow zinc vapors to escape without disrupting the weld pool, resulting in smooth, pore-free welds. Their researchers have also created adaptive control algorithms that automatically adjust laser parameters based on material variations, joint geometry changes, and thermal conditions throughout the welding process[8].

Strengths: Cutting-edge research-based solutions addressing fundamental process physics; comprehensive sensor integration for quality assurance; adaptability to wide range of materials including challenging alloys. Weaknesses: Some technologies remain at research/prototype stage rather than full commercial deployment; solutions may require significant customization for specific industrial applications; higher implementation complexity compared to turnkey systems.

TRUMPF Laser GmbH + Co. KG

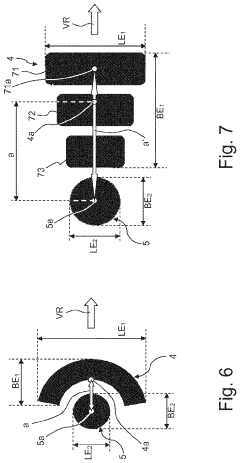

Technical Solution: TRUMPF has developed advanced laser welding solutions focused on creating seamless finishes through their BrightLine Weld technology. This approach utilizes beam splitting and combination techniques that precisely control energy distribution during the welding process. Their system employs a dual-core laser beam with an inner core for deep penetration and an outer ring for stabilizing the weld pool and controlling spatter[1]. TRUMPF's PFO (Programmable Focusing Optics) technology enables on-the-fly adjustment of focal position and spot size, critical for maintaining consistent weld quality across varying material thicknesses. Their seam tracking systems use real-time optical monitoring to detect and compensate for gaps or misalignments, ensuring seamless welds even with workpiece variations[3]. For particularly challenging materials like aluminum, TRUMPF has developed specialized oscillation welding techniques that reduce porosity and improve surface finish quality.

Strengths: Superior beam quality control allowing precise energy distribution; integrated process monitoring capabilities that ensure consistent weld quality; versatility across different materials including challenging ones like aluminum and copper. Weaknesses: Higher initial investment costs compared to conventional welding systems; requires specialized operator training; some solutions may be over-engineered for simpler applications.

Critical Patents and Innovations in Weld Seam Control

Method for joining components using laser welding

PatentWO2015176947A1

Innovation

- A laser welding method that applies defined contact pressure to the components using a laser welding device with a contact pressure device, forming a seamless weld with reduced waviness and allowing for a narrower flange width, which can be integrated into existing systems with low investment costs.

Method for splash-free welding, in particular using a solid-state laser

PatentActiveUS11786989B2

Innovation

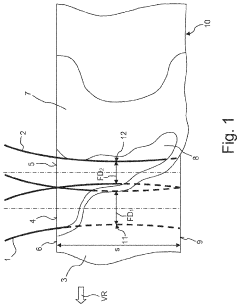

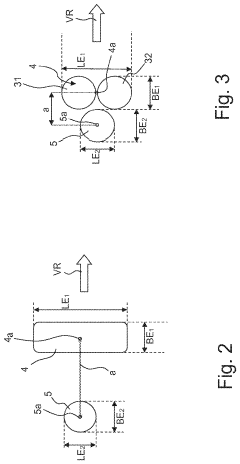

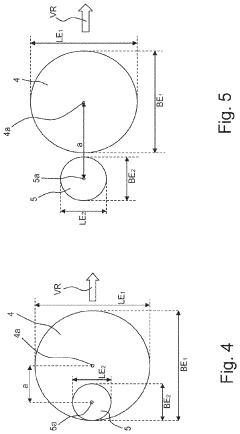

- A method involving the use of a first beam area generated by a first laser beam and a second beam area generated by a second laser beam, where the centroids do not coincide, with the first beam area running ahead and having a greater length, width, and surface area than the second beam area, and the second laser beam is irradiated into the weld pool formed by the first beam, allowing for low energy input and minimized spatter formation on the bottom side.

Material Compatibility and Selection Strategies

Material compatibility represents a critical factor in achieving seamless laser welding finishes. The selection of appropriate materials directly impacts weld quality, appearance, and structural integrity. When pairing materials for laser welding, their thermal conductivity, melting points, and coefficient of thermal expansion must be carefully evaluated. Materials with similar properties generally produce more consistent and aesthetically pleasing welds, while dissimilar materials often require specialized techniques to overcome inherent challenges.

For optimal results, materials should be categorized based on their laser weldability characteristics. Class A materials (including most stainless steels, nickel alloys, and titanium) demonstrate excellent laser weldability with minimal post-processing required. Class B materials (such as aluminum alloys and certain copper alloys) can achieve good results but may require specific parameter optimization. Class C materials (including highly reflective metals and certain dissimilar metal combinations) present significant challenges and often require advanced techniques to achieve seamless finishes.

Surface preparation plays a crucial role in material compatibility. Even compatible materials can produce suboptimal welds if surface contaminants, oxides, or coatings are present. Standard preparation protocols include chemical cleaning, mechanical abrasion, and in some cases, specialized coatings to enhance laser absorption and weld quality. For high-precision applications, vacuum or inert gas environments may be necessary to prevent oxidation during the welding process.

The thickness ratio between joined materials significantly impacts seamless finish achievement. Research indicates that maintaining a thickness ratio below 3:1 generally produces more consistent results. When this ratio cannot be maintained, stepped joint designs or variable power distribution techniques can compensate for the thermal imbalance, ensuring more uniform melting and solidification patterns.

Alloy composition must be carefully considered, particularly regarding elements that may cause brittleness, porosity, or cracking. Elements like sulfur, phosphorus, lead, and zinc can vaporize during welding, creating defects that compromise both appearance and strength. Modern material selection strategies often incorporate computational modeling to predict material behavior during laser welding, allowing for proactive adjustments to parameters or material selection before physical testing begins.

For industries requiring exceptional aesthetic quality, such as medical device manufacturing or luxury goods production, specialized material grades with controlled impurity levels and consistent composition are increasingly available. These premium materials command higher prices but significantly reduce the variability in weld appearance and quality, making them cost-effective for applications where seamless finishes are paramount.

For optimal results, materials should be categorized based on their laser weldability characteristics. Class A materials (including most stainless steels, nickel alloys, and titanium) demonstrate excellent laser weldability with minimal post-processing required. Class B materials (such as aluminum alloys and certain copper alloys) can achieve good results but may require specific parameter optimization. Class C materials (including highly reflective metals and certain dissimilar metal combinations) present significant challenges and often require advanced techniques to achieve seamless finishes.

Surface preparation plays a crucial role in material compatibility. Even compatible materials can produce suboptimal welds if surface contaminants, oxides, or coatings are present. Standard preparation protocols include chemical cleaning, mechanical abrasion, and in some cases, specialized coatings to enhance laser absorption and weld quality. For high-precision applications, vacuum or inert gas environments may be necessary to prevent oxidation during the welding process.

The thickness ratio between joined materials significantly impacts seamless finish achievement. Research indicates that maintaining a thickness ratio below 3:1 generally produces more consistent results. When this ratio cannot be maintained, stepped joint designs or variable power distribution techniques can compensate for the thermal imbalance, ensuring more uniform melting and solidification patterns.

Alloy composition must be carefully considered, particularly regarding elements that may cause brittleness, porosity, or cracking. Elements like sulfur, phosphorus, lead, and zinc can vaporize during welding, creating defects that compromise both appearance and strength. Modern material selection strategies often incorporate computational modeling to predict material behavior during laser welding, allowing for proactive adjustments to parameters or material selection before physical testing begins.

For industries requiring exceptional aesthetic quality, such as medical device manufacturing or luxury goods production, specialized material grades with controlled impurity levels and consistent composition are increasingly available. These premium materials command higher prices but significantly reduce the variability in weld appearance and quality, making them cost-effective for applications where seamless finishes are paramount.

Quality Assurance and Inspection Technologies

Quality assurance in laser welding has evolved significantly with the integration of advanced inspection technologies that enable real-time monitoring and post-weld verification of seamless finishes. Traditional methods such as visual inspection and destructive testing are increasingly being supplemented or replaced by sophisticated non-destructive testing (NDT) techniques specifically adapted for laser welding applications.

Optical monitoring systems represent a cornerstone of modern quality assurance in laser welding. These systems utilize high-speed cameras and specialized sensors to capture the welding process in real-time, detecting anomalies such as porosity, cracks, or inconsistent weld penetration that would compromise the seamless finish. Advanced image processing algorithms can analyze the melt pool dynamics and thermal signatures, providing immediate feedback for process adjustment.

Spectroscopic analysis has emerged as another critical inspection technology, allowing for the monitoring of plasma emissions during the welding process. By analyzing the spectral characteristics of the plasma plume, these systems can detect variations in material composition and identify potential contaminants that might affect weld quality and appearance.

Ultrasonic testing has been refined for laser welding applications, offering high-resolution imaging of internal weld structures without damaging the workpiece. Phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) techniques provide detailed information about weld integrity, helping to ensure that the internal structure supports the seamless external appearance.

X-ray and computed tomography (CT) scanning technologies have become more accessible for industrial applications, enabling comprehensive volumetric inspection of welded joints. These methods can detect subsurface defects that might eventually compromise the weld's integrity or appearance, even when the surface finish appears seamless to the naked eye.

Machine learning and artificial intelligence are revolutionizing quality assurance by enabling predictive defect identification. These systems can learn from historical data to recognize patterns associated with defect formation, allowing for preemptive adjustments to welding parameters before quality issues manifest in the finished product.

Digital twin technology represents the cutting edge of quality assurance, creating virtual replicas of the welding process that can simulate outcomes based on input parameters. This allows for optimization of welding conditions to achieve seamless finishes without extensive physical testing, significantly reducing development time and material waste.

Standardization efforts in quality assurance protocols specifically for laser welding have led to the development of industry-specific metrics and acceptance criteria for what constitutes a truly seamless finish, ensuring consistency across different manufacturing environments and applications.

Optical monitoring systems represent a cornerstone of modern quality assurance in laser welding. These systems utilize high-speed cameras and specialized sensors to capture the welding process in real-time, detecting anomalies such as porosity, cracks, or inconsistent weld penetration that would compromise the seamless finish. Advanced image processing algorithms can analyze the melt pool dynamics and thermal signatures, providing immediate feedback for process adjustment.

Spectroscopic analysis has emerged as another critical inspection technology, allowing for the monitoring of plasma emissions during the welding process. By analyzing the spectral characteristics of the plasma plume, these systems can detect variations in material composition and identify potential contaminants that might affect weld quality and appearance.

Ultrasonic testing has been refined for laser welding applications, offering high-resolution imaging of internal weld structures without damaging the workpiece. Phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) techniques provide detailed information about weld integrity, helping to ensure that the internal structure supports the seamless external appearance.

X-ray and computed tomography (CT) scanning technologies have become more accessible for industrial applications, enabling comprehensive volumetric inspection of welded joints. These methods can detect subsurface defects that might eventually compromise the weld's integrity or appearance, even when the surface finish appears seamless to the naked eye.

Machine learning and artificial intelligence are revolutionizing quality assurance by enabling predictive defect identification. These systems can learn from historical data to recognize patterns associated with defect formation, allowing for preemptive adjustments to welding parameters before quality issues manifest in the finished product.

Digital twin technology represents the cutting edge of quality assurance, creating virtual replicas of the welding process that can simulate outcomes based on input parameters. This allows for optimization of welding conditions to achieve seamless finishes without extensive physical testing, significantly reducing development time and material waste.

Standardization efforts in quality assurance protocols specifically for laser welding have led to the development of industry-specific metrics and acceptance criteria for what constitutes a truly seamless finish, ensuring consistency across different manufacturing environments and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!