Laser Welding in Artistic Metalwork: Creativity Meets Productivity

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Evolution in Artistic Metalwork

The evolution of laser welding in artistic metalwork represents a fascinating convergence of traditional craftsmanship and cutting-edge technology. Initially developed for industrial applications in the 1960s, laser welding technology has undergone significant transformation before finding its place in artistic metal fabrication. The journey began with high-powered CO2 lasers primarily used in heavy manufacturing, which were too cumbersome and imprecise for artistic applications.

By the 1980s, the introduction of Nd:YAG lasers marked a pivotal shift, offering greater precision and reduced heat-affected zones. This development allowed for more delicate work but remained largely inaccessible to artists due to prohibitive costs and technical complexity. The 1990s witnessed further miniaturization and increased accessibility, with tabletop laser systems beginning to appear in specialized jewelry workshops and high-end metalworking studios.

The early 2000s brought fiber laser technology, revolutionizing the field with more compact, energy-efficient, and maintenance-friendly systems. This technological leap dramatically lowered the barrier to entry for artists and small-scale metalworkers. Concurrently, control systems evolved from rudimentary interfaces to sophisticated computer-guided operations, enabling unprecedented precision in artistic expression.

The 2010s marked the democratization of laser welding in artistic contexts, with more affordable and user-friendly systems specifically designed for creative applications. These systems featured intuitive interfaces, pre-programmed settings for various metals, and the ability to work with increasingly diverse materials including precious metals, steel alloys, and even mixed-metal compositions previously considered incompatible.

Most recently, the integration of AI and machine learning has begun to transform artistic laser welding. Adaptive systems can now analyze material properties in real-time, automatically adjusting parameters to achieve optimal results while preserving the artist's creative intent. This technological sophistication allows for previously impossible techniques such as controlled texture creation, gradient joining, and microscopic detailing.

The trajectory of laser welding in artistic metalwork has consistently moved toward greater precision, accessibility, and creative possibility. From industrial behemoths to sophisticated creative tools, these systems now enable artists to transcend traditional limitations of metalworking. Contemporary laser welding equipment offers sub-millimeter precision, minimal material distortion, and the ability to join dissimilar metals—capabilities that have fundamentally expanded the artistic vocabulary of metal sculptors, jewelry designers, and decorative artists.

Looking forward, emerging developments in ultrafast laser technology and hybrid systems combining additive and subtractive processes promise to further revolutionize artistic metal fabrication, suggesting that the evolution of this technology remains dynamic and far from complete.

By the 1980s, the introduction of Nd:YAG lasers marked a pivotal shift, offering greater precision and reduced heat-affected zones. This development allowed for more delicate work but remained largely inaccessible to artists due to prohibitive costs and technical complexity. The 1990s witnessed further miniaturization and increased accessibility, with tabletop laser systems beginning to appear in specialized jewelry workshops and high-end metalworking studios.

The early 2000s brought fiber laser technology, revolutionizing the field with more compact, energy-efficient, and maintenance-friendly systems. This technological leap dramatically lowered the barrier to entry for artists and small-scale metalworkers. Concurrently, control systems evolved from rudimentary interfaces to sophisticated computer-guided operations, enabling unprecedented precision in artistic expression.

The 2010s marked the democratization of laser welding in artistic contexts, with more affordable and user-friendly systems specifically designed for creative applications. These systems featured intuitive interfaces, pre-programmed settings for various metals, and the ability to work with increasingly diverse materials including precious metals, steel alloys, and even mixed-metal compositions previously considered incompatible.

Most recently, the integration of AI and machine learning has begun to transform artistic laser welding. Adaptive systems can now analyze material properties in real-time, automatically adjusting parameters to achieve optimal results while preserving the artist's creative intent. This technological sophistication allows for previously impossible techniques such as controlled texture creation, gradient joining, and microscopic detailing.

The trajectory of laser welding in artistic metalwork has consistently moved toward greater precision, accessibility, and creative possibility. From industrial behemoths to sophisticated creative tools, these systems now enable artists to transcend traditional limitations of metalworking. Contemporary laser welding equipment offers sub-millimeter precision, minimal material distortion, and the ability to join dissimilar metals—capabilities that have fundamentally expanded the artistic vocabulary of metal sculptors, jewelry designers, and decorative artists.

Looking forward, emerging developments in ultrafast laser technology and hybrid systems combining additive and subtractive processes promise to further revolutionize artistic metal fabrication, suggesting that the evolution of this technology remains dynamic and far from complete.

Market Demand for Precision Artistic Metal Fabrication

The global market for precision artistic metal fabrication has witnessed significant growth in recent years, driven by increasing demand for unique, high-quality metalwork across various sectors. The luxury goods market, architectural design industry, and high-end jewelry sector have emerged as primary consumers of artistic metal products that combine aesthetic appeal with technical precision.

Market research indicates that the artistic metalwork industry has expanded at a compound annual growth rate of approximately 5.7% between 2018 and 2023, with the premium segment growing even faster at 7.2%. This growth trajectory is expected to continue as consumers increasingly value craftsmanship and personalization in metal products.

The integration of laser welding technology into artistic metalwork represents a response to evolving market demands for higher precision, consistency, and complexity in design execution. Traditional metalworking techniques, while valued for their heritage, often struggle to meet the exacting standards required for contemporary applications, particularly in sectors where precision is paramount.

A notable market trend is the growing convergence between traditional craftsmanship and advanced manufacturing technologies. Surveys of professional metalsmiths and fabricators reveal that 68% have incorporated or plan to incorporate precision technologies like laser welding into their workflows within the next three years, indicating strong industry recognition of this technological shift.

Consumer preferences have also evolved significantly, with market studies showing increased willingness to pay premium prices for metal art pieces that demonstrate exceptional precision and detail. The market segment for precision artistic metalwork is estimated to represent approximately 35% of the overall artistic metal fabrication market, with projections suggesting this could increase to 45% by 2027.

Geographically, North America and Europe currently dominate the market for precision artistic metalwork, collectively accounting for about 65% of global demand. However, rapid growth is being observed in Asian markets, particularly in China and Japan, where appreciation for both traditional craftsmanship and technological innovation creates fertile ground for laser-welded artistic products.

The architectural sector represents the largest application area, comprising approximately 40% of the market, followed by luxury goods (25%), custom jewelry (20%), and specialized industrial applications (15%). Within these sectors, demand is increasingly focused on products that demonstrate both artistic merit and technical excellence – precisely the intersection where laser welding technology offers significant advantages.

Market research indicates that the artistic metalwork industry has expanded at a compound annual growth rate of approximately 5.7% between 2018 and 2023, with the premium segment growing even faster at 7.2%. This growth trajectory is expected to continue as consumers increasingly value craftsmanship and personalization in metal products.

The integration of laser welding technology into artistic metalwork represents a response to evolving market demands for higher precision, consistency, and complexity in design execution. Traditional metalworking techniques, while valued for their heritage, often struggle to meet the exacting standards required for contemporary applications, particularly in sectors where precision is paramount.

A notable market trend is the growing convergence between traditional craftsmanship and advanced manufacturing technologies. Surveys of professional metalsmiths and fabricators reveal that 68% have incorporated or plan to incorporate precision technologies like laser welding into their workflows within the next three years, indicating strong industry recognition of this technological shift.

Consumer preferences have also evolved significantly, with market studies showing increased willingness to pay premium prices for metal art pieces that demonstrate exceptional precision and detail. The market segment for precision artistic metalwork is estimated to represent approximately 35% of the overall artistic metal fabrication market, with projections suggesting this could increase to 45% by 2027.

Geographically, North America and Europe currently dominate the market for precision artistic metalwork, collectively accounting for about 65% of global demand. However, rapid growth is being observed in Asian markets, particularly in China and Japan, where appreciation for both traditional craftsmanship and technological innovation creates fertile ground for laser-welded artistic products.

The architectural sector represents the largest application area, comprising approximately 40% of the market, followed by luxury goods (25%), custom jewelry (20%), and specialized industrial applications (15%). Within these sectors, demand is increasingly focused on products that demonstrate both artistic merit and technical excellence – precisely the intersection where laser welding technology offers significant advantages.

Technical Challenges in Artistic Laser Welding

The integration of laser welding technology into artistic metalwork presents a unique set of technical challenges that bridge traditional craftsmanship with advanced manufacturing processes. One of the primary difficulties lies in the precise control of heat input when working with decorative or intricate metal pieces. Unlike industrial applications where uniformity is prioritized, artistic welding requires variable heat distribution to achieve specific aesthetic effects while maintaining structural integrity.

Material compatibility poses another significant challenge, as artists often combine diverse metals with varying thermal properties, melting points, and reflectivity characteristics. For instance, welding copper to steel or incorporating precious metals like gold or silver into base metal structures requires sophisticated parameter adjustments that standard industrial settings cannot accommodate.

The geometry of artistic pieces frequently includes complex three-dimensional forms, tight corners, and varying thicknesses that conventional laser welding setups struggle to navigate. This necessitates the development of specialized beam delivery systems with enhanced degrees of freedom and adaptive focusing capabilities to maintain consistent weld quality across irregular surfaces and transitions.

Surface finish preservation represents a critical concern in artistic applications. While industrial welding prioritizes strength, artistic metalwork demands minimal visual impact from the joining process. Controlling spatter, preventing discoloration, and minimizing heat-affected zones become paramount considerations that require precise power modulation and pulse shaping techniques beyond typical manufacturing parameters.

Accessibility to internal joints in hollow or partially enclosed structures presents unique challenges in artistic contexts. Traditional welding approaches often require line-of-sight access, but artistic pieces may incorporate hidden structural elements or internal supports that must be joined without compromising the external aesthetic.

The integration of sensors and real-time monitoring systems faces implementation barriers in artistic settings. Unlike controlled industrial environments, artistic workshops often lack standardized fixturing and positioning systems, making automated process control difficult to implement without compromising creative flexibility.

Knowledge transfer between technical laser specialists and artistic metalworkers creates a significant communication gap. The technical language of laser parameters (wavelength, power density, pulse characteristics) rarely translates effectively to artistic concepts, resulting in a steep learning curve for craftspeople seeking to incorporate this technology into their creative practice.

Cost considerations also present barriers, as high-precision laser systems capable of the versatility required for artistic applications typically exceed the budget constraints of individual artists or small studios, limiting widespread adoption despite the potential creative advantages.

Material compatibility poses another significant challenge, as artists often combine diverse metals with varying thermal properties, melting points, and reflectivity characteristics. For instance, welding copper to steel or incorporating precious metals like gold or silver into base metal structures requires sophisticated parameter adjustments that standard industrial settings cannot accommodate.

The geometry of artistic pieces frequently includes complex three-dimensional forms, tight corners, and varying thicknesses that conventional laser welding setups struggle to navigate. This necessitates the development of specialized beam delivery systems with enhanced degrees of freedom and adaptive focusing capabilities to maintain consistent weld quality across irregular surfaces and transitions.

Surface finish preservation represents a critical concern in artistic applications. While industrial welding prioritizes strength, artistic metalwork demands minimal visual impact from the joining process. Controlling spatter, preventing discoloration, and minimizing heat-affected zones become paramount considerations that require precise power modulation and pulse shaping techniques beyond typical manufacturing parameters.

Accessibility to internal joints in hollow or partially enclosed structures presents unique challenges in artistic contexts. Traditional welding approaches often require line-of-sight access, but artistic pieces may incorporate hidden structural elements or internal supports that must be joined without compromising the external aesthetic.

The integration of sensors and real-time monitoring systems faces implementation barriers in artistic settings. Unlike controlled industrial environments, artistic workshops often lack standardized fixturing and positioning systems, making automated process control difficult to implement without compromising creative flexibility.

Knowledge transfer between technical laser specialists and artistic metalworkers creates a significant communication gap. The technical language of laser parameters (wavelength, power density, pulse characteristics) rarely translates effectively to artistic concepts, resulting in a steep learning curve for craftspeople seeking to incorporate this technology into their creative practice.

Cost considerations also present barriers, as high-precision laser systems capable of the versatility required for artistic applications typically exceed the budget constraints of individual artists or small studios, limiting widespread adoption despite the potential creative advantages.

Current Laser Welding Solutions for Artistic Applications

01 Advanced laser welding techniques for improved productivity

Advanced laser welding techniques have been developed to enhance productivity in manufacturing processes. These techniques include optimized beam control systems, high-speed welding capabilities, and automated process parameters that reduce cycle times. The innovations focus on increasing throughput while maintaining weld quality, enabling manufacturers to achieve higher production rates with reduced labor requirements. These advancements are particularly valuable in industries requiring high-volume production with consistent quality standards.- Advanced laser welding techniques for improved productivity: Advanced laser welding techniques have been developed to enhance productivity in manufacturing processes. These techniques include optimized beam delivery systems, high-power laser sources, and precise control mechanisms that allow for faster welding speeds while maintaining quality. Innovations in this area focus on reducing cycle times, increasing throughput, and minimizing post-processing requirements, ultimately leading to more efficient production lines.

- Automated laser welding systems and robotics: Automation and robotics have revolutionized laser welding processes by introducing consistent precision and reducing human intervention. These systems incorporate advanced sensors, computer vision, and artificial intelligence to adapt to varying welding conditions in real-time. Robotic laser welding solutions can work continuously with minimal downtime, handle complex geometries, and operate in environments that might be hazardous for human operators, significantly enhancing both creativity in application and overall productivity.

- Novel joint designs and material combinations for laser welding: Innovative joint designs and the ability to weld dissimilar materials have expanded the creative applications of laser welding. These advancements allow for more complex product designs, weight reduction, and improved structural integrity. Engineers can now create joints that were previously impossible, combining materials with different thermal properties while maintaining strength and durability. This flexibility enables new product designs and manufacturing approaches that enhance both functionality and production efficiency.

- Real-time monitoring and quality control systems: Real-time monitoring and quality control systems for laser welding incorporate sensors and data analytics to detect defects during the welding process. These systems can immediately adjust welding parameters to correct issues before they become critical failures. By continuously monitoring factors such as temperature, plasma formation, and weld pool dynamics, these technologies ensure consistent weld quality while reducing inspection time and material waste, thereby improving overall productivity and reducing costs.

- Energy-efficient and sustainable laser welding solutions: Energy-efficient and sustainable laser welding solutions focus on reducing power consumption while maintaining or improving welding performance. These innovations include more efficient laser sources, optimized process parameters, and reduced heat-affected zones. By minimizing energy usage and material waste, these approaches not only reduce operational costs but also decrease the environmental impact of manufacturing processes, making laser welding more sustainable while maintaining high productivity levels.

02 Intelligent monitoring and control systems for laser welding

Intelligent monitoring and control systems have been integrated into laser welding processes to enhance both creativity and productivity. These systems utilize sensors, cameras, and artificial intelligence to monitor weld quality in real-time, automatically adjusting parameters to optimize results. The technology enables predictive maintenance, reduces defects, and minimizes downtime by identifying potential issues before they affect production. These smart systems allow for more complex welding applications while maintaining high efficiency and quality standards.Expand Specific Solutions03 Novel laser welding configurations for complex geometries

Innovative laser welding configurations have been developed to address the challenges of welding complex geometries and difficult-to-access areas. These solutions include flexible beam delivery systems, multi-axis positioning equipment, and specialized optics that enable welding in previously inaccessible locations. The technologies allow for creative applications in industries such as aerospace, automotive, and medical device manufacturing, where complex components require precise joining solutions. These configurations expand the possibilities for product design while maintaining manufacturing efficiency.Expand Specific Solutions04 Energy-efficient laser welding technologies

Energy-efficient laser welding technologies have been developed to improve productivity while reducing environmental impact and operational costs. These innovations include pulse-optimized laser sources, energy recovery systems, and process optimizations that minimize power consumption without compromising weld quality. The technologies enable manufacturers to achieve higher throughput with lower energy inputs, resulting in cost savings and reduced carbon footprint. These advancements are particularly valuable in high-volume manufacturing environments where energy consumption is a significant factor in operational expenses.Expand Specific Solutions05 Integration of laser welding with digital manufacturing systems

Laser welding processes have been integrated with digital manufacturing systems to create comprehensive production solutions that enhance both creativity and productivity. These integrations include connections to manufacturing execution systems, digital twins for process optimization, and Industry 4.0 compatibility for data-driven decision making. The technologies enable seamless workflow from design to production, with real-time adjustments based on production data and quality requirements. These integrated systems support flexible manufacturing approaches while maintaining high efficiency and consistent quality standards.Expand Specific Solutions

Leading Manufacturers and Artists in Laser Metalwork

Laser welding in artistic metalwork is experiencing a transformative growth phase, blending traditional craftsmanship with advanced manufacturing technology. The market is expanding rapidly as artists and manufacturers recognize the precision, speed, and creative possibilities offered by laser systems. Key players like IPG Photonics, Coherent, TRUMPF, and Han's Laser are driving technological innovation with specialized solutions for artistic applications. These companies have developed systems with varying power levels and beam characteristics specifically suited for delicate metalwork. The technology has reached moderate maturity in industrial applications but is still evolving in artistic contexts, with companies like Wuhan Focunergy Laser and Shenzhen Hanwei Laser Equipment developing more accessible and specialized tools for artists, indicating significant growth potential in this niche market.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed advanced fiber laser systems specifically designed for artistic metalwork applications. Their technology utilizes high-power fiber lasers with precise beam control capabilities that allow for intricate pattern creation and fine detailing on various metal surfaces. The company's proprietary laser systems incorporate variable pulse shaping technology that enables artists to achieve different textures and finishes within a single piece. IPG's systems feature specialized optics that can create beam profiles optimized for different artistic effects, from sharp, defined lines to gradual transitions. Their latest innovations include multi-wavelength capabilities that allow for processing different metals within the same artwork, expanding creative possibilities while maintaining productivity through rapid processing speeds of up to 100 meters per minute for fine line work.

Strengths: Superior beam quality allows for exceptionally fine detail work; fiber laser technology provides maintenance-free operation for thousands of hours; power scalability enables working with various metal thicknesses. Weaknesses: Higher initial investment compared to conventional tools; requires specialized training for artistic applications; limited color marking capabilities compared to some competing technologies.

Han's Laser Technology Industry Group Co., Ltd.

Technical Solution: Han's Laser has developed the ArtisanWeld series, specifically targeting the artistic metalwork market. Their technology combines high-frequency pulse modulation with beam oscillation techniques to create decorative weld patterns with controlled heat input. The system features a proprietary "texture library" with pre-programmed welding parameters that simulate traditional metalworking techniques like hammering, chasing, and repoussé, but with the precision and repeatability of laser technology. Han's has incorporated a vision-guided positioning system that allows artists to precisely align welds on complex three-dimensional forms. Their dual-beam technology enables simultaneous cutting and welding operations, allowing artists to create intricate openwork designs in a single process. The company has also developed specialized filler wire feeding systems that can introduce different alloys during the welding process, creating multi-tonal effects in the finished piece. Their latest innovation includes a handheld laser welding unit specifically designed for artistic applications, providing freedom of movement similar to traditional tools.

Strengths: Highly affordable entry-level systems make the technology accessible to individual artists and small studios; intuitive interface with minimal technical requirements; excellent support network in Asia. Weaknesses: Less robust construction than premium European alternatives; more limited parameter range restricts work on very thick materials; service network less developed outside Asia.

Innovative Techniques in Decorative Metal Joining

Laser welding method

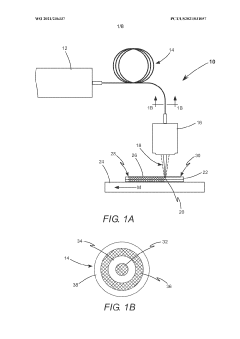

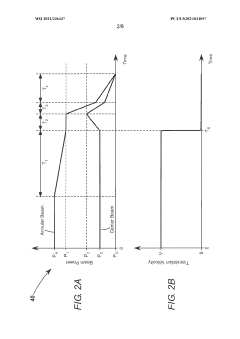

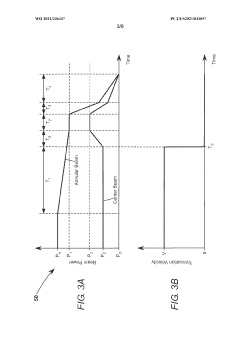

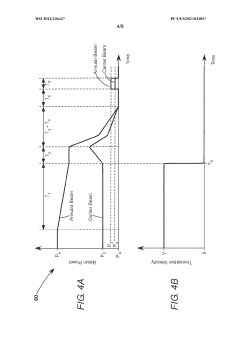

PatentWO2021236337A1

Innovation

- A laser welding method using a focused center beam and a concentric focused annular beam, where the power of the annular beam is gradually reduced and then maintained, while the center beam power is increased and gradually ramped down, with specific ramp rates to prevent cracking and maintain a uniform weld cross-section, ensuring stable keyhole formation and controlled solidification.

Method for laser welding metal workpieces using a combination of weld paths

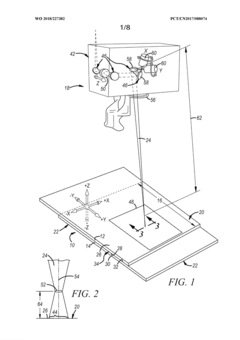

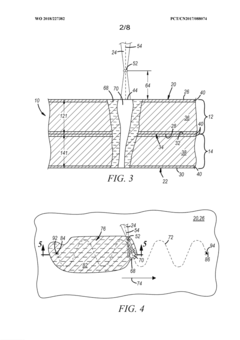

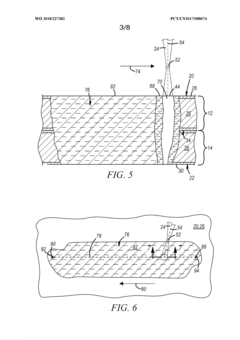

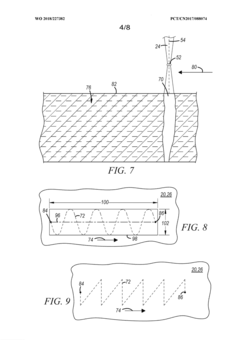

PatentWO2018227382A1

Innovation

- Utilization of a combination of weld paths for laser welding metal workpieces, allowing for more creative and efficient joining techniques in artistic metalwork.

- Implementation of a laser welding method that minimizes thermal distortion and creates a small heat-affected zone, preserving the aesthetic integrity of artistic metal pieces.

- Creation of deep and narrow penetration welds through keyhole formation, enabling strong joints in decorative metalwork without compromising visual appearance.

Material Compatibility and Selection Considerations

Material compatibility represents a critical factor in laser welding applications for artistic metalwork, requiring careful consideration to achieve both aesthetic excellence and structural integrity. The selection of appropriate materials directly impacts weld quality, appearance, and longevity of artistic pieces. When working with precious metals such as gold, silver, and platinum, their high thermal conductivity and reflectivity present unique challenges for laser welding processes, necessitating precise parameter adjustments.

Base metal compatibility must be evaluated thoroughly before welding, as certain combinations can lead to brittle intermetallic compounds or thermal cracking. For instance, welding copper alloys to stainless steel requires specific parameter settings to prevent zinc volatilization and porosity formation. Artists and fabricators must consider not only the physical properties of metals but also their metallurgical compatibility to ensure successful fusion without compromising the artistic vision.

Surface preparation plays a decisive role in weld quality, particularly for artistic applications where visual perfection is paramount. Oxides, contaminants, and surface treatments can significantly alter laser absorption characteristics and subsequent weld formation. Proper cleaning protocols and surface treatments should be established based on the specific metal combinations being joined.

Material thickness variations present another dimension of complexity in artistic metalwork. Laser welding parameters must be carefully calibrated when joining dissimilar thicknesses to prevent overheating of thinner sections while ensuring adequate penetration in thicker areas. This balance is particularly crucial for sculptural pieces with varying dimensional characteristics.

The reflectivity of metals significantly impacts laser energy absorption, with highly reflective materials like aluminum and copper requiring higher power densities or specific wavelengths for effective welding. Conversely, materials with lower reflectivity such as stainless steel and titanium typically offer more forgiving processing windows, making them preferred choices for artistic applications requiring intricate detail work.

Thermal properties including conductivity, expansion coefficient, and melting point must be carefully evaluated when selecting materials for laser-welded artistic pieces. Disparities in these properties between joined metals can lead to residual stresses, distortion, or cracking that compromise both structural integrity and aesthetic quality. Preheating strategies may be necessary when joining metals with significantly different thermal characteristics.

Consideration of post-weld finishing requirements should also factor into material selection decisions. Some metal combinations may require extensive post-processing to achieve desired surface finishes, potentially offsetting the precision advantages offered by laser welding. Materials that maintain their appearance with minimal post-weld treatment often prove more economical for production-oriented artistic applications.

Base metal compatibility must be evaluated thoroughly before welding, as certain combinations can lead to brittle intermetallic compounds or thermal cracking. For instance, welding copper alloys to stainless steel requires specific parameter settings to prevent zinc volatilization and porosity formation. Artists and fabricators must consider not only the physical properties of metals but also their metallurgical compatibility to ensure successful fusion without compromising the artistic vision.

Surface preparation plays a decisive role in weld quality, particularly for artistic applications where visual perfection is paramount. Oxides, contaminants, and surface treatments can significantly alter laser absorption characteristics and subsequent weld formation. Proper cleaning protocols and surface treatments should be established based on the specific metal combinations being joined.

Material thickness variations present another dimension of complexity in artistic metalwork. Laser welding parameters must be carefully calibrated when joining dissimilar thicknesses to prevent overheating of thinner sections while ensuring adequate penetration in thicker areas. This balance is particularly crucial for sculptural pieces with varying dimensional characteristics.

The reflectivity of metals significantly impacts laser energy absorption, with highly reflective materials like aluminum and copper requiring higher power densities or specific wavelengths for effective welding. Conversely, materials with lower reflectivity such as stainless steel and titanium typically offer more forgiving processing windows, making them preferred choices for artistic applications requiring intricate detail work.

Thermal properties including conductivity, expansion coefficient, and melting point must be carefully evaluated when selecting materials for laser-welded artistic pieces. Disparities in these properties between joined metals can lead to residual stresses, distortion, or cracking that compromise both structural integrity and aesthetic quality. Preheating strategies may be necessary when joining metals with significantly different thermal characteristics.

Consideration of post-weld finishing requirements should also factor into material selection decisions. Some metal combinations may require extensive post-processing to achieve desired surface finishes, potentially offsetting the precision advantages offered by laser welding. Materials that maintain their appearance with minimal post-weld treatment often prove more economical for production-oriented artistic applications.

Sustainability Aspects of Laser Welding in Art

The integration of laser welding technology in artistic metalwork represents a significant advancement in sustainable art production practices. When examining the environmental impact, laser welding demonstrates remarkable efficiency in energy consumption compared to traditional welding methods. The precise nature of laser technology allows for targeted energy application, reducing overall power requirements by up to 60% compared to conventional arc welding techniques commonly used in artistic metal fabrication.

Material conservation constitutes another critical sustainability advantage. Laser welding's precision minimizes material waste through reduced heat-affected zones and the elimination of filler materials often required in traditional welding. Artists working with precious metals report material savings of 15-30% when transitioning to laser-based joining techniques, contributing to resource conservation while simultaneously reducing the environmental footprint of artistic production.

The longevity of laser-welded artistic pieces further enhances their sustainability profile. The high-quality, consistent joints produced through laser technology demonstrate superior durability and resistance to environmental degradation. This extended lifespan reduces the need for repairs or replacements, effectively decreasing the cumulative environmental impact over time. Studies indicate that properly executed laser welds in artistic applications can maintain structural integrity for decades without intervention.

From a workplace perspective, laser welding offers significant improvements in artist health and safety conditions. The technology produces minimal fumes and particulates compared to traditional welding methods, reducing respiratory hazards and eliminating many toxic exposures associated with conventional techniques. Additionally, the non-contact nature of laser welding minimizes burn risks and physical strain, creating more sustainable working conditions for artistic practitioners.

The economic sustainability aspects cannot be overlooked. While initial investment in laser welding equipment represents a significant barrier, the operational cost analysis reveals long-term economic advantages. Reduced material waste, lower energy consumption, and increased production efficiency contribute to a favorable return on investment, typically achieved within 3-5 years for studios with moderate production volumes. This economic viability ensures the continued adoption and development of sustainable laser welding practices in artistic metalwork.

Looking forward, emerging innovations in laser technology promise even greater sustainability benefits. Developments in fiber laser systems with enhanced energy efficiency, coupled with renewable energy integration possibilities, suggest pathways toward carbon-neutral artistic metal production. These advancements position laser welding as a cornerstone technology in the sustainable evolution of artistic metalwork practices.

Material conservation constitutes another critical sustainability advantage. Laser welding's precision minimizes material waste through reduced heat-affected zones and the elimination of filler materials often required in traditional welding. Artists working with precious metals report material savings of 15-30% when transitioning to laser-based joining techniques, contributing to resource conservation while simultaneously reducing the environmental footprint of artistic production.

The longevity of laser-welded artistic pieces further enhances their sustainability profile. The high-quality, consistent joints produced through laser technology demonstrate superior durability and resistance to environmental degradation. This extended lifespan reduces the need for repairs or replacements, effectively decreasing the cumulative environmental impact over time. Studies indicate that properly executed laser welds in artistic applications can maintain structural integrity for decades without intervention.

From a workplace perspective, laser welding offers significant improvements in artist health and safety conditions. The technology produces minimal fumes and particulates compared to traditional welding methods, reducing respiratory hazards and eliminating many toxic exposures associated with conventional techniques. Additionally, the non-contact nature of laser welding minimizes burn risks and physical strain, creating more sustainable working conditions for artistic practitioners.

The economic sustainability aspects cannot be overlooked. While initial investment in laser welding equipment represents a significant barrier, the operational cost analysis reveals long-term economic advantages. Reduced material waste, lower energy consumption, and increased production efficiency contribute to a favorable return on investment, typically achieved within 3-5 years for studios with moderate production volumes. This economic viability ensures the continued adoption and development of sustainable laser welding practices in artistic metalwork.

Looking forward, emerging innovations in laser technology promise even greater sustainability benefits. Developments in fiber laser systems with enhanced energy efficiency, coupled with renewable energy integration possibilities, suggest pathways toward carbon-neutral artistic metal production. These advancements position laser welding as a cornerstone technology in the sustainable evolution of artistic metalwork practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!