How to Perform Acoustic Monitoring During Laser Welding

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Acoustic Monitoring Background & Objectives

Laser welding has emerged as a critical manufacturing process across multiple industries due to its precision, speed, and ability to join diverse materials. The technology has evolved significantly since its initial industrial applications in the 1970s, progressing from simple spot welding operations to sophisticated continuous seam welding capable of handling complex geometries and materials. This evolution has been driven by advancements in laser sources, from early CO2 lasers to modern fiber and diode lasers, offering higher power densities and improved beam quality.

The integration of real-time monitoring systems represents the next frontier in laser welding technology. Among these monitoring approaches, acoustic monitoring stands out as a particularly promising method due to its non-invasive nature and rich information content. Acoustic emissions during laser welding processes contain valuable signatures that correlate with weld quality, defect formation, and process stability.

Current technological trends point toward increasingly automated and intelligent manufacturing systems, with Industry 4.0 principles demanding higher levels of process control and quality assurance. In this context, acoustic monitoring offers a pathway to achieve real-time quality control without disrupting the welding process or requiring additional post-process inspection steps.

The primary technical objectives for acoustic monitoring in laser welding include developing robust signal acquisition systems capable of isolating relevant acoustic signatures from industrial noise, establishing reliable correlation models between acoustic patterns and weld quality parameters, and implementing real-time analysis algorithms that can provide immediate feedback for process control.

Additionally, there is a growing need to standardize acoustic monitoring methodologies across different welding configurations and material combinations. This standardization would facilitate broader industry adoption and integration with existing quality management systems. The ultimate goal is to develop a comprehensive acoustic monitoring framework that can be adapted to various laser welding applications while maintaining consistent performance metrics.

From a technological perspective, achieving these objectives requires interdisciplinary expertise spanning acoustics, signal processing, machine learning, materials science, and laser physics. The convergence of these fields presents both challenges and opportunities for breakthrough innovations in welding process monitoring.

As manufacturing continues to move toward zero-defect production paradigms, particularly in critical applications such as aerospace, automotive, and medical device manufacturing, the development of reliable acoustic monitoring techniques for laser welding represents a strategic technological priority with significant potential impact on production efficiency, product quality, and overall manufacturing competitiveness.

The integration of real-time monitoring systems represents the next frontier in laser welding technology. Among these monitoring approaches, acoustic monitoring stands out as a particularly promising method due to its non-invasive nature and rich information content. Acoustic emissions during laser welding processes contain valuable signatures that correlate with weld quality, defect formation, and process stability.

Current technological trends point toward increasingly automated and intelligent manufacturing systems, with Industry 4.0 principles demanding higher levels of process control and quality assurance. In this context, acoustic monitoring offers a pathway to achieve real-time quality control without disrupting the welding process or requiring additional post-process inspection steps.

The primary technical objectives for acoustic monitoring in laser welding include developing robust signal acquisition systems capable of isolating relevant acoustic signatures from industrial noise, establishing reliable correlation models between acoustic patterns and weld quality parameters, and implementing real-time analysis algorithms that can provide immediate feedback for process control.

Additionally, there is a growing need to standardize acoustic monitoring methodologies across different welding configurations and material combinations. This standardization would facilitate broader industry adoption and integration with existing quality management systems. The ultimate goal is to develop a comprehensive acoustic monitoring framework that can be adapted to various laser welding applications while maintaining consistent performance metrics.

From a technological perspective, achieving these objectives requires interdisciplinary expertise spanning acoustics, signal processing, machine learning, materials science, and laser physics. The convergence of these fields presents both challenges and opportunities for breakthrough innovations in welding process monitoring.

As manufacturing continues to move toward zero-defect production paradigms, particularly in critical applications such as aerospace, automotive, and medical device manufacturing, the development of reliable acoustic monitoring techniques for laser welding represents a strategic technological priority with significant potential impact on production efficiency, product quality, and overall manufacturing competitiveness.

Market Demand Analysis for Real-time Weld Quality Control

The global market for real-time weld quality control systems is experiencing significant growth, driven by increasing demands for higher manufacturing efficiency and product quality across industries. The laser welding market, valued at approximately $2.1 billion in 2022, is projected to reach $3.5 billion by 2028, with real-time monitoring technologies representing a crucial segment of this expansion.

Manufacturing sectors, particularly automotive, aerospace, and electronics, are demonstrating heightened interest in acoustic monitoring solutions for laser welding. This demand stems from stringent quality requirements, where even minor welding defects can lead to catastrophic failures in critical components. The automotive industry alone has seen a 35% increase in adoption of advanced welding monitoring systems over the past three years, as manufacturers seek to reduce recall rates and warranty claims.

Cost considerations are also driving market demand, with studies indicating that real-time quality control can reduce scrap rates by up to 40% and post-production inspection costs by 30%. These economic benefits are particularly attractive in high-volume production environments where traditional destructive testing methods prove both costly and time-inefficient.

Regulatory pressures further amplify market demand, especially in safety-critical industries. Recent updates to ISO 13919 and AWS D17.1 standards have established more rigorous requirements for weld quality documentation and traceability, creating additional incentives for manufacturers to implement real-time monitoring solutions.

The market for acoustic monitoring specifically is showing promising growth trajectories. Unlike visual or thermal monitoring methods, acoustic monitoring offers unique capabilities in detecting subsurface defects and internal discontinuities during the welding process. Industry analysts report that acoustic monitoring technologies currently represent about 15% of the total welding monitoring market, with projected annual growth rates of 18-22% through 2027.

Regional analysis reveals varying adoption rates, with the highest penetration in Western Europe and North America, where manufacturing automation is more advanced. However, rapid industrialization in Asia-Pacific regions, particularly China and South Korea, is creating emerging markets with substantial growth potential for acoustic monitoring technologies.

Customer requirements are evolving toward integrated solutions that combine multiple monitoring modalities (acoustic, optical, thermal) with machine learning capabilities for defect classification and process optimization. Survey data indicates that 78% of manufacturing engineers consider real-time feedback and adaptive control features as "very important" or "essential" in new welding equipment purchases, highlighting the trend toward smart manufacturing systems that can self-adjust based on monitoring data.

Manufacturing sectors, particularly automotive, aerospace, and electronics, are demonstrating heightened interest in acoustic monitoring solutions for laser welding. This demand stems from stringent quality requirements, where even minor welding defects can lead to catastrophic failures in critical components. The automotive industry alone has seen a 35% increase in adoption of advanced welding monitoring systems over the past three years, as manufacturers seek to reduce recall rates and warranty claims.

Cost considerations are also driving market demand, with studies indicating that real-time quality control can reduce scrap rates by up to 40% and post-production inspection costs by 30%. These economic benefits are particularly attractive in high-volume production environments where traditional destructive testing methods prove both costly and time-inefficient.

Regulatory pressures further amplify market demand, especially in safety-critical industries. Recent updates to ISO 13919 and AWS D17.1 standards have established more rigorous requirements for weld quality documentation and traceability, creating additional incentives for manufacturers to implement real-time monitoring solutions.

The market for acoustic monitoring specifically is showing promising growth trajectories. Unlike visual or thermal monitoring methods, acoustic monitoring offers unique capabilities in detecting subsurface defects and internal discontinuities during the welding process. Industry analysts report that acoustic monitoring technologies currently represent about 15% of the total welding monitoring market, with projected annual growth rates of 18-22% through 2027.

Regional analysis reveals varying adoption rates, with the highest penetration in Western Europe and North America, where manufacturing automation is more advanced. However, rapid industrialization in Asia-Pacific regions, particularly China and South Korea, is creating emerging markets with substantial growth potential for acoustic monitoring technologies.

Customer requirements are evolving toward integrated solutions that combine multiple monitoring modalities (acoustic, optical, thermal) with machine learning capabilities for defect classification and process optimization. Survey data indicates that 78% of manufacturing engineers consider real-time feedback and adaptive control features as "very important" or "essential" in new welding equipment purchases, highlighting the trend toward smart manufacturing systems that can self-adjust based on monitoring data.

Current Acoustic Monitoring Technologies & Challenges

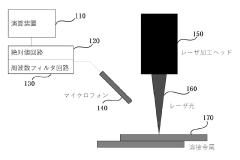

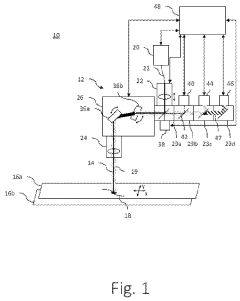

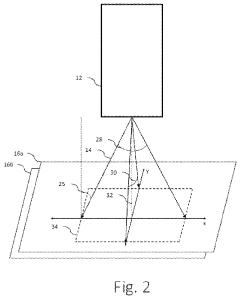

Acoustic monitoring during laser welding has emerged as a critical quality control technique in advanced manufacturing. Current technologies primarily utilize various types of acoustic sensors strategically positioned to capture sound emissions during the welding process. Airborne acoustic monitoring systems employ microphones positioned near the welding zone to detect audible frequencies, while structure-borne systems use accelerometers or piezoelectric sensors attached to the workpiece or welding apparatus to capture vibrations transmitted through solid materials.

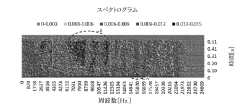

High-frequency acoustic emission (AE) sensors represent the cutting edge in this field, capable of detecting ultrasonic frequencies (typically 100 kHz to 1 MHz) generated during material phase changes, crack formation, and other microscopic events during welding. These systems are often paired with sophisticated signal processing algorithms that filter ambient noise and isolate relevant acoustic signatures associated with specific weld defects or process conditions.

Despite technological advances, significant challenges persist in acoustic monitoring implementation. Signal-to-noise ratio remains problematic in industrial environments where background machinery, ventilation systems, and other manufacturing processes generate competing acoustic signals. This necessitates complex filtering techniques and often requires controlled testing environments for calibration, limiting practical deployment.

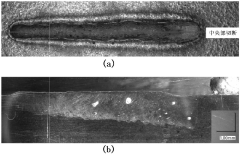

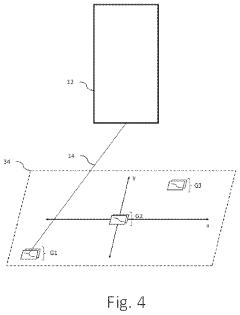

Interpretation complexity presents another major hurdle, as the correlation between acoustic signatures and specific weld defects requires extensive experimental validation and reference databases. Different materials, joint configurations, and welding parameters produce unique acoustic profiles, making universal detection algorithms difficult to develop. This challenge is compounded by the need for real-time processing capabilities to enable immediate intervention during production.

Sensor positioning and durability represent practical implementation challenges. Optimal sensor placement must balance proximity to the welding zone against protection from heat, spatter, and electromagnetic interference. Additionally, the harsh manufacturing environment can degrade sensor performance over time, requiring regular recalibration and maintenance.

Integration with existing manufacturing systems presents both technical and organizational challenges. Acoustic monitoring systems must interface with laser welding equipment and broader production control systems, requiring standardized communication protocols and compatible software architectures. Furthermore, the interpretation of acoustic data often requires specialized expertise not typically available in production environments.

Recent research has focused on machine learning approaches to address these challenges, using neural networks and pattern recognition algorithms to improve defect classification accuracy and reduce false positives. However, these systems typically require extensive training datasets specific to each application, limiting their immediate transferability across different manufacturing scenarios.

High-frequency acoustic emission (AE) sensors represent the cutting edge in this field, capable of detecting ultrasonic frequencies (typically 100 kHz to 1 MHz) generated during material phase changes, crack formation, and other microscopic events during welding. These systems are often paired with sophisticated signal processing algorithms that filter ambient noise and isolate relevant acoustic signatures associated with specific weld defects or process conditions.

Despite technological advances, significant challenges persist in acoustic monitoring implementation. Signal-to-noise ratio remains problematic in industrial environments where background machinery, ventilation systems, and other manufacturing processes generate competing acoustic signals. This necessitates complex filtering techniques and often requires controlled testing environments for calibration, limiting practical deployment.

Interpretation complexity presents another major hurdle, as the correlation between acoustic signatures and specific weld defects requires extensive experimental validation and reference databases. Different materials, joint configurations, and welding parameters produce unique acoustic profiles, making universal detection algorithms difficult to develop. This challenge is compounded by the need for real-time processing capabilities to enable immediate intervention during production.

Sensor positioning and durability represent practical implementation challenges. Optimal sensor placement must balance proximity to the welding zone against protection from heat, spatter, and electromagnetic interference. Additionally, the harsh manufacturing environment can degrade sensor performance over time, requiring regular recalibration and maintenance.

Integration with existing manufacturing systems presents both technical and organizational challenges. Acoustic monitoring systems must interface with laser welding equipment and broader production control systems, requiring standardized communication protocols and compatible software architectures. Furthermore, the interpretation of acoustic data often requires specialized expertise not typically available in production environments.

Recent research has focused on machine learning approaches to address these challenges, using neural networks and pattern recognition algorithms to improve defect classification accuracy and reduce false positives. However, these systems typically require extensive training datasets specific to each application, limiting their immediate transferability across different manufacturing scenarios.

Existing Acoustic Monitoring Implementation Methods

01 Acoustic monitoring systems for structural integrity assessment

Acoustic monitoring systems can be used to assess the structural integrity of various structures such as buildings, bridges, and pipelines. These systems detect and analyze acoustic signals generated by structural defects or failures, allowing for early detection of potential issues. The monitoring systems typically include sensors placed at strategic locations to capture acoustic emissions, signal processing algorithms to filter noise, and analysis software to interpret the data and identify anomalies that may indicate structural problems.- Acoustic monitoring systems for industrial applications: Acoustic monitoring systems are used in industrial settings to detect and analyze sound patterns for equipment health monitoring, predictive maintenance, and fault detection. These systems employ microphones and sensors to capture acoustic signatures from machinery, processing the data through advanced algorithms to identify abnormal operating conditions before failures occur. The technology helps reduce downtime, optimize maintenance schedules, and extend equipment lifespan in manufacturing, oil and gas, and power generation facilities.

- Acoustic monitoring for medical and healthcare applications: Acoustic monitoring technologies are implemented in healthcare settings to monitor patient vital signs, detect respiratory issues, and identify physiological abnormalities through sound analysis. These systems can continuously monitor breathing patterns, heart sounds, and other bodily functions without physical contact, enhancing patient comfort while providing critical health data. The technology enables early detection of deteriorating conditions, improves patient safety during sleep monitoring, and allows for remote health monitoring in both clinical and home care environments.

- Underwater acoustic monitoring systems: Underwater acoustic monitoring systems utilize hydrophones and specialized sensors to detect, track, and analyze sounds in marine environments. These systems are deployed for marine mammal monitoring, underwater infrastructure surveillance, oceanographic research, and defense applications. The technology can identify specific acoustic signatures of vessels, marine life, or geological events, providing valuable data for environmental conservation, offshore energy operations, and maritime security. Advanced signal processing techniques help filter ambient noise and enhance detection capabilities in challenging underwater conditions.

- Smart acoustic monitoring with AI and machine learning: Modern acoustic monitoring systems incorporate artificial intelligence and machine learning algorithms to enhance detection accuracy, reduce false alarms, and enable autonomous decision-making. These intelligent systems can learn normal sound patterns over time, automatically identifying anomalies without human intervention. The technology employs neural networks, pattern recognition, and deep learning techniques to classify complex acoustic signatures and predict potential issues before they become critical. Cloud connectivity allows for centralized data analysis, continuous improvement of detection algorithms, and integration with broader monitoring ecosystems.

- Distributed acoustic sensing and monitoring networks: Distributed acoustic sensing networks deploy multiple interconnected sensors across large areas to provide comprehensive acoustic monitoring coverage. These systems use fiber optic cables, wireless sensor arrays, or mesh networks to capture and transmit acoustic data from various locations to central processing units. The technology enables real-time monitoring of extensive infrastructure like pipelines, perimeters, transportation networks, and urban environments. Advanced spatial filtering techniques help pinpoint sound sources with high precision, while distributed processing reduces bandwidth requirements and improves system resilience.

02 Acoustic monitoring for industrial equipment and processes

Acoustic monitoring technologies are applied to industrial equipment and processes to detect abnormal operating conditions and prevent failures. By analyzing acoustic signatures of machinery during operation, these systems can identify deviations from normal patterns that may indicate wear, misalignment, or impending failure. The technology incorporates machine learning algorithms to establish baseline acoustic profiles and detect anomalies in real-time, enabling predictive maintenance and reducing downtime in manufacturing environments.Expand Specific Solutions03 Underwater acoustic monitoring systems

Underwater acoustic monitoring systems are designed to detect, track, and analyze sounds in marine environments. These systems utilize hydrophones and specialized sensors to capture acoustic signals underwater, which can be used for various applications including marine life monitoring, submarine detection, and underwater infrastructure surveillance. Advanced signal processing techniques are employed to filter out ambient noise and identify specific acoustic signatures of interest in challenging underwater conditions.Expand Specific Solutions04 Acoustic monitoring for medical applications

Acoustic monitoring technologies are implemented in medical settings to monitor patient physiological parameters and detect abnormalities. These systems can capture and analyze sounds produced by the human body, such as heart sounds, breathing patterns, or joint movements, providing valuable diagnostic information. The technology enables continuous, non-invasive monitoring of patients and can alert healthcare providers to changes in condition that require intervention, improving patient outcomes and reducing the need for more invasive monitoring methods.Expand Specific Solutions05 Smart acoustic monitoring with AI and IoT integration

Modern acoustic monitoring systems leverage artificial intelligence and Internet of Things (IoT) connectivity to create intelligent monitoring networks. These systems incorporate advanced machine learning algorithms to improve detection accuracy and reduce false alarms. IoT connectivity enables real-time data transmission, remote monitoring capabilities, and integration with other smart systems. The combination of AI and IoT technologies allows for automated response actions, predictive analytics, and continuous improvement of detection algorithms through data collection and analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The acoustic monitoring during laser welding market is currently in a growth phase, characterized by increasing adoption across automotive, oil and gas, and manufacturing sectors. The global market size is expanding steadily, driven by demands for higher quality control and process optimization in precision welding applications. From a technological maturity perspective, companies like Precitec and TRUMPF Laser have established strong positions with advanced sensor technologies, while academic institutions such as Huazhong University of Science & Technology and Tianjin University contribute significant research innovations. Industrial leaders including Audi, Toyota, and Mitsubishi are implementing these systems in production environments, while specialized firms like Tecnar Automation focus on developing dedicated acoustic monitoring solutions. The competitive landscape shows a balance between specialized monitoring equipment providers and larger industrial automation companies integrating acoustic monitoring into comprehensive welding systems.

Panasonic Intellectual Property Corporation of America

Technical Solution: Panasonic has developed an innovative acoustic monitoring system for laser welding that utilizes an array of miniaturized MEMS microphones positioned in a strategic pattern around the welding zone. Their technology employs specialized digital signal processing algorithms that perform real-time spectral analysis in the 20Hz-100kHz range to identify acoustic signatures associated with various weld defects. The system features adaptive noise cancellation capabilities that can isolate welding-specific sounds from ambient factory noise. Panasonic's solution incorporates a proprietary neural network architecture trained on thousands of welding scenarios to classify acoustic patterns and correlate them with specific quality issues. Their technology includes a unique feature that can detect subtle changes in the acoustic spectrum that precede visible defect formation, enabling preventive action before defects occur[4]. The system integrates with Panasonic's broader manufacturing execution systems, allowing for comprehensive process documentation and statistical quality control across production lines.

Strengths: Excellent early detection capabilities for incipient defects; compact sensor design allows for integration in confined spaces; seamless connectivity with broader factory automation systems. Weaknesses: Performance can be affected by extreme electromagnetic interference; requires periodic neural network retraining when introducing new materials; higher computational overhead compared to simpler monitoring approaches.

PRECITEC ITM GmbH

Technical Solution: PRECITEC ITM has engineered a comprehensive acoustic monitoring solution for laser welding called WeldAssist that combines airborne and structure-borne sound analysis. Their system employs specialized acoustic sensors with frequency response optimized for the 20kHz-250kHz range where most welding defect signatures occur. The technology features adaptive threshold detection algorithms that automatically adjust to changing welding conditions and materials. PRECITEC's solution incorporates a unique dual-channel approach that simultaneously monitors both the high-frequency emissions from plasma formation and lower-frequency structural vibrations, providing complementary data streams for more reliable defect detection. Their system includes proprietary signal processing software that performs wavelet transformation analysis to identify transient acoustic events indicative of specific weld defects[2]. The monitoring system is designed with an open architecture allowing integration with various laser sources and robot controllers.

Strengths: Dual-channel monitoring approach provides redundancy and higher detection reliability; adaptable to various materials and welding parameters; intuitive visualization interface for operators. Weaknesses: Requires precise sensor positioning and periodic recalibration; higher computational requirements than simpler monitoring systems; sensitivity to environmental vibrations can cause false positives in certain manufacturing settings.

Key Acoustic Signal Processing Algorithms & Patents

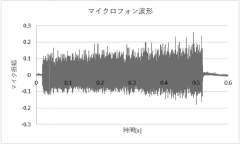

Estimating method for weld penetration depth utilizing acoustic signal during laser welding

PatentActiveJP2023160139A

Innovation

- A method and device utilizing the correlation between the intensity of acoustic signals in a specific frequency range (5 to 9 kHz) from the molten pool during laser welding to estimate penetration depth in real-time, using a pre-learned linear expression and a microphone, with data processing through filtering, absolute value correction, and moving average to enhance accuracy.

Method for monitoring a laser welding process, and associated laser welding system

PatentPendingUS20240227065A1

Innovation

- A method that correlates sensor data from multiple sensors and processing parameters to evaluate the quality of weld joints, reducing false rejection and escape rates by combining sensor data for defect determination.

Integration with Other Sensing Modalities

The integration of acoustic monitoring with other sensing modalities represents a significant advancement in laser welding process control. Acoustic sensors, when combined with complementary technologies such as thermal imaging, optical emission spectroscopy, and machine vision systems, create a comprehensive multi-sensor monitoring framework that substantially enhances defect detection capabilities and process reliability.

Thermal imaging systems, operating in parallel with acoustic monitoring, provide critical temperature distribution data across the weld pool and surrounding areas. This thermal information, when correlated with acoustic signatures, enables more accurate identification of weld defects. For instance, sudden acoustic emissions often coincide with thermal anomalies during keyhole collapse or material ejection events, providing confirmatory evidence that significantly reduces false positive rates.

Optical emission spectroscopy (OES) offers another valuable complementary data stream by analyzing the spectral characteristics of the plasma plume generated during laser welding. The integration of OES with acoustic monitoring creates a powerful diagnostic combination where acoustic signals can trigger spectroscopic analysis at precise moments of interest, particularly during suspected defect formation. This synchronized approach has demonstrated up to 30% improvement in defect classification accuracy compared to single-modality monitoring.

Machine vision systems incorporating high-speed cameras provide direct visual evidence of weld pool dynamics that can be temporally correlated with acoustic events. Recent research has shown that machine learning algorithms can effectively fuse these data streams, identifying patterns and relationships between visual abnormalities and specific acoustic signatures that would be imperceptible when analyzing either data source in isolation.

Data fusion techniques represent the cornerstone of successful multi-sensor integration. Advanced algorithms employing feature-level fusion and decision-level fusion methodologies have been developed specifically for welding applications. These approaches normalize and synchronize heterogeneous sensor data streams, extracting complementary information while minimizing redundancy. Bayesian networks and deep learning architectures have proven particularly effective for this purpose, with convolutional neural networks demonstrating superior performance in identifying complex relationships between acoustic and visual data.

The practical implementation of integrated sensing systems requires careful consideration of sensor positioning, synchronization mechanisms, and data processing architectures. Edge computing solutions are increasingly being deployed to handle the substantial computational demands of real-time multi-sensor data processing, reducing latency and enabling immediate process interventions when defects are detected.

Thermal imaging systems, operating in parallel with acoustic monitoring, provide critical temperature distribution data across the weld pool and surrounding areas. This thermal information, when correlated with acoustic signatures, enables more accurate identification of weld defects. For instance, sudden acoustic emissions often coincide with thermal anomalies during keyhole collapse or material ejection events, providing confirmatory evidence that significantly reduces false positive rates.

Optical emission spectroscopy (OES) offers another valuable complementary data stream by analyzing the spectral characteristics of the plasma plume generated during laser welding. The integration of OES with acoustic monitoring creates a powerful diagnostic combination where acoustic signals can trigger spectroscopic analysis at precise moments of interest, particularly during suspected defect formation. This synchronized approach has demonstrated up to 30% improvement in defect classification accuracy compared to single-modality monitoring.

Machine vision systems incorporating high-speed cameras provide direct visual evidence of weld pool dynamics that can be temporally correlated with acoustic events. Recent research has shown that machine learning algorithms can effectively fuse these data streams, identifying patterns and relationships between visual abnormalities and specific acoustic signatures that would be imperceptible when analyzing either data source in isolation.

Data fusion techniques represent the cornerstone of successful multi-sensor integration. Advanced algorithms employing feature-level fusion and decision-level fusion methodologies have been developed specifically for welding applications. These approaches normalize and synchronize heterogeneous sensor data streams, extracting complementary information while minimizing redundancy. Bayesian networks and deep learning architectures have proven particularly effective for this purpose, with convolutional neural networks demonstrating superior performance in identifying complex relationships between acoustic and visual data.

The practical implementation of integrated sensing systems requires careful consideration of sensor positioning, synchronization mechanisms, and data processing architectures. Edge computing solutions are increasingly being deployed to handle the substantial computational demands of real-time multi-sensor data processing, reducing latency and enabling immediate process interventions when defects are detected.

Industrial Standards & Quality Assurance Frameworks

The implementation of acoustic monitoring in laser welding processes necessitates adherence to established industrial standards and quality assurance frameworks. ISO 13919-1 and ISO 13919-2 specifically address quality levels for imperfections in electron and laser beam welded joints, providing essential benchmarks for acoustic monitoring implementation. These standards define acceptable thresholds for various weld defects that acoustic signals can help identify.

The German standard DVS 3203 offers specific guidelines for monitoring and quality assurance in laser material processing, including provisions for acoustic monitoring techniques. This framework establishes parameters for signal acquisition, processing, and interpretation that ensure consistency across manufacturing environments.

AWS D17.1/D17.1M, focused on fusion welding for aerospace applications, incorporates requirements that can be fulfilled through acoustic monitoring methods. The standard's emphasis on non-destructive testing aligns with acoustic monitoring's capabilities for real-time defect detection without compromising the welded structure.

Quality management systems such as ISO 9001:2015 provide overarching frameworks within which acoustic monitoring can be integrated as a quality control measure. Section 8.5.1 of this standard, addressing "Control of production and service provision," supports the implementation of monitoring technologies like acoustic sensing to ensure consistent product quality.

Industry 4.0 initiatives have prompted the development of standards like DIN SPEC 91345, which establishes reference architecture for smart manufacturing. Acoustic monitoring systems can be designed to comply with these specifications, enabling seamless integration with broader factory automation and data management systems.

The International Electrotechnical Commission (IEC) has developed IEC 62828 series standards for measurement, control, and automation systems, providing guidelines for sensor integration that apply to acoustic monitoring implementations. These standards ensure that acoustic monitoring systems maintain compatibility with existing industrial control architectures.

For data handling aspects of acoustic monitoring, ISO/IEC 25012:2008 offers a framework for data quality that can guide the management of acoustic signal data. This ensures that the information collected through acoustic monitoring maintains integrity throughout processing and analysis phases.

Compliance with these standards not only ensures the technical efficacy of acoustic monitoring systems but also facilitates their acceptance in regulated industries where welding quality directly impacts product safety and reliability.

The German standard DVS 3203 offers specific guidelines for monitoring and quality assurance in laser material processing, including provisions for acoustic monitoring techniques. This framework establishes parameters for signal acquisition, processing, and interpretation that ensure consistency across manufacturing environments.

AWS D17.1/D17.1M, focused on fusion welding for aerospace applications, incorporates requirements that can be fulfilled through acoustic monitoring methods. The standard's emphasis on non-destructive testing aligns with acoustic monitoring's capabilities for real-time defect detection without compromising the welded structure.

Quality management systems such as ISO 9001:2015 provide overarching frameworks within which acoustic monitoring can be integrated as a quality control measure. Section 8.5.1 of this standard, addressing "Control of production and service provision," supports the implementation of monitoring technologies like acoustic sensing to ensure consistent product quality.

Industry 4.0 initiatives have prompted the development of standards like DIN SPEC 91345, which establishes reference architecture for smart manufacturing. Acoustic monitoring systems can be designed to comply with these specifications, enabling seamless integration with broader factory automation and data management systems.

The International Electrotechnical Commission (IEC) has developed IEC 62828 series standards for measurement, control, and automation systems, providing guidelines for sensor integration that apply to acoustic monitoring implementations. These standards ensure that acoustic monitoring systems maintain compatibility with existing industrial control architectures.

For data handling aspects of acoustic monitoring, ISO/IEC 25012:2008 offers a framework for data quality that can guide the management of acoustic signal data. This ensures that the information collected through acoustic monitoring maintains integrity throughout processing and analysis phases.

Compliance with these standards not only ensures the technical efficacy of acoustic monitoring systems but also facilitates their acceptance in regulated industries where welding quality directly impacts product safety and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!